Continuous compaction production line for recombinant bamboo-wood integrated square material

A technology of laminated wood and production line, applied in the direction of wood processing utensils, flat products, household components, etc., can solve the problems of unsimplified process, high production cost, and many scraps, etc., to simplify the process and equipment, and to achieve good product quality. The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The accompanying drawings of the above description show a specific embodiment of the present invention. The following will further illustrate the construction principle of the present invention in conjunction with the elaboration of this embodiment, so as to further understand the purpose and beneficial technical effects of the present invention.

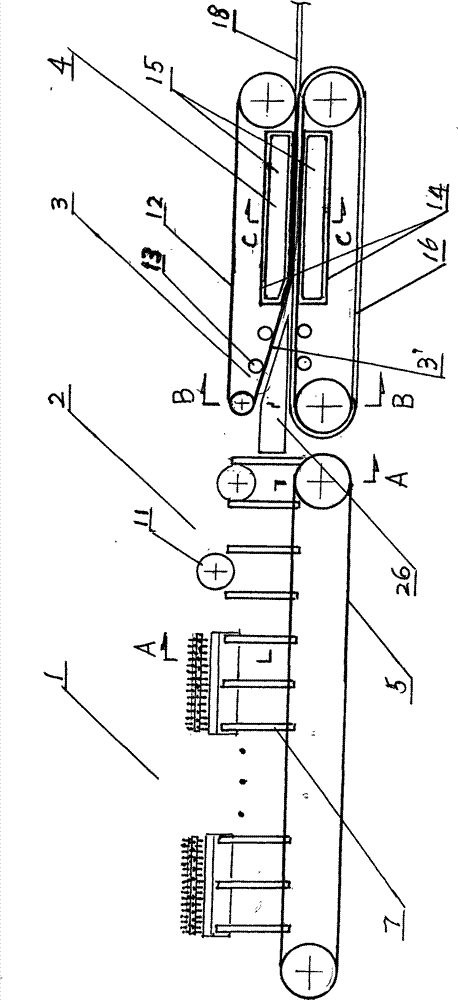

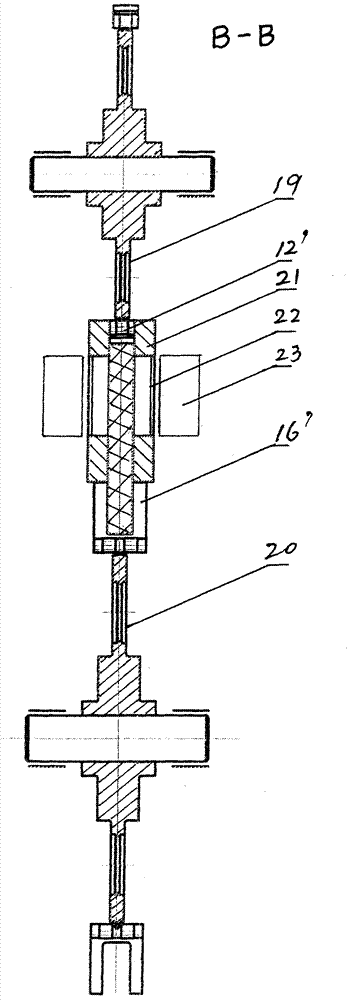

[0031] The invention relates to a continuous pressing production line for recombined bamboo and wood glulam square materials, comprising four parts: a charging device, a pre-pressing device, a gradual pressing device, and a constant pressure device, which are sequentially connected to form a continuous moving pressing production line.

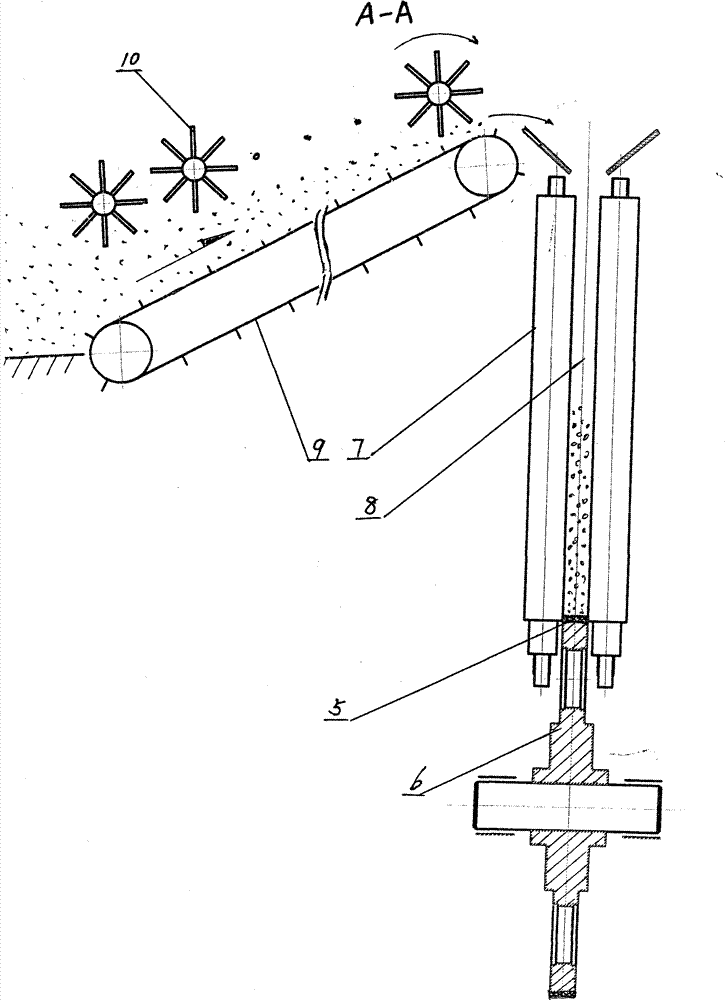

[0032] The charging device 1 comprises a hopper 8 formed by a drive wheel 6, a conveyor belt 5 and a row of vertical rollers 7 formed on its two sides, and a feeding device for feeding in the chute. The feeding device includes a conveyor belt 5- A plurality of feeding conveyor belts 9 arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com