Patents

Literature

85results about How to "Prevent water hammer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

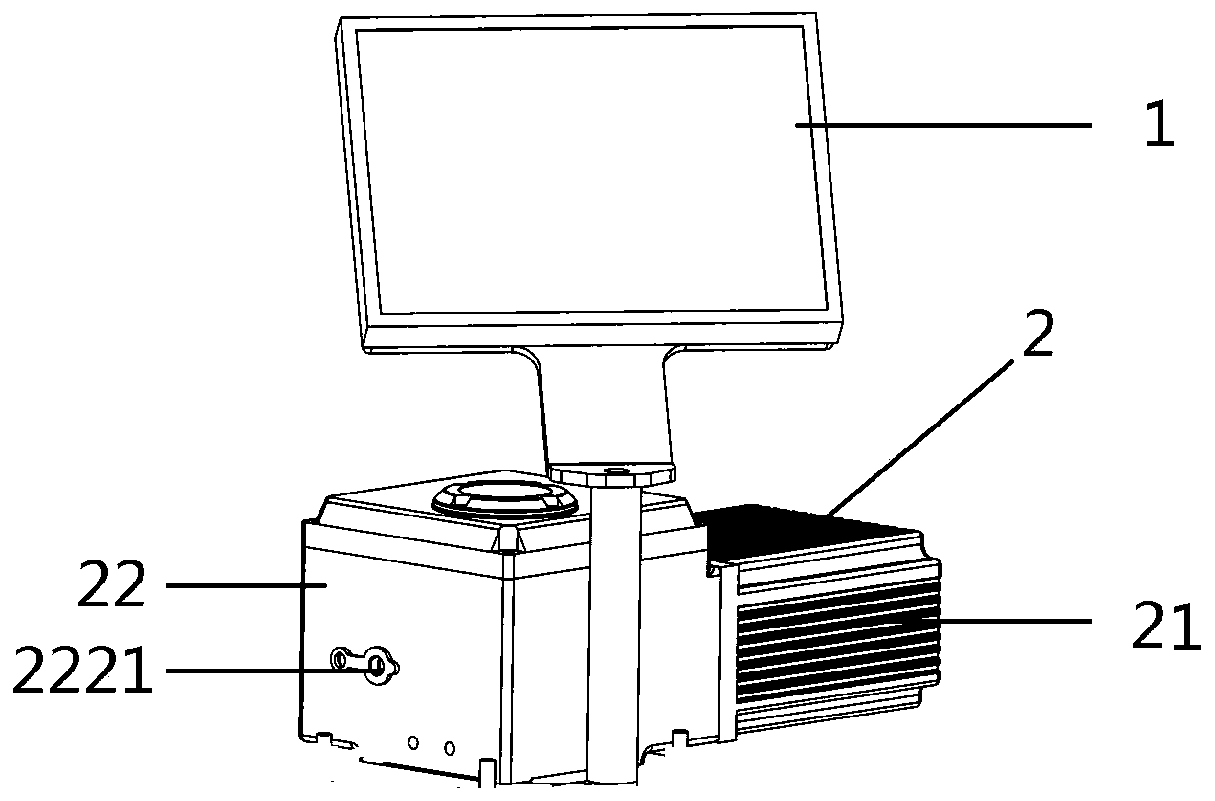

Frequency conversion type intellective electromotion unit for valve

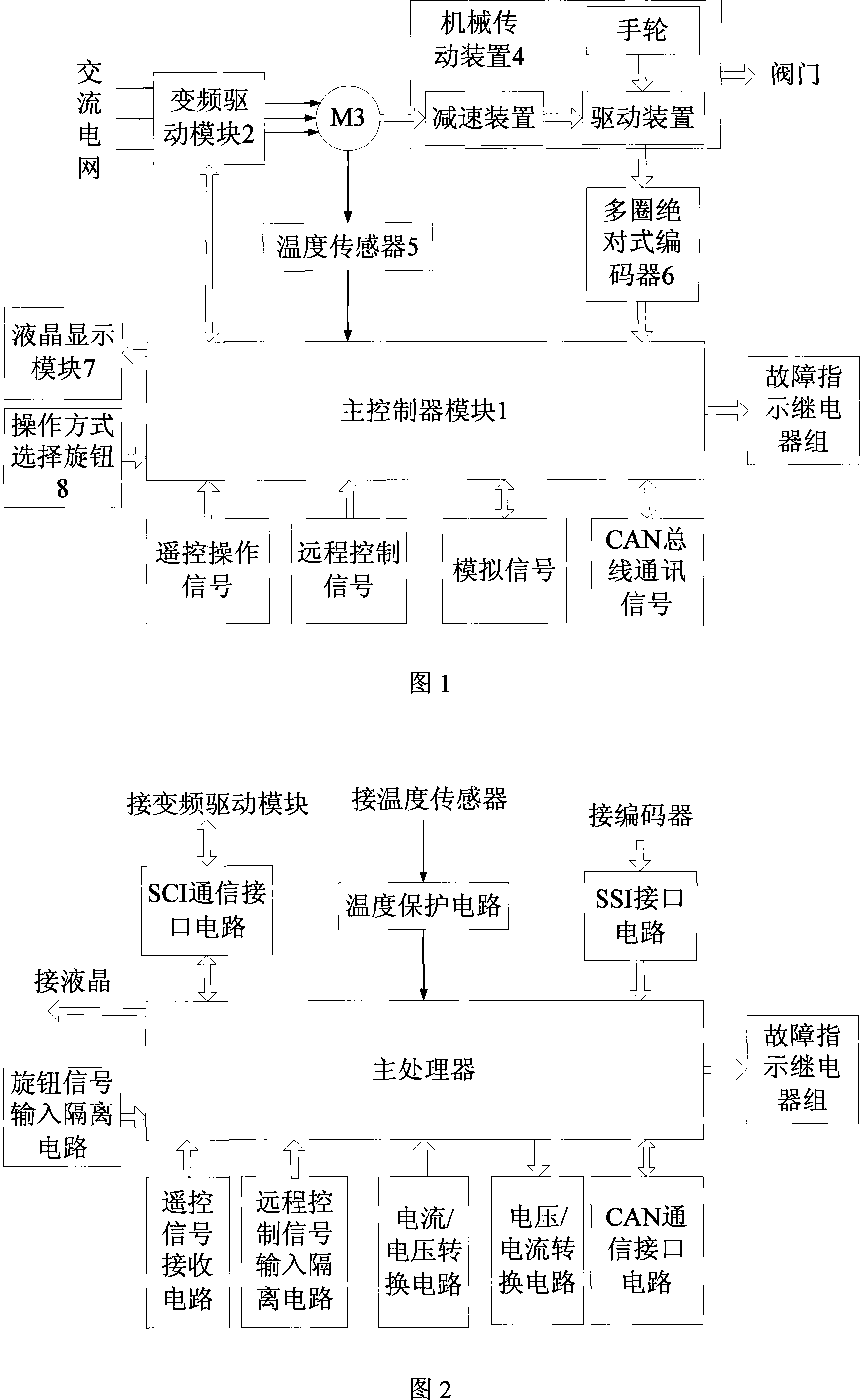

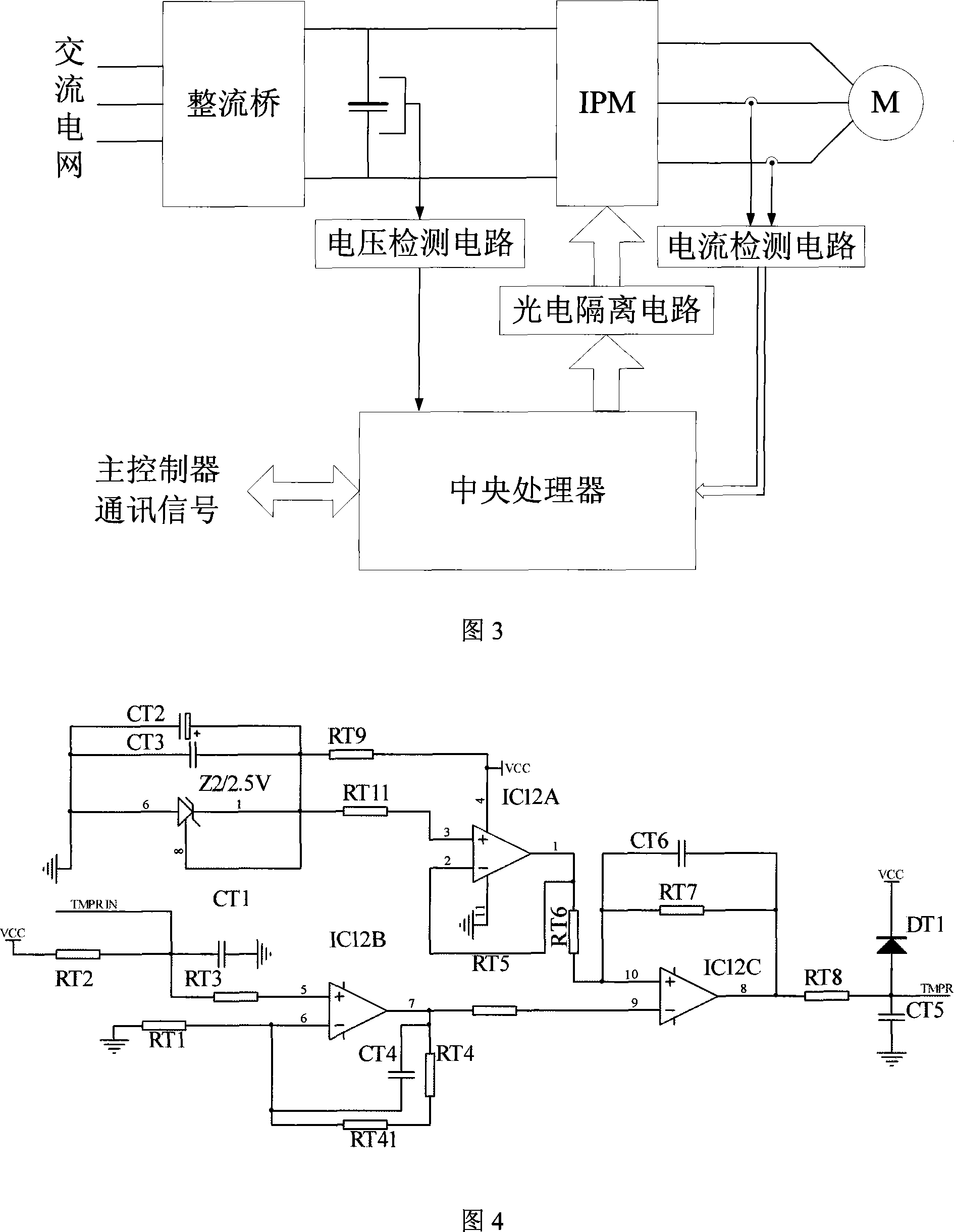

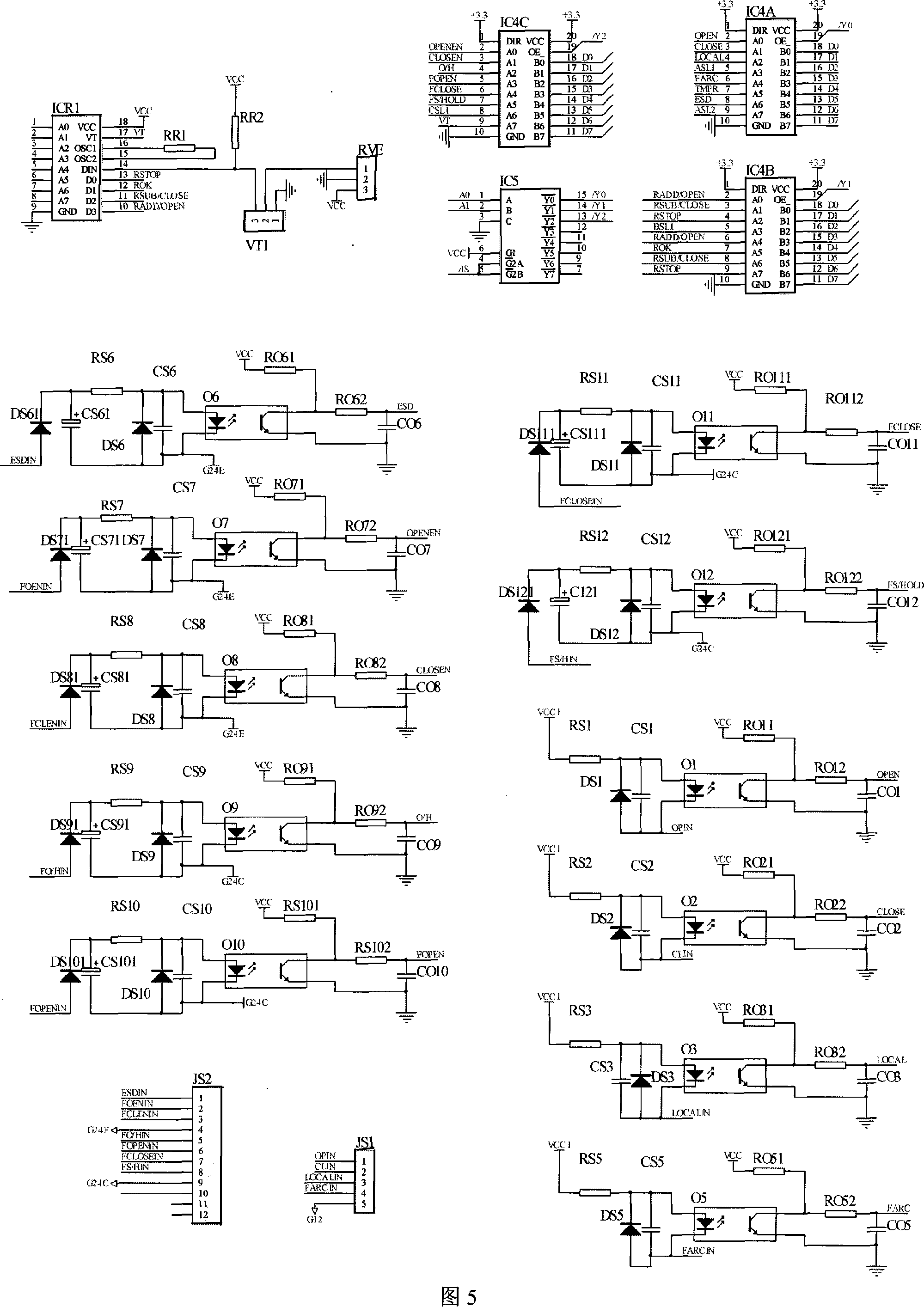

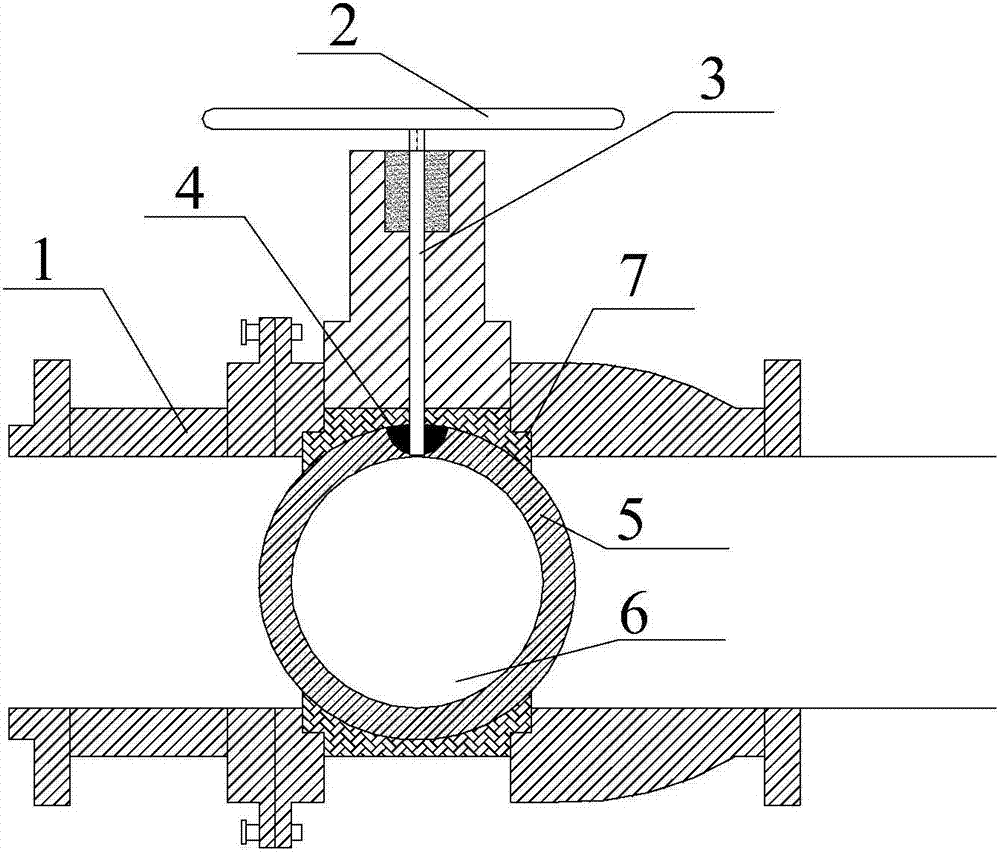

InactiveCN101093033AWith bus control functionImplement mutable operationsElectric signal transmission systemsAC motor controlControl mannerOperation mode

This invention relates to a conversion intelligent valve electric device including a master controller module, a conversion drive module, an asynchronous motor, a mechanical drive device, a temperature sensor, a multi-coil absolute coder, a LCD and an operation mode selecting button characterizing in using a conversion drive module to drive the asynchronous motor, testing output torque by computing electricity and taking the coder as a location sensor and a temperature sensor is installed in the asynchronous motor, and the control mode includes local control, remote control, remote control to switch volume, remote control to simulation volume and bus line control.

