Flow control method for gypsum mortar preparation

A gypsum mortar and flow control technology, which is applied in the direction of mixing operation control, chemical instruments and methods, and mixing operation control devices, can solve the problems that the amount of raw materials added affects the quality of the finished gypsum mortar, and achieve safe and convenient use and improved control accuracy , Reduce waste of raw materials and waste of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

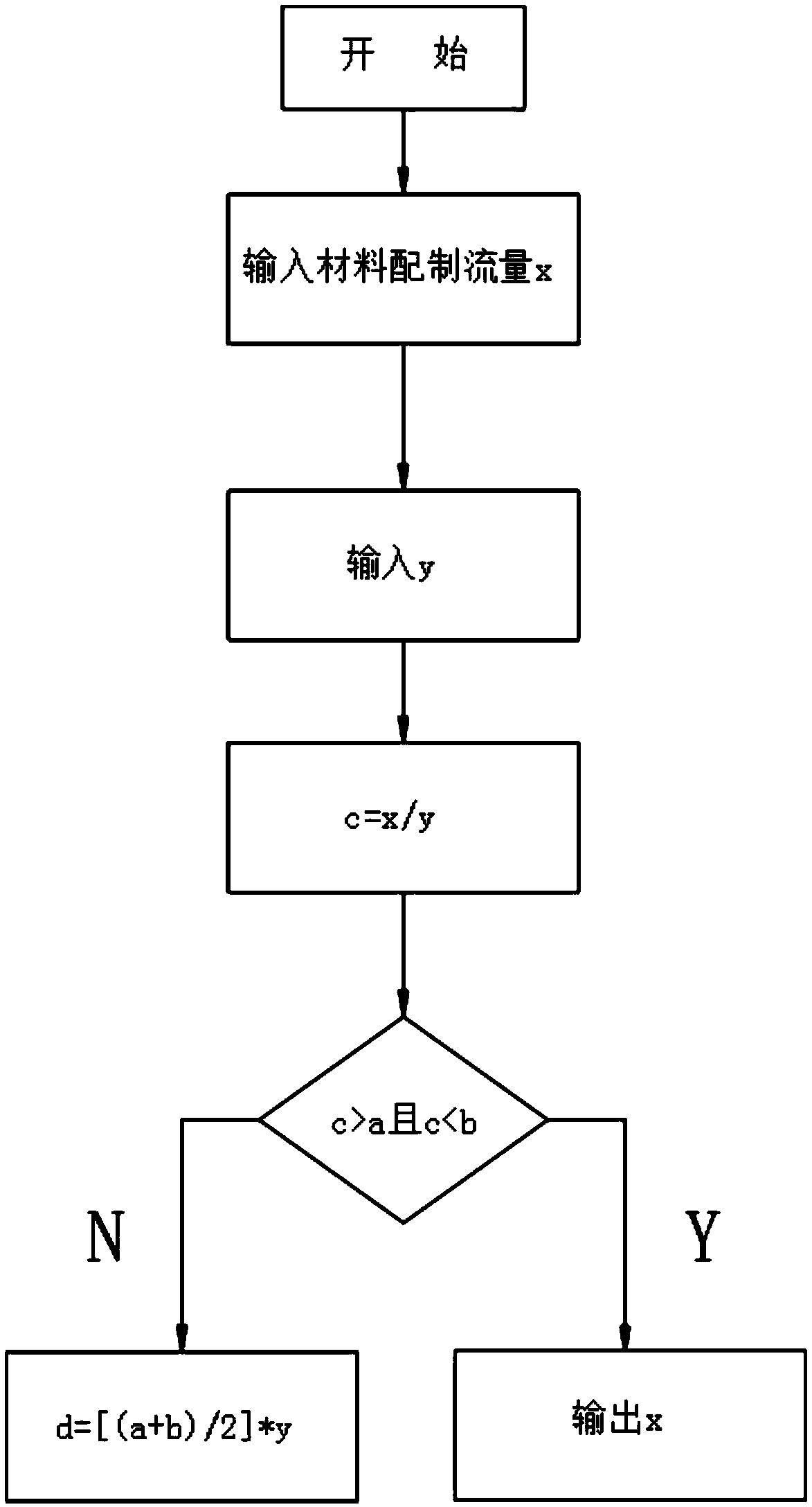

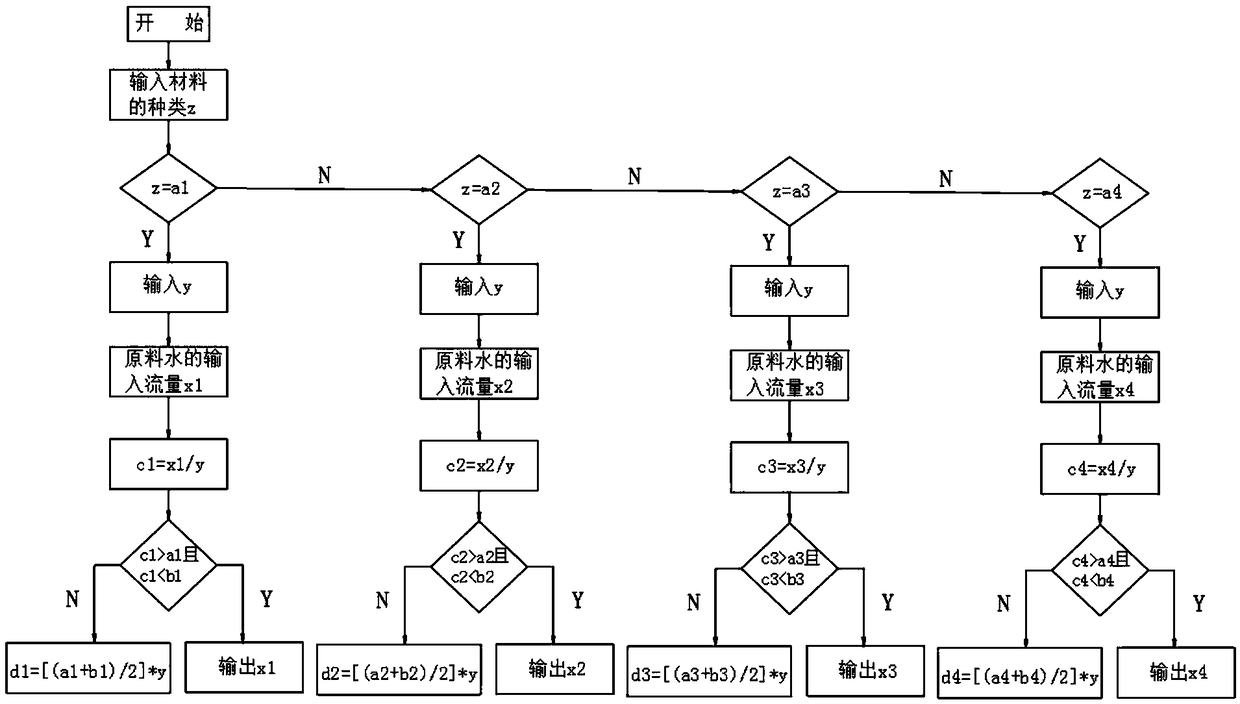

[0018] Example: such as Figure 1-2 As shown, the present invention provides a flow chart of a flow control method for gypsum mortar preparation and dispensing according to an embodiment.

[0019] Before flow control, it is necessary to compare and identify the types of input raw materials for gypsum preparation. In the process of comparison and identification, firstly, the types of multiple raw materials are preset as a1, a2, a3, and a4, where the type of a1 is the raw material water, the type of a2 is the raw material sandstone aggregate, the type of a3 is the raw material talcum powder, and the type of a4 is the raw material heavy calcium, in which the maximum particle size of the raw material sandstone aggregate is controlled to be less than 1.0mm, and then by inputting the type of raw material z is compared with a1, a2, a3 and a4 respectively, so as to obtain the flow control of different raw material types.

[0020] In step S1, the input flow value x of raw materials in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com