Patents

Literature

43results about How to "Meet the needs of modern industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

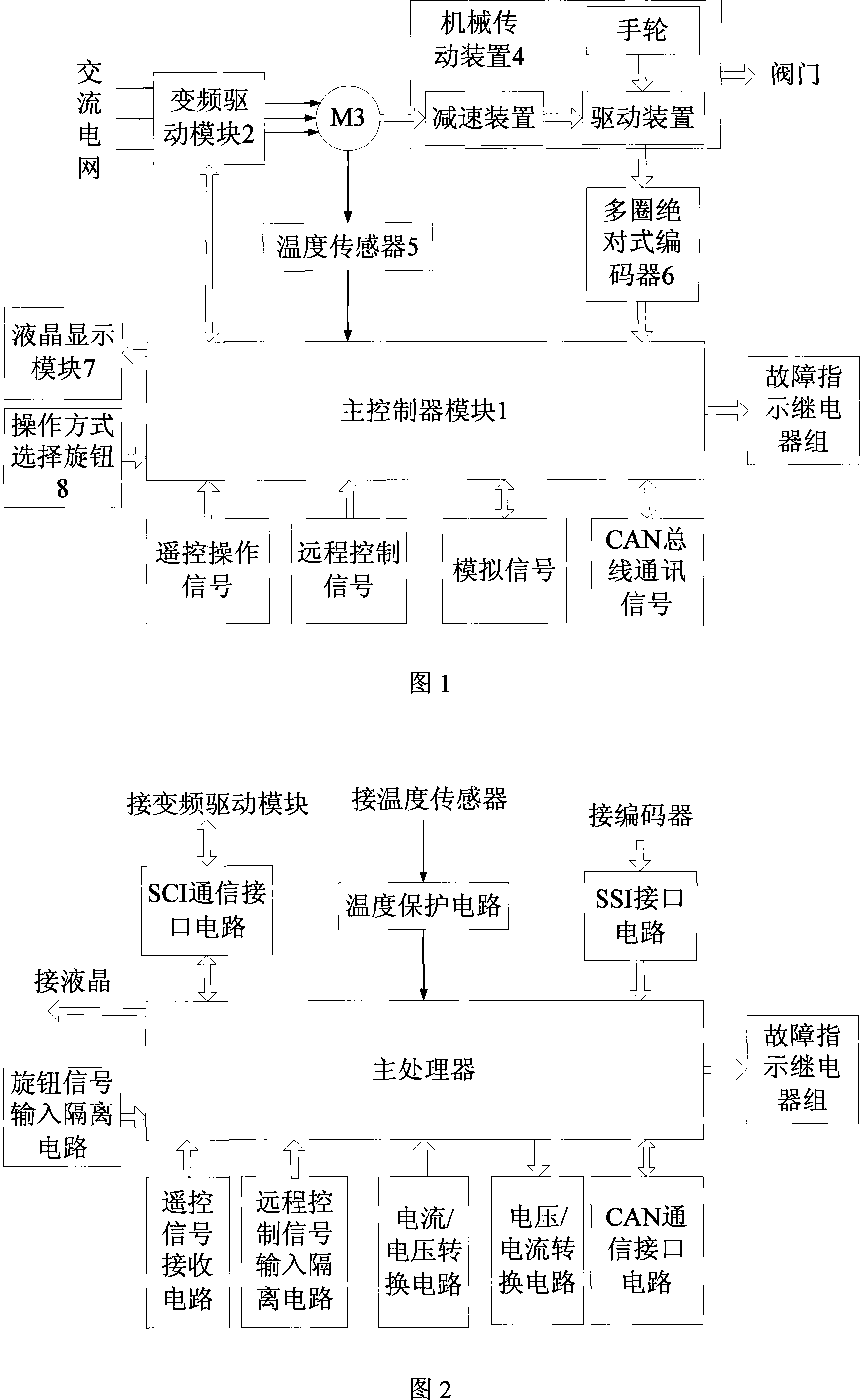

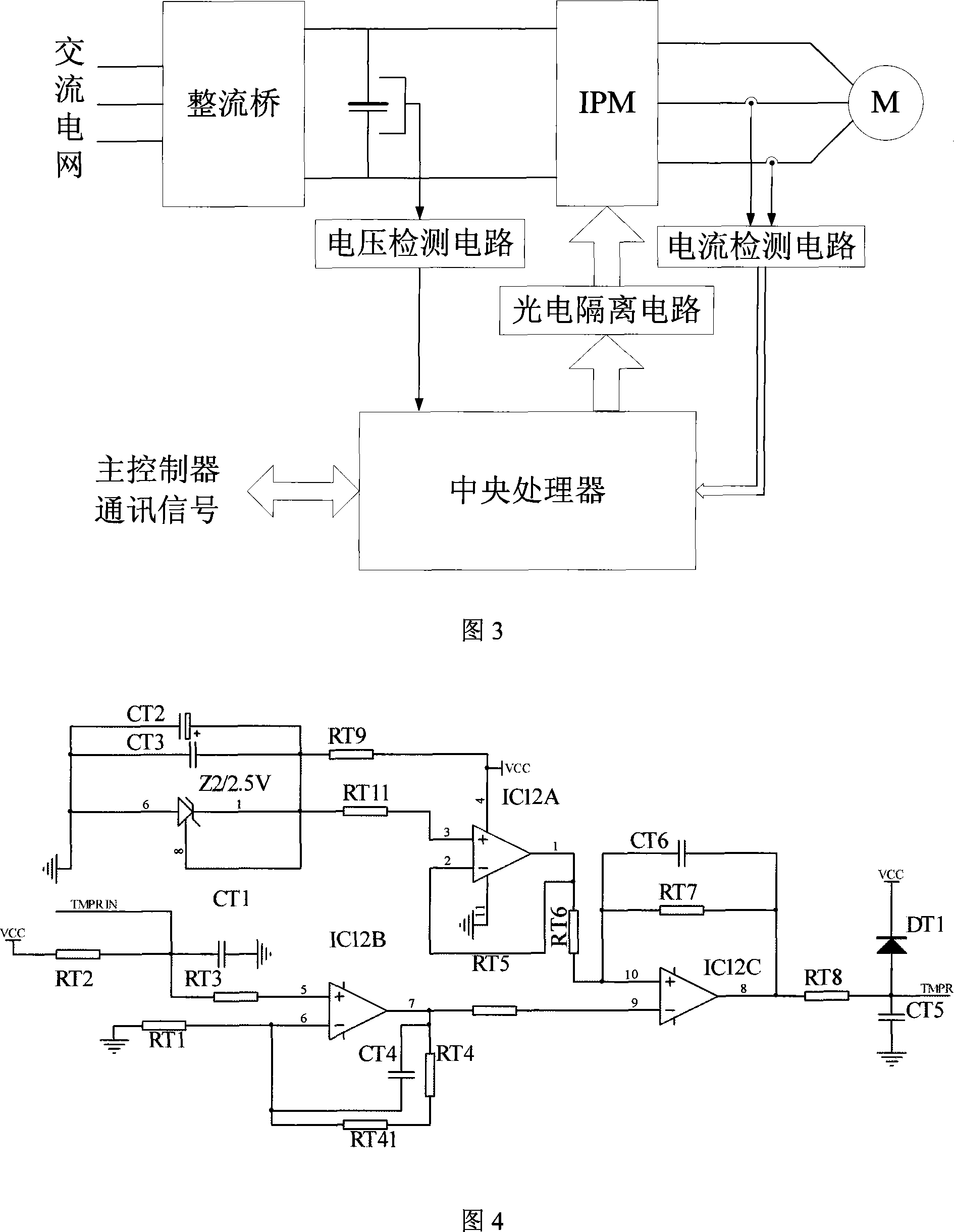

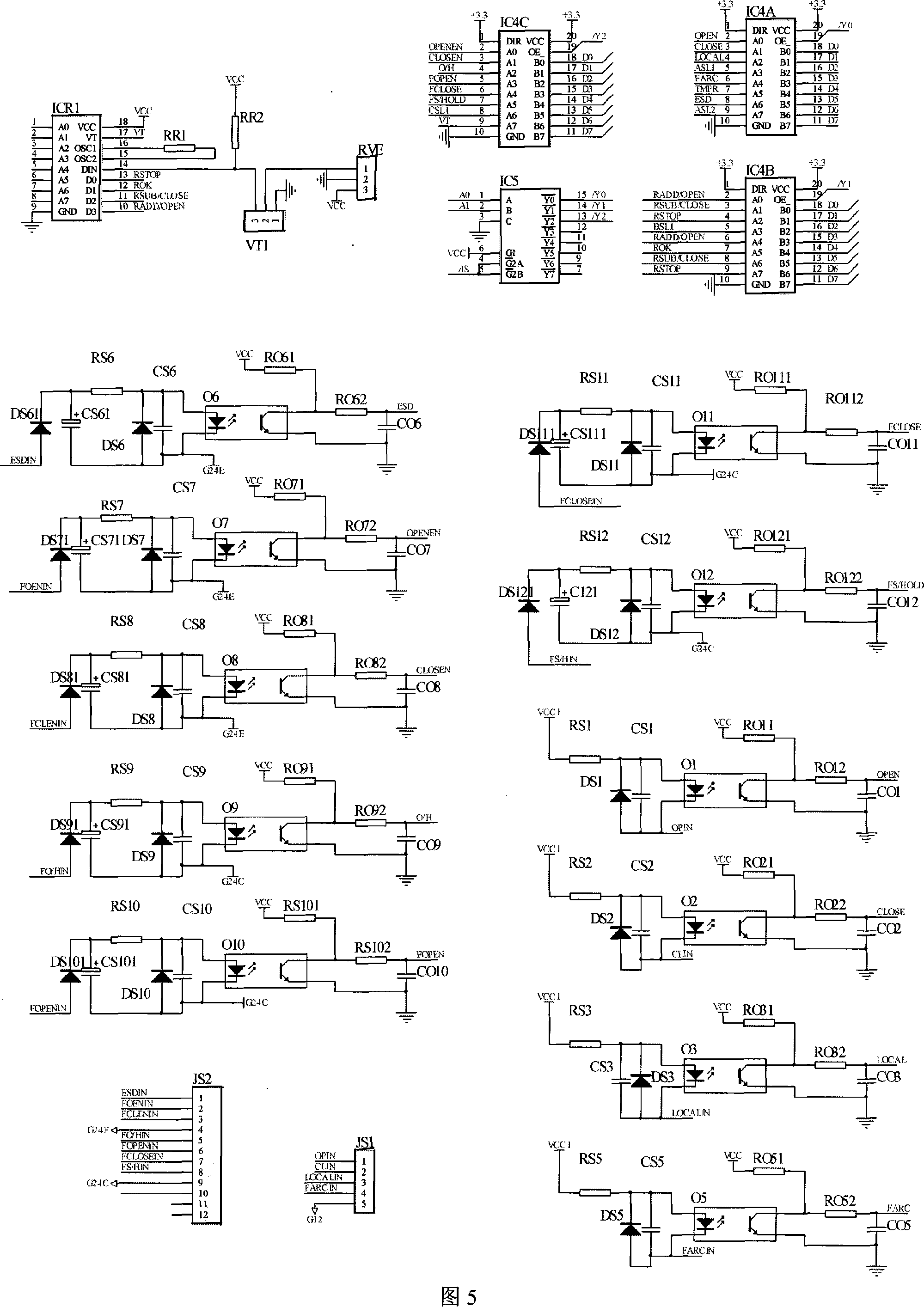

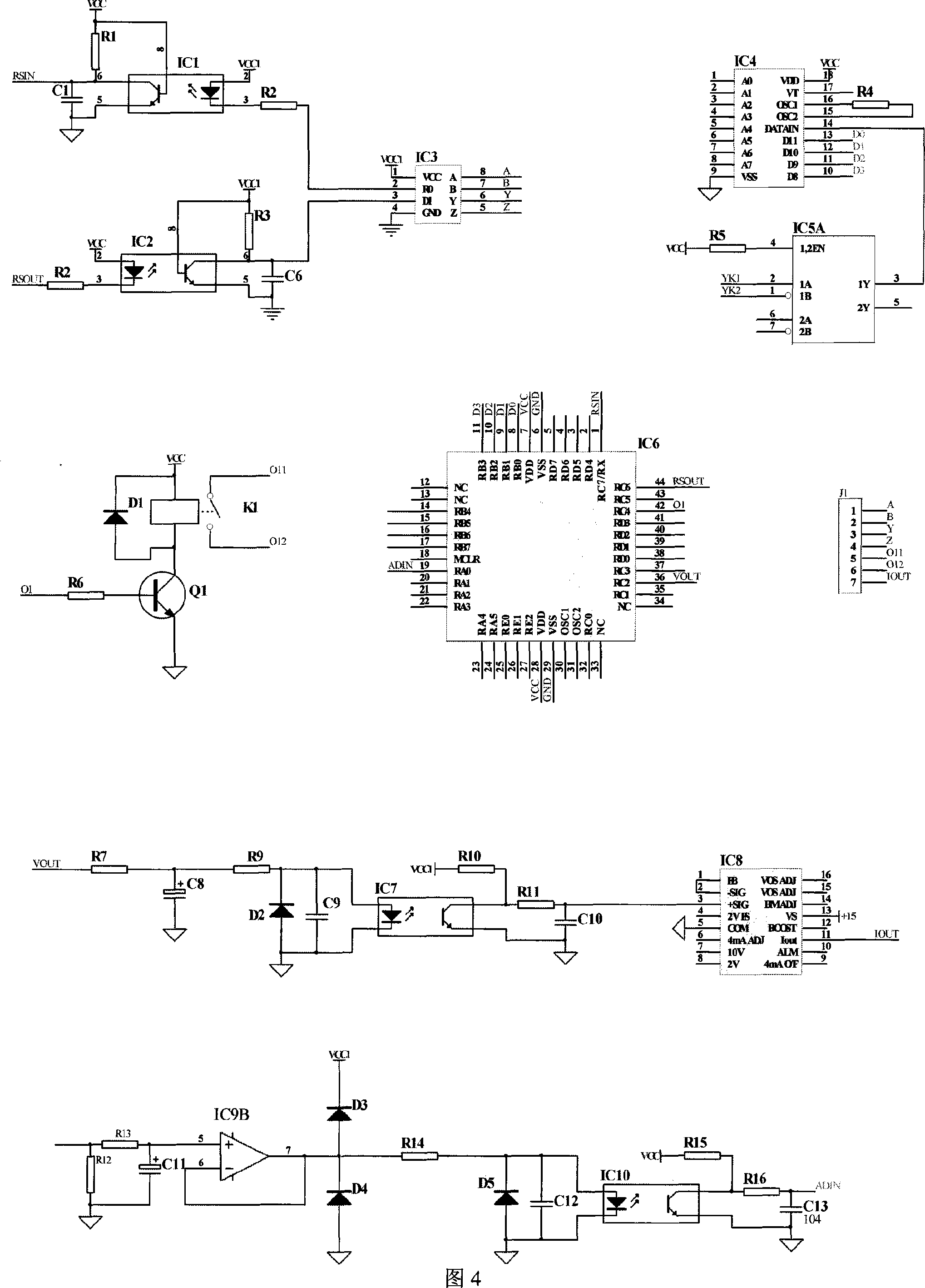

Frequency conversion type intellective electromotion unit for valve

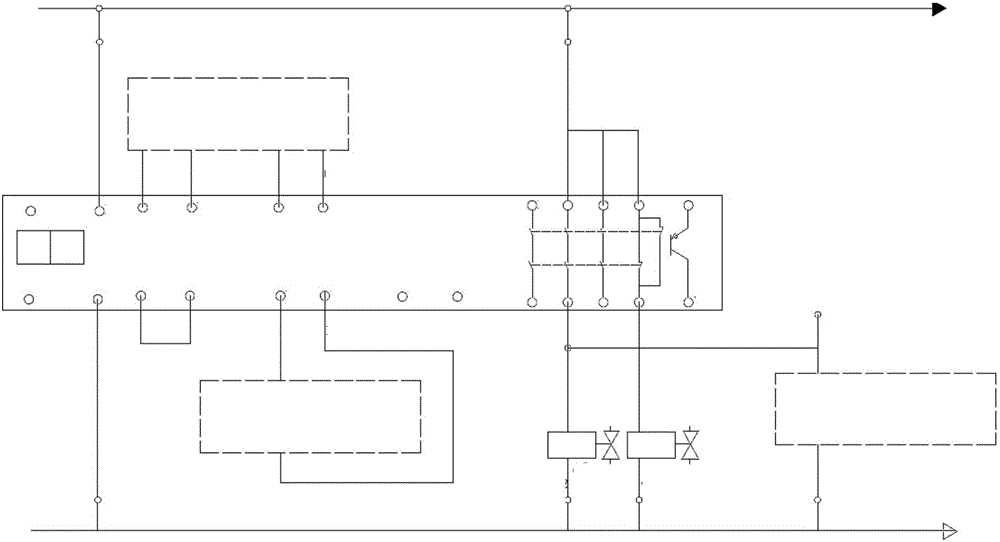

InactiveCN101093033AWith bus control functionImplement mutable operationsElectric signal transmission systemsAC motor controlControl mannerOperation mode

This invention relates to a conversion intelligent valve electric device including a master controller module, a conversion drive module, an asynchronous motor, a mechanical drive device, a temperature sensor, a multi-coil absolute coder, a LCD and an operation mode selecting button characterizing in using a conversion drive module to drive the asynchronous motor, testing output torque by computing electricity and taking the coder as a location sensor and a temperature sensor is installed in the asynchronous motor, and the control mode includes local control, remote control, remote control to switch volume, remote control to simulation volume and bus line control.