Owner:孙力

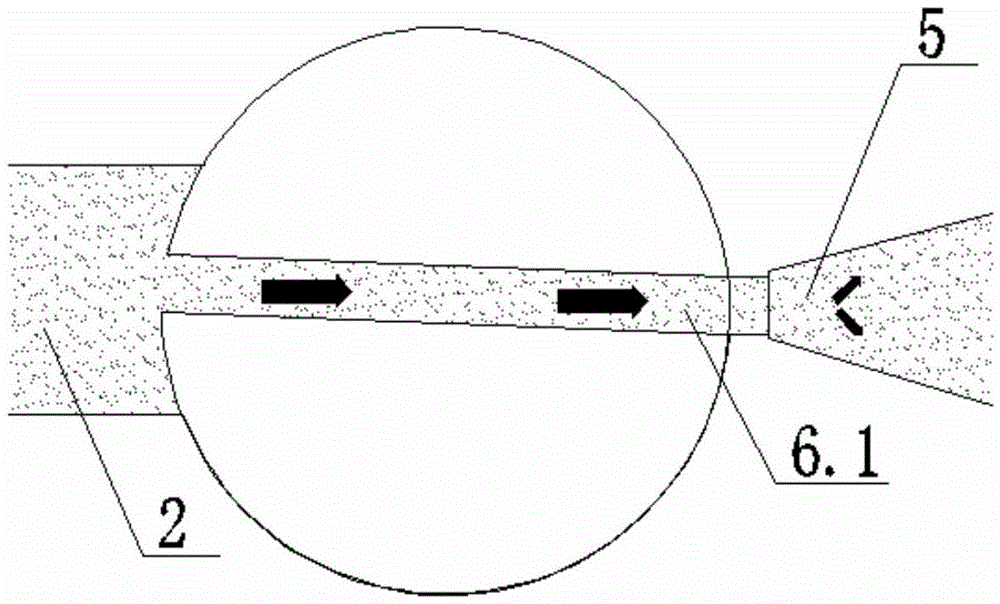

Ball valve system for agricultural irrigation throttling and pipe water hammer protection and control method thereof

ActiveCN104747749AEliminate hazardsPrevent water hammerPlug valvesValve members for absorbing fluid energySystem safetyBall valve

Owner:HOHAI UNIV

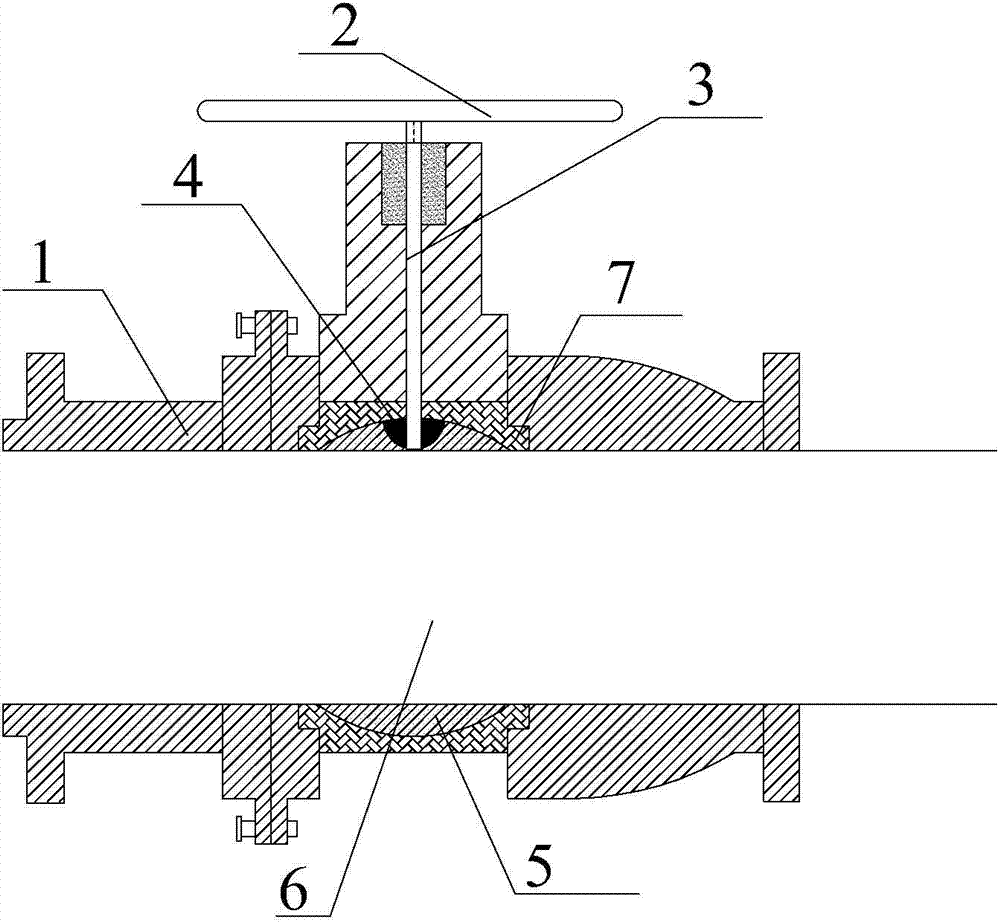

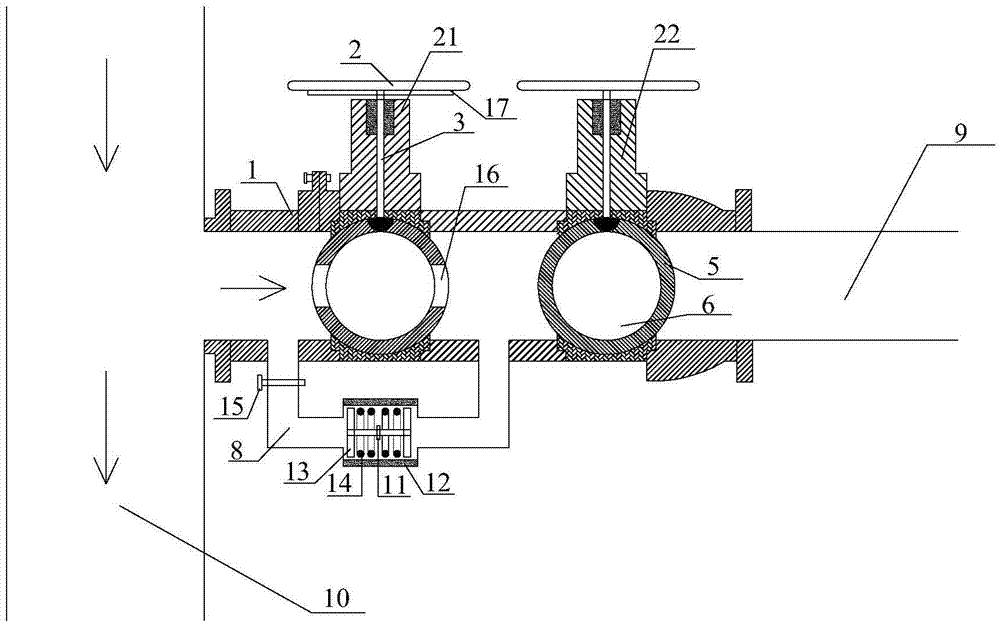

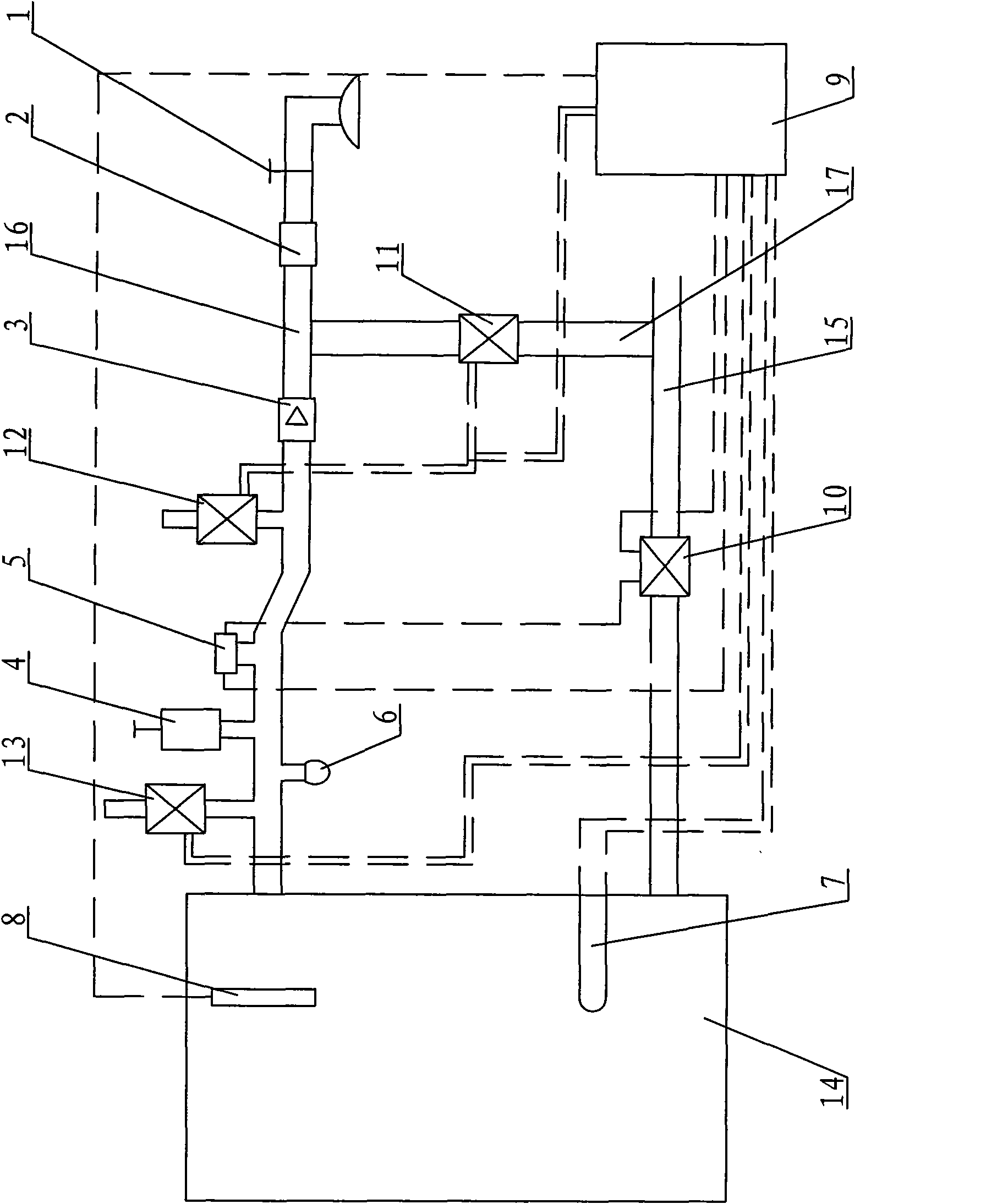

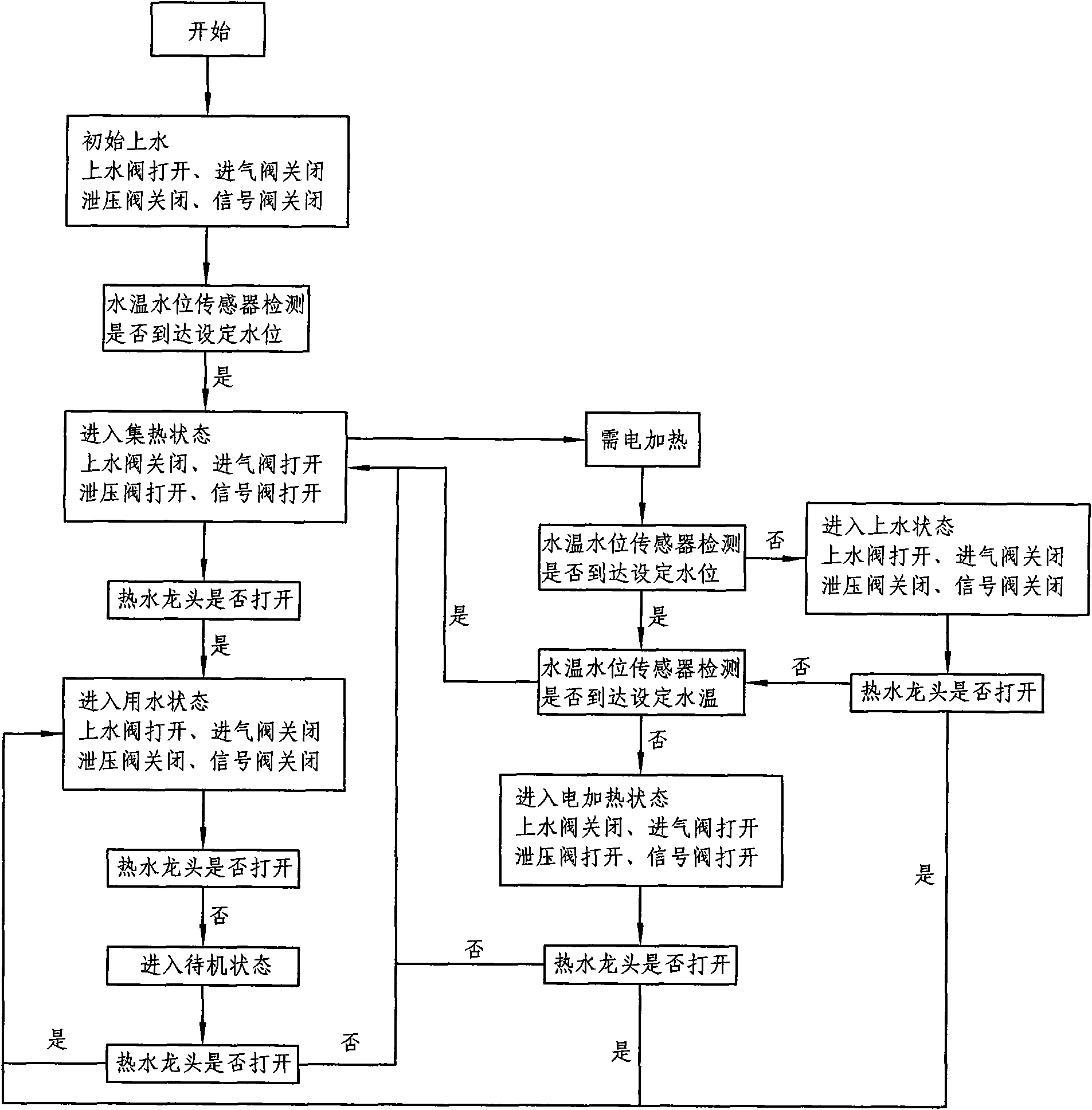

Control system of pressure-limiting glass evacuated solar water heater without water tank

ActiveCN101650050AImprove securityExtended service lifeSolar heating energySpace heating and ventilation detailsSolar waterInlet valve

The invention relates to a control system of a pressure-limiting glass evacuated solar water heater without a water tank. An electric heating pipe and a water temperature / level sensor are arranged ina heat collector. A water feeding valve is arranged on a water inlet pipe of the heat collector. A hot water faucet, a water flow sensor, a check valve, a relief valve, a water pressure switch, a safety valve, an expansion valve and an intake valve are sequentially arranged in the direction from the water outlet of a water outlet pipe of the heat collector to the heat collector. The water pressureswitch is electrically connected with the water feeding valve and a controller. The water outlet pipe between the check valve and the water flow sensor is connected with the water inlet of the waterinlet pipe by a cold water pipe which is provided with a signal valve. The water flow sensor, the intake valve, the relief valve and the signal valve are all connected with the controller. The systemadopts the water pressure switch on the water outlet pipe to detect the water pressure in the heat collector and to combine the signal valve on the cold water pipe to ensure the water heater to supplywater normally, which is simple in structure, reasonable in design, safe, convenient, good in freeze-proof and shock-proof effects, high in intelligent control degree and free from potential safety hazard.

