Pachymaran extraction method, pachymaran extract and poria cocos product combined production process

A technology for extracting polysaccharides from Poria cocos, which is applied in the field of natural product extraction, can solve problems such as cumbersome operation steps, low product quality, and environmental impact, and achieve the effects of avoiding the use of organic solvents, reducing production costs, and reducing process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

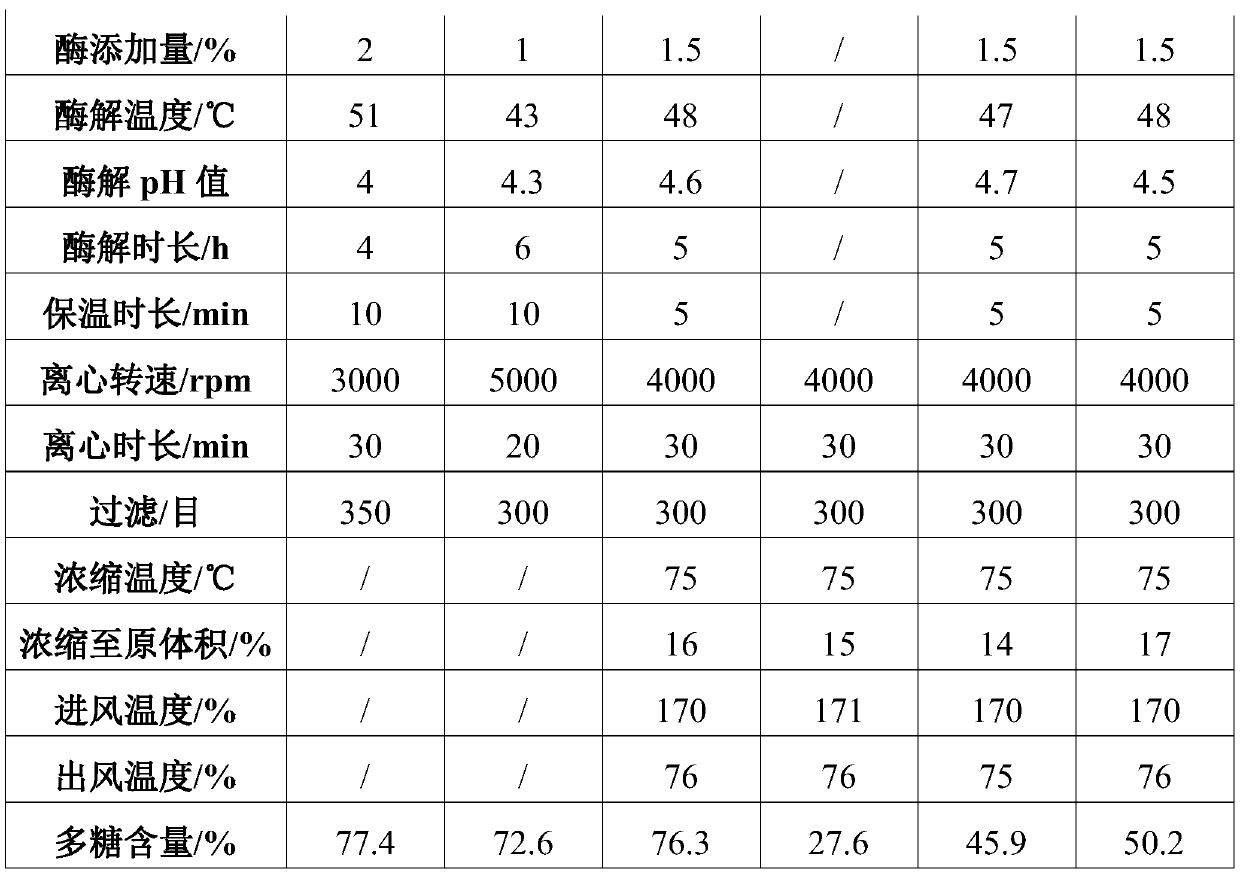

Embodiment 1

[0079] The extraction method of the Poria cocos extract of the present embodiment comprises the following steps:

[0080] (1) Take an appropriate amount of boiled Poria cocos coarse particles, and dry at 70° C. to obtain net Poria cocos coarse particles;

[0081] (2) Get 10kg of net poria cocos coarse particles, put into 40B type universal pulverizer and pulverize, and filter and collect powder with 80 mesh vibrating sieves, then adopt AB06 type airflow pulverizer to carry out broken wall pulverization, and the broken wall powder adopts 300 mesh vibrations Sieve for filtration collection;

[0082] (3) Add 4 times the amount of water to the broken wall powder (that is, the mass ratio of the broken wall powder to water is 1:4) to stir and mix evenly, and add it to the JMS-80B colloid grinder to grind for 1.5 hours, wait for the Poria cocos milk turbid liquid; and add β-(1→3) glucan hydrolase, the addition amount is 2% (w / w), the temperature is 51 ° C, the pH value is 4.0, and t...

Embodiment 2

[0085] The extraction method of the Poria cocos extract of the present embodiment comprises the following steps:

[0086] (1) Take an appropriate amount of boiled Poria cocos coarse particles, and dry at 75° C. to obtain net Poria cocos coarse particles;

[0087] (2) Get 10 kg of clean poria cocos coarse particles, put into 40B type universal pulverizer and pulverize, and filter and collect powder with 100 mesh vibrating sieves, then adopt AB06 type jet pulverizer to carry out broken wall pulverization, and the broken wall powder adopts 350 mesh vibrations Sieve for filtration collection;

[0088] (3) Add 4 times the amount of water to the wall-breaking powder (that is, the mass ratio of the wall-breaking powder to water is 1:4) to stir and mix evenly, and add it to a JMS-80B colloid grinder for grinding for 1 hour, and wait for Poria cocos milk Turbid liquid; and add β-(1→3) glucan hydrolase, the addition amount is 1% (w / w), the temperature is 43 ℃, the pH value is 4.3, stir...

Embodiment 3

[0091] The extraction method of the Poria cocos extract of the present embodiment comprises the following steps:

[0092] (1) Take an appropriate amount of boiled Poria cocos coarse particles, and dry at 80° C. to obtain clean Poria cocos coarse particles;

[0093] (2) Get 10kg of net poria cocos coarse particles, put into 40B type universal pulverizer and pulverize, and filter and collect powder with 80 mesh vibrating sieves, then adopt AB06 type airflow pulverizer to carry out broken wall pulverization, and the broken wall powder adopts 300 mesh vibrations Sieve for filtration collection;

[0094] (3) Add 6 times the amount of water to the broken wall powder (that is, the mass ratio of broken wall powder and water is 1:6) to stir and mix evenly, and add it to the JMS-80B colloid grinder for grinding for 2 hours, and wait for the Poria cocos milk Turbid liquid; and add β-(1→3) glucan hydrolase, the addition amount is 1.5% (w / w), the temperature is 48 ℃, the pH value is 4.6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com