Owner:孙力

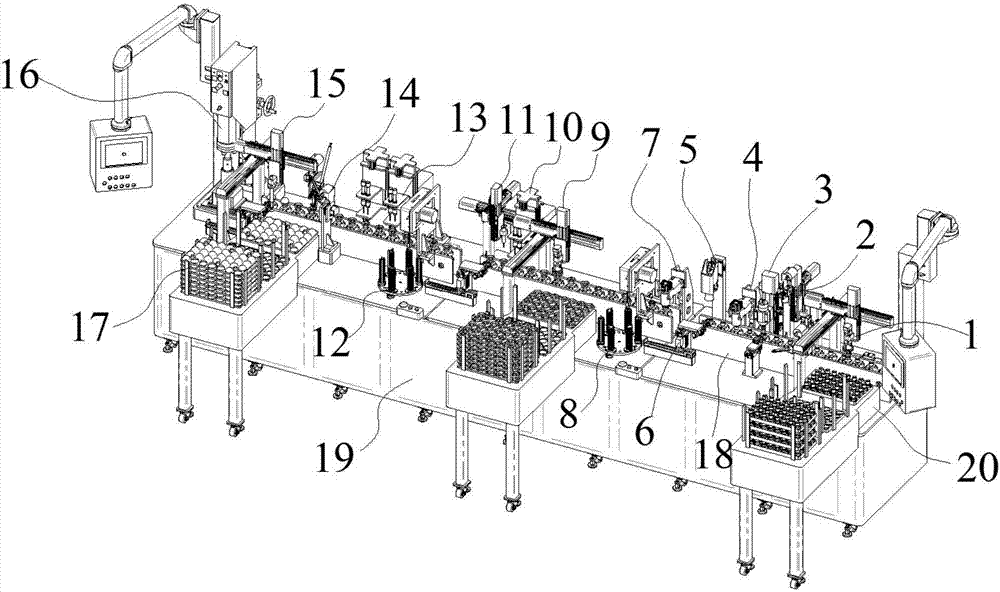

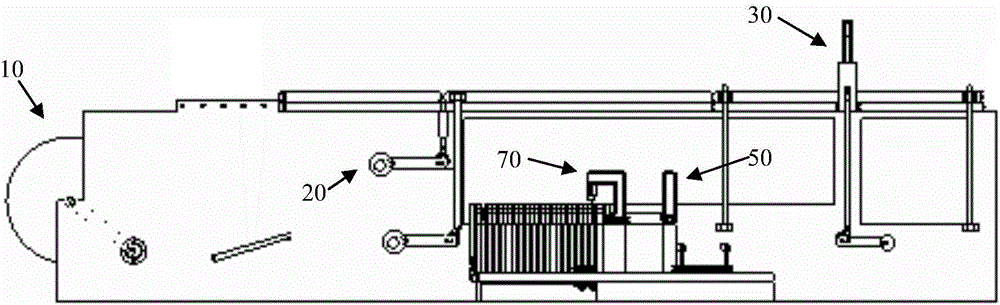

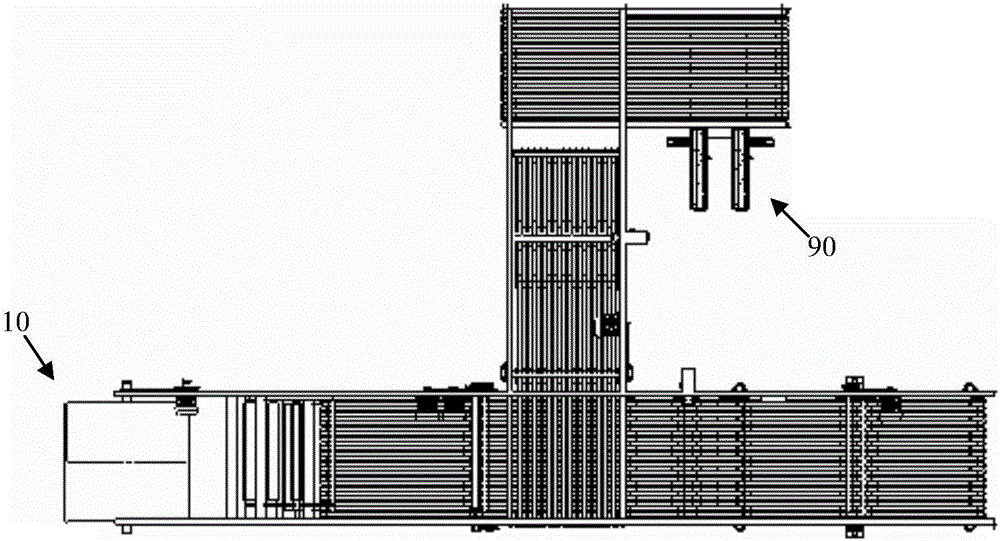

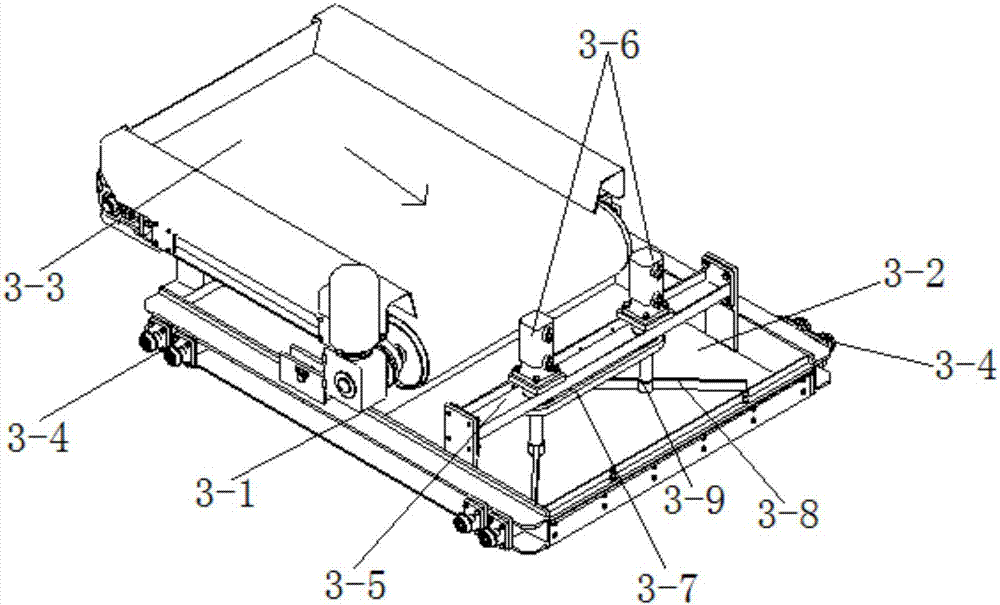

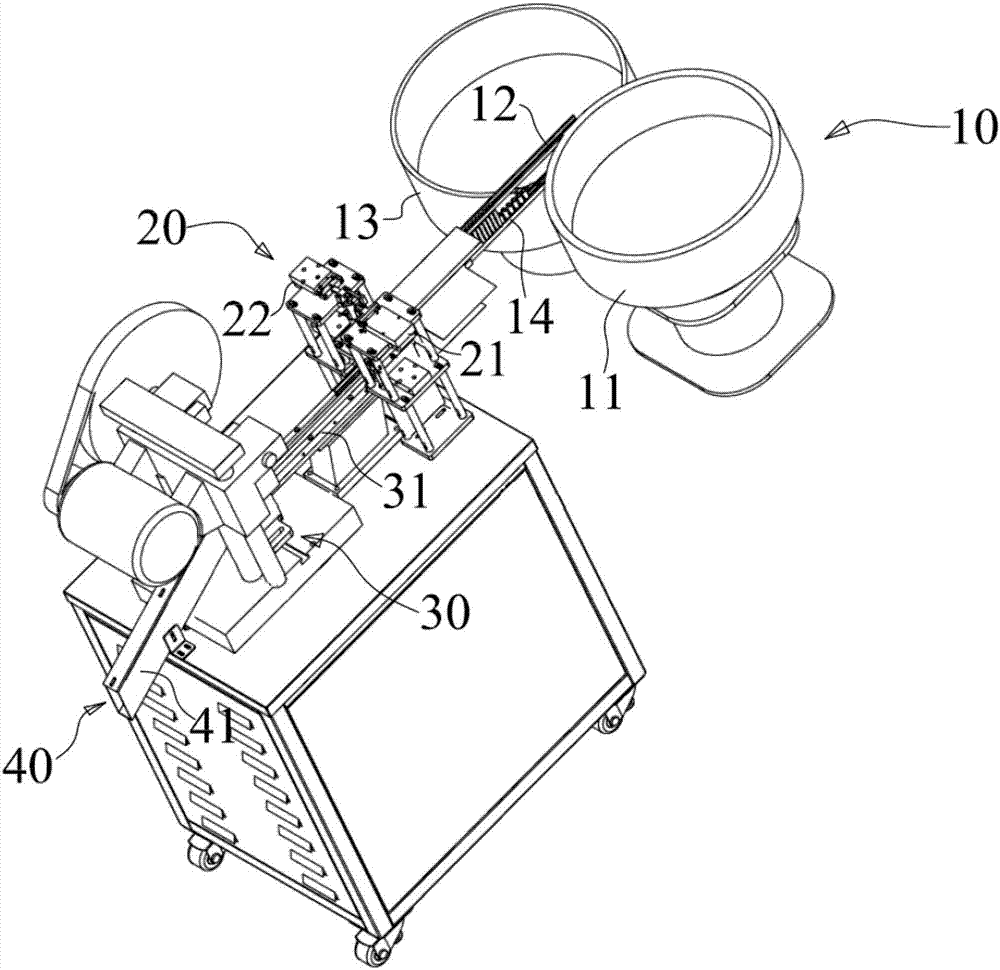

LED bulb lamp assembling system

PendingCN107263098ARealize automatic assemblyImprove assembly efficiencyAssembly machinesSemiconductor devices for light sourcesEngineeringAssembly line

The invention provides an LED bulb lamp assembling system. The LED bulb lamp assembling system comprises an automatic feeding station, a screw welding station, a mouth metal fixing station, a grinding station, a checking station, an overturning and carrying station, a re-positioning station, a heating plate assembling station, a lower lampshade assembling station, a first screw assembling station, a glue injection station, a lamp panel assembling station, a second screw assembling station, a wire tidying welding station, an upper lampshade assembling station, a lampshade fusion point lamp station and a discharging station. The above stations are sequentially arranged along a conveying assembly line of the LED bulb lamp assembling system. The stations and the conveying assembly line are integrated on a machine table of the LED bulb lamp assembling system. The LED bulb lamp assembling system achieves automatic LED bulb lamp assembling and is high in assembling efficiency and good in precision, the problems existing in the prior art are solved, and the modern industry production requirement is sufficiently met.