Owner:JIANGSU YONGSHENG NEW ENERGY TECH CO LTD

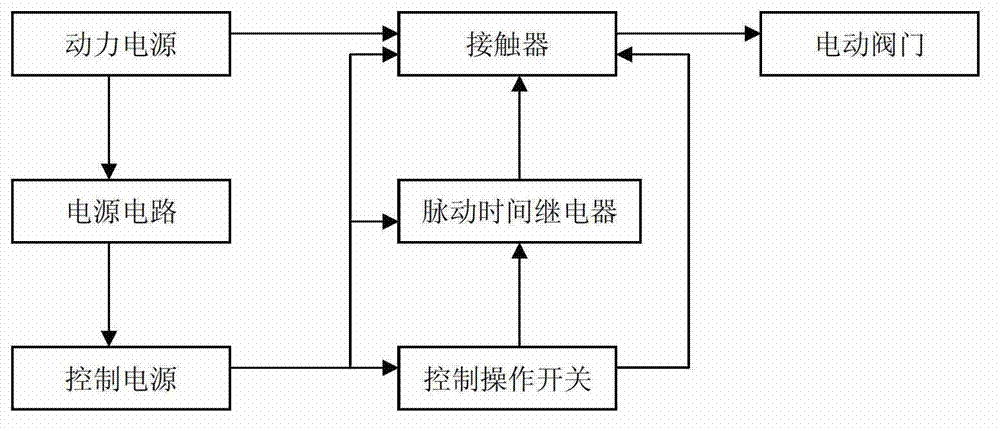

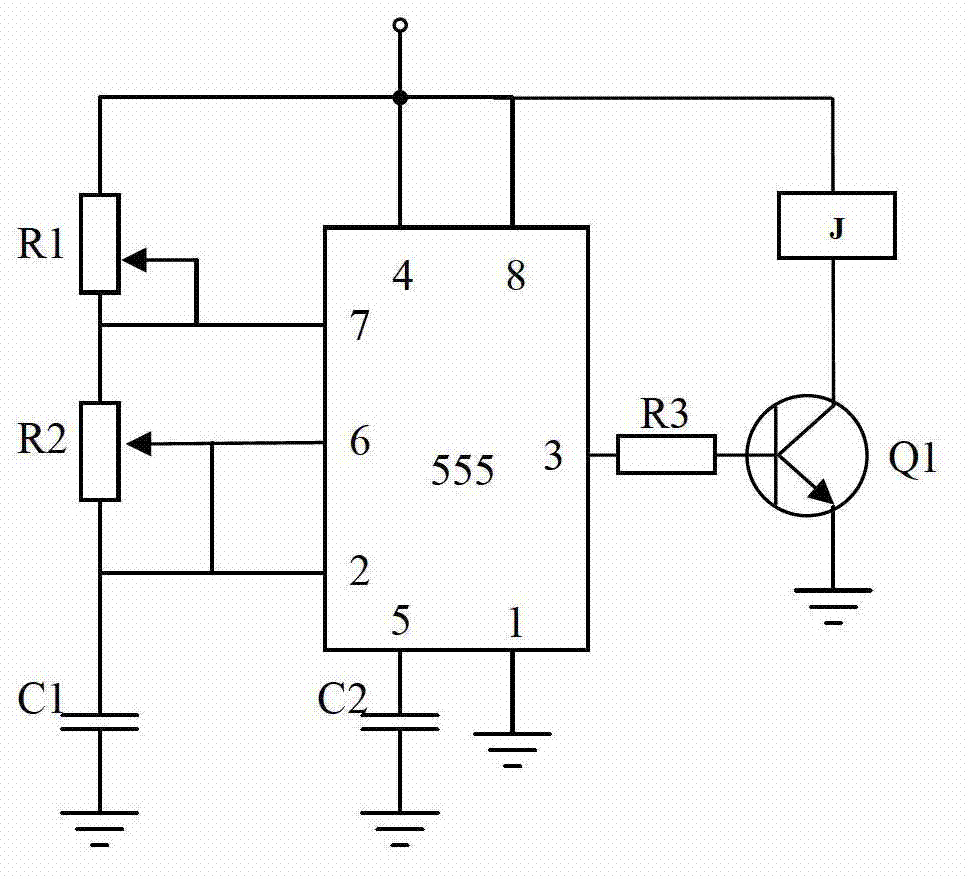

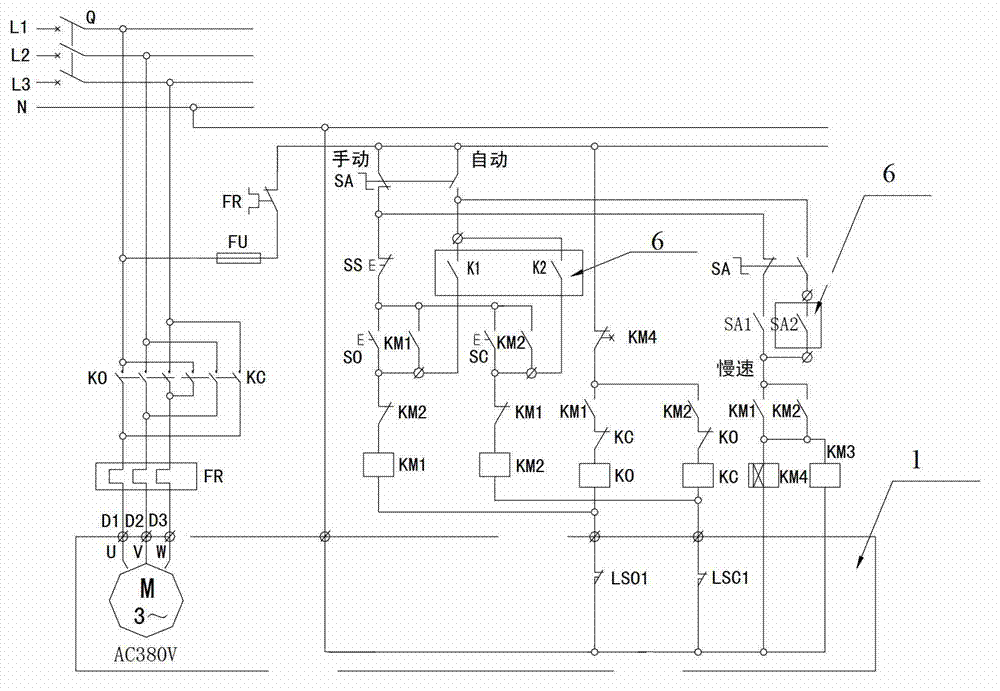

Control method and control device of slow speed type electric valve

ActiveCN102777661APrevent water hammerAvoid burningOperating means/releasing devices for valvesEngineeringDetonation

The invention discloses a control method and a control device of a slow speed type electric valve. The control method is characterized in that a control box is internally provided with a ripple time relay, thereby achieving the purpose of adjusting the rotation speed of an electric valve motor and the running time in the opening and closing process. The control method not only can prevent a pipeline from generating a water hammer when the electric valve is rapidly opened and closed, and the deformation and detonation of the pipeline are avoided; and a valve electromotion device is prevented from abidingly operating for a long time, the burnt phenomenon of the valve electromotion device is avoided, the power of a motor is reduced, and the investment cost and operating cost are reduced.

Owner:林永江 +2

A drip irrigation system

InactiveCN106106053AAvoid harmSimple structureWatering devicesPressurised distribution of liquid fertiliserDrip irrigationEngineering

The invention is mainly applied to the field of irrigation and fertilization in an apple planting process and in particular relates to a drip irrigation system. The system comprises a pump house head, a field head and a field pipe network. The pump house head comprises a water pump, an automatic backwash filter and a fertilizer injection device, wherein a water inlet end of the water pump is connected with a water pipe; an end of the water pipe is provided with a first filter; a water outlet end of the water pump is connected with the automatic backwash filter; a water outlet end of the automatic backwash filter is connected with the field head via a mixing pipe; the fertilizer injection device comprises fertilizer injection tanks which are connected with proportional fertilizer injectors via pipes; the proportional fertilizer injectors are connected with the mixing pipe via fertilizer injection pipes; one end of a water intaking hose is connected with the mixing pipe and the other end is connected with the fertilizer injection tanks. The drip irrigation system realizes water drip irrigation and fertilizer drip irrigation at the same time and prevents damage to the water pump and the pipe network; the service life of the system is prolonged and maintenance is convenient; the intelligent control system realizes intelligent irrigation and fertilization, increases the irrigation and fertilization efficiency, reduces manual operation and improves quality.

Owner:沂源县沂冠通农业科技发展有限公司

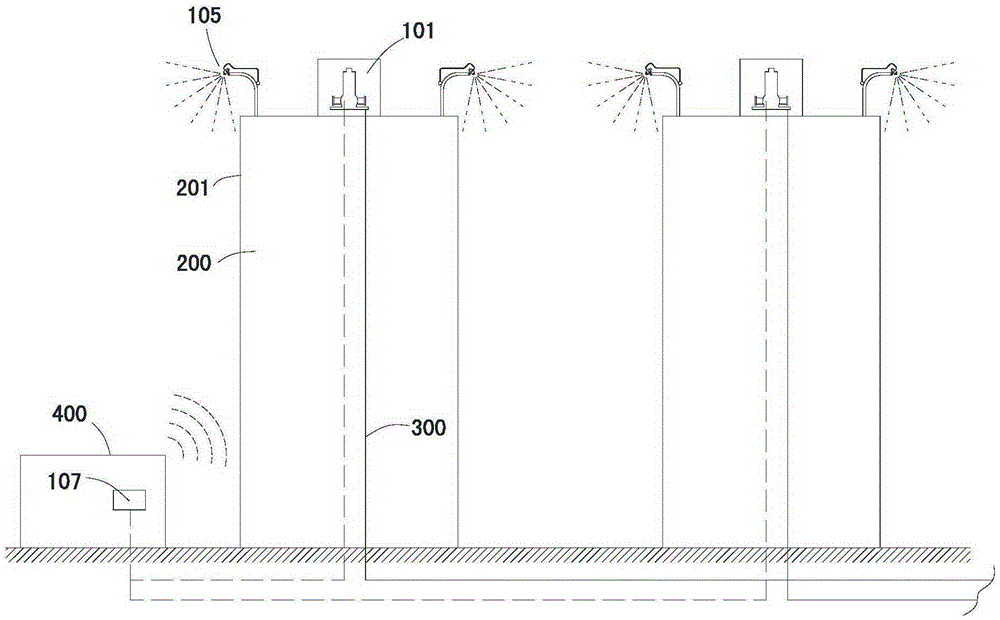

Haze-removing, dedusting and cooling system for buildings

InactiveCN105180323APrevent water hammerEliminate water hammerLighting and heating apparatusUsing liquid separation agentElectricityWater source

The invention provides a haze-removing, dedusting and cooling system for buildings, and relates to the field of the buildings. The haze-removing, dedusting and cooling system comprises a booster water pump, a water supply pipe, a water distribution pipe, branch pipes and a plurality of nozzles which are arranged on the top of a building, wherein the water supply pipe, the water distribution pipe and the branch pipes are orderly communicated; the input end of the booster water pump is connected with a water source, and the output end of the booster water pump is communicated with the water supply pipe; the nozzles are connected with the branch pipes and arranged around the buildings. The haze-removing, dedusting and cooling system breaks through the traditional thinking, corresponding spraying equipment are additionally mounted at the top of the conventional buildings and used for spraying atomized water around the buildings, and therefore the purpose of improving the micro-climate of the buildings is achieved. If most of buildings in the city adopt the haze-removing, dedusting and cooling system, the microclimatic environment of whole city can also be improved. The haze-removing, dedusting and cooling system only consumes small amount of electricity and atomized water, therefore being more energy-efficient and realizing better environmental protection.

