A method for rapidly preparing colored titanium oxide thin films on the surface of substrate materials

A titanium oxide film and base material technology, applied in surface reaction electrolytic coating, metal material coating process, electrolytic coating, etc., can solve the problems of poor stability, large number of large droplets, increase of large particles in the film, etc. Long service life, fast deposition rate, and small substrate temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for rapidly preparing a colored titanium oxide film on the surface of a base material, comprising the following steps:

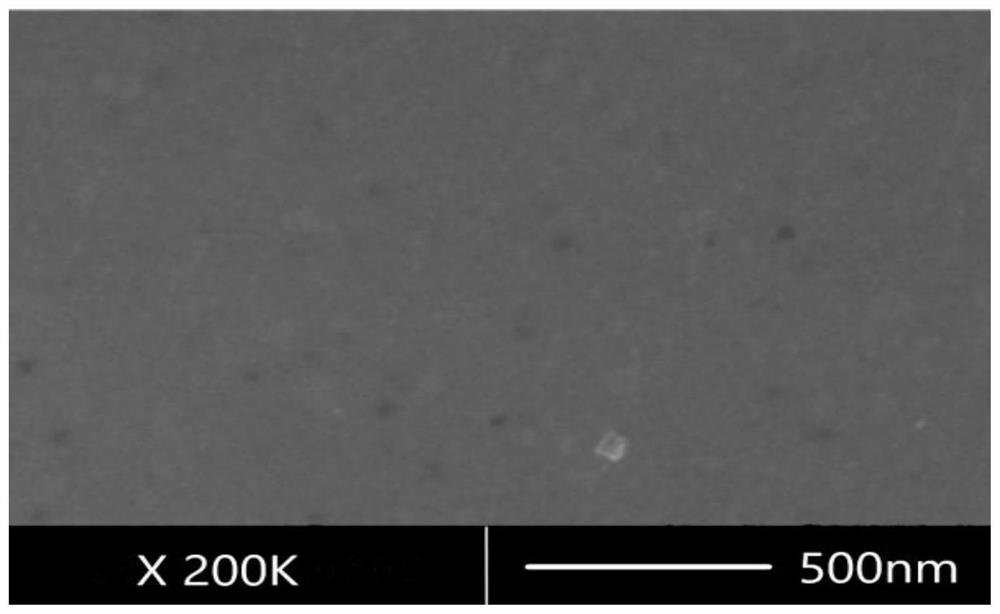

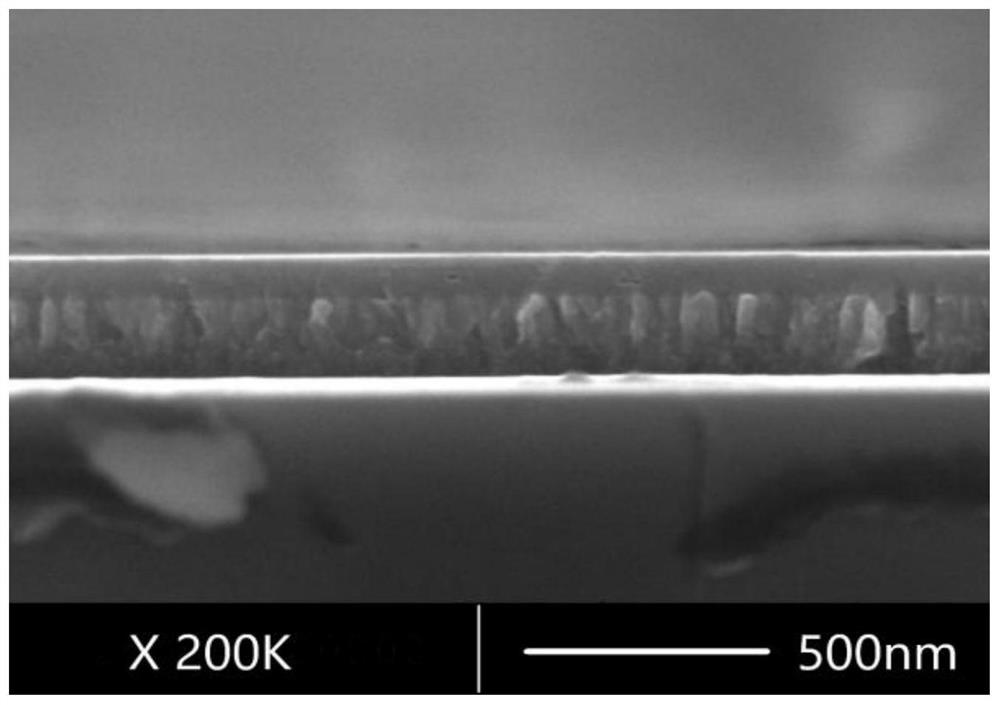

[0036] A. Use magnetron sputtering titanium coating on the surface of the substrate material, so that the surface of the substrate material is covered with titanium film, magnetron sputtering titanium coating parameters: sputtering power is 150W, sputtering pressure is 0.8Pa, argon gas is 60sccm, anti The rotation time is 1 μs, the inversion frequency is 50 Hz, the sputtering target voltage is 314 V, the sputtering target current is 0.48 A, and the sputtering rate of the titanium target is 13.3 nm / min. in the electrolytic cell;

[0037] B, add electrolytic solution in the electrolyzer in step A, electrolytic solution comprises the sodium gluconate of 100g / L, the ammonium fluoride of 0.3g / L, the cerium sulfate tetrahydrate of 1.3g / L, the 30% of 50mL / L concentration of hydrogen peroxide and 100mL / L of 30% concentration of phosphoric acid;

[...

Embodiment 2

[0043] The difference from Example 1 is that the oxidation power supply uses a direct current of 20V, and the color of the titanium oxide film on the surface of the substrate material is dark purple.

Embodiment 3

[0045] The difference from Example 1 is that the oxidation power supply uses a direct current of 30V, and the color of the titanium oxide film on the surface of the substrate material is blue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com