Owner:苏州凯良拓自动化科技有限公司

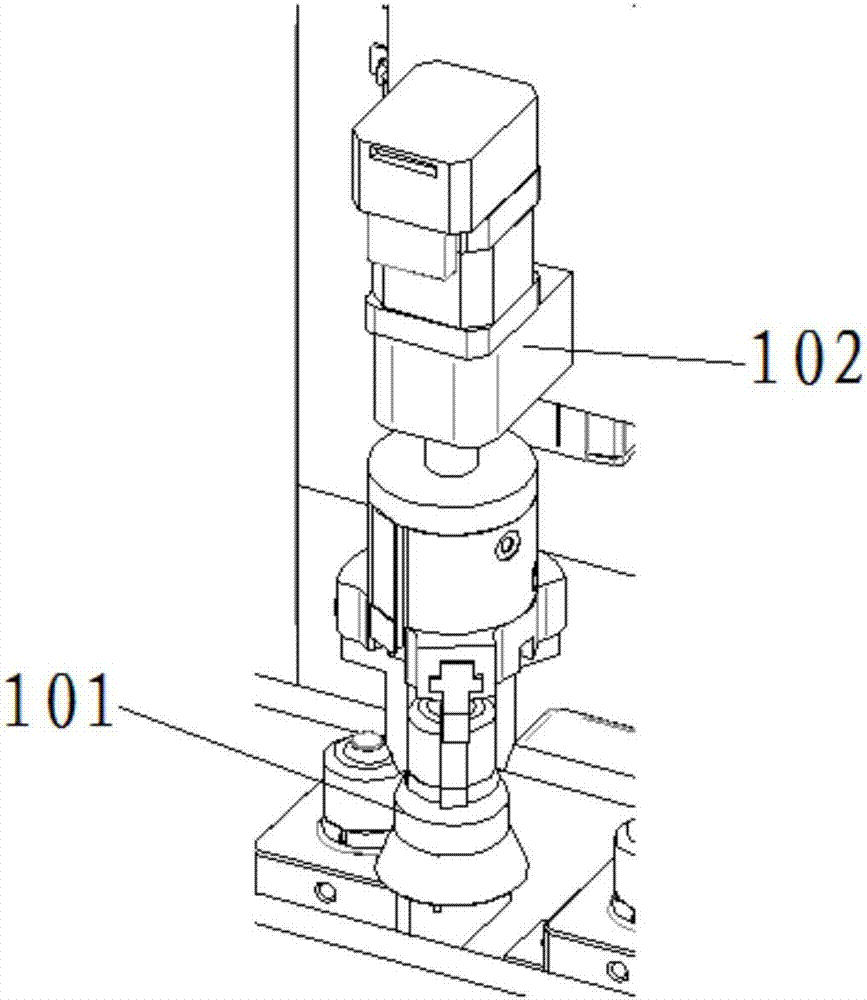

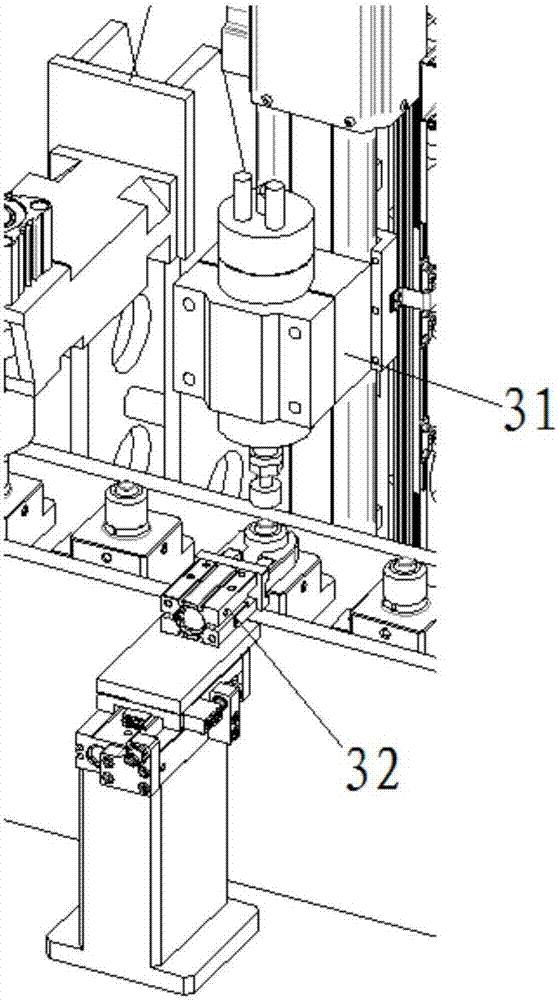

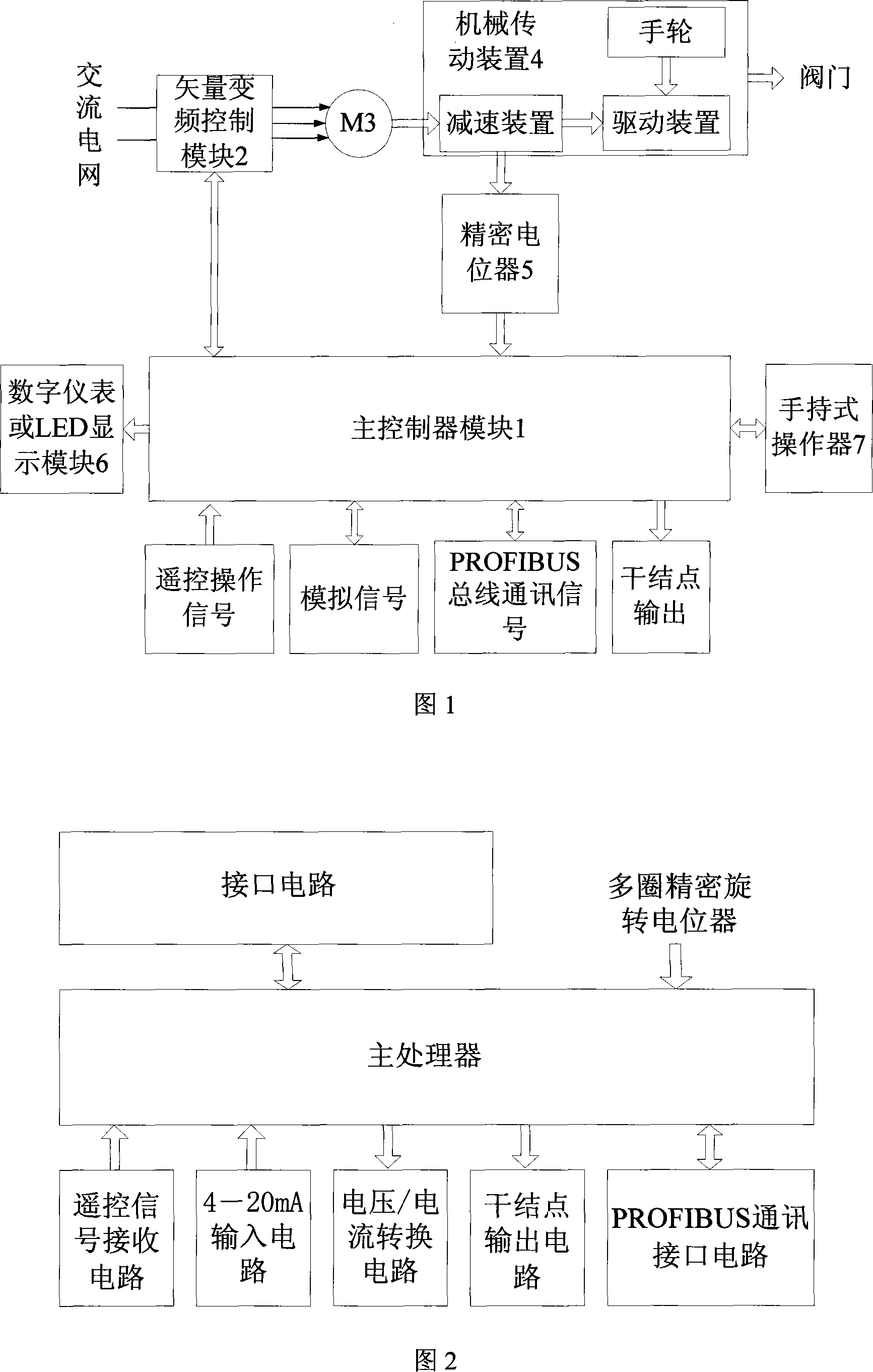

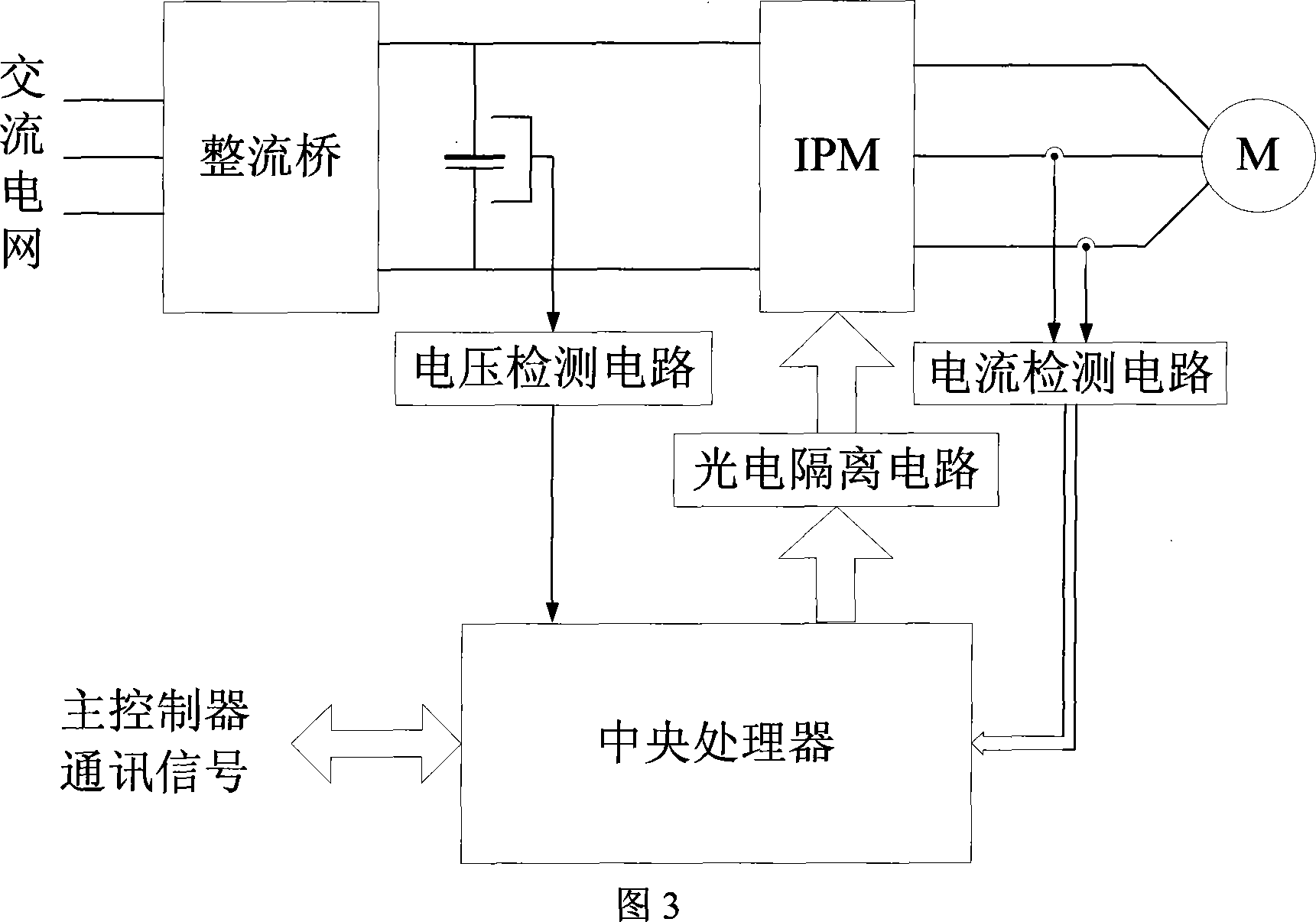

Frequency conversion type intelligent type valve actuator

InactiveCN101113793ASimplify the actuator structureContinuously adjustable running speedElectric signal transmission systemsAC motor controlSingle phaseControl mode

The invention relates to frequency conversion intelligent valve executing mechanism, comprising a main controller module 1, a vector frequency conversion control module 2, an asynchronous motor 3, a mechanical transmission device 4, a multi-circle precision rotating potentialmeter 5, a display module 6, and a handy operator 7. The invention is mainly characterized in that: the asynchronous motor is driven by the vector frequency conversion control module, and the precision rotating potentialmeter is used as a position sensor, to control the valve position by adopting whole digital proportional close-loop regulation type, and the control type comprises a plurality of control modes such as local remote control operation, handy operator control, long distance analog control, and bus control, etc, and a low temperature-rise special frequency conversion motor. The invention has the advantages of small size, high reliability, high positioning precision, having servo control characteristics, and easy networked control, etc. Compared with traditional executing mechanism, the invention greatly enhances the positioning precision, can continuously work for a long time, and automatically adapt to the working condition of single phase or three phase DC power.

Owner:孙力

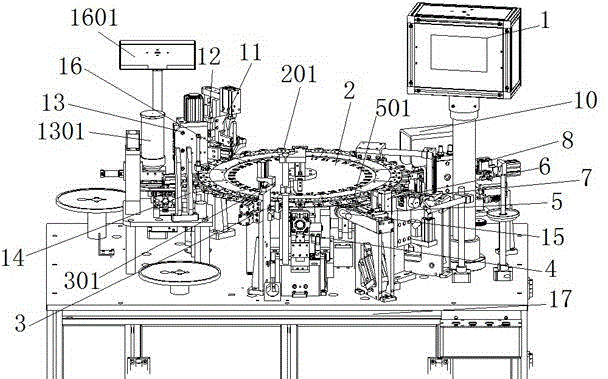

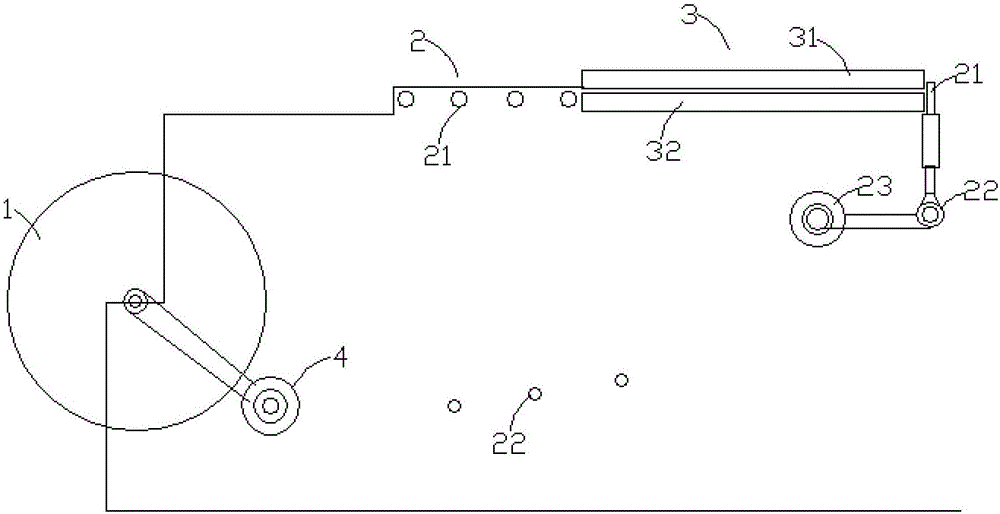

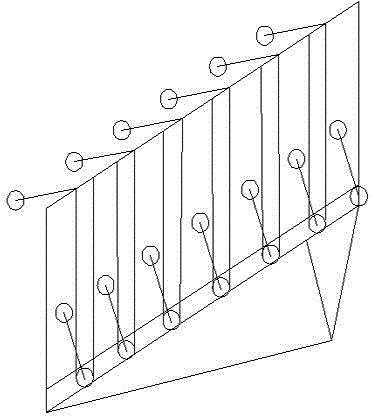

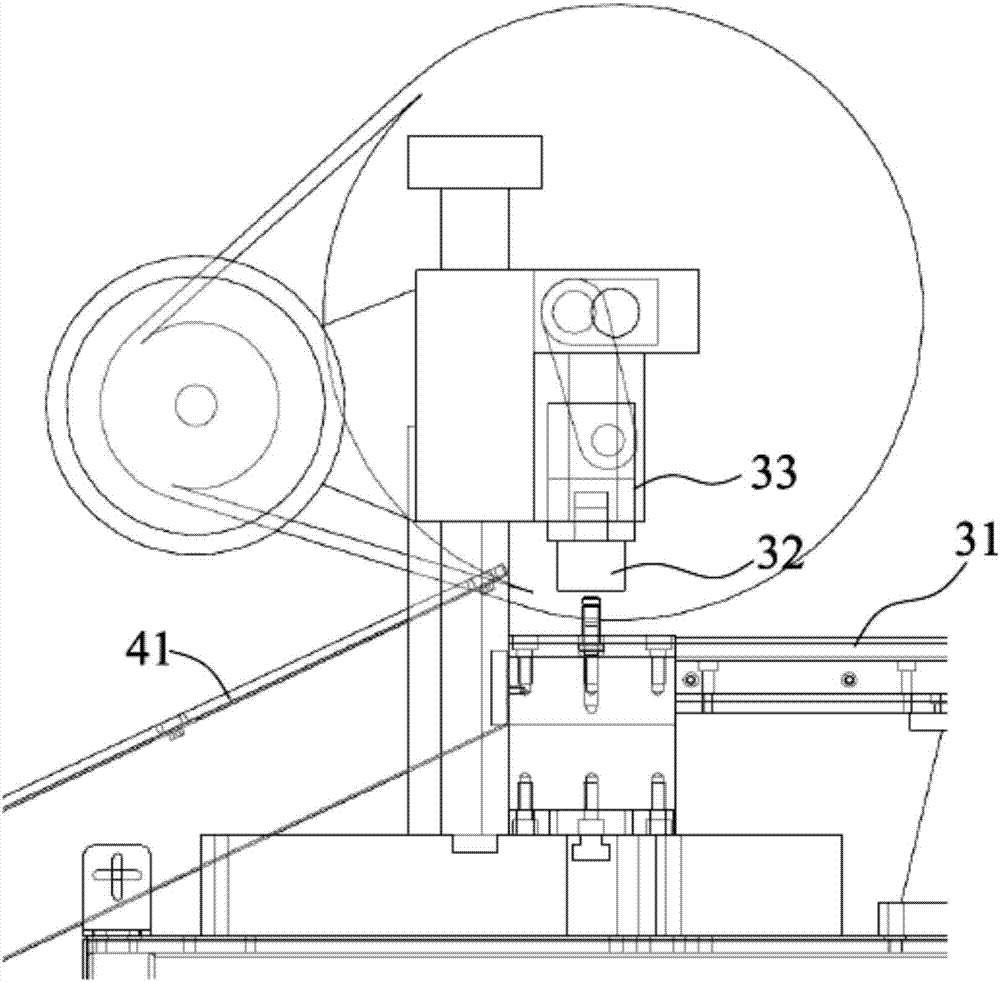

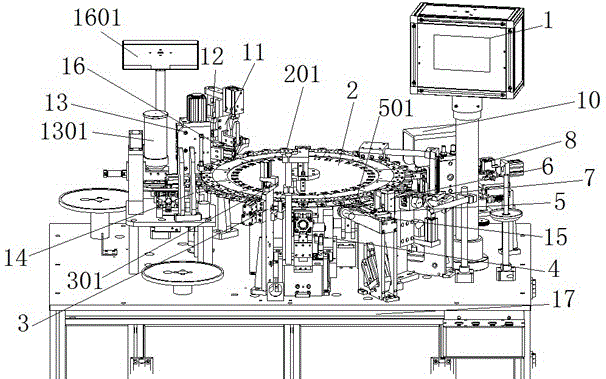

Automatic threading?welding machine applied to fuse production

ActiveCN103824730AQuality assuranceFast processingFuse device manufactureRapid processingEngineering

The invention discloses an automatic threading?welding machine applied to fuse production, which comprises a controller and a dividing disk. The circumference of the dividing disk is sequentially provided with a feeding mechanism, a loading station, a threading station for threading two wires inside an inner shell and cutting the wires to a fixed length, a flatting station, a rosin water-staining station, a tin-staining station, a corner-folding station, a fuse-wrapping station, a double-spot welding station, a wire-pulling station, an outer shell-assembling station for coating the inner shell with an outer shell for producing a finished product, and an unloading station for finished product collection. The automatic threading?welding machine applied to fuse production has the beneficial effects that multiple types of work of the fuse can be simultaneously and synchronously carried out with one machine, functions of mechanical, electronic and detection aspects are integrated as one, quick processing and manufacturing can be realized, product performances can be detected via a detection station and an impedance test?station, inferior-quality?products are removed to ensure the finished product quality, time and labor are saved, the labor cost is greatly reduced, flexibility is high, and demands of modernized industrial?production can be well met.

Owner:ZHEJIANG CANYUAN HOME TEXTILE

Analysis method of chromium content in chromium additive for aluminum alloy

InactiveCN102495060AOvercome costsOvercome accuracyMaterial analysis by observing effect on chemical indicatorAmmonium ferrous sulfatePotassium dichromate

The invention relates to an analysis method of chromium content in a chromium additive for an aluminum alloy, solving the problems of an existing detection method of the chromium content in the chromium additive that the cost is high, the detected result is not accurate and the efficiency is low. The analysis method comprises the following steps of: titrating a potassium dichromate standard solution by an ammonium ferrous sulfate standard solution by consuming the ammonium ferrous sulfate standard solution with the volume of V1; utilizing the ammonium ferrous sulfate standard solution to titrate a chromium element in a chromium additive sample by consuming the ammonium ferrous sulfate standard solution with the volume of V; and calculating to obtain the chromium content by using a formula W%=C*V*M / 3m, wherein C is the concentration of the ammonium ferrous sulfate standard solution, M is the molar mass of the chromium, and m is the mass of the chromium-powder additive sample. According to the invention, by utilizing a titration method, the analysis method has the advantages of simplicity in operation, capabilities of saving cost and improving efficiency, less interference and accurate detected result, and can solve the problems that the existing detection method is high in cost, inaccurate in the detected result and low in efficiency, thereby meeting the requirements of the modern industry production.

Owner:哈尔滨东盛金材科技(集团)股份有限公司

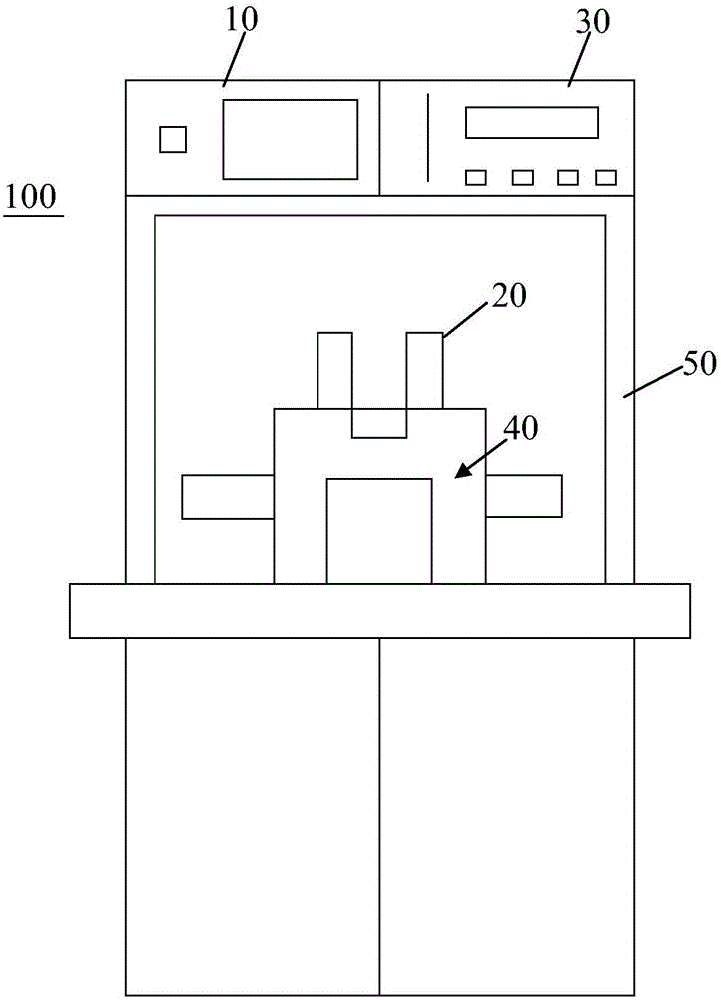

Leakage testing device

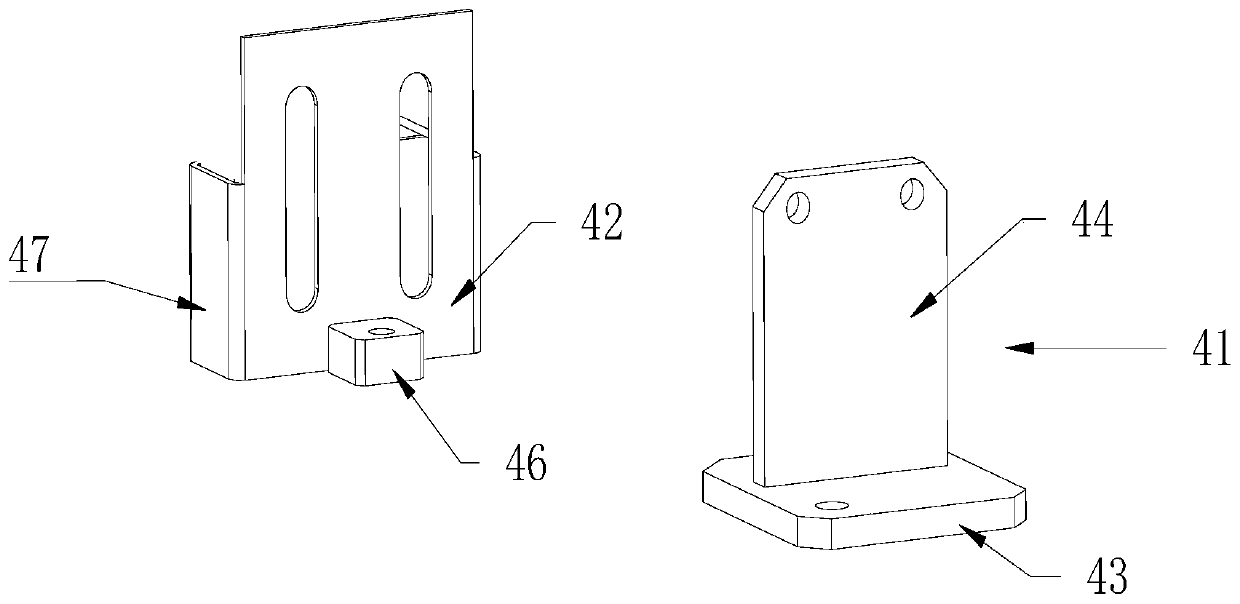

InactiveCN105067192AEfficient detectionQuick checkFluid-tightness measurement using fluid/vacuumEngineeringTest fixture

The invention provides a leakage testing device. The leakage testing device comprises a control unit, a pneumatic unit, a control panel, a testing unit and a framework, wherein the control unit, the pneumatic unit, the control panel and the testing unit are integrally installed on the framework; the control unit is installed on the top part of the framework and comprises a controller and a display panel; the pneumatic unit comprises a testing pneumatic pipeline and a clamping assembly, the testing pneumatic pipeline comprises a leakage tester and a cylinder, and the leakage tester and the cylinder are connected through a gas source pipeline; the control panel is installed on the top part of the framework, and a sudden stop button, a reset button, a starting button and an indicating lamp are integrated on the control panel; and the testing unit is installed below the control unit and the pneumatic unit and comprises a testing tool and a testing bench. The leakage testing device provided by the invention is capable of effectively and rapidly detecting a safety module, the detection efficiency is high, the accuracy is good, the quality of the safety module is ensured, and the requirements of modern industrial production are met.