Owner:白健荣

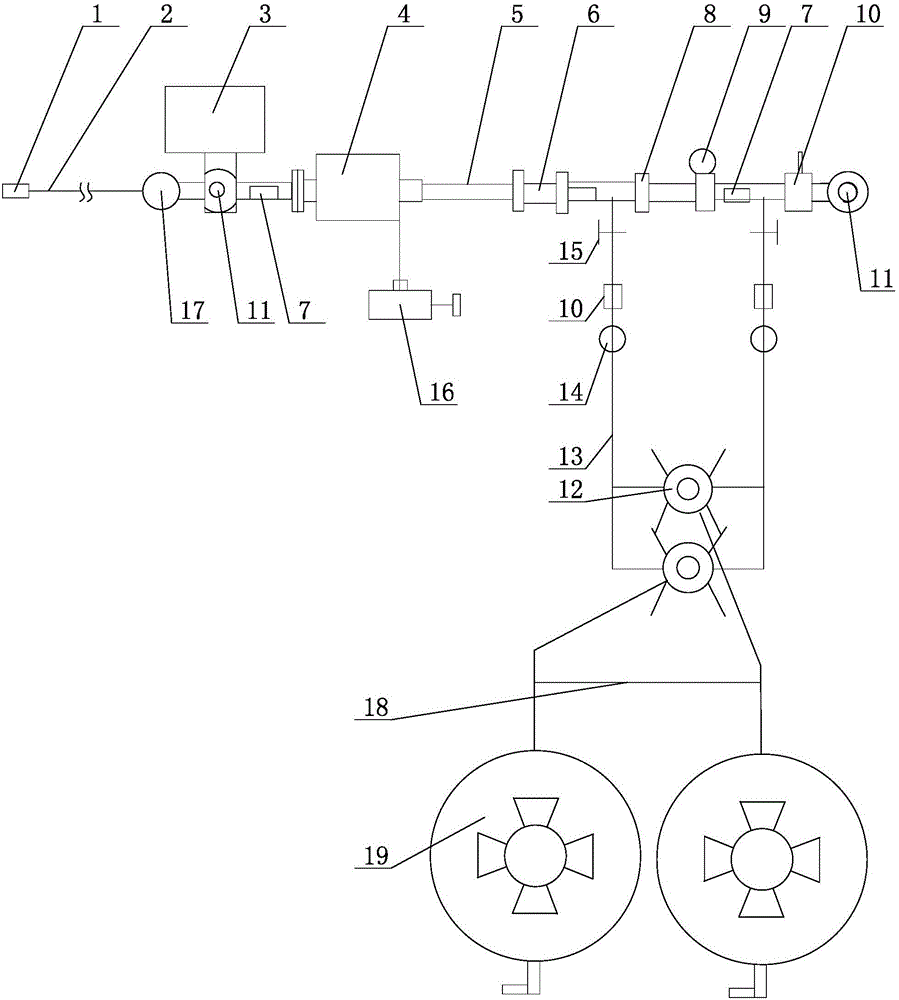

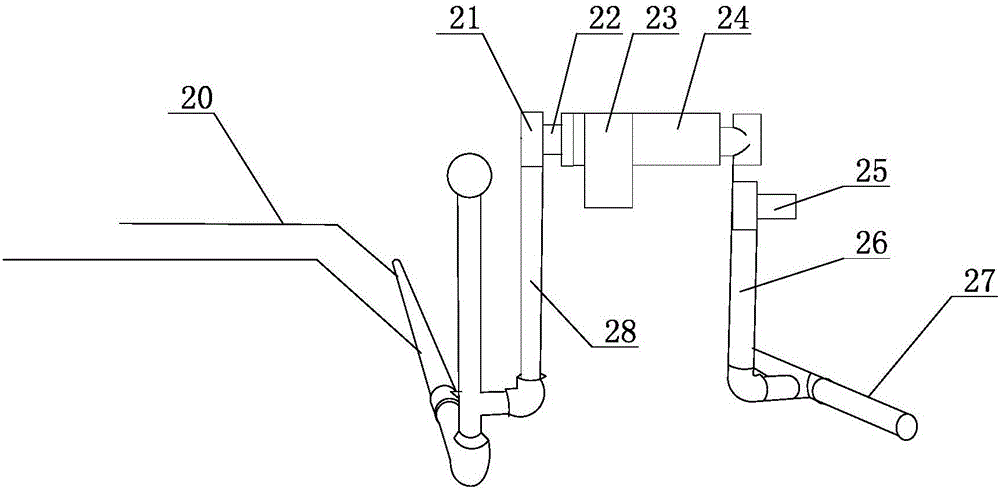

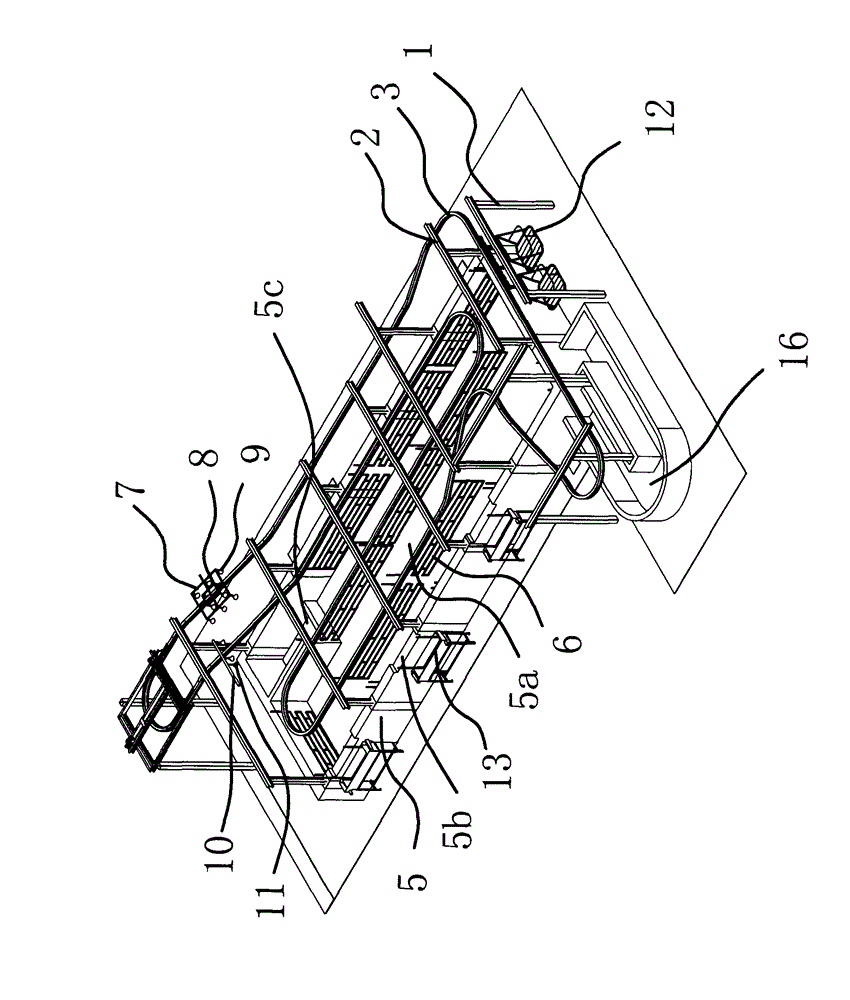

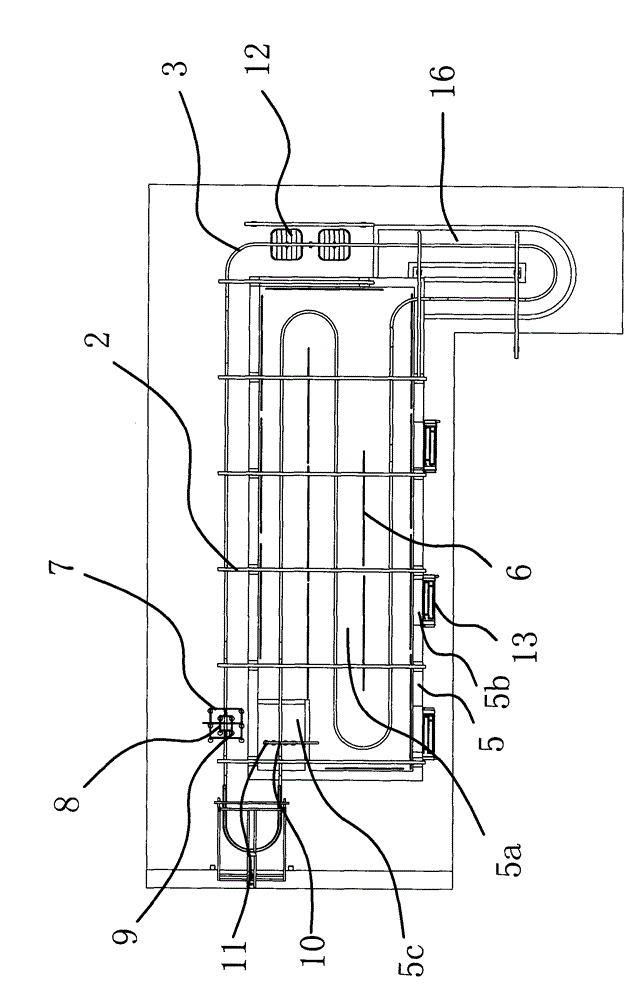

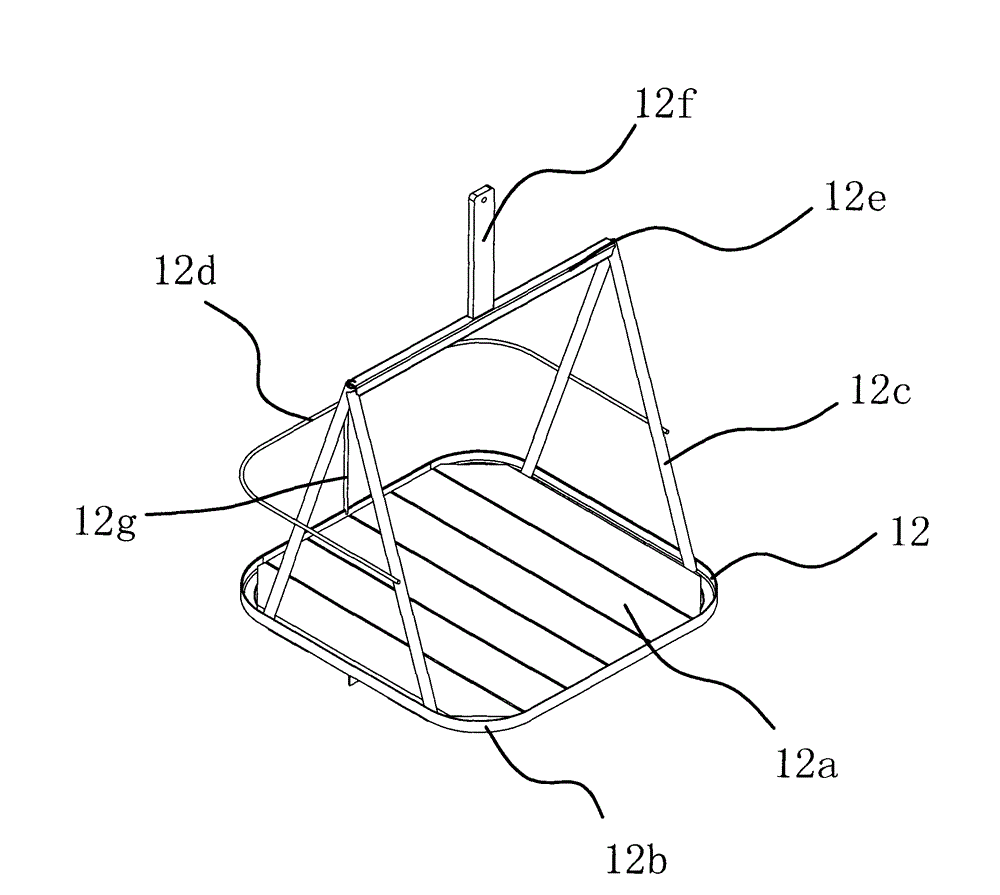

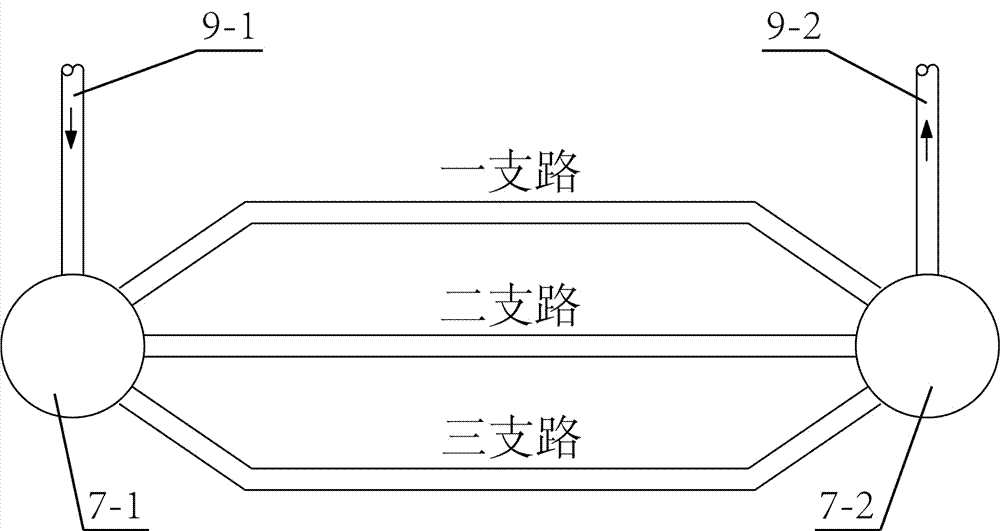

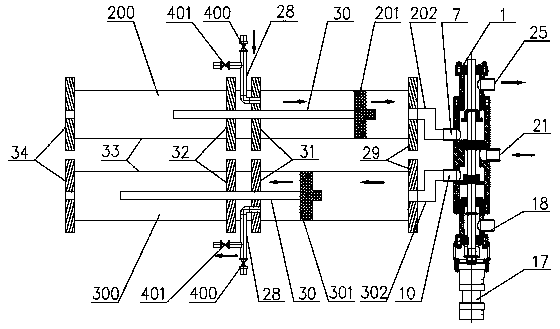

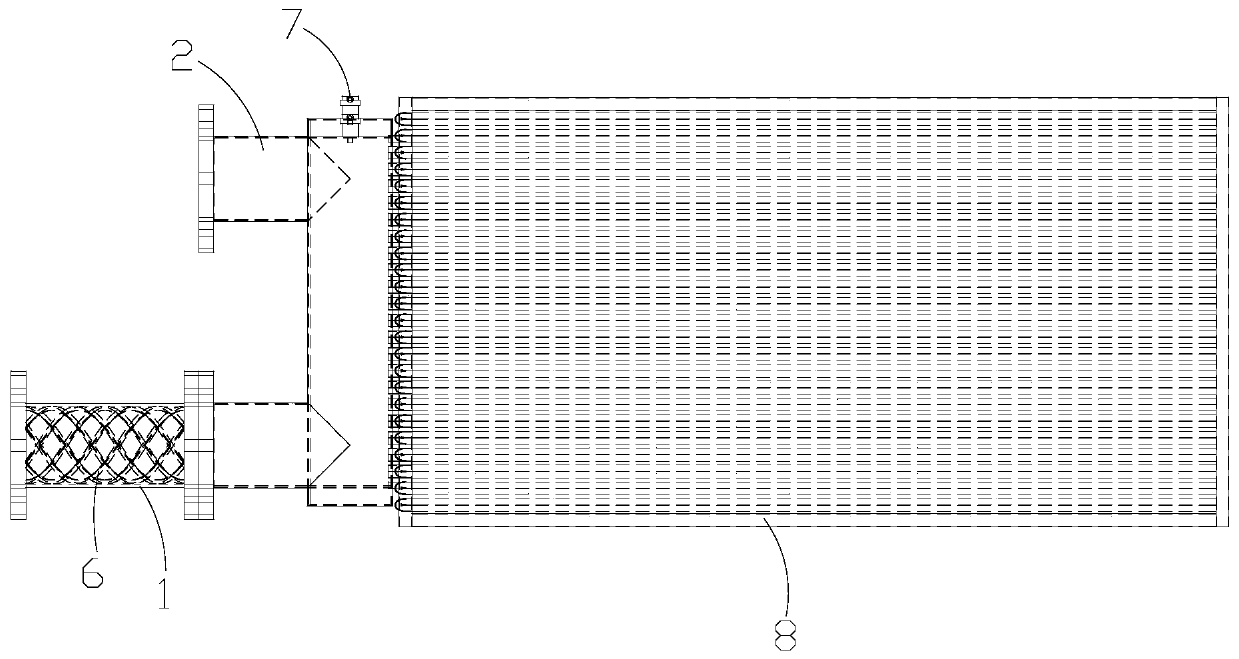

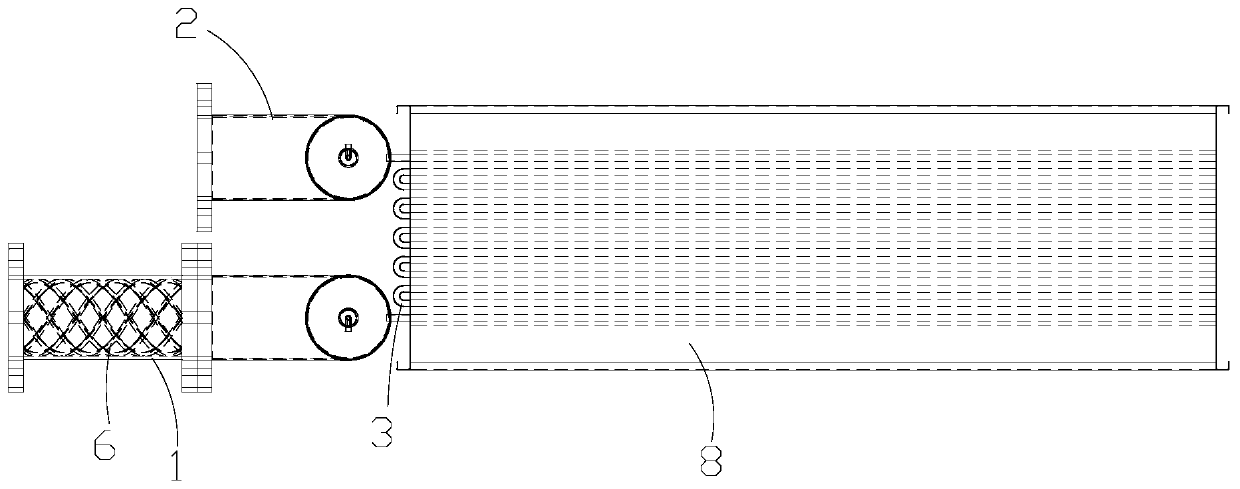

Dewaxing assembly line

InactiveCN102909318AAvoid problems with impuritiesAvoid enteringFoundry mouldsFoundry coresFoundryWax

The invention provides a dewaxing assembly line, belongs to the technical field of foundry machinery, and solves the problems that impurities are mixed into wax recovered by the existing dewaxing assembly line formwork when the wax is molten, and grains of sand are attached inside the formwork. The dewaxing assembly line comprises a frame and a pool; a chain track is fixed on the frame and a hanging box moving along the chain track is arranged on the chain track; a cold water shower device and a hot water shower device are arranged on the frame; the cold water shower device is arranged at the outer side part of the pool; the hot water shower device is arranged above the inlet end of the pool; the cold water shower device, the hot water shower device and the pool are orderly arranged clockwise or anticlockwise; the hanging box can be driven to pass through the cold water shower device, the hot water shower device and the pool through the chain track; a plurality of heating sheets connected with a hot steam source are vertically arranged inside the pool, and the heating sheets partition the pool into a plurality of S-shaped channels connected in series. The dewaxing assembly line is simple in structure, good in wax melting effect, high in work efficiency and high in yield of the formwork.

Owner:宁波创二代机械科技有限公司

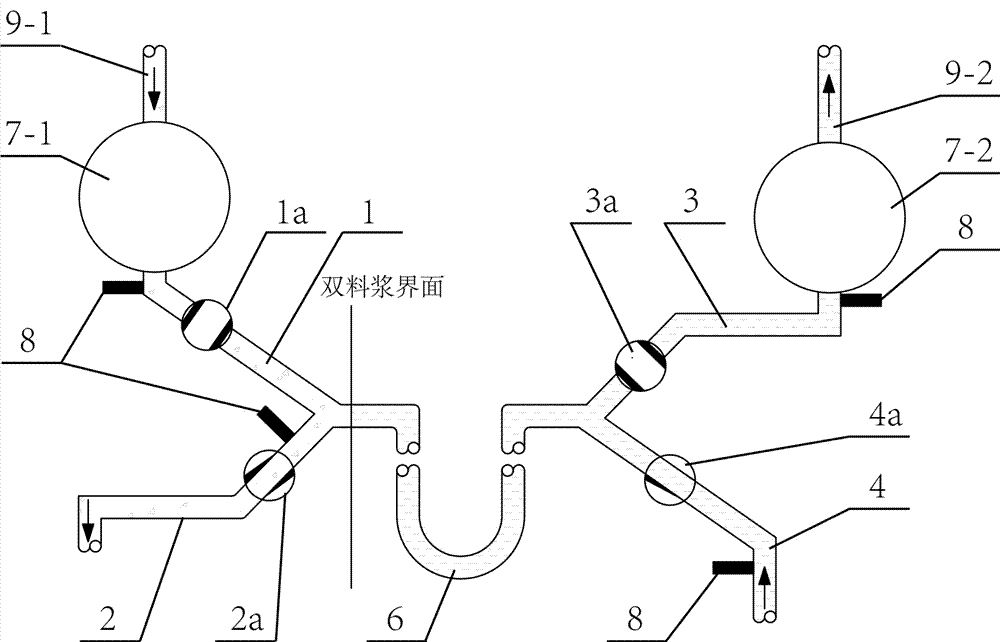

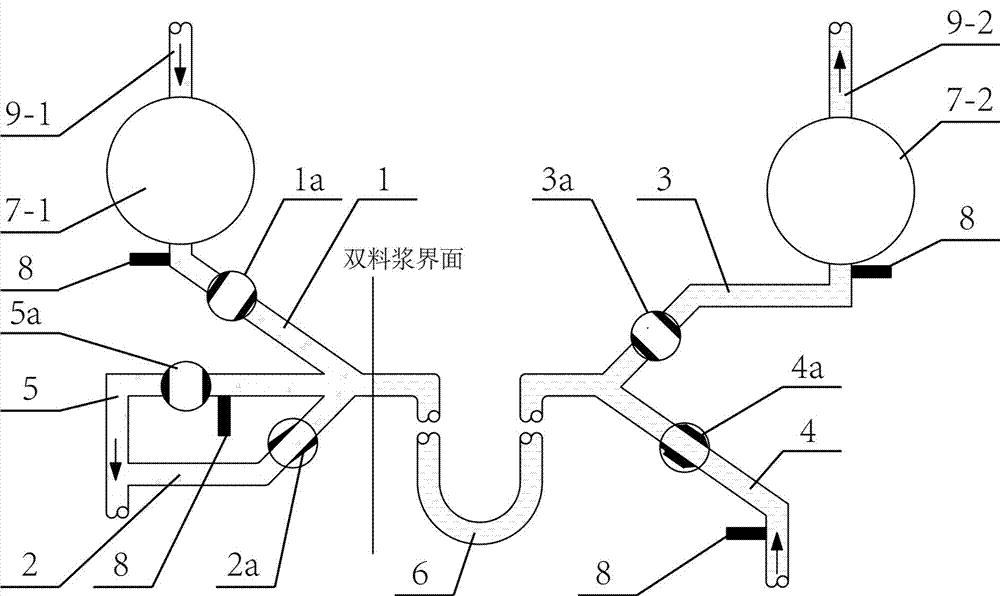

Energy-saving method and system for underground mine double-slurry inputting and discharging

The invention discloses an energy-saving method and system for underground mine double-slurry inputting and discharging. Energy of underground slurry transferred from the earth's surface serves as main power which is used for raising underground slurry to be discharged to the earth's surface. By the aid of the method and the system, the energy is saved, and production costs for ventilation, temperature reduction, pipeline abrasion and the like are reduced.

Owner:王书铭

Proportional pressure reducing valve for waterworks

InactiveCN106015666AStop water leakPrevent water leakageCheck valvesValve members for absorbing fluid energyWater flowEngineering

