Automatic threading?welding machine applied to fuse production

A fuse and welding machine technology, applied in fuse manufacturing and other directions, can solve the problems of product quality decline, low efficiency, and high cost, and achieve the effects of ensuring finished product quality, reducing labor costs, and rapid processing and manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

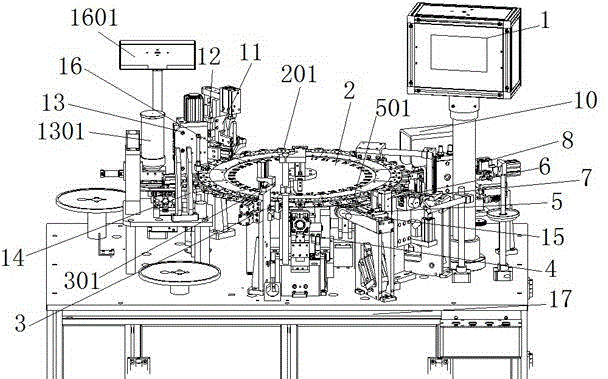

[0015] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0016] see figure 1 , the automatic threading welding machine applicable to the production of fuses of the present invention includes: a controller 1 that is convenient for manually setting the working parameters of each station, an adjustable rotating speed and an indexing plate 2 that is provided with a plurality of clamping structures 201, and adopts PLC For the man-machine interface control system, the preferred number of clamping structures 201 is 36, and the circumferential direction of the index plate 2 is set in sequence for each workstation for processing and testing fuses, which will be described in detail below.

[0017] (1) Feeding mechanism: a spiral vibrating plate is preferred to transport the inner shell in an orderly manner;

[0018] (2) Loading station 3: its function is to load the inner shell from the feeding mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com