Owner:SUZHOU IND PARK YIDA PRECISION ENG CO LTD

Bag making machine

InactiveCN106476326AIncrease productivityOvercome defectsBag making operationsPaper-makingProduction lineFlanging

The invention provides a bag making machine comprising a feeding device, a hot cutting device, a folding device, a flanging device, a first sewing device, a reversing and flanging device, a second sewing device, a bag collecting device and a bag tying device which are sequentially arranged. The bag making machine provided by the invention is high in production efficiency, low in equipment cost and capable of overcoming defects existing in the existing packaging bag making machine, realizing continuous automatic production of packaging bags on one production line and sufficiently meeting the requirement of modern industrial production.

Owner:苏州万洋精密机械有限公司

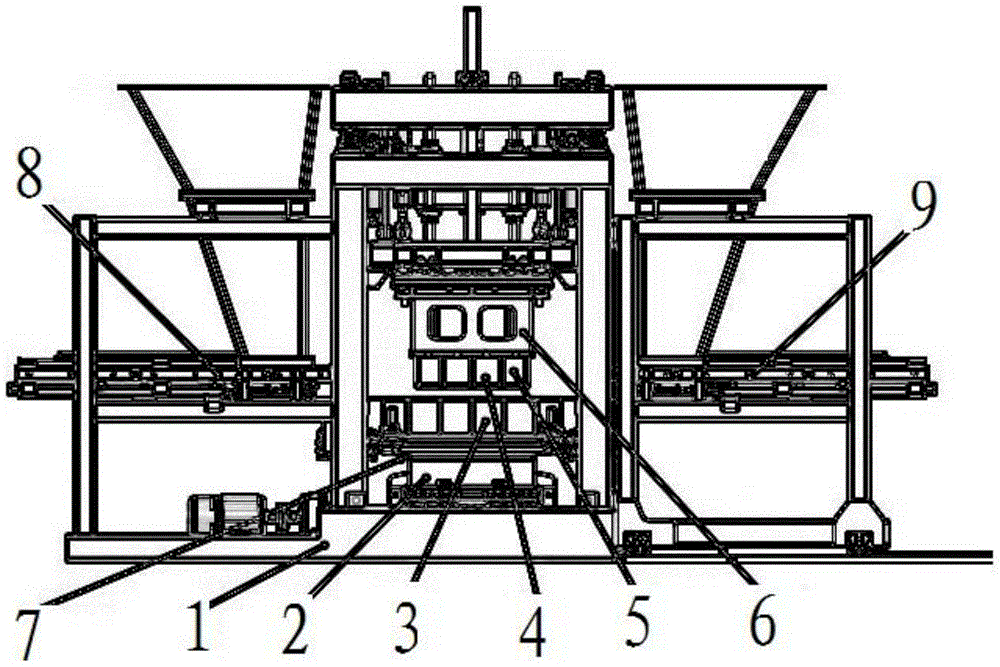

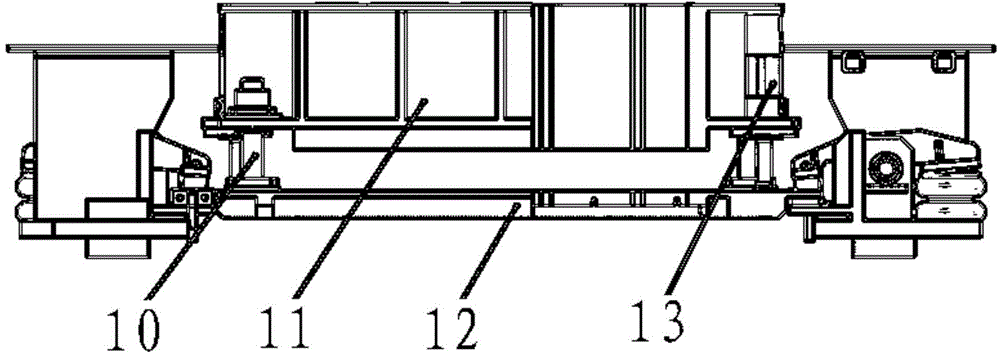

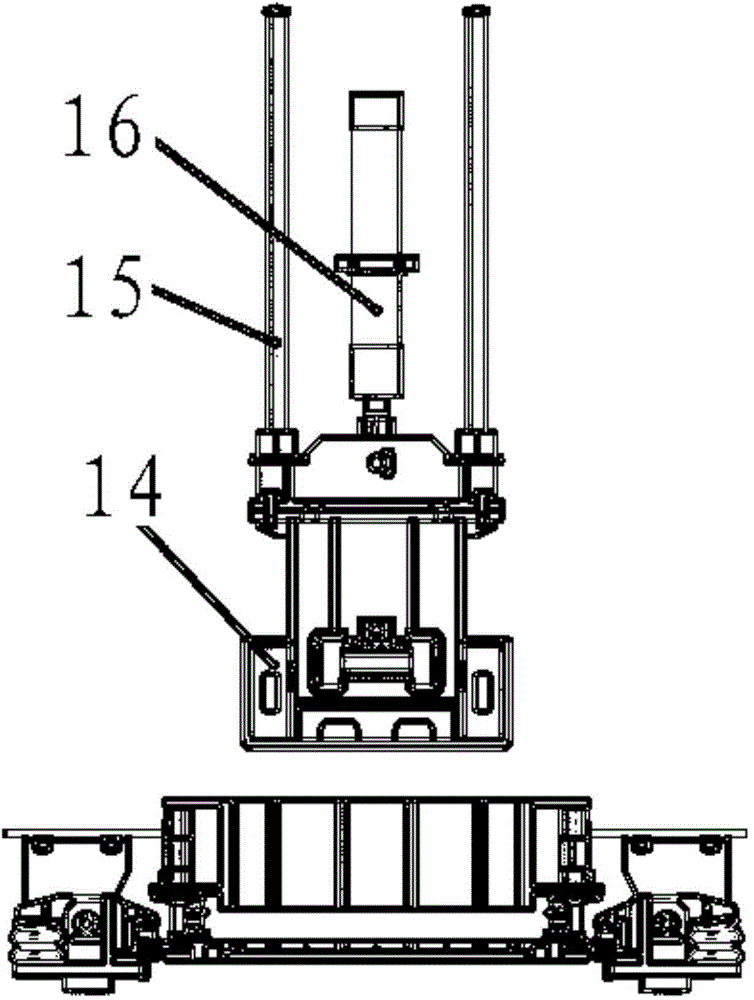

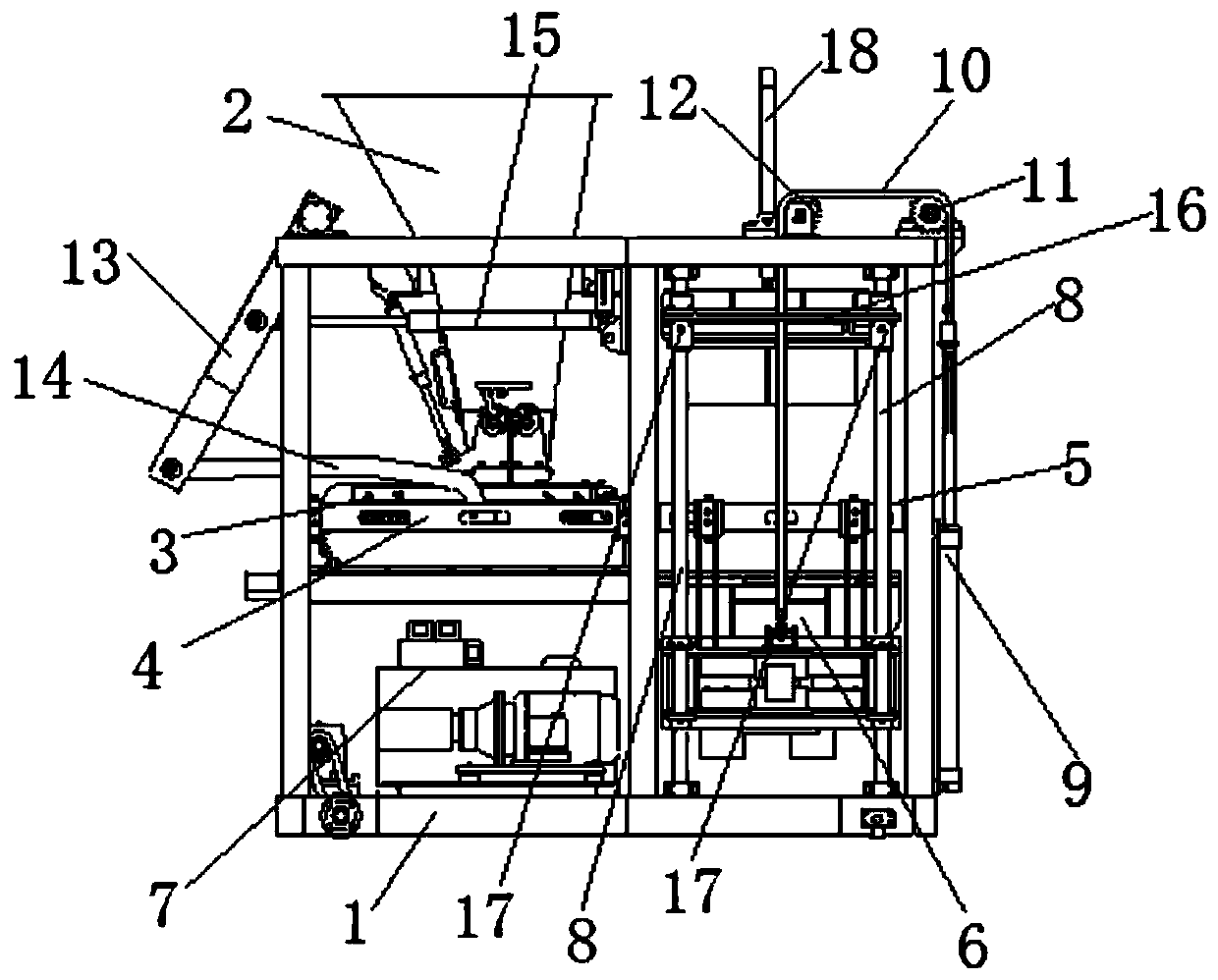

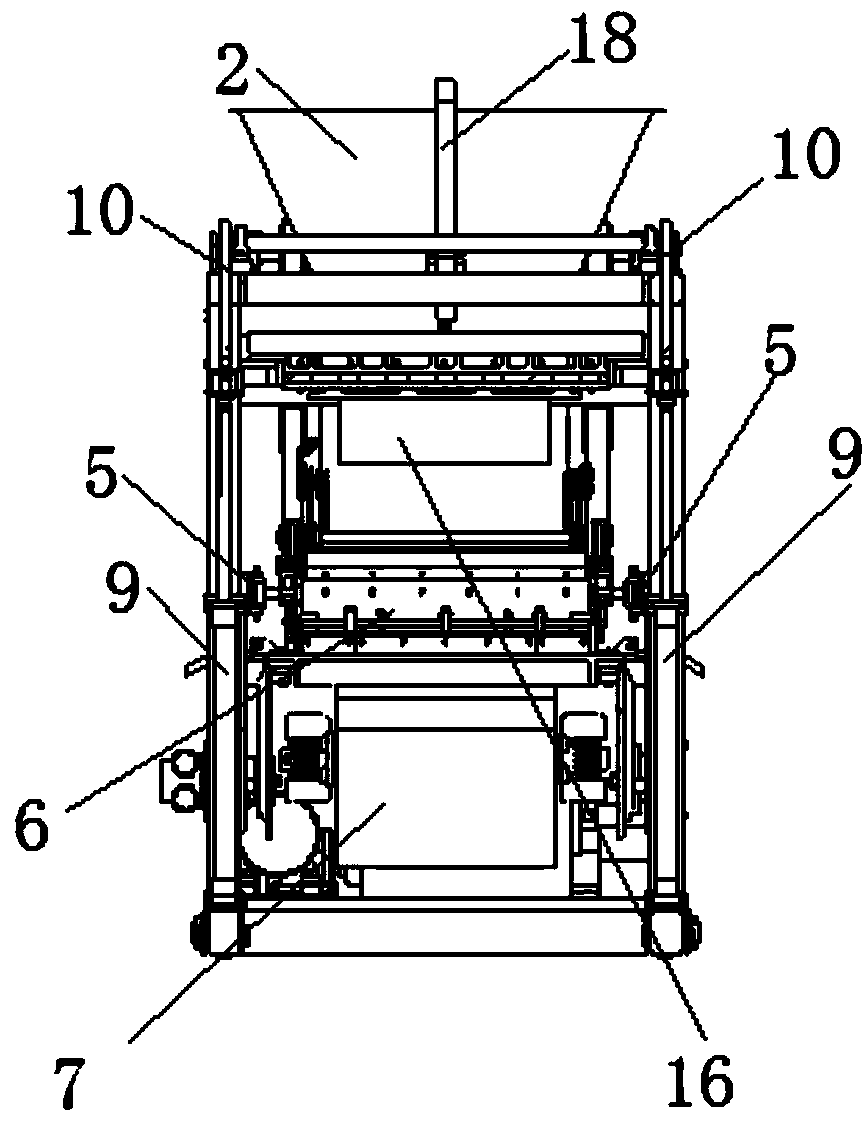

Thin-wall concrete hollow shell forming machine

ActiveCN104552558AImprove inner qualityReduce consumptionFeeding arrangmentsMaterial consumptionEconomic benefits

The invention discloses a thin-wall concrete hollow shell forming machine. The thin-wall concrete hollow shell forming machine comprises a frame; a base table vibrating device is arranged on the frame; a matching combined die is arranged at the upper end of the base table vibrating device; a die core device is arranged at the upper end of the combined die; a matching die core vibrating device is arranged at the upper end of the die core device; a matching die head device is arranged at the upper end of the die core vibrating device; a base plate distribution device is further arranged at the rear end of the combined die; matched left and right side plate distribution devices are arranged on the left and right sides of the base plate distribution device, respectively. The thin-wall concrete hollow shell forming machine has the beneficial effects: full-automatic mechanical production is realized, the production efficiency is high, the product is remarkably improved in inherent quality and surface quality, the product consistency is good, the production site and the maintenance time are saved, the turnover dies are reduced, the production energy consumption and the material energy consumption are reduced, and excellent economic benefit can be produced; the thin-wall concrete hollow shell forming machine can be applied to producing high-strength thin-film concrete products from dry hard concrete, in particular thin-wall products having the height of greater than 200mm.

Owner:BEIJING REIT TECH DEV

High density silicon carbide ceramic and pressureless sintering method thereof

The invention discloses a high density silicon carbide ceramic and a pressureless sintering method thereof. The pressureless sintering method comprises mixing silicon carbide, epoxy resin, bentonite, diatomite, boron carbide, glass fibers, carbon black, petroleum coke and anhydrous ethanol, carrying out ball milling to obtain slurry M, drying the slurry M, carrying out granulation and aging to obtain powder N, mixing the powder N and a sintering aid, and carrying out pressing molding and sintering to obtain the high density silicon carbide ceramic. The method solves the problem that silicon carbide ceramic is difficult to form a compact structure after atmospheric pressure sintering because of silicon carbide ceramic characteristics and thus the silicon carbide ceramic has low density and high porosity and cannot satisfy the needs of industrial production.