Owner:KANE KOUGYOU

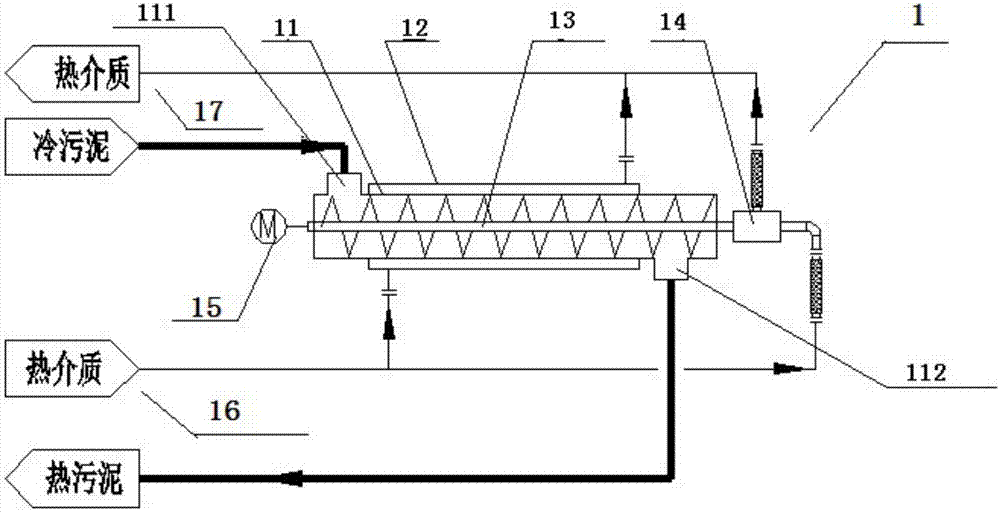

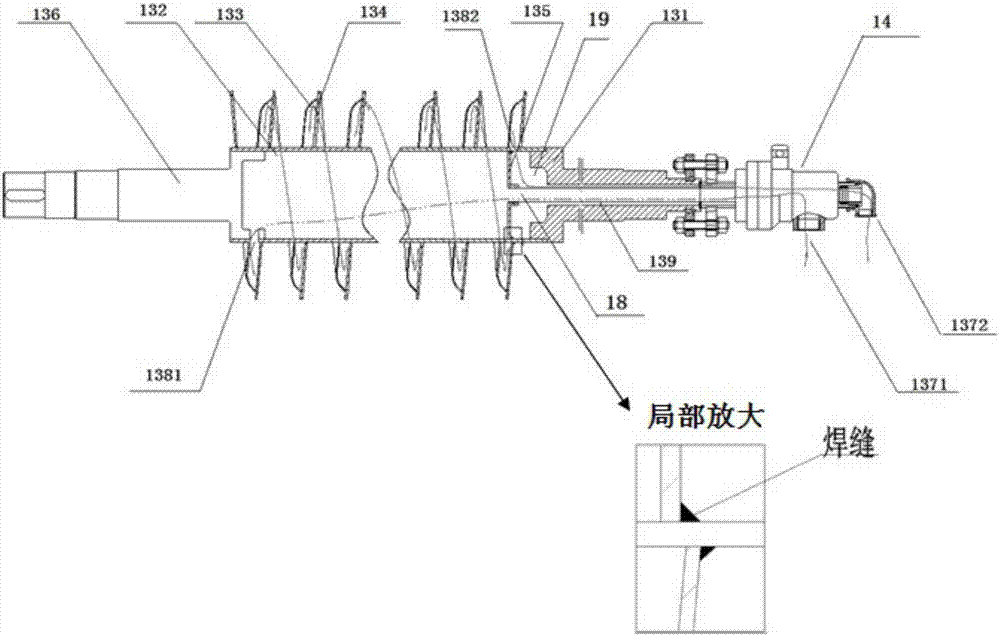

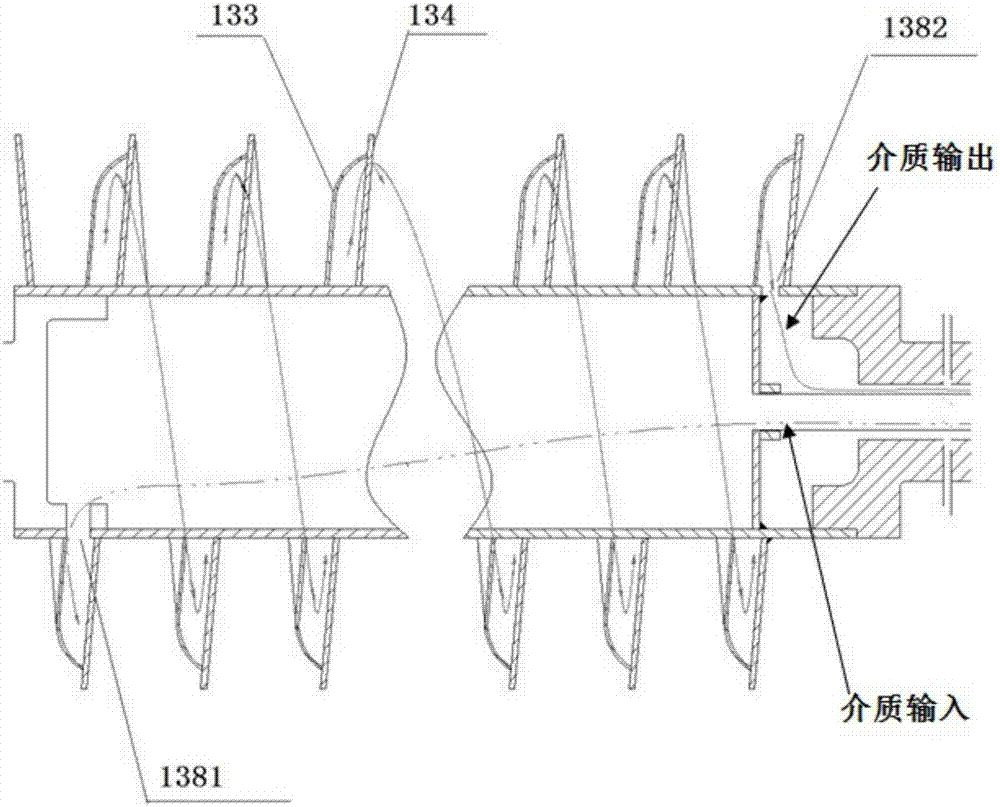

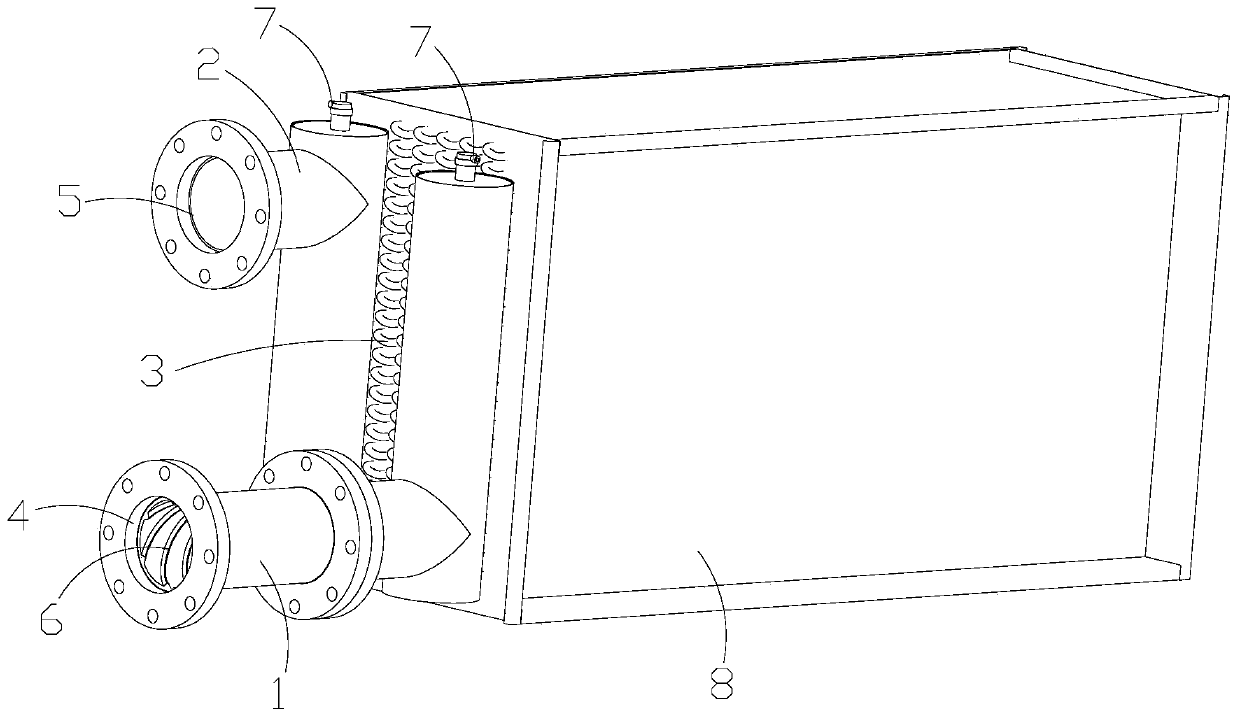

Sludge preheating device and sludge drying system

ActiveCN107352772AAchieve warm-upEfficient reuseSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentDual actionSludge

The invention provides a sludge preheating device. The sludge preheating device comprises a casing, a hollow screw shaft, a rotating joint and a driving device, wherein a feeding port and a discharging port are formed in the casing; the hollow screw shaft penetrates in the casing; the driving device is used for driving the hollow screw shaft to rotate; a hollow cavity structure capable of allowing thermal media to circulate is arranged in the hollow screw shaft, and the rotating joint is communicated with the hollow cavity structure in the hollow screw shaft to serve as a channel allowing the thermal media to enter or exit from the hollow screw shaft. Furthermore, the invention discloses a sludge drying system. The sludge drying system comprises the sludge preheating device, a sludge drying device and a thermal energy recovery device. Materials can be preheated and pushed by the aid of the sludge preheating device, and waste heat can be effectively reused by the aid of the sludge drying system, so that the energy consumption is minimized.

Owner:NANJING CEC ENVIRONMENTAL ENGINEERING CO LTD

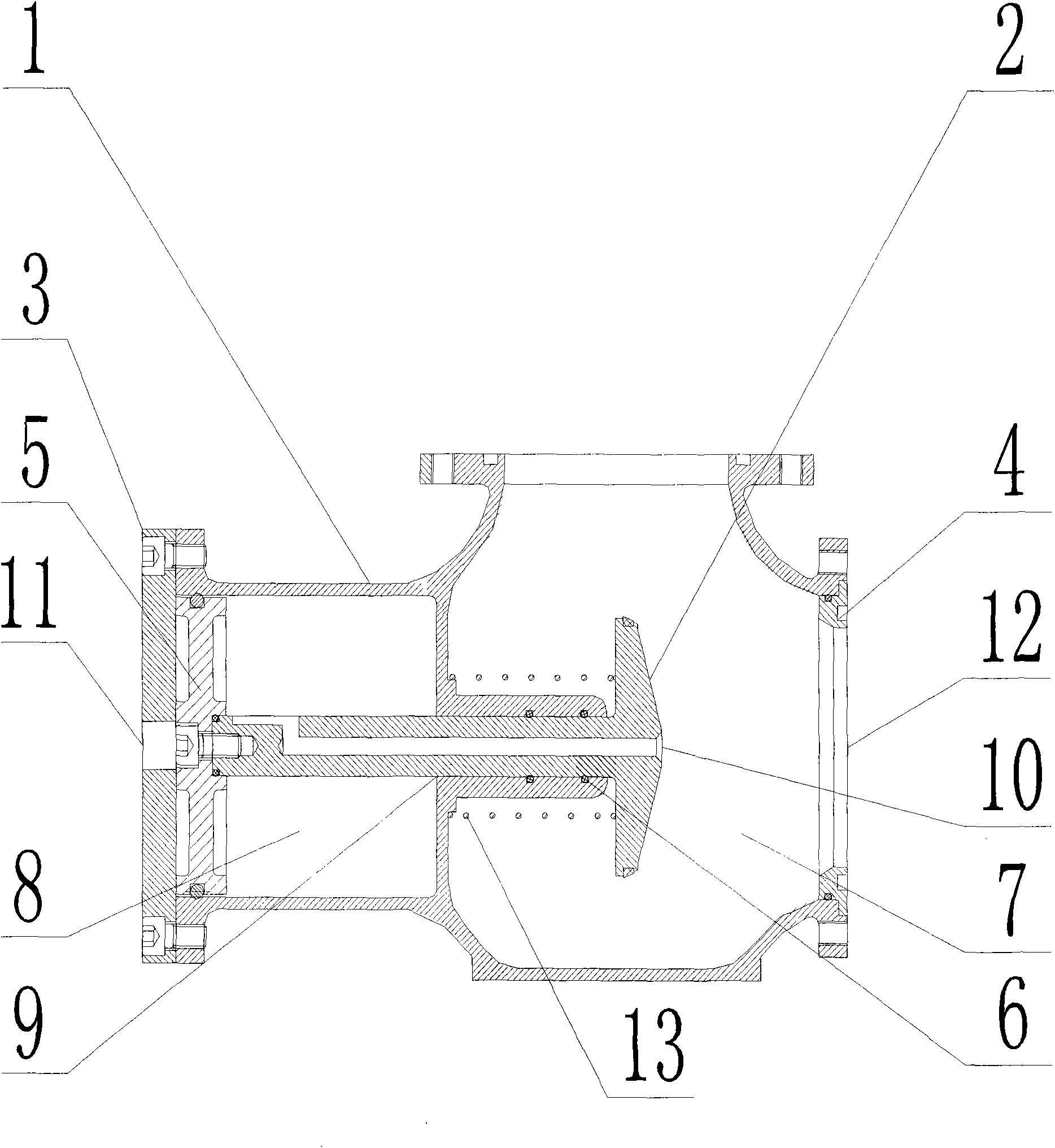

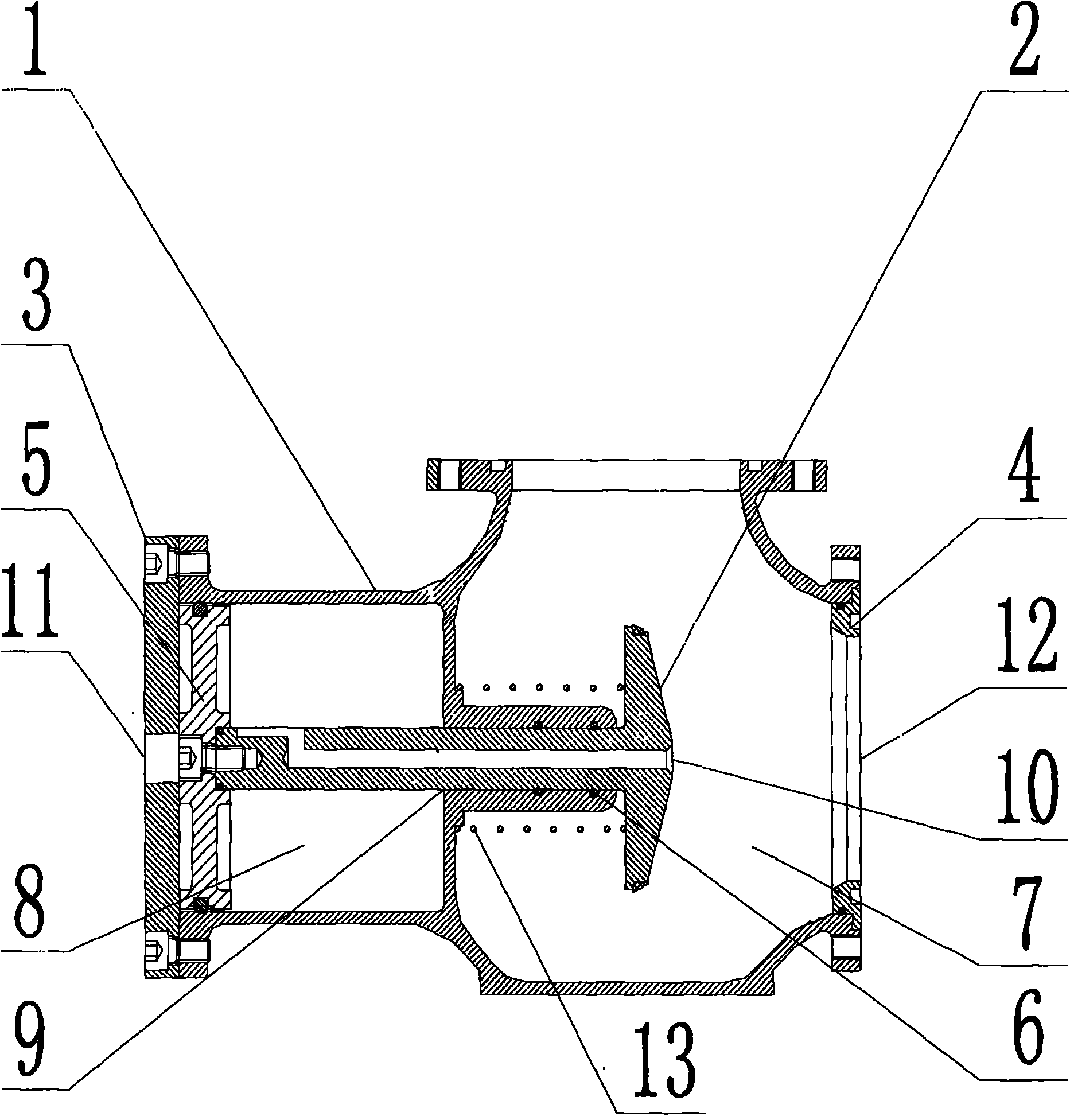

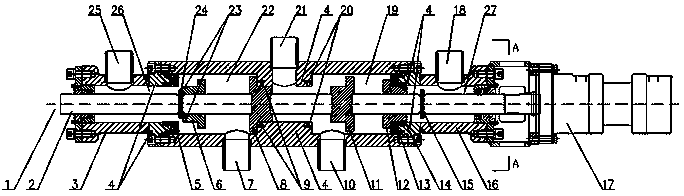

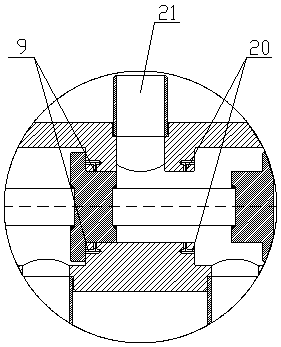

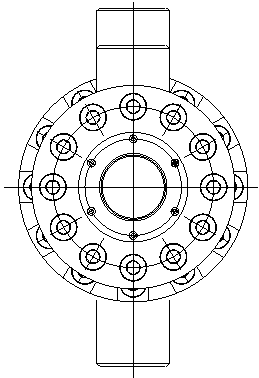

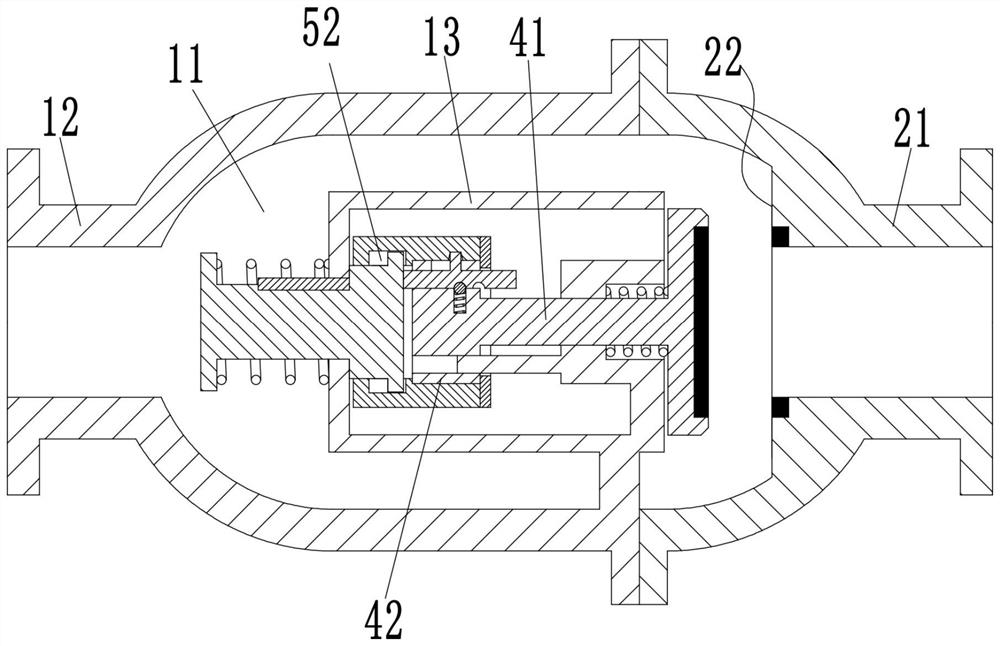

Low-resistance slow-closure type check valve

InactiveCN101876380AReduce hydraulic lossTo achieve the purpose of non-returnCheck valvesValve housingsEngineeringHigh pressure water

The invention relates to a low-resistance slow-closure type check valve. Since a hollow hole is arranged in a valve clack, when flowing through the low-resistance slow-closure type check valve, high-pressure water firstly flows through a valve clack hole and then enters a piston cavity, and since a vent hole is arranged on a rear cover, a pressure difference is formed, the high-pressure water pushes a piston to operate backwards, the valve clack is driven to operate backwards, the valve is in an opening state, water operates in a barrier-less expedite environment, and hydraulic loss is correspondingly reduced greatly. When the pressure of the water inlet of the valve is reduced or water is stopped, the high-pressure water in the piston cavity and the system flows to the low-pressure part, a backflow state occurs, and because the valve clack and water are in a radial force operating state, the valve clack operates backwards slowly, the low-resistance slow-closure type check valve is finally in a closed state, the non-return purpose is achieved, and the water hammer is avoided.

Owner:SHANGHAI PANDA MACHINEGRP CO LTD

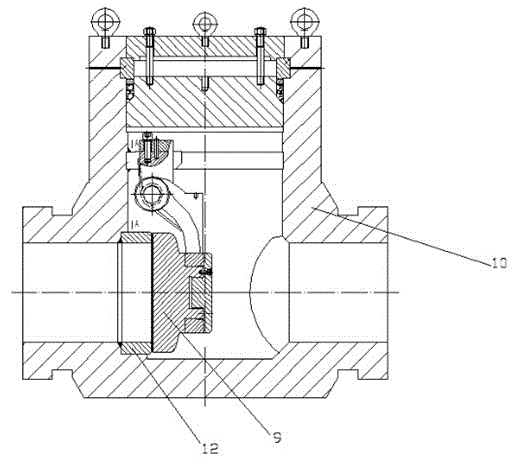

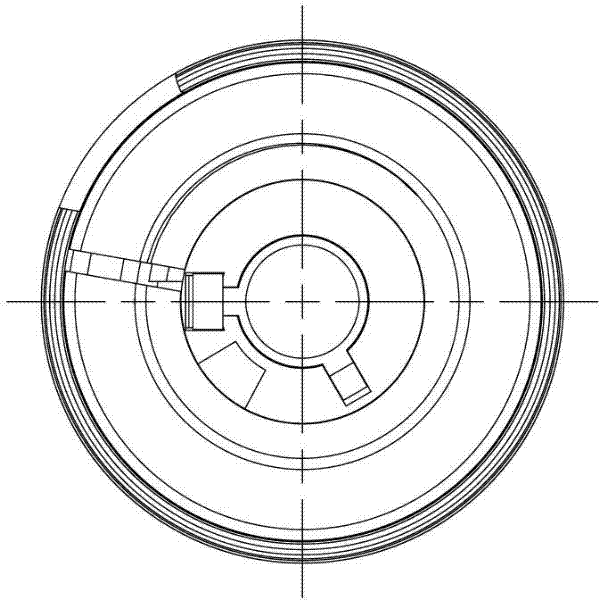

Rotary valve type pump protecting device

InactiveCN105626551AAchieve decompressionMeet the design requirementsPump controlNon-positive displacement fluid enginesRotary valveEngineering

The invention discloses a rotary valve type pump protecting device. The problems that an existing pump protecting device is complex to operate and high in equipment investment, and safety needs to be further improved are solved. According to the technical scheme, the rotary valve type pump protecting device comprises a sealing valve body with a first flow channel, and a check valve is arranged in the first flow channel; the device further comprises a bypass valve body with a second flow channel, and the part, blow the check valve, of the first flow channel communicates with the second flow channel through a flow hole in a ball valve; the ball valve is fixedly connected with one end of a guide rod, and the other end of the guide rod is hinged to the check valve. The rotary valve type pump protecting device is simple in structure, free of manual operation, controllable in pressure, low in cost, efficient and safe.

Owner:WUHUAN ENG

Screwing opening type check valve capable of balancing pressure automatically

InactiveCN104180029AProtect operational safetyExtend your lifeCheck valvesValve members for absorbing fluid energyEngineeringCheck valve

The invention relates to a screwing opening type check valve capable of balancing pressure automatically. The check valve comprises a valve body. An inlet and an outlet are arranged in two ends of the valve body on the same horizontal line, a valve seat is arranged on one side in the valve body facing the outlet, a horizontal valve shaft perpendicular to the axes of the inlet and the outlet is arranged above the valve seat, a valve clack matched with the valve seat is hinged to the horizontal valve shaft, a valve cover is arranged on the upper side of the valve body, an exhaust hole is formed in the valve cover and is communicated with a communication pipe on the inlet side of the valve body, the exhaust hole is closed through a valve element, and a spring assembly sleeves the valve element to control lifting of the valve element. Compared with the prior art, the check valve can achieve the effect that the pressure of the outlet side of the valve body can be controlled conveniently to prevent water hammers and prolong the service life.