Owner:WUHU QIANKAI MATERIAL TECH CO LTD

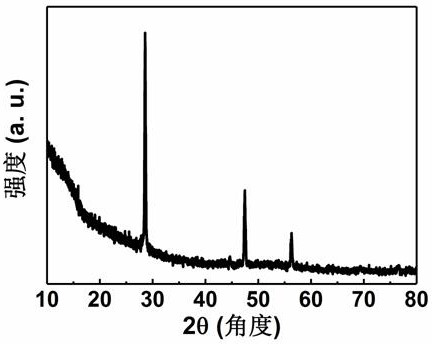

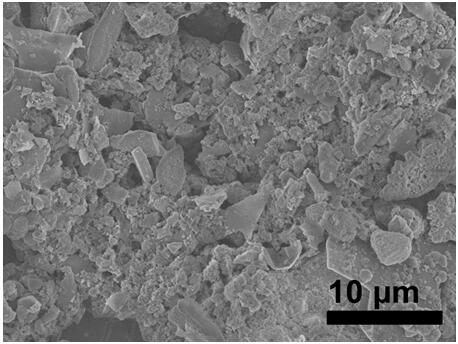

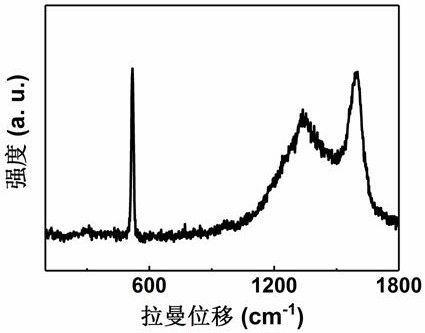

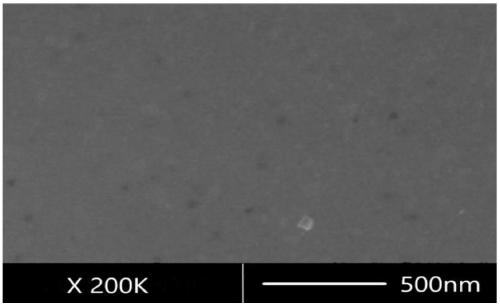

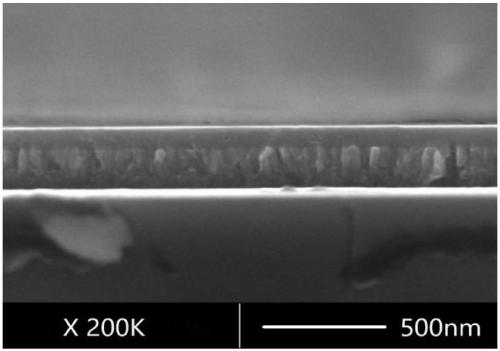

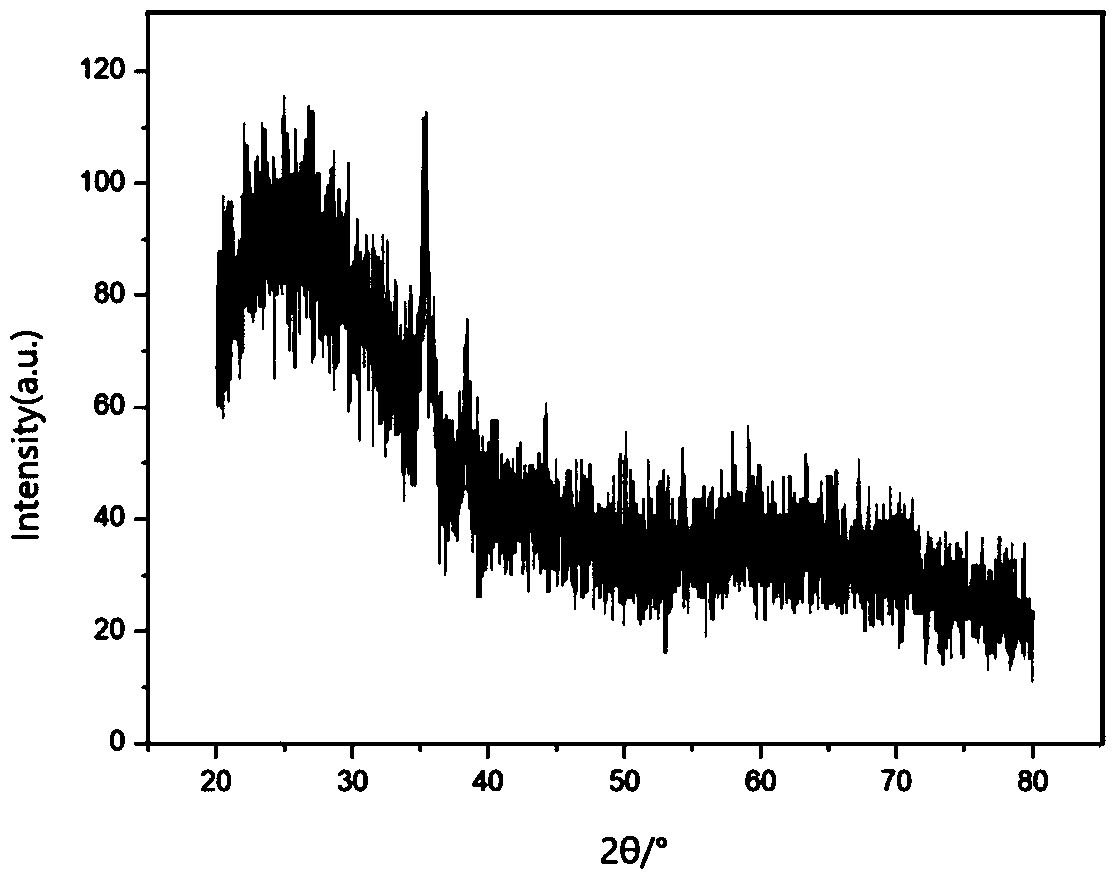

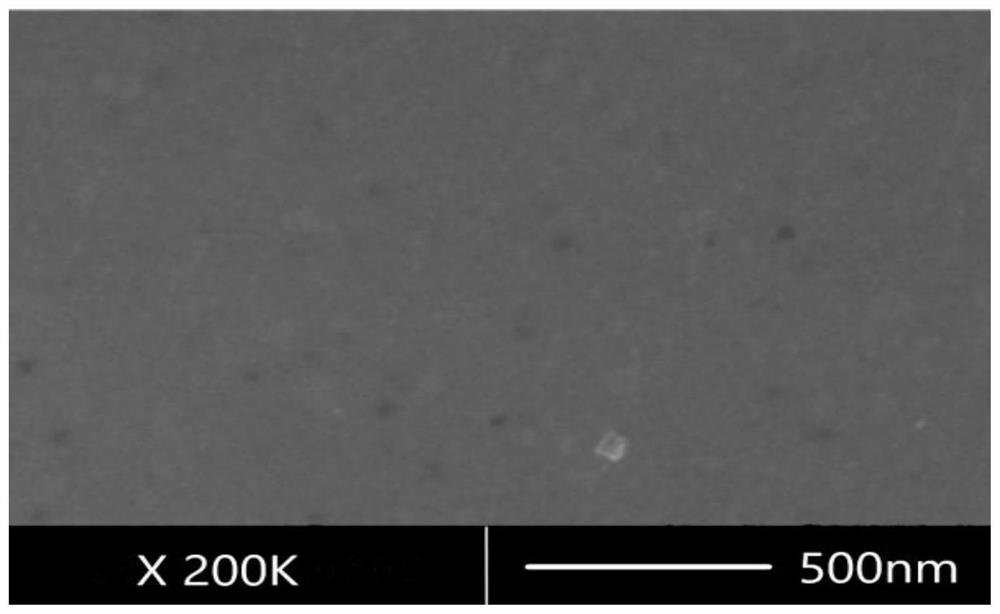

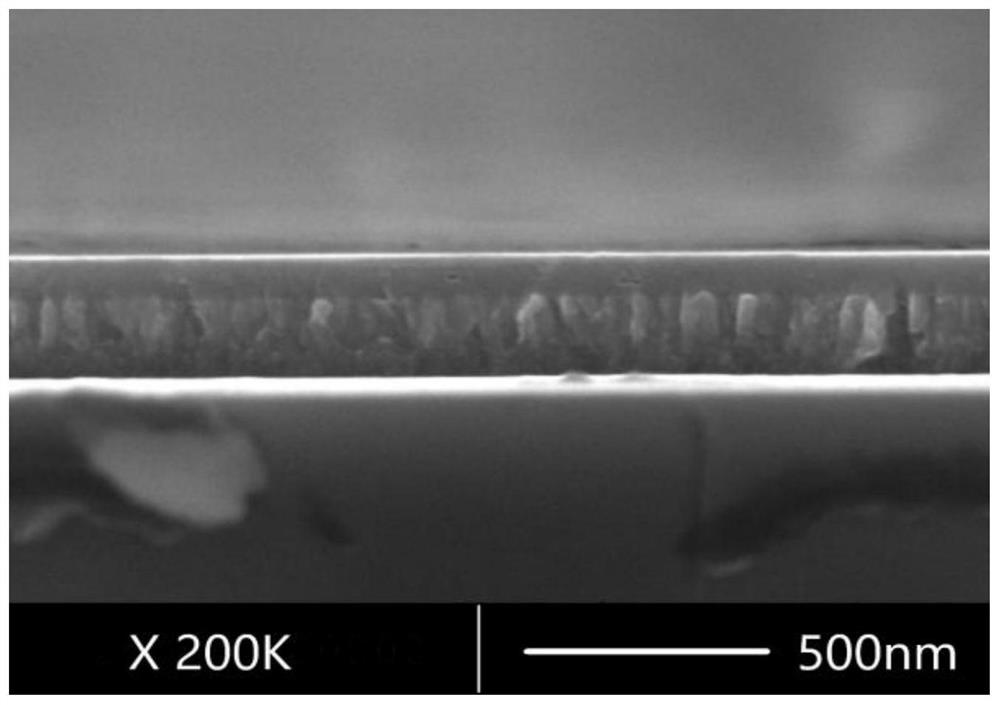

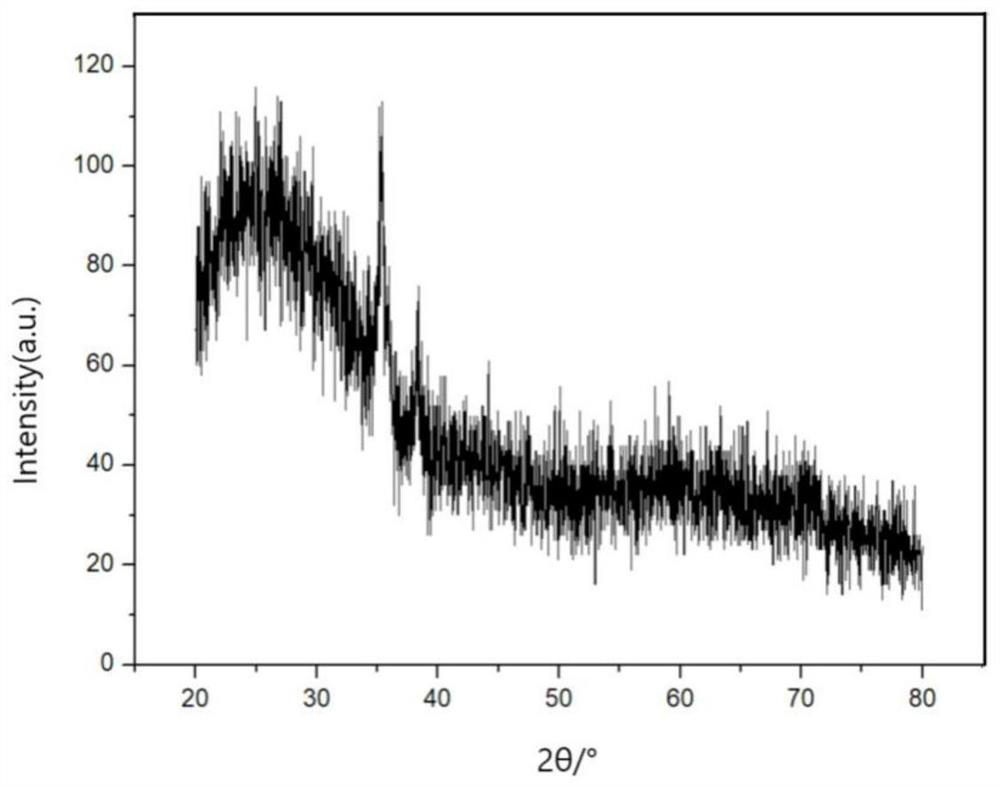

Method for preparing carbon-silicon composite material by utilizing algae biomass and application of carbon-silicon composite material in lithium ion battery

PendingCN114014320ASimple processLow costCell electrodesNanotechnologyComposite materialAlgae biomass

The invention discloses a method for preparing a carbon-silicon composite material by utilizing algae biomass and application of the carbon-silicon composite material in a lithium ion battery. A molten salt method is adopted, algal biomass causing environmental pollution is fully utilized to prepare the carbon-silicon composite material, the process is simple, the cost is low, amorphous carbon formed by carbonization of carbon elements contained in an algal biomass precursor is uniformly and hierarchically compounded with silicon, and the conductivity of the material is effectively improved, in addition, sufficient coating of carbon can effectively relieve volume expansion in the charge-discharge process and inhibit pulverization of the electrode material, and can sufficiently maintain the structural integrity of the electrode, so that the cycle stability is improved, the cycle life of the battery is sufficiently and effectively improved, the requirements of modern industrial production can be sufficiently met, commercial large-scale production is realized, and the application prospect is very wide.

Owner:LANZHOU CITY UNIV

Method for rapidly preparing colorful titanium oxide thin film on surface of substrate material

ActiveCN109487222AReduce temperature riseAvoid damageVacuum evaporation coatingSurface reaction electrolytic coatingTitaniumTitanium oxide

The invention relates to the technical field of film coating, in particular to a method for rapidly preparing a colorful titanium oxide thin film on the surface of substrate material. The method comprises the following steps: at first, a layer of titanium film is sprayed on the surface of the substrate material through the magnetron sputtering technology, then, the substrate material is put into an electrolytic cell which has been set up, the electrolytic cell is filled with electrolyte, the to-be-coated substrate material is put on the cathode, and a stainless steel plate is hung on the anode. Generation and color of the titanium oxide thin film are controlled through changing the voltage of the electrolytic cell, so that the titanium film on the surface of the substrate material generates oxidizing reaction to generate a layer of colorful titanium oxide thin film to protect the titanium film. The electrolyte can be recycled and meets the requirements of environmental protection and industrial production; and in addition, the generated titanium oxide thin film can alleviate abrasion, scratch and contact corrosion of titanium, so that the problems about maintenance and abrasion during the using process of titanium are solved. With adoption of the method, the titanium oxide thin film can be rapidly prepared on the surface of common substrate material, and in addition, the colorof the titanium oxide thin film is easy to control and uniform. The thickness of the titanium oxide thin film prepared through the method is slightly influenced by the material shape.

Owner:SHANDONG UNIV

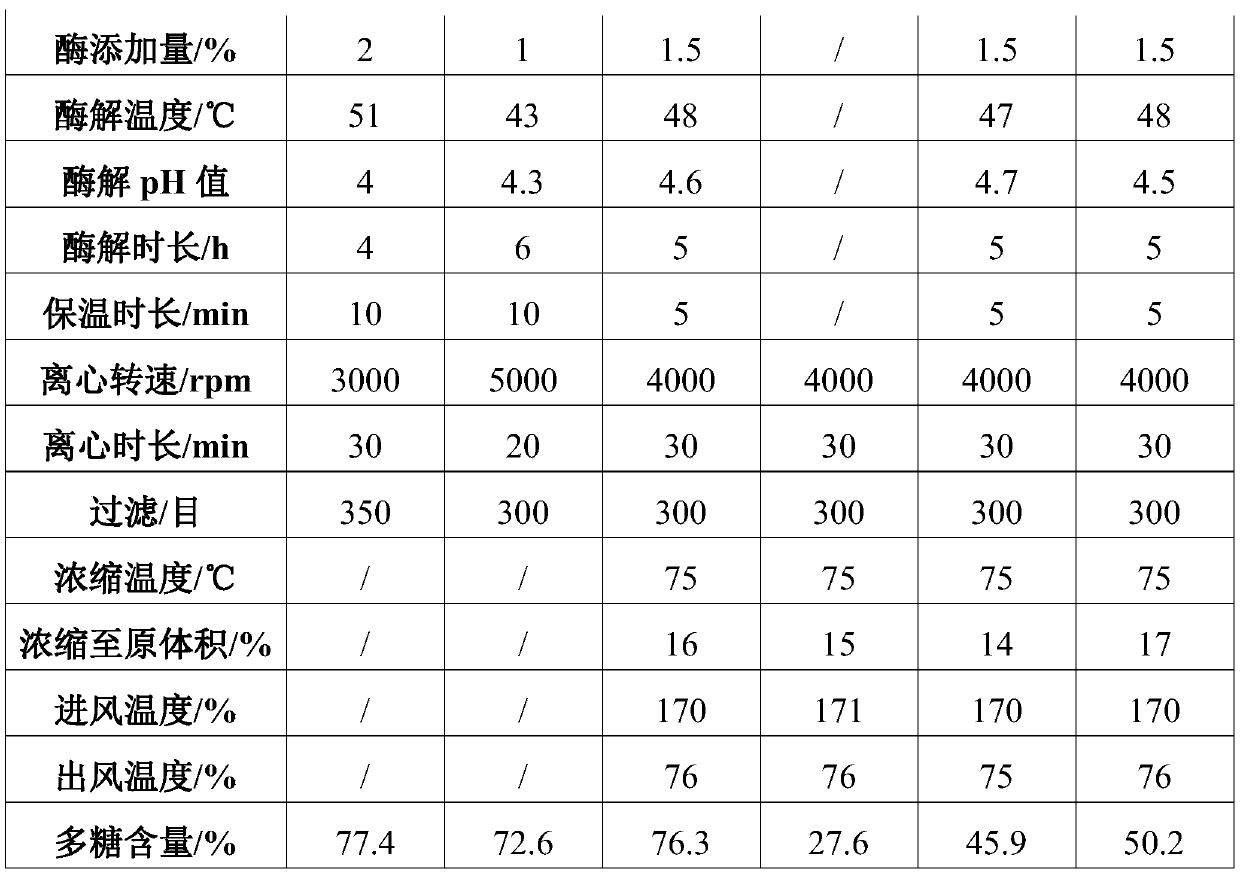

Pachymaran extraction method, pachymaran extract and poria cocos product combined production process

The invention relates to a pachymaran extraction method, a pachymaran extract and a poria cocos product combined production process. The pachymaran extraction method comprises the following steps: providing a poria cocos crude product; performing superfine grinding on the poria cocos crude product to obtain poria cocos wall-broken powder; mixing the poria cocos wall-broken powder with water, and grinding to prepare a poria cocos emulsion; carrying out enzymolysis on the poria cocos emulsion by adopting glucanohydrolase to prepare enzymatic hydrolysate; and inactivating the enzymatic hydrolysate, carrying out solid-liquid separation, and collecting the filtrate to obtain the pachymaran extract. According to the pachymaran extraction method, on the basis of ensuring the extraction rate, theuse of an organic solvent can be effectively avoided, and the product safety is improved.

Owner:GUANGDONG YIFANG PHARMA

A silicon carbide sealing material and a sintering method thereof

A silicon carbide sealing material and a sintering method thereof are provided. The method includes mixing silicon carbide, epoxy resin, bentonite, diatomite, boron carbide, glass fibers, carbon black, petroleum coke and absolute ethyl alcohol; performing ball milling to obtain slurry M; drying, granulating and ageing the slurry M to obtain powder N; mixing the powder N and a sintering auxiliary agent; and then performing compressed forming and sintering to obtain the sealing material. The sealing material and the method overcome a problem that compact silicon carbide sealing materials are difficult to prepare through atmospheric-pressure sintering and silicon carbide sealing materials are low in density, poor in leakproofness and high in porosity and cannot meet production requirements due to characteristics of the silicon carbide sealing materials.

Owner:ANHUI DONGXUN SEALING TECH

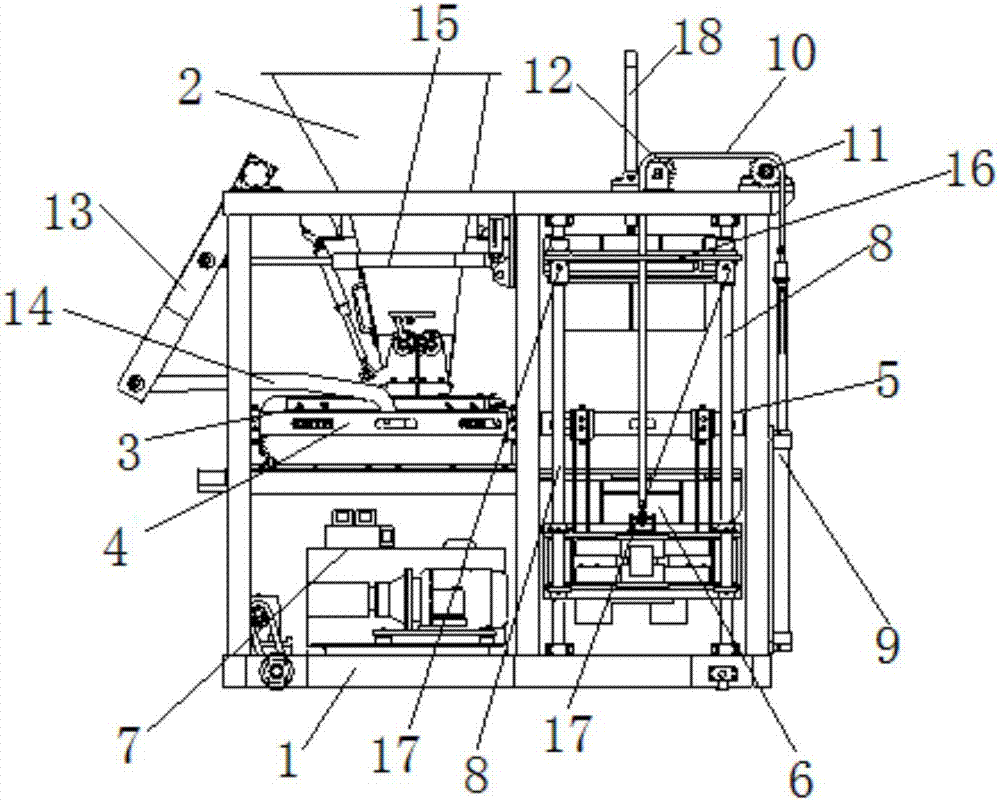

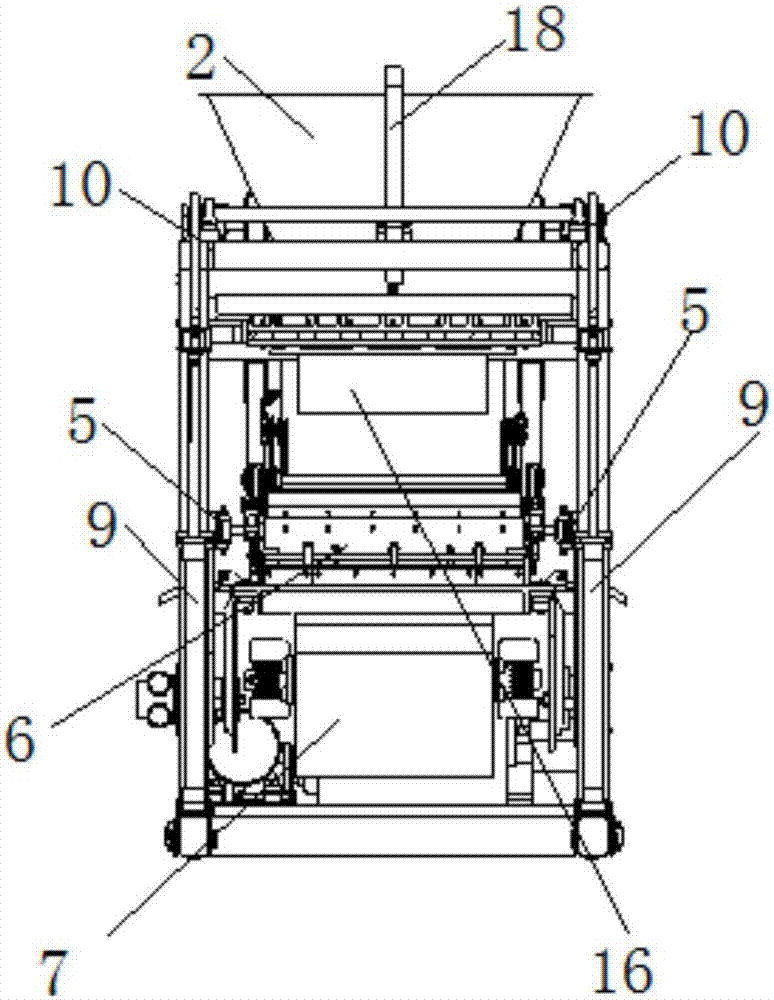

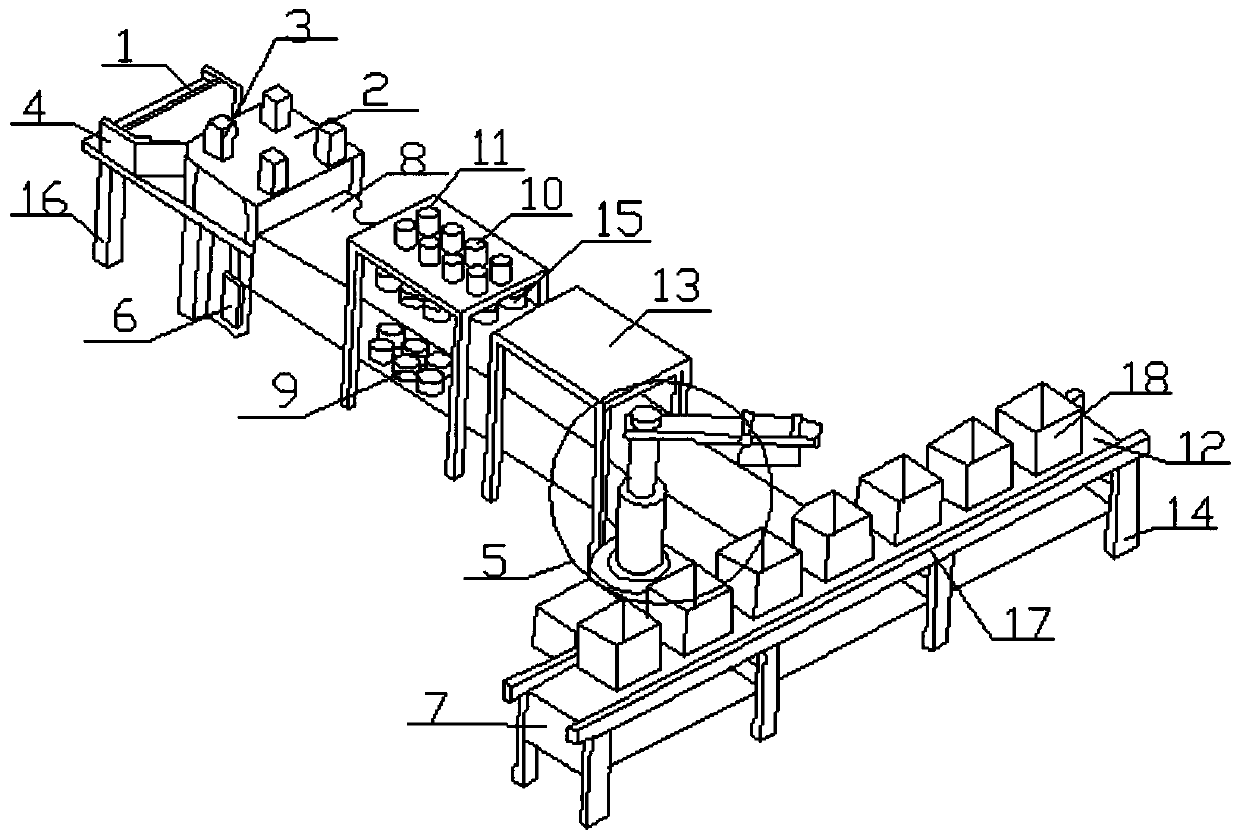

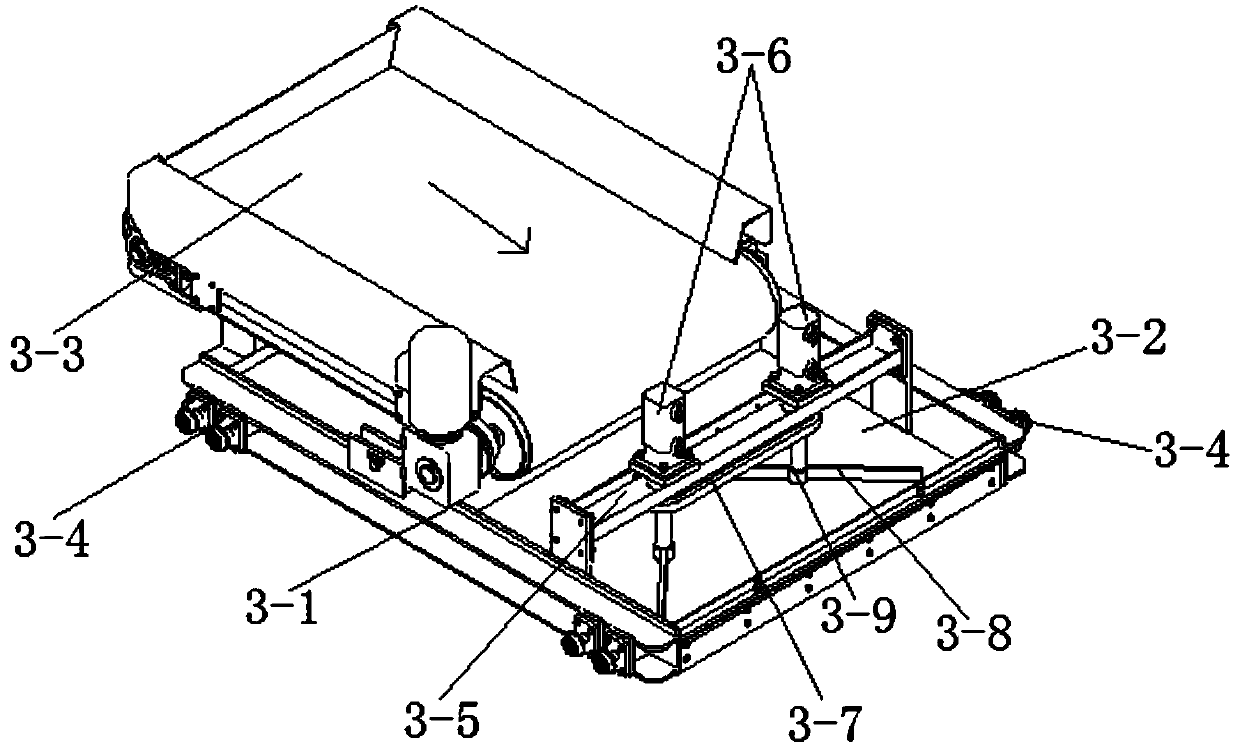

Rotary die type concrete product forming machine

ActiveCN107088950AImprove inner qualityRealize automatic mechanized productionDischarging arrangementFeeding arrangmentsEngineeringMaterial storage

The invention discloses a rotary die type concrete product forming machine. The rotary die type concrete product forming machine comprises a rack. A material storage hopper is arranged at the upper end of the rack. A material distributing trolley is arranged below the material storage hopper. Two parallel guide rails a and two parallel guide rails b located at the same height position with the guide rails a are arranged at the middle portion of the rack, and the guide rails a and the guide rails b are sequentially spliced and located on the same straight line. The two guide rails b are arranged on a rotary die vibration forming device. The rotary die vibration forming device is connected with a demoulding mechanism. A forming press head assembly is arranged above the rotary die vibration forming device. The rotary die vibration forming device is arranged on one side of the material distributing trolley. The material distributing trolley is connected with a material distributing driving device. The material distributing driving device and the demoulding mechanism are located at the two ends of the rack correspondingly. The rotary die vibration forming device, the demoulding mechanism, the forming press head assembly, the material distributing trolley and a hydraulic station providing power for the material distributing drive device are further arranged at the bottom of the rack. The problems that an existing forming machine cannot achieve uniform material distributing, and demoulding is difficult are solved.

Owner:BEIJING REIT TECH DEV

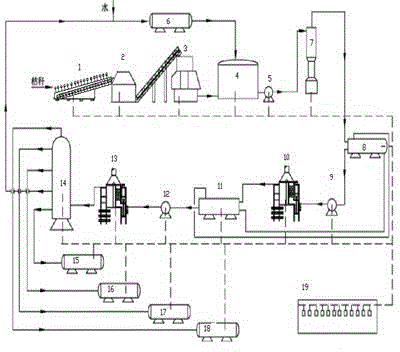

Biomass recycling and recovering equipment

InactiveCN105733694AReduce useLow costLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionIntercoolerBiomass

Biomass recycling and recovering equipment is disclosed. The equipment comprises a biomass roller-way screening and cleaning machine, a cutter, a chain grinder, a high-concentration pulper, a material pulp pump, a water purifying system, a high-concentration dreg removing machine, a waste-heat exchanger, a material pulp high-pressure pump I, a supercritical hydrolysis liquefaction reactor, an intercooler, a material pulp high-pressure pump II, a subcritical hydrolysis liquefaction reactor, a distillation and rectification device, a storage tank I, a storage tank II, a storage tank III, a storage tank IV and an operation control center which are connected in order, wherein inlets and outlets of fluid mechanical material pipes are provided with electromagnetic valves. According to the equipment, a large amount of waste heat generated in a middle process can be fully utilized, conveying, screening and cleaning are finished in one conveying line in a raw material conveying and primary processing process, devices are reduced, previous preparation steps are reduced, the cost is saved, a final product is subjected to separation through a distillation and rectification process, requirements on modern industrial production can be met, and wider application of biomass energy can be achieved.

Owner:QINGDAO QINGQUAN BIOTECH CO LTD

9W bulb lamp automatic assembly line

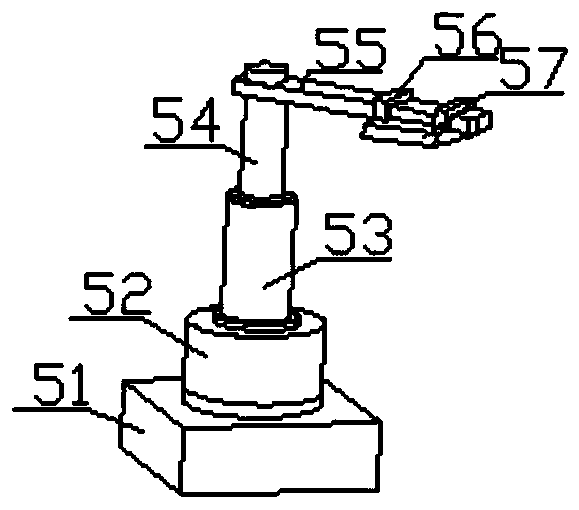

InactiveCN109732162AImprove transmission efficiencyFully automatedSoldering apparatusMetal working apparatusHydraulic cylinderAssembly line

The invention discloses a 9W bulb lamp automatic assembly line. The 9W bulb lamp automatic assembly line comprises a first conveying device and a second conveying device; an automatic loading stationis arranged at one end of the second conveying device; an overturning carrying device is arranged on one side of the other end of the second conveying device; the overturning carrying device comprisesa base; a rotating motor is mounted above the base; a lifting hydraulic cylinder is arranged at the upper part of the rotating motor; a lifting hydraulic rod is arranged above the lifting hydraulic cylinder; a cross beam is mounted at the top of the lifting hydraulic rod; a wire arrangement welding station is arranged on one side of the automatic loading station; an assembly device is arranged onthe side, far from the automatic loading station, of the wire arrangement welding station; the assembly device comprises a screw assembly station and an upper lamp cover assembly station; and the first conveying device comprises a conveying frame. The 9W bulb lamp automatic assembly line is simple in structure, and realizes automation through cooperative use of the overturning carrying device, the first conveying device and the second conveying device.

Owner:深圳市拓野智能股份有限公司

Silicon carbide ceramic material for bearings and preparation method of silicon carbide ceramic material for bearings

The invention discloses a silicon carbide ceramic material for bearings and a preparation method of the silicon carbide ceramic material for the bearings. The preparation method includes: mixing silicon carbide, aluminum oxide powder, zirconium oxide powder, methylene bisacrylamide, acrylamide, glass fibers, graphite powder, petroleum coke and absolute ethyl alcohol, and performing ball milling toobtain slurry M; subjecting the slurry M to drying, granulating and aging to obtain powder N; mixing the powder N with sintering additives, and performing pressure forming and sintering to obtain thesilicon carbide ceramic material. The problem of failure in meeting of industrial production demands due to low density and high porosity of silicon carbide ceramics which can be hardly compacted bysintering under the normal pressure owing to characteristics of the silicon carbide ceramics is solved.

Owner:芜湖市尚行会务服务有限公司

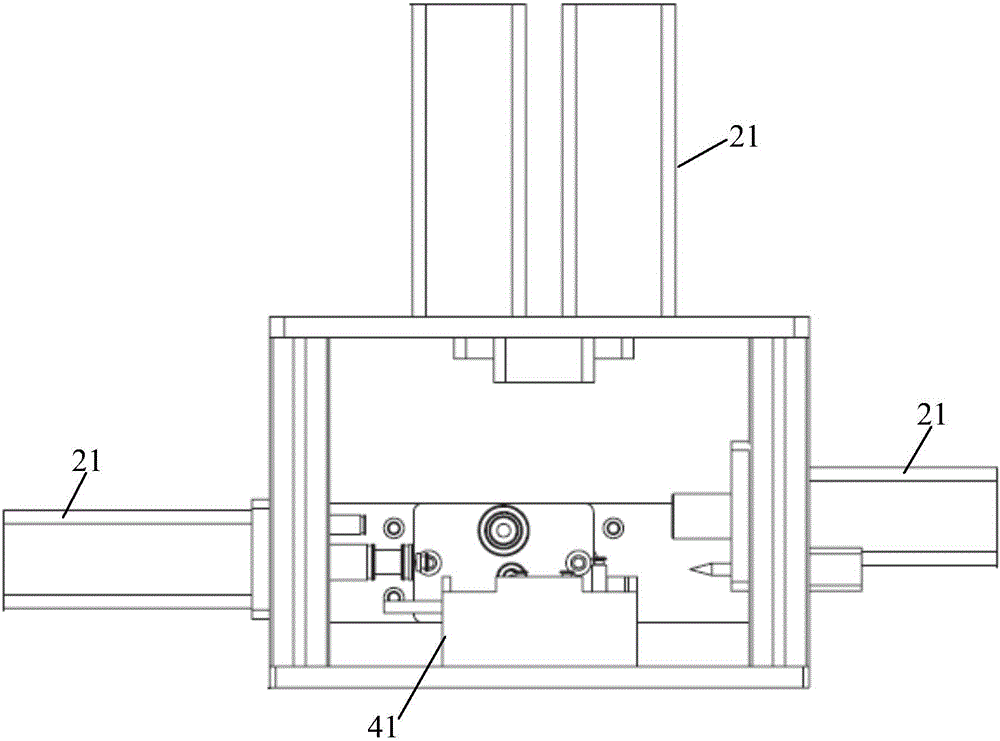

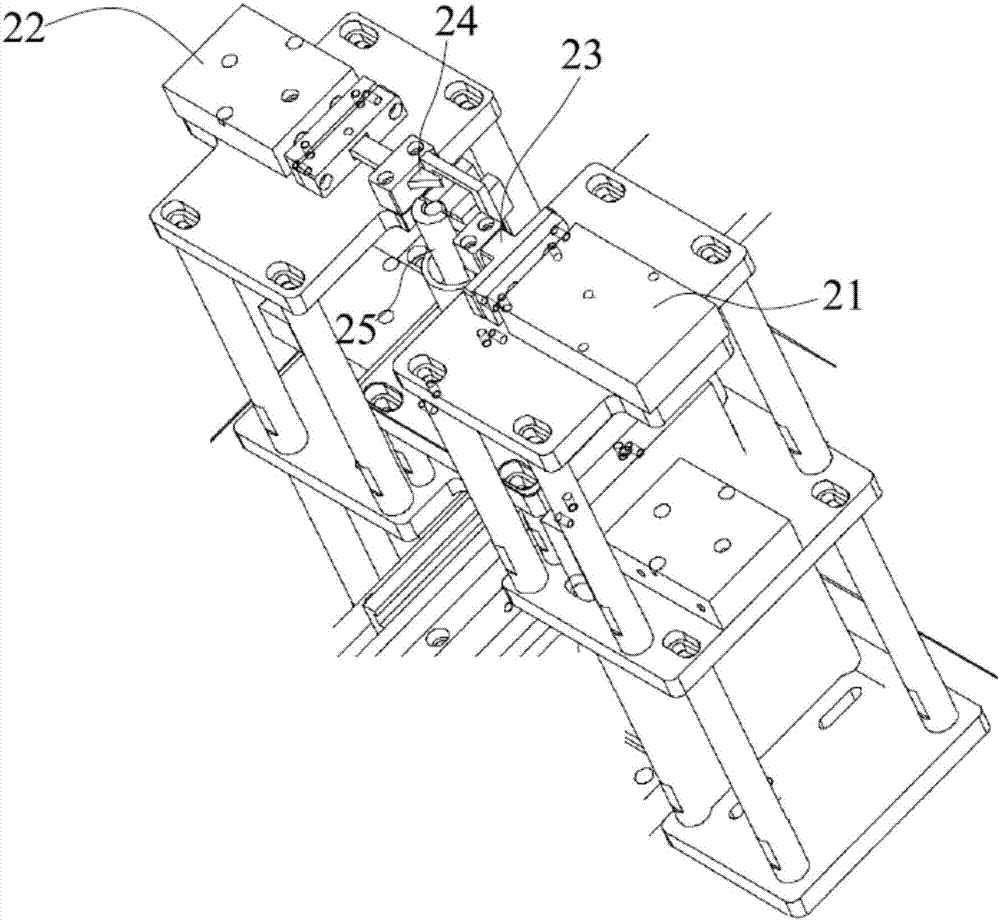

Automatic assembly device

PendingCN107081591AImprove assembly efficiencyGood precisionMetal working apparatusMechanical engineering

The invention provides an automatic assembly device. The automatic assembly device comprises a feeding station, a sleeving station, a pressing-fit station and a discharging station which are sequentially arranged. The feeding station comprises a first vibration disc and a first guide rail and further comprises a second vibration disc and a second guide rail. The first guide rail used for conveying nail rods is located above the second guide rail used for conveying nail sleeves. The sleeving station comprises a first air cylinder and a second air cylinder which are oppositely arranged and do not synchronously work. The first air cylinder applies fixing acting force onto the nail rods conveyed through the first guide rail, and the second air cylinder applies pushing force which enables the nail rods to fall off onto the nail rods conveyed through the first guide rail. The pressing-fit station comprises a stamping head and a power mechanism used for driving the stamping head to conduct stamping. The discharging station comprises an obliquely-arranged discharging slide rail with one end being connected with the pressing-fit station. According to the automatic assembly device, automatic assembly of the nail rods and the nail sleeves can be achieved, assembly efficiency of the automatic assembly device is high, precision is good, and the requirements of modern industry production are sufficiently met.

Owner:苏州市中智远创机械科技有限公司

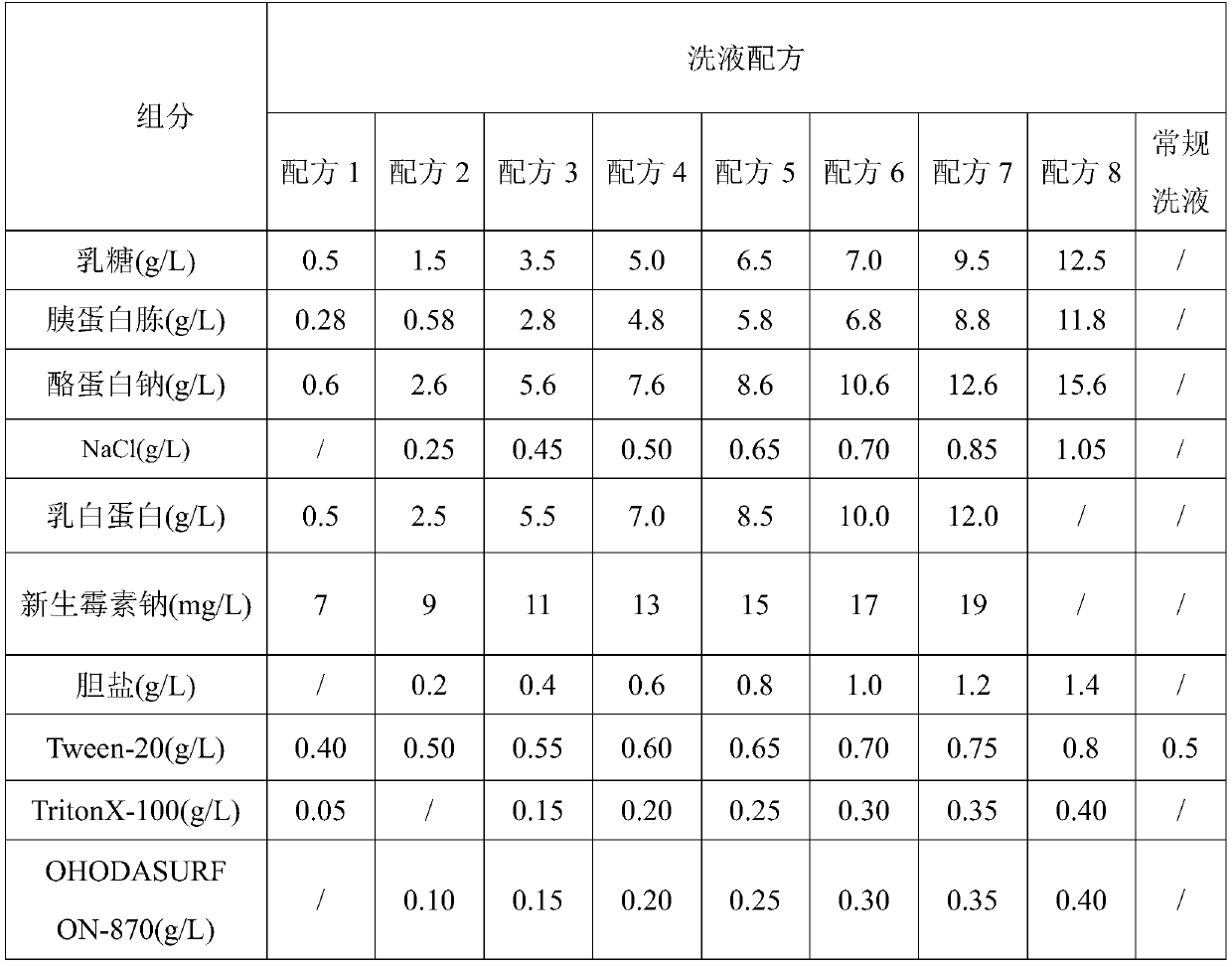

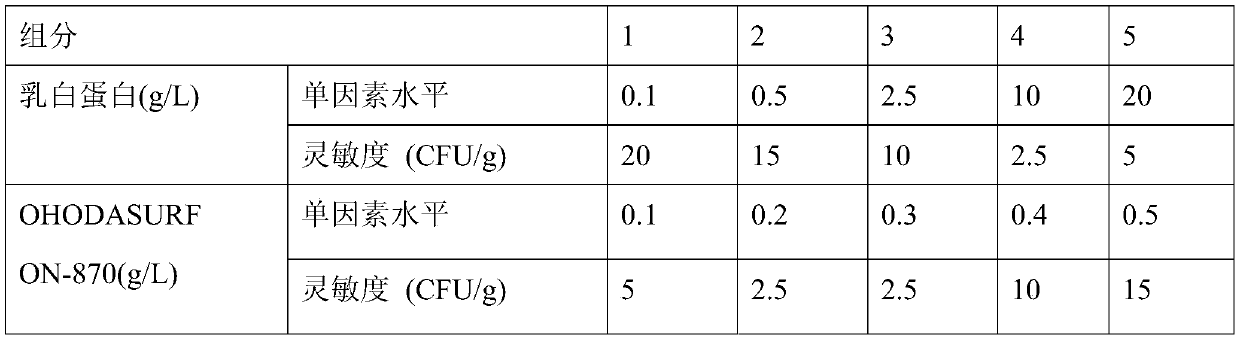

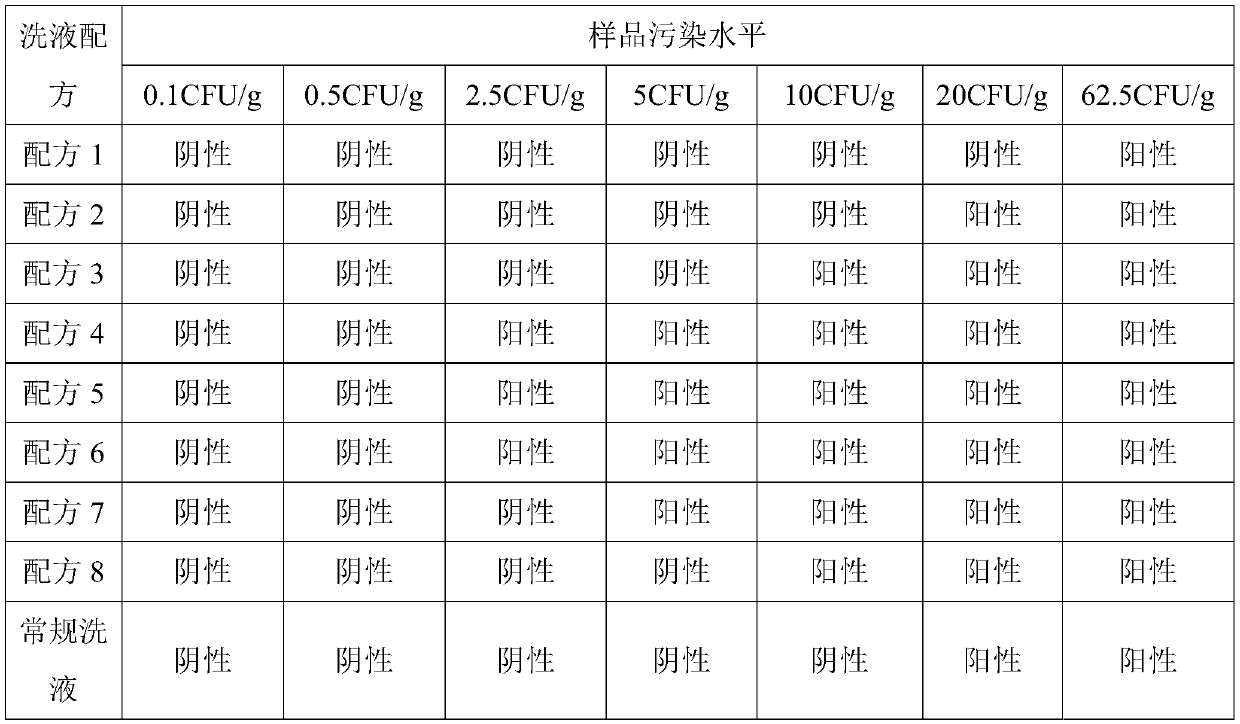

Escherichia coli O157 immunizing magnetic bead lotion

PendingCN110819687AImprove the detection rateImprove accuracyMicrobiological testing/measurementBiotechnologyEscherichia coli

The invention discloses an Escherichia coli O157 immunizing magnetic bead lotion. The Escherichia coli O157 immunizing magnetic bead lotion is prepared through mixing a surfactant, proteins, water-soluble saccharides, inorganic salts and a bacteriostatic agent at a specific ratio, wherein a buffer solution serves as a solvent. Compared with the conventional magnetic bead lotions, the Escherichia coli O157 immunizing magnetic bead lotion has the advantages that besides the cleaning effect is improved, bacteria are further specifically and continuously increased, and the detectable rate of Escherichia coli O157 is increased. Furthermore, the interference caused by food matrixes is effectively reduced, the sensitivity of the immunizing magnetic bead lotion is improved, and defects of the conventional magnetic bead lotions are overcome.

Owner:GUANGDONG HUANKAI BIOLOGICAL SCI & TECH CO LTD +2

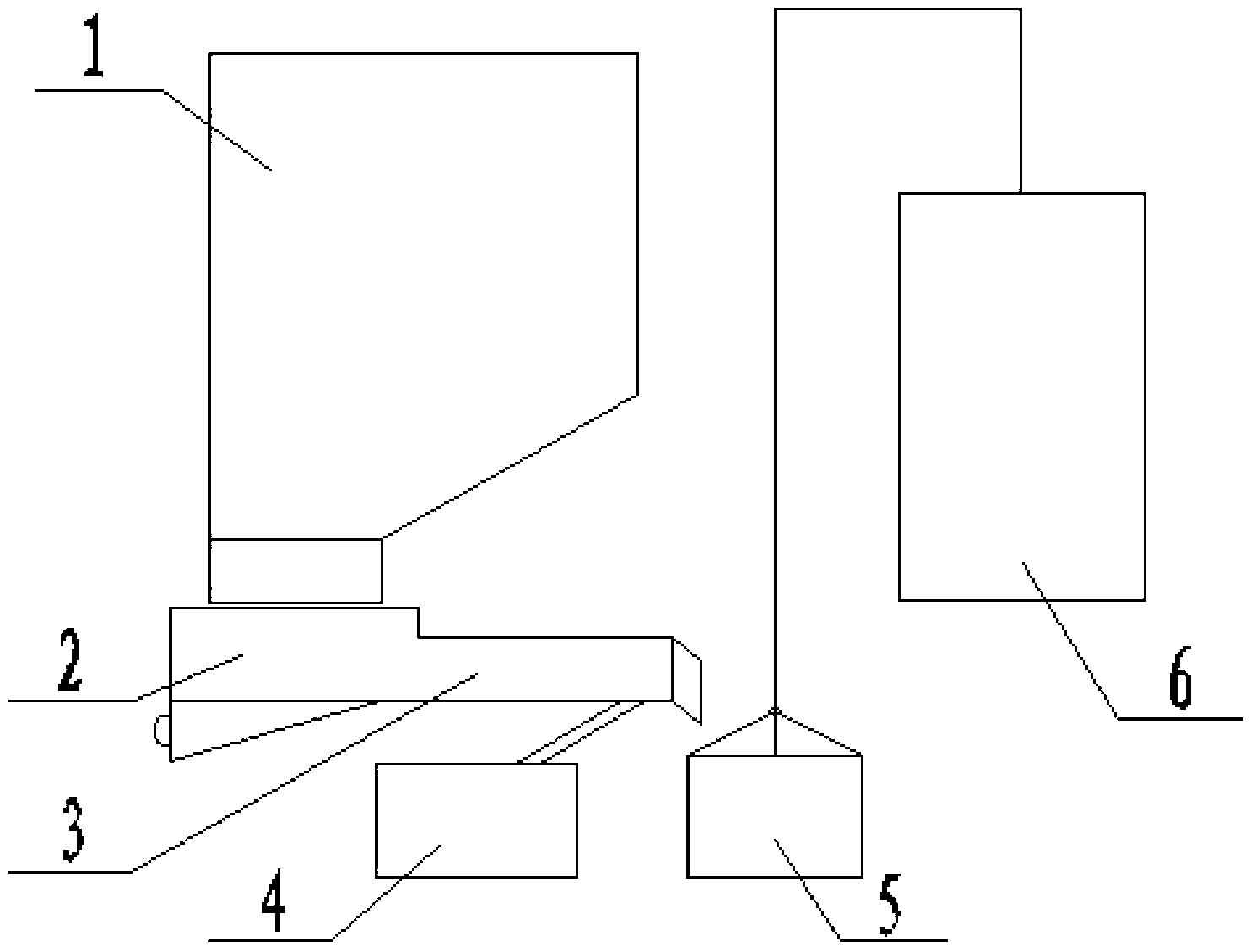

Coal storing, transporting and screening device

InactiveCN103303697ARealize automated one-stop operation modeReduce manual labor intensitySievingScreeningBiochemical engineeringCoal storage

The invention discloses a coal storing, transporting and screening device, and belongs to the technical field of automatic coal processing. The coal storing, transporting and screening device comprises a coal storage bunker (1), a vibrating feeder (2), a screening device (3), a coal ash collection bin (4), an elevator bucket (5) and a gas producer (6), wherein the vibrating feeder is arranged below the coal storage bunker and connected with one end of the screening device; the elevator bucket is arranged at the other end of the screening device; the coal ash collection bin is arranged below the screening device. Compared with the prior art, by the aid of a matching connection manner of the coal storage bunker, the vibrating feeder, the screening device, the coal ash collection bin and the elevator bucket, an automatic coordinated process operation manner of coal storing, transporting and screening is realized, the manual operation strength is greatly reduced, the mechanical automation degree is increased, the production efficiency is improved greatly, and the demand for modern industrial production is met.

Owner:JIANGSU YETAI GLASS

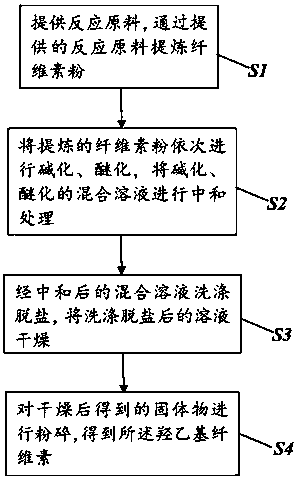

Production process of hydroxyethyl cellulose

The invention provides a production process of hydroxyethyl cellulose. The production process comprises the following steps: S1, providing raw materials for reaction and refining cellulose powder fromthe provided raw materials for reaction; S2, carrying out alkalization and etherification on the refined cellulose powder in order, and carrying out neutralization treatment on the alkalized and etherified mixed solution; S3, washing and desalting the neutralized mixed solution, and drying the washed and desalted solution; and S4, crushing the dried solid matter obtained in the step S3 to obtainthe hydroxyethyl cellulose. The production process of the hydroxyethyl cellulose provided by the invention has the advantages of simple process and high efficiency, and when the hydroxyethyl celluloseis produced by the production process, the generation of by-products is avoided, so that the utilization rate of the raw materials is high. The production process of hydroxyethyl cellulose provided by the invention fully meets the requirements of modern industrial production, and acquires good economic and environmental benefits.