Owner:SHANGHAI KARON VALVES MACHINERY +1

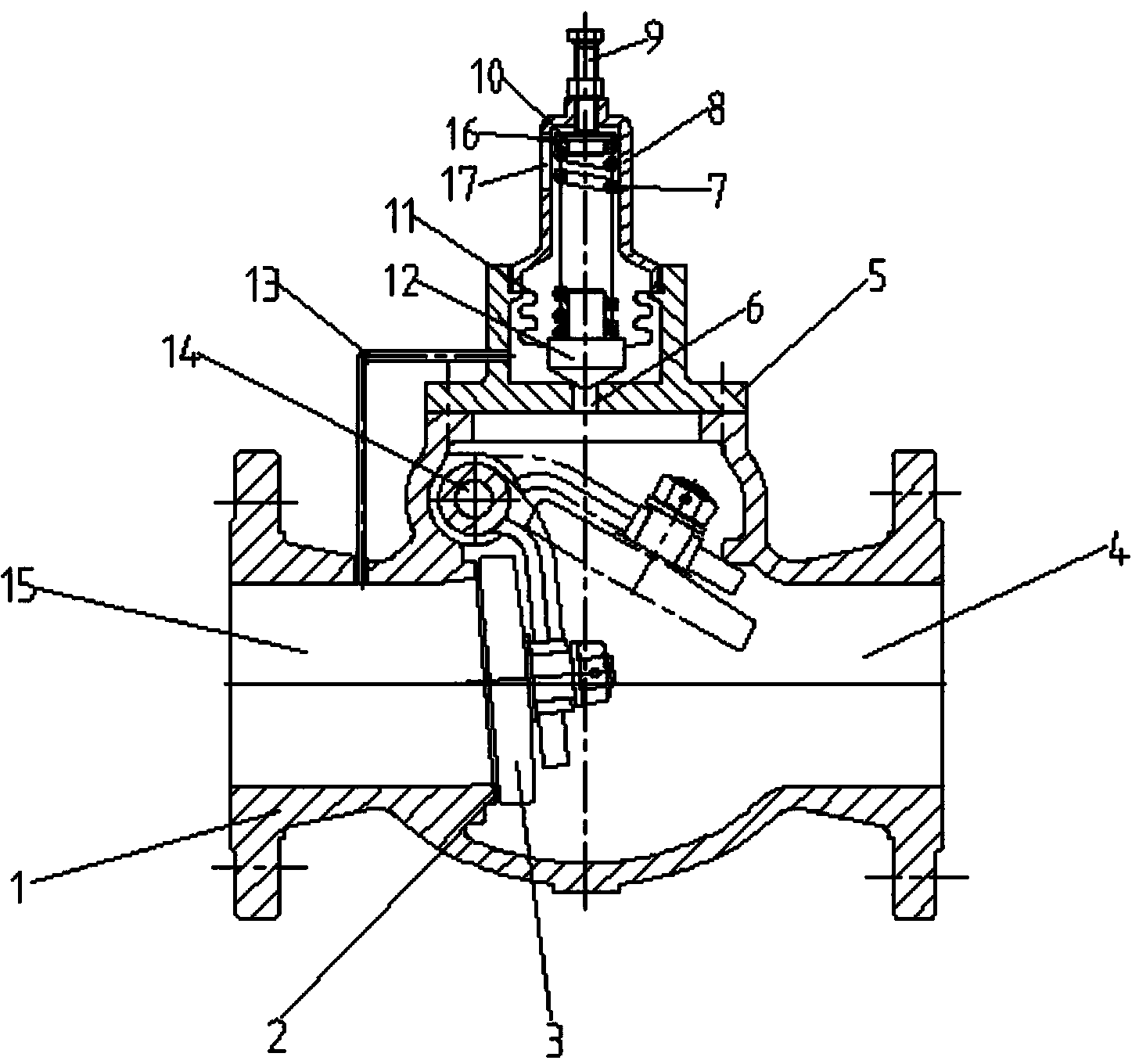

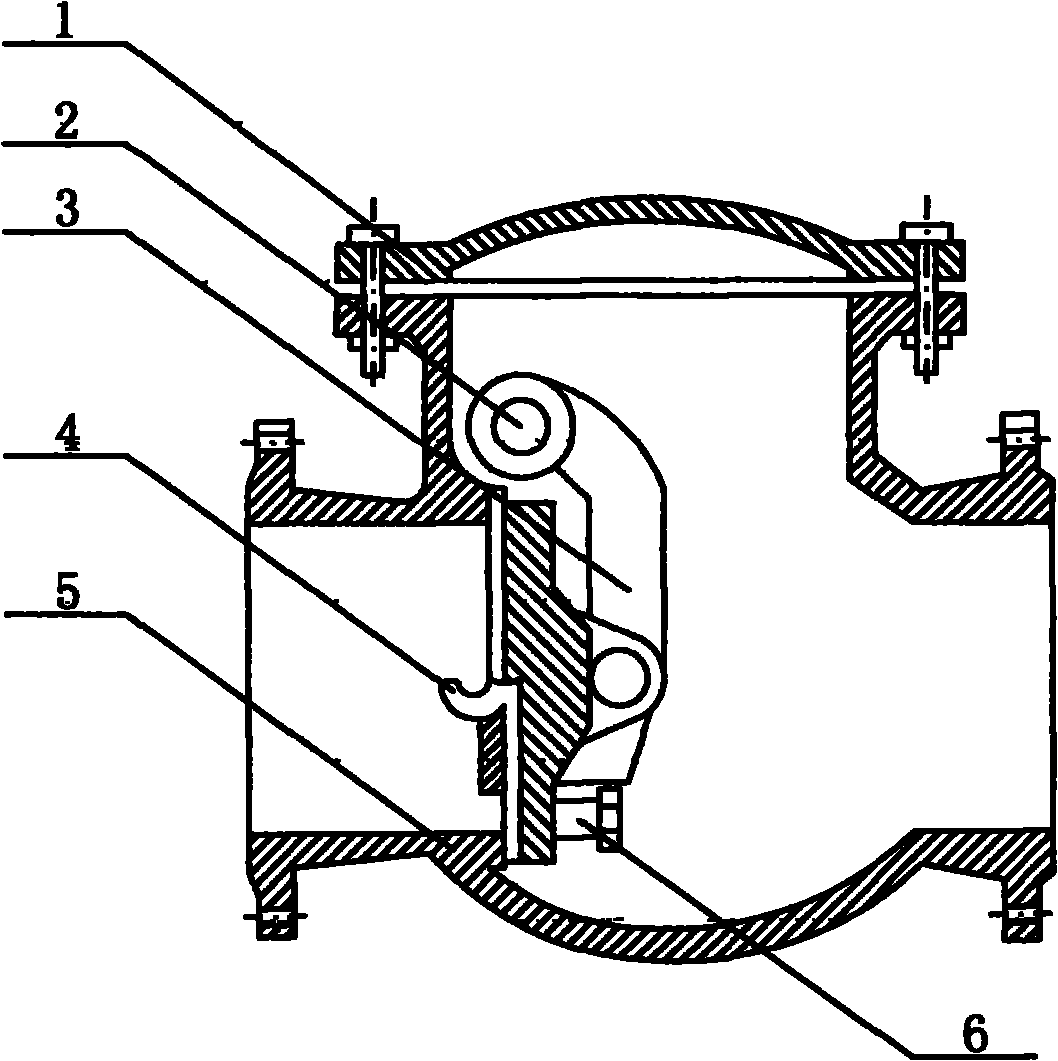

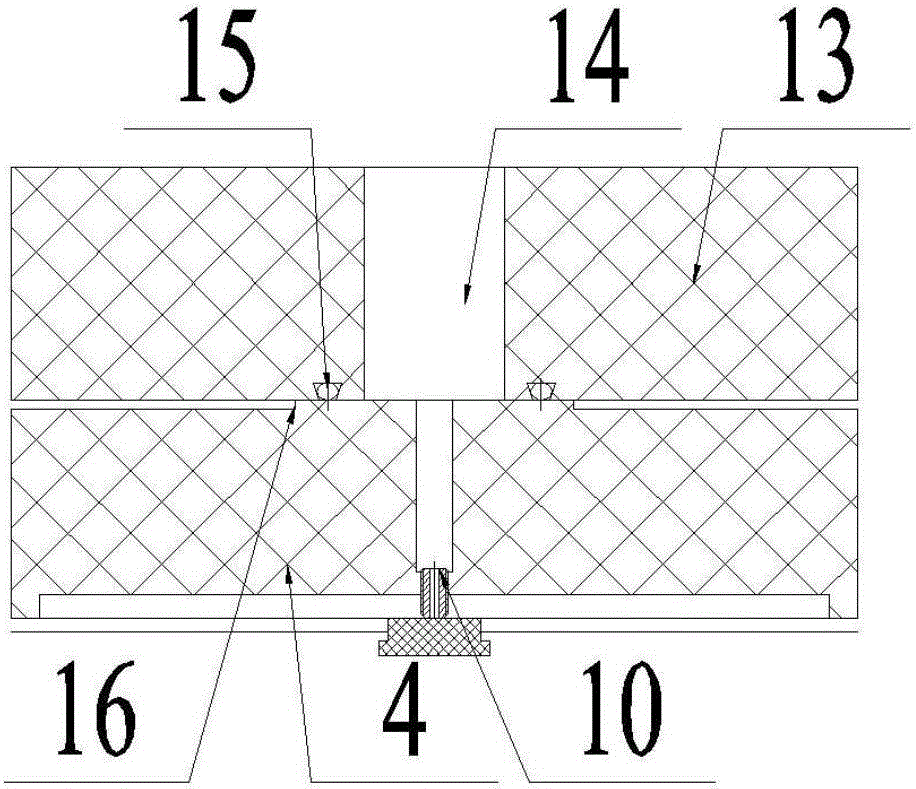

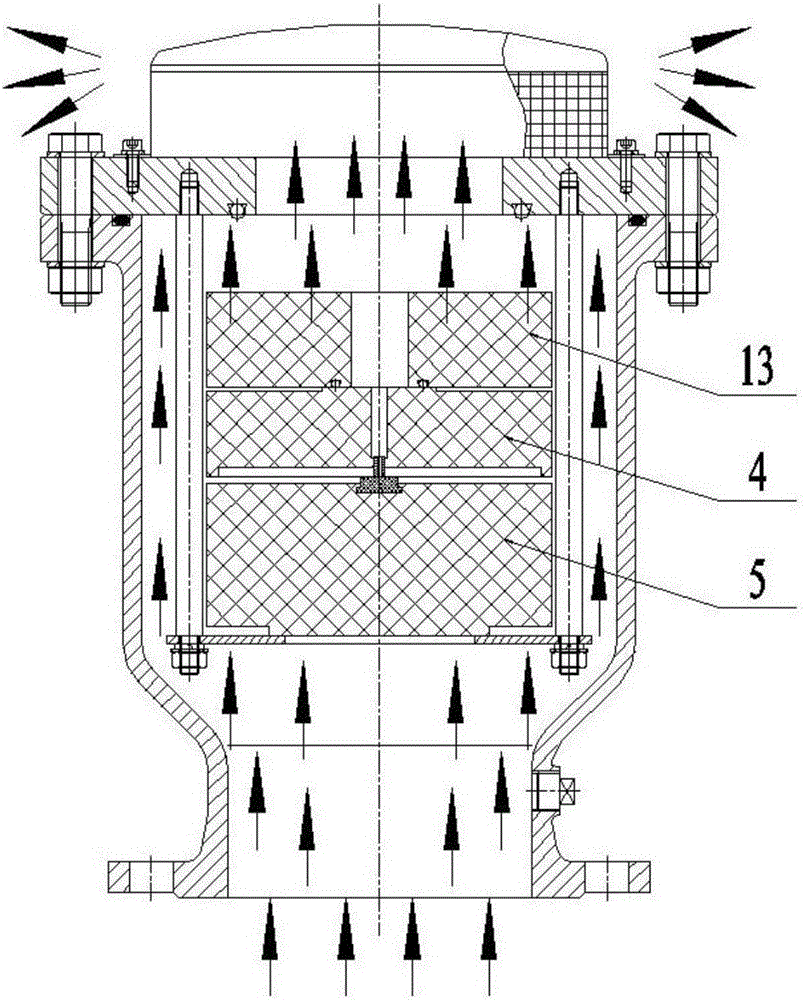

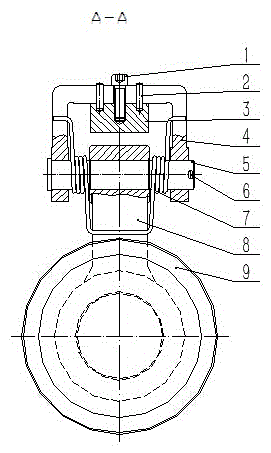

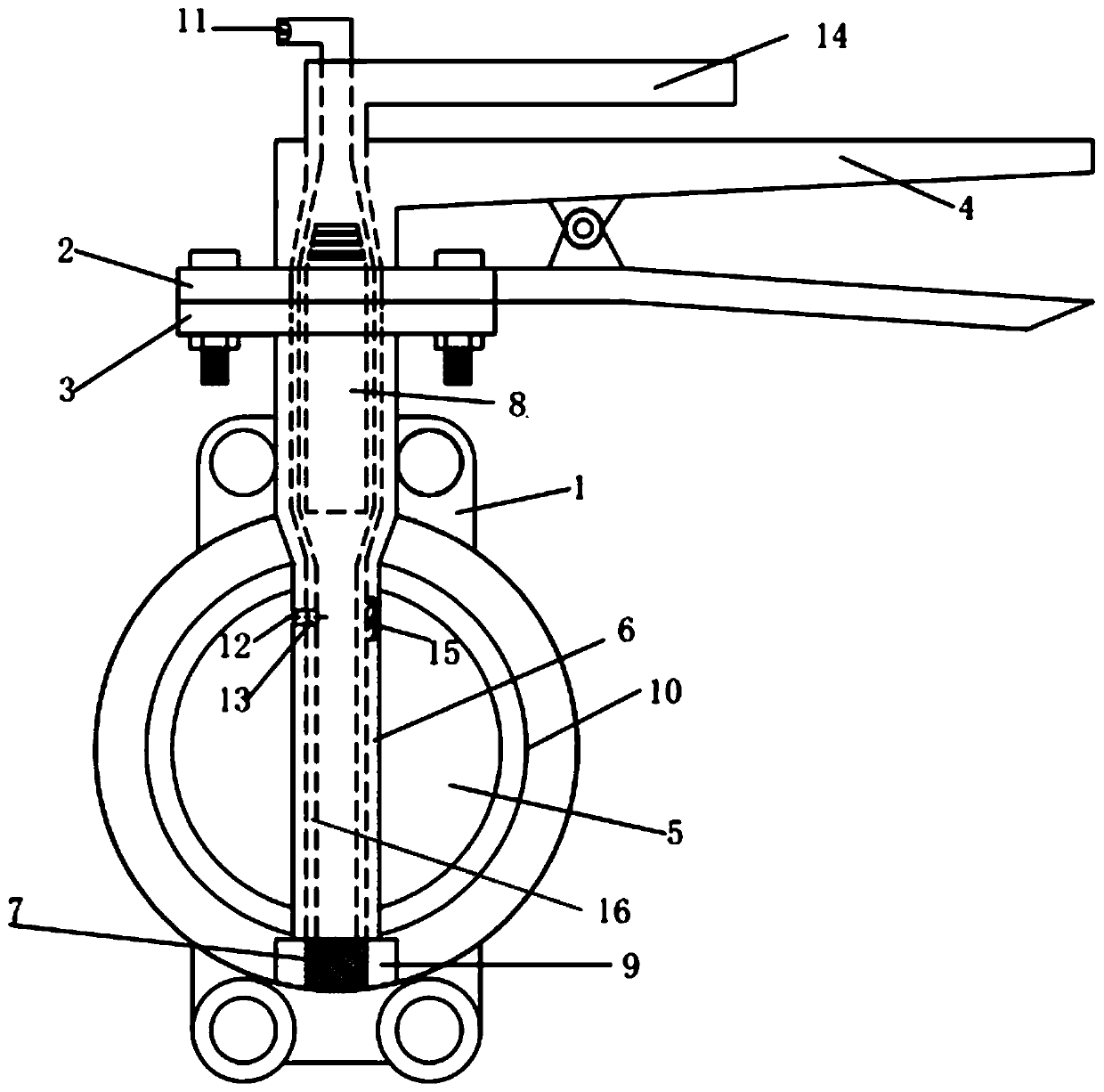

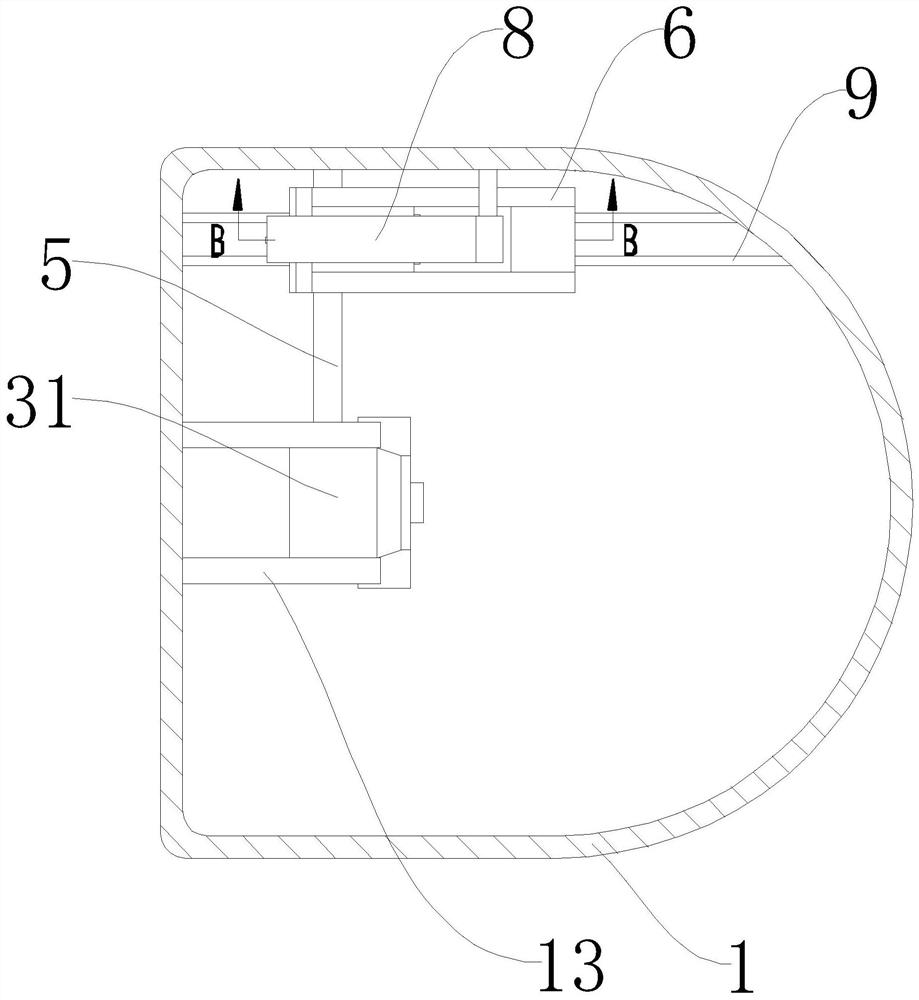

Novel swing check valve

InactiveCN102042428APrevent water hammerEasy to useCheck valvesValve members for absorbing fluid energyEngineeringWater hammer

The invention discloses a novel swing check valve, relating to a check valve. The novel swing check valve consists of a valve cap (1), a hinge pin (2), a rocking bar (3), a valve clack (4), a valve body (5) and an auxiliary valve (6), wherein the valve cap (1) is arranged on the upper end of the valve body (5), the hinge pin (2) is arranged on the upper end of the interior of the valve body (5), the rocking bar (3) is connected with the hinge pin (2), the auxiliary valve (6) is arranged on the lower side of the valve clack (4), and the valve clack (4) is connected with the rocking bar (3). The auxiliary valve is additionally arranged, thus the novel swing check valve has the advantages that the water hammer which damages a pipeline system and is caused by the traditional similar check valve is solved; the use range of the check valve is expanded; and the novel swing check valve is convenient to use.

Owner:王晓宏

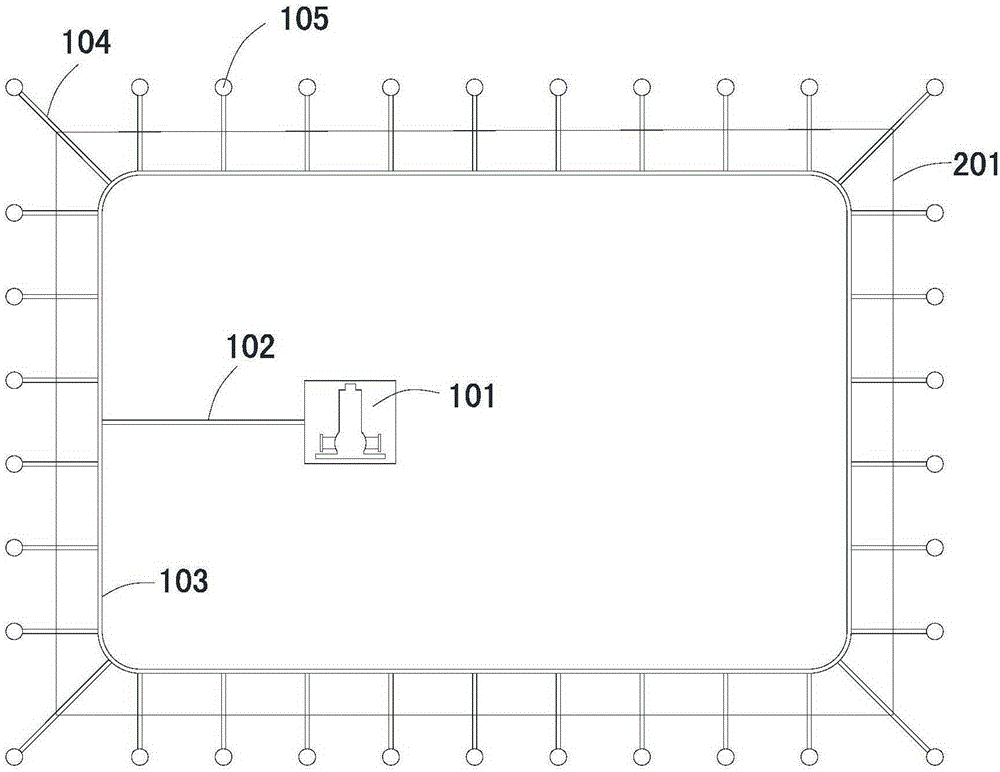

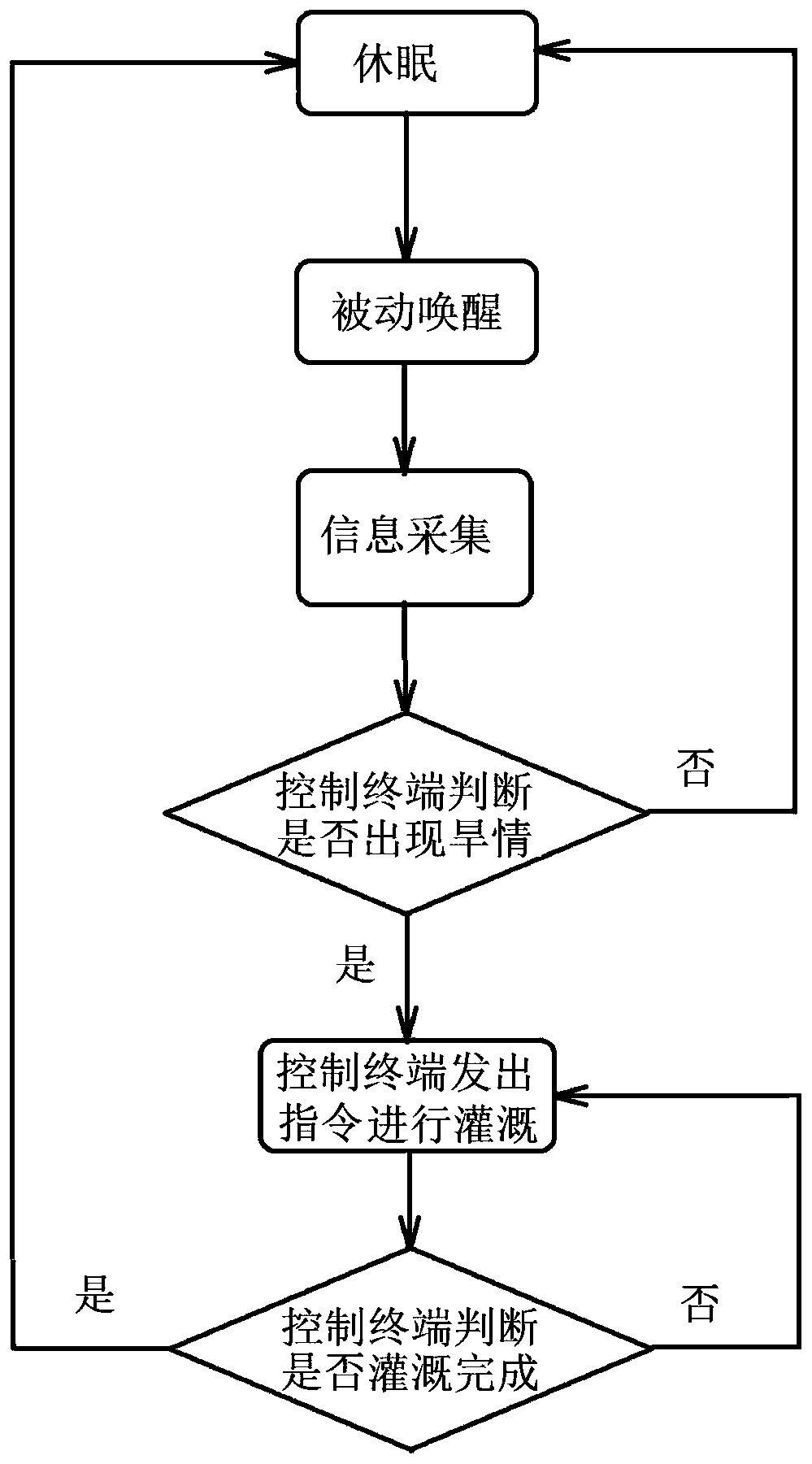

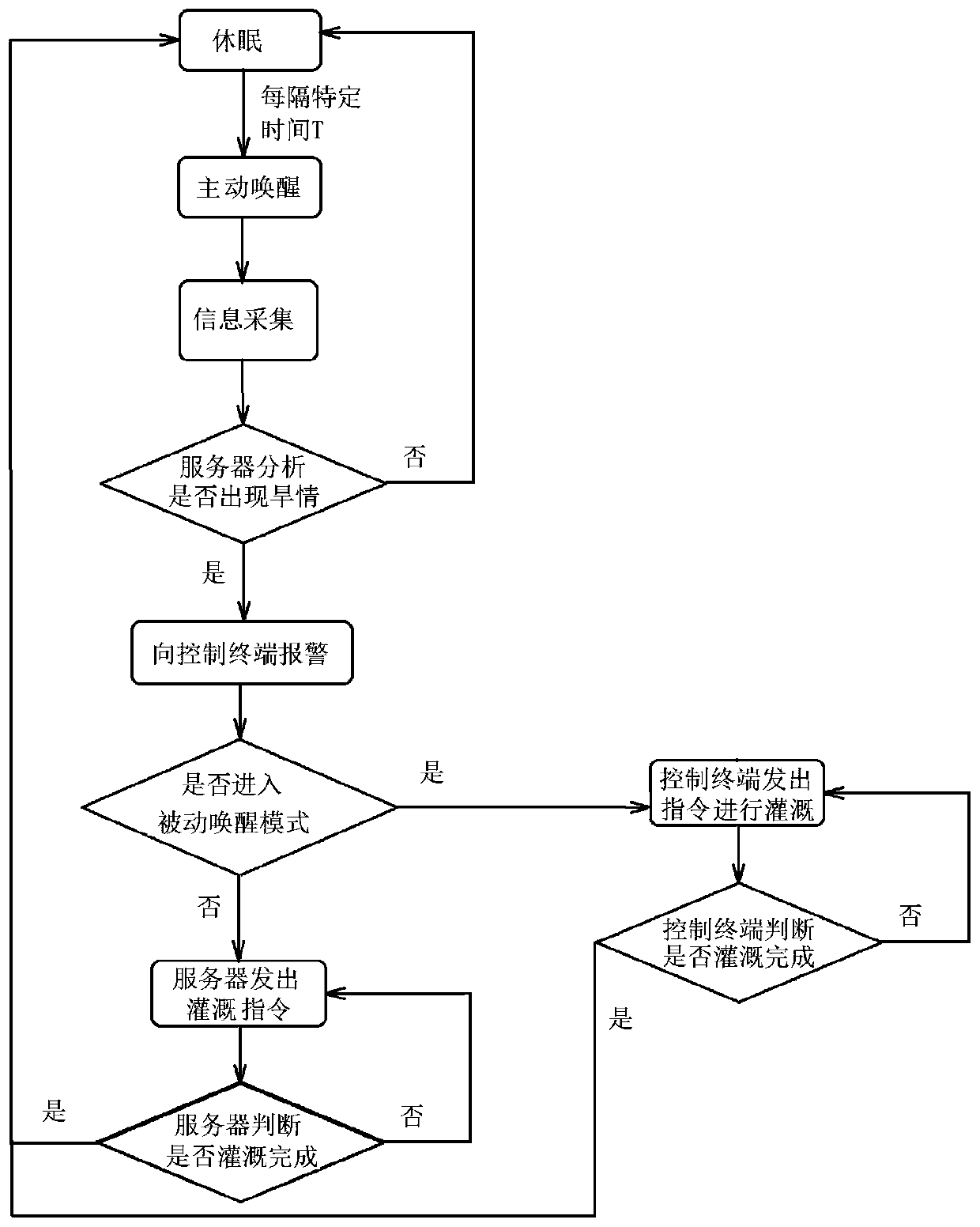

Intelligent irrigation unit and system

PendingCN111280034ALighten the power supply burdenReduce volumeOperating means/releasing devices for valvesWatering devicesAgricultural scienceData information

The invention provides an intelligent irrigation unit. The intelligent irrigation unit comprises a sensor group, a solar energy storage system, a valve driving system and a control system, wherein thecontrol system comprises a control panel, the control panel has a sleep mode and a wakeup mode, and the solar energy storage system does not supply electric power to the control system or only supplies the minimum electric quantity capable of waking up a master chip of the control panel to the master chip when the control panel is in the sleep mode; and the wakeup mode comprises a passive wakeupmode, and in the passive wakeup mode, a control terminal sends a control command to the control panel through a remote communication module, data information of the sensor group is acquired and the valve driving system is controlled to execute corresponding irrigation actions according to the data information.

Owner:陈华

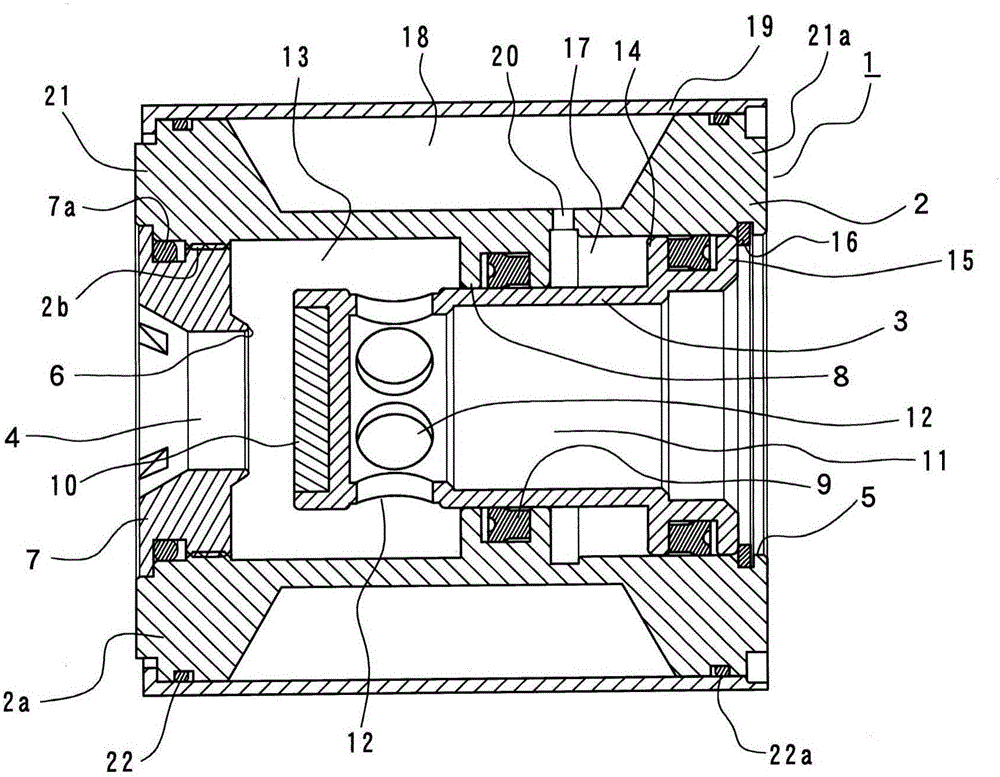

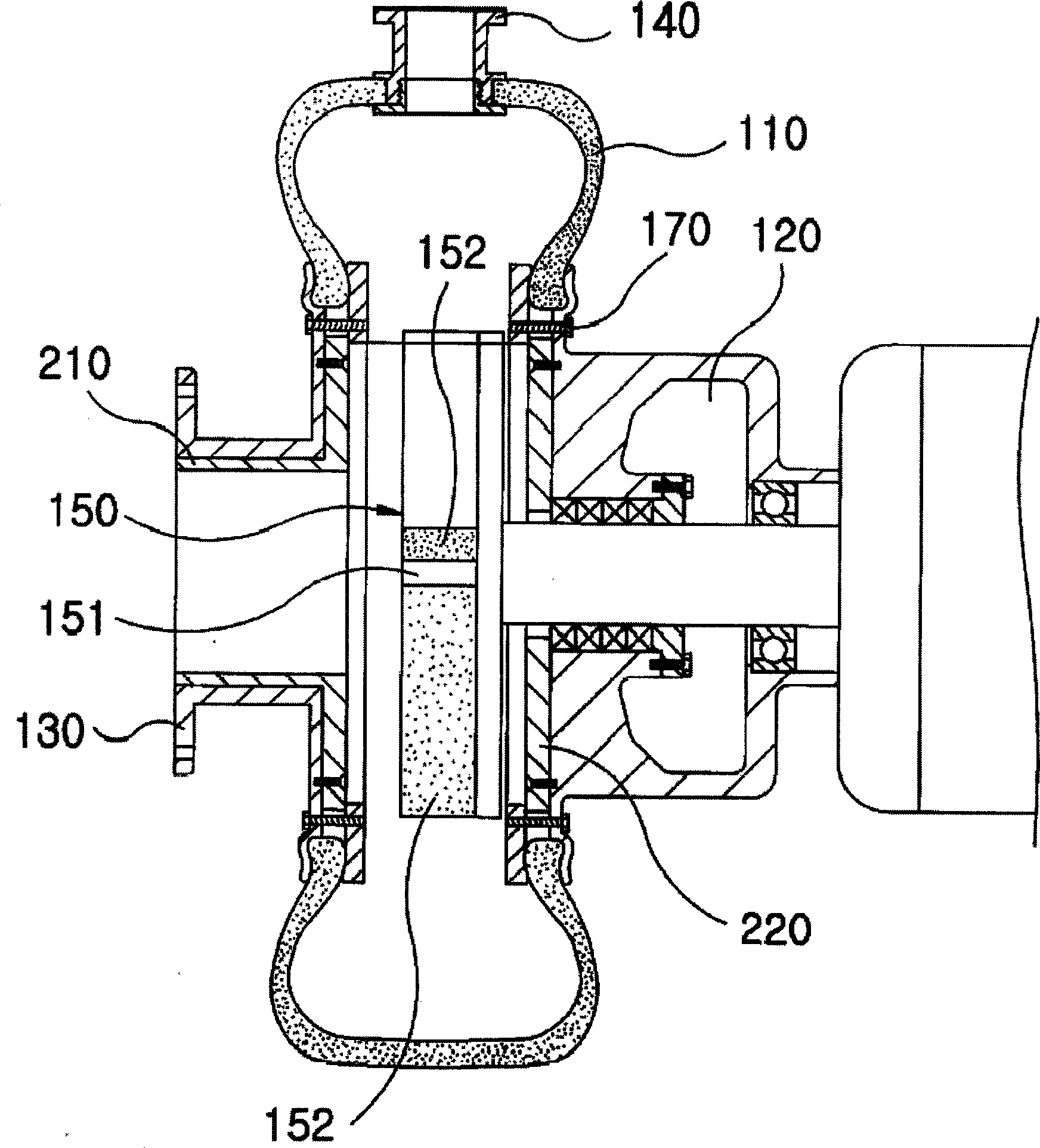

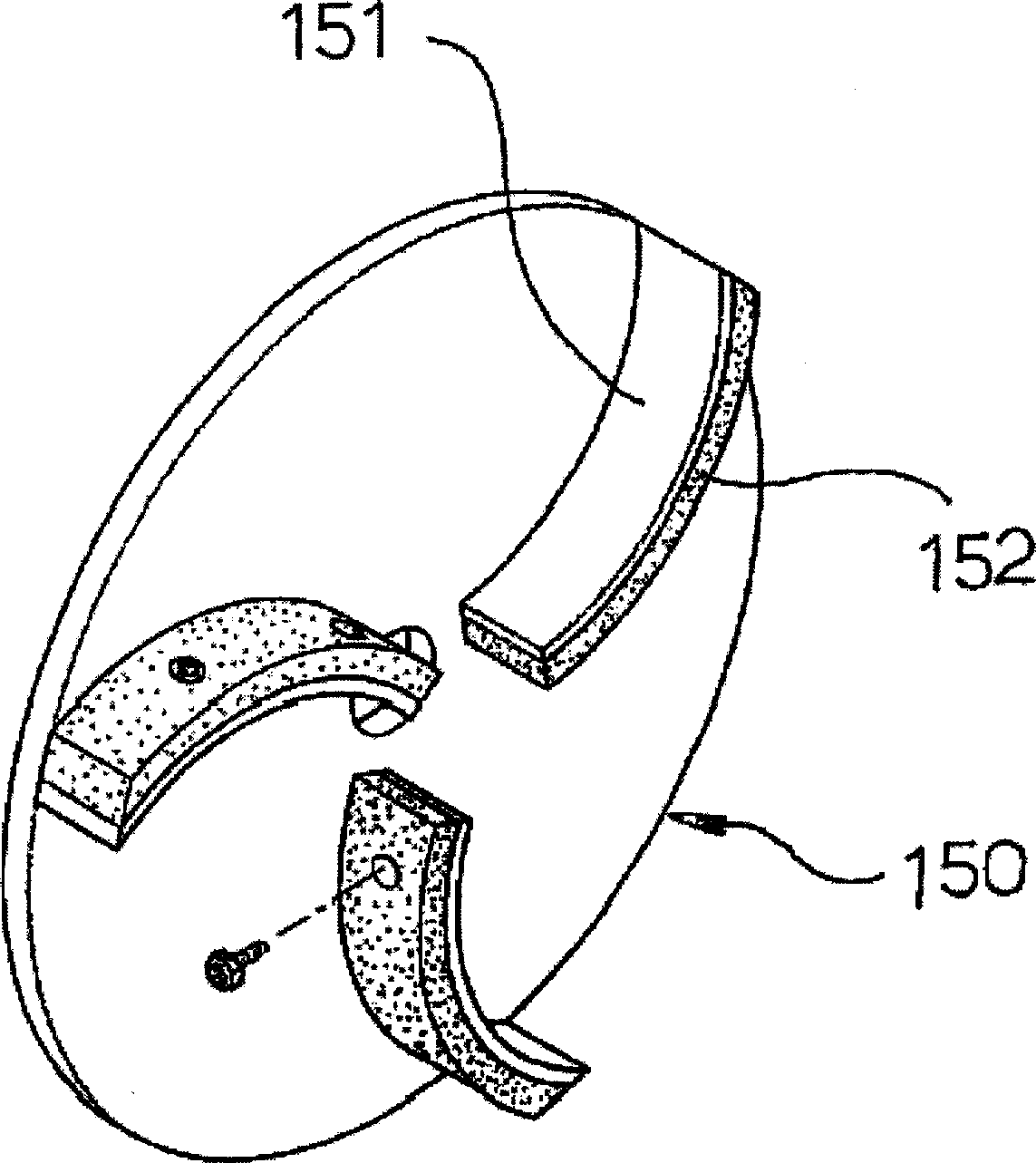

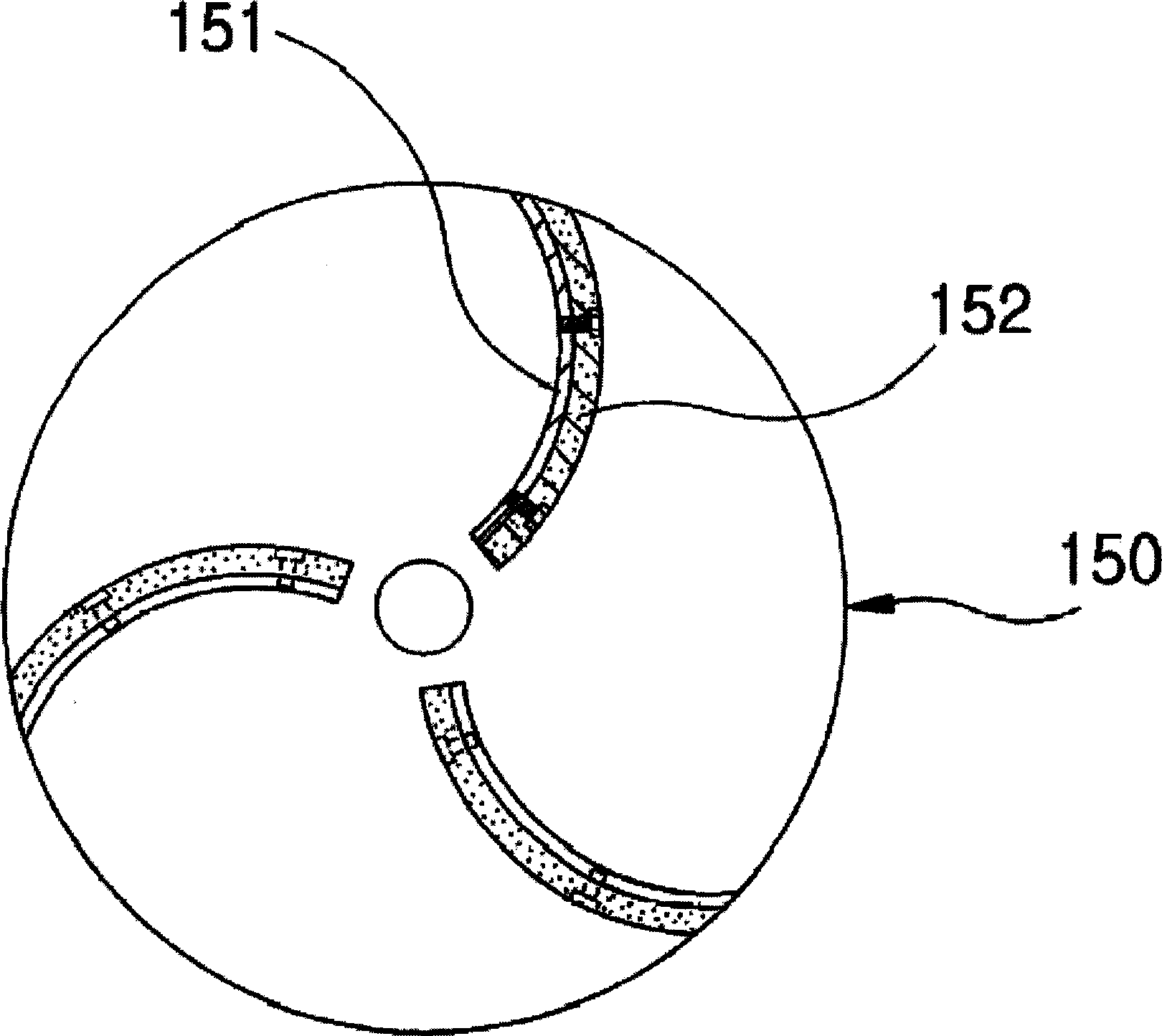

Pump using waste tire

InactiveCN1620555AEasy to manufactureReduce manufacturing costPump componentsRadial flow pumpsImpellerWaste tires

The invention discloses a pump made of waste tires, which has high wear resistance and corrosion resistance, is easy to manufacture and maintain, and can prevent water hammer and frost cracking. In the pump of the present invention, the casing main body (110) is made of scrap tires. The inlet unit (130) is installed at the first opening on one side of the waste tire, and the housing (120) is installed at the second opening on the other side of the waste tire, so that the impeller is installed inside the housing body (110) . An outlet unit (140) is installed at a predetermined portion of the waste tire so as to serve as an outlet of the housing body. Secondary blades (152) made of scrap tires are movably mounted on the main blades of the impeller.

Owner:李相荣

Combined air valve

InactiveCN106195381AStructural influenceEasy dischargeOperating means/releasing devices for valvesValve members for absorbing fluid energyMechanical engineering

The invention relates to the technical field of pipeline valves and particularly relates to a combined air valve comprising a valve body and a valve cover; an exhaust port is formed in the valve cover, and an upper floating body and a lower floating body which are overlaid up and down and of which the densities are smaller than the density of a fluid are arranged in a valve cavity of the valve body; a guide device is mounted on the valve cover; the upper floating body and the lower floating body can be arranged in the valve cavity in a way of vertically moving up and down through the limitation of the guide device, gas exhaust gaps are remained between the upper floating body and the inner wall of the valve body and between the lower floating body and the inner wall of the valve body, and an exhaust microchannel communicating with the exhaust port is formed in the upper floating body; the lower end of the exhaust microchannel is connected with the upper end surface of the lower floating body in a sealing way when the upper floating body and the lower floating body are connected together; and the lower end of the exhaust microchannel communicates with the gaps between the floating bodies and the inner wall of the valve body when the upper floating body and the lower floating body are disconnected. The combined air valve is simple in structure, convenient to mount, free of artificial unattendance, capable of rapidly and safely exhausting gases in a pipeline and prolonging the service life of a main structure of the pipeline and extremely high in popularization value.

Owner:WUHAN DAYU VALVE

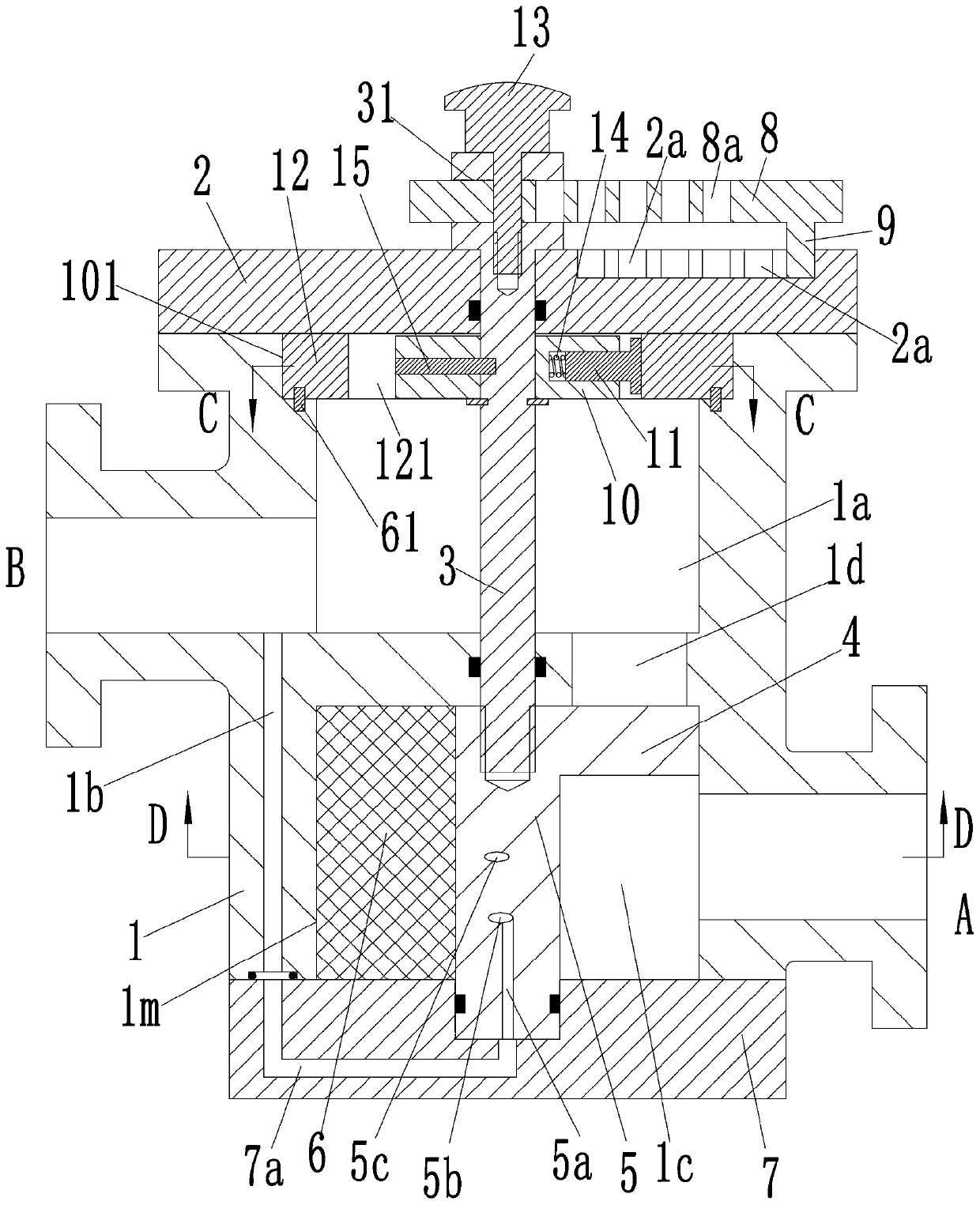