Owner:张家港市金港镇宏业海绵复合厂

Gutter oil degumming and metal salt removing process

PendingCN111718800AEvenly dispersedReduce moisture contentFatty oils/acids recovery from wasteFatty substance recoveryDemulsifierGutter oil

The invention discloses a gutter oil degumming and metal salt removing process. The process comprises the following steps: colloid components in the illegal cooking oil are gathered and separated through acidifying and hydrating, and then the gutter oil is subjected to electric desalting treatment to separate the water phase in which the metal salt is dissolved from the oil phase and thus metal salt components and water components in the gutter oil are removed; specifically, the gutter oil is subjected to degumming and metal salt removal through a gutter oil degumming and metal salt removal device, wherein the mixing cavity is used for processing, the deionized water, the demulsifier and the acid can be uniformly dispersed in the gutter oil, acidification and hydration are facilitated, liquid drops are polymerized in the electric desalting process and thus the degumming rate is improved and the moisture content in the gutter oil is reduced; meanwhile, due to the integrated arrangement,the occupied area can be reduced, the integration degree of the device is improved, the power output device, the output adjusting device and the mixing cavity are arranged in a scattered mode, the convenience during overhauling is improved, meanwhile, the working efficiency is improved through continuous production, and the modern industrial production requirement is met.

Owner:YANGZHOU JIANYUAN BIOLOGICAL TECH CO LTD

A rotary mode concrete product molding machine

ActiveCN107088950BImprove inner qualityRealize automatic mechanized productionDischarging arrangementFeeding arrangmentsTransfer modeMaterial storage

The invention discloses a rotary die type concrete product forming machine. The rotary die type concrete product forming machine comprises a rack. A material storage hopper is arranged at the upper end of the rack. A material distributing trolley is arranged below the material storage hopper. Two parallel guide rails a and two parallel guide rails b located at the same height position with the guide rails a are arranged at the middle portion of the rack, and the guide rails a and the guide rails b are sequentially spliced and located on the same straight line. The two guide rails b are arranged on a rotary die vibration forming device. The rotary die vibration forming device is connected with a demoulding mechanism. A forming press head assembly is arranged above the rotary die vibration forming device. The rotary die vibration forming device is arranged on one side of the material distributing trolley. The material distributing trolley is connected with a material distributing driving device. The material distributing driving device and the demoulding mechanism are located at the two ends of the rack correspondingly. The rotary die vibration forming device, the demoulding mechanism, the forming press head assembly, the material distributing trolley and a hydraulic station providing power for the material distributing drive device are further arranged at the bottom of the rack. The problems that an existing forming machine cannot achieve uniform material distributing, and demoulding is difficult are solved.

Owner:瑞图生态科技有限公司

Automatic threading and welding machine for the production of fuses

Owner:ZHEJIANG CANYUAN HOME TEXTILE

Silicon carbide ceramic material for bearings and preparation method of silicon carbide ceramic material

The invention discloses silicon carbide ceramic material for bearings and a preparation method of the silicon carbide ceramic material. The preparation method includes: subjecting silicon carbide, epoxy resin, bentonite, methylene bisacrylamide, acrylamide, glass fiber, graphite powder, petroleum coke and absolute ethyl alcohol to mixing and then ball-milling to obtain slurry M; subjecting slurryM to drying, pelleting and decaying to obtain powder N; mixing the powder N with a sintering additive for pressure molding and sintering to obtain the silicon carbide ceramic material. With the method, problems that silicon carbide ceramics are difficult to be sintered and densified at atmospheric pressure due to properties of the same, and the obtained silicon carbide ceramics are low in density,high in porosity and incapable of meeting demands of industrial production are solved.

Owner:芜湖市尚行会务服务有限公司

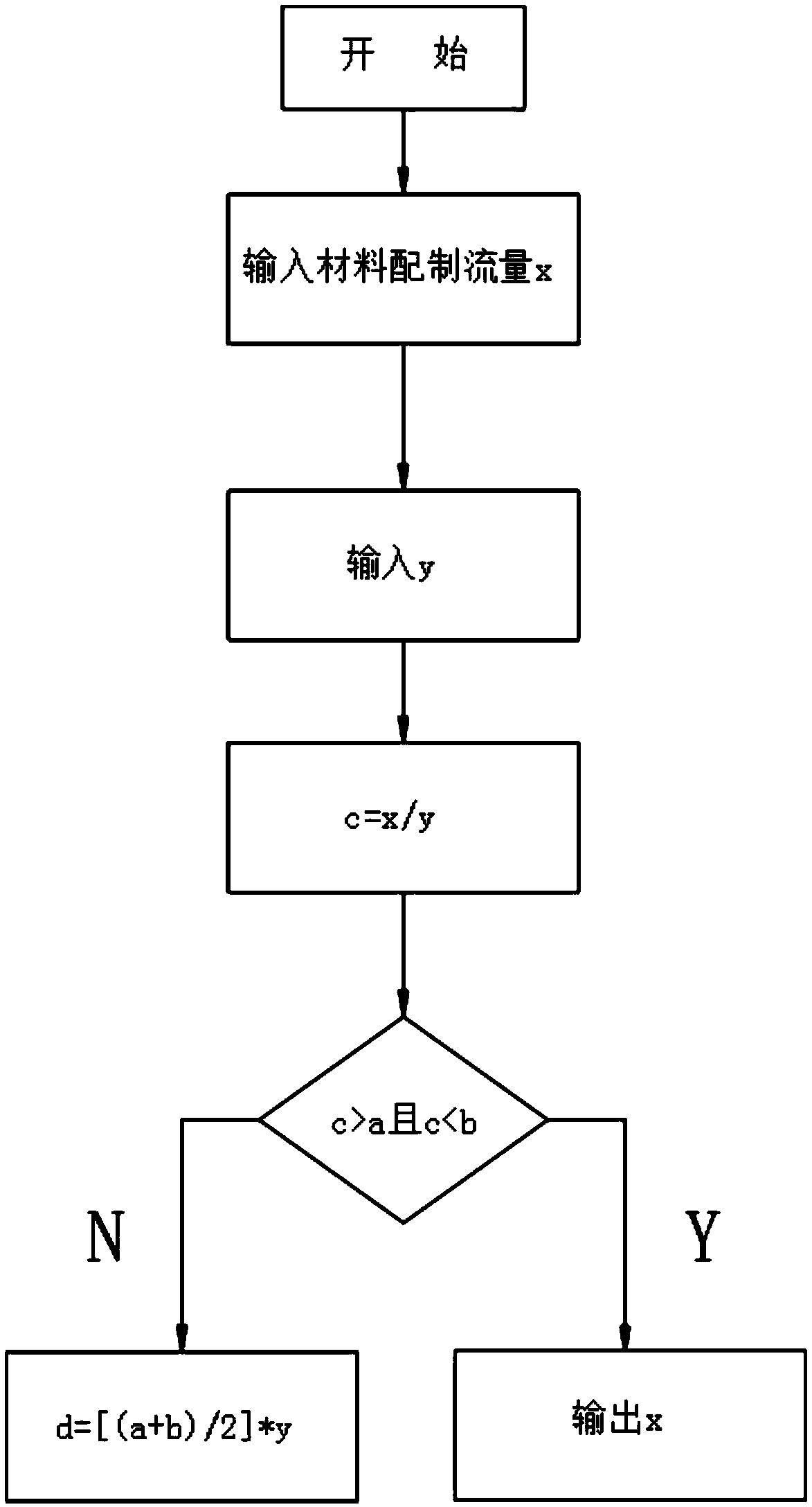

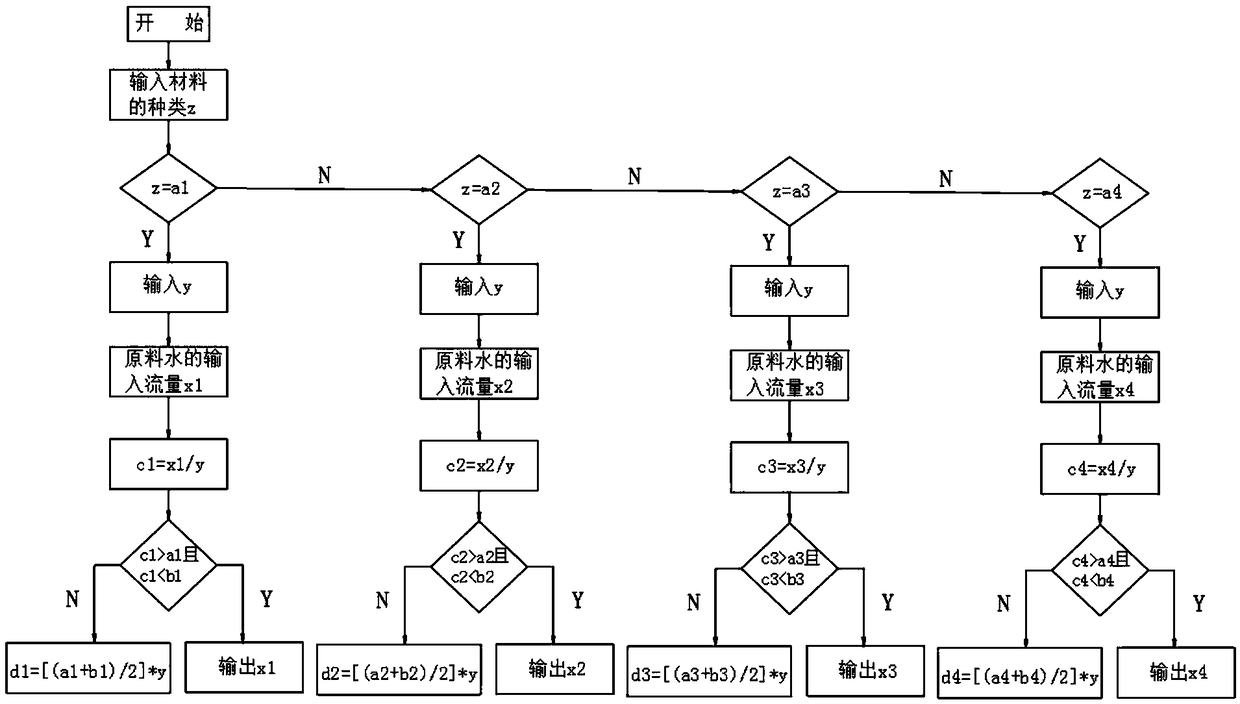

Flow control method for gypsum mortar preparation

InactiveCN108858787AScientific and reasonable processEasy to useMixing operation control apparatusGypsumMaterials science

The invention discloses a flow control method for gypsum mortar preparation. The flow control method is characterized by comprising the steps that (1) the input flow value x of raw materials in gypsummortar preparation is determined; (2) the total mass y of input target gypsum mortar preparation is determined; (3) the mass fraction c of the raw material type z in gypsum mortar preparation is determined, wherein c=x / y; (4) whether the value of the mass fraction c is larger than the preparation set initial value a and smaller than the preparation set initial value b or not is determined, wherein the initial value a is the minimum mass fraction of raw material optimum preparation of gypsum mortar preparation, and the initial value b is the maximum mass fraction of raw material optimum preparation of gypsum mortar preparation; (5) if the input flow value x of the raw materials is smaller than a or larger than b, the output flow value is d; and (6) if the input flow value of the raw materials is larger than a and smaller than b, the input flow value x of the raw materials is output, and flow control over the raw materials for gypsum mortar preparation is completed.

Owner:GAOLVE ARCHITECTURAL TECH

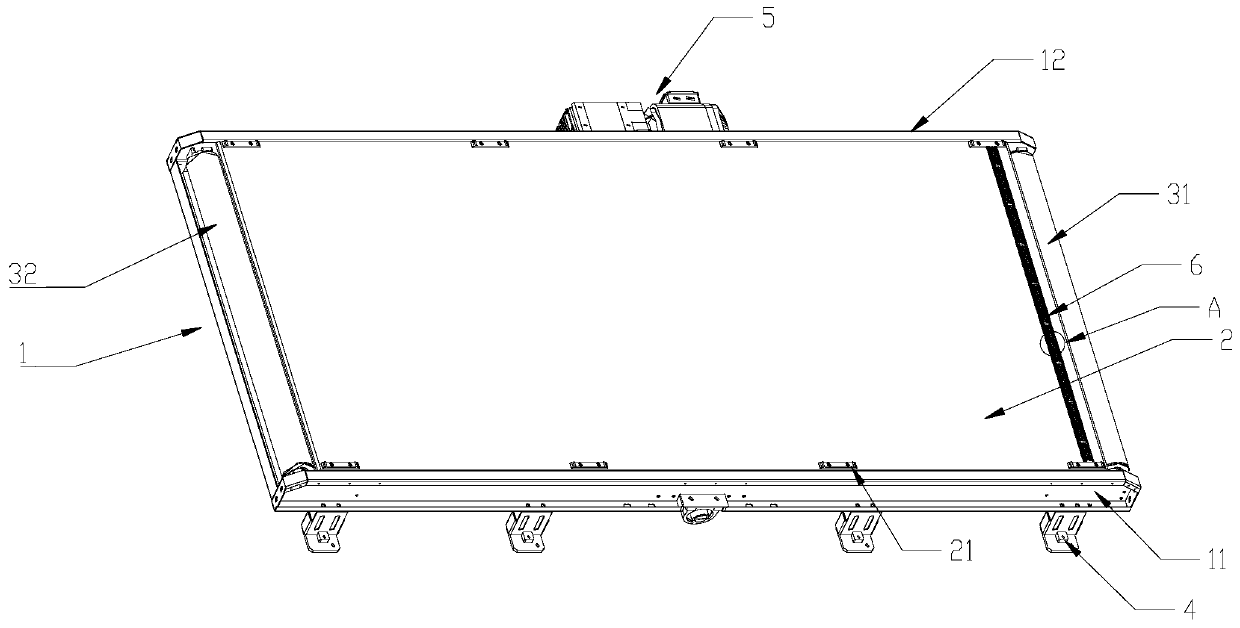

Ground roller heavy load transport line

PendingCN110817279AGuaranteed load capacityIncrease carrying capacityConveyorsGround rollerDrive shaft

The invention discloses a ground roller heavy load transport line. The ground roller heavy load transport line comprises a support, a rotation shaft rotatably connected with the support and a conveyorbelt arranged on the rotation shaft in a winding mode, wherein the support comprises a first side plate and a second side plate which are relatively parallel, the rotation shaft comprises a transmission shaft and a roller, the transmission shaft is transversely installed between the first side plate and the second side plate, the roller comprises a first roller and a second roller, the first roller and the second roller are respectively and transversely installed at two ends of the first side plate and two ends of the second side plate, a drive assembly is arranged on the support, the drive assembly drives the transmission shaft to drive the conveyor belt to move around the first roller and the second roller, a bearing plate in a flat plate shape is arranged between the conveyor belt andthe support, and the bearing plate is fixed between the first side plate and the second side plate, and supports the conveyor belt. By adding the bearing plate, a load from the conveyor belt to the roller or a wear-resisting strip in the transport process is reduced, and carrying capacity and durability of the transport line are improved.

Owner:XINHAI IND BELTING

Method for preparing high-performance asphalt-based carbon fiber through rapid pre-oxidation

The invention provides a method for preparing high-performance asphalt-based carbon fiber through rapid pre-oxidation, which comprises the following steps: (1) putting an asphalt-based carbon fiber precursor into a reaction cavity, and introducing mixed gas into the reaction cavity to achieve the purpose of pressurization and keep the pressure constant; (2) carrying out two-stage heating on the interior of the reaction cavity through a heating device to obtain pre-oxidized asphalt-based carbon fibers; and (3) vacuumizing the reaction cavity, introducing inert gas to ensure normal pressure, and then carbonizing and graphitizing the pre-oxidized asphalt-based carbon fiber. According to the method, the diffusion rate of oxygen in the asphalt fiber is obviously improved in a pressurization mode, so that rapid homogeneous pre-oxidation of the asphalt fiber is realized, the pre-oxidation period is obviously shortened, meanwhile, the material performance is improved, the material defects are reduced, and the production cost is reduced.

Owner:WUHAN UNIV OF SCI & TECH

A method for rapidly preparing colored titanium oxide thin films on the surface of substrate materials

ActiveCN109487222BReduce temperature riseAvoid damageVacuum evaporation coatingSurface reaction electrolytic coatingElectrolytic agentThin membrane

The invention relates to the technical field of film coating, in particular to a method for rapidly preparing a colorful titanium oxide thin film on the surface of substrate material. The method comprises the following steps: at first, a layer of titanium film is sprayed on the surface of the substrate material through the magnetron sputtering technology, then, the substrate material is put into an electrolytic cell which has been set up, the electrolytic cell is filled with electrolyte, the to-be-coated substrate material is put on the cathode, and a stainless steel plate is hung on the anode. Generation and color of the titanium oxide thin film are controlled through changing the voltage of the electrolytic cell, so that the titanium film on the surface of the substrate material generates oxidizing reaction to generate a layer of colorful titanium oxide thin film to protect the titanium film. The electrolyte can be recycled and meets the requirements of environmental protection and industrial production; and in addition, the generated titanium oxide thin film can alleviate abrasion, scratch and contact corrosion of titanium, so that the problems about maintenance and abrasion during the using process of titanium are solved. With adoption of the method, the titanium oxide thin film can be rapidly prepared on the surface of common substrate material, and in addition, the colorof the titanium oxide thin film is easy to control and uniform. The thickness of the titanium oxide thin film prepared through the method is slightly influenced by the material shape.

Owner:SHANDONG UNIV

A kind of preparation method of polyaniline/n-doped graphitized carbon composite conductive film electrode

ActiveCN110724840BEffective complexationHigh selectivityCarbon compoundsHybrid capacitor electrodesCarbon compositesConductive polymer

A preparation method of polyaniline / N-doped graphitized carbon composite conductive film electrode, using pretreated waste biomass sugarcane hawthorn as raw material, preparing N-doped graphite through alkali activation, N doping, pre-carbonization and high-temperature carbonization Carbonized carbon; then use N-doped graphitized carbon and conductive polymer (polyaniline) to compound to prepare polyaniline / N-doped graphitized carbon composite conductive film electrode, polyaniline / N-doped graphitized carbon composite conductive film electrode It has a high specific surface area, good electrical conductivity and chemical stability. When it is used to extract uranium from brine by electro-adsorption, it has a high extraction rate of uranium in brine and good adsorption selectivity, which can meet the needs of modern industrial production.

Owner:EAST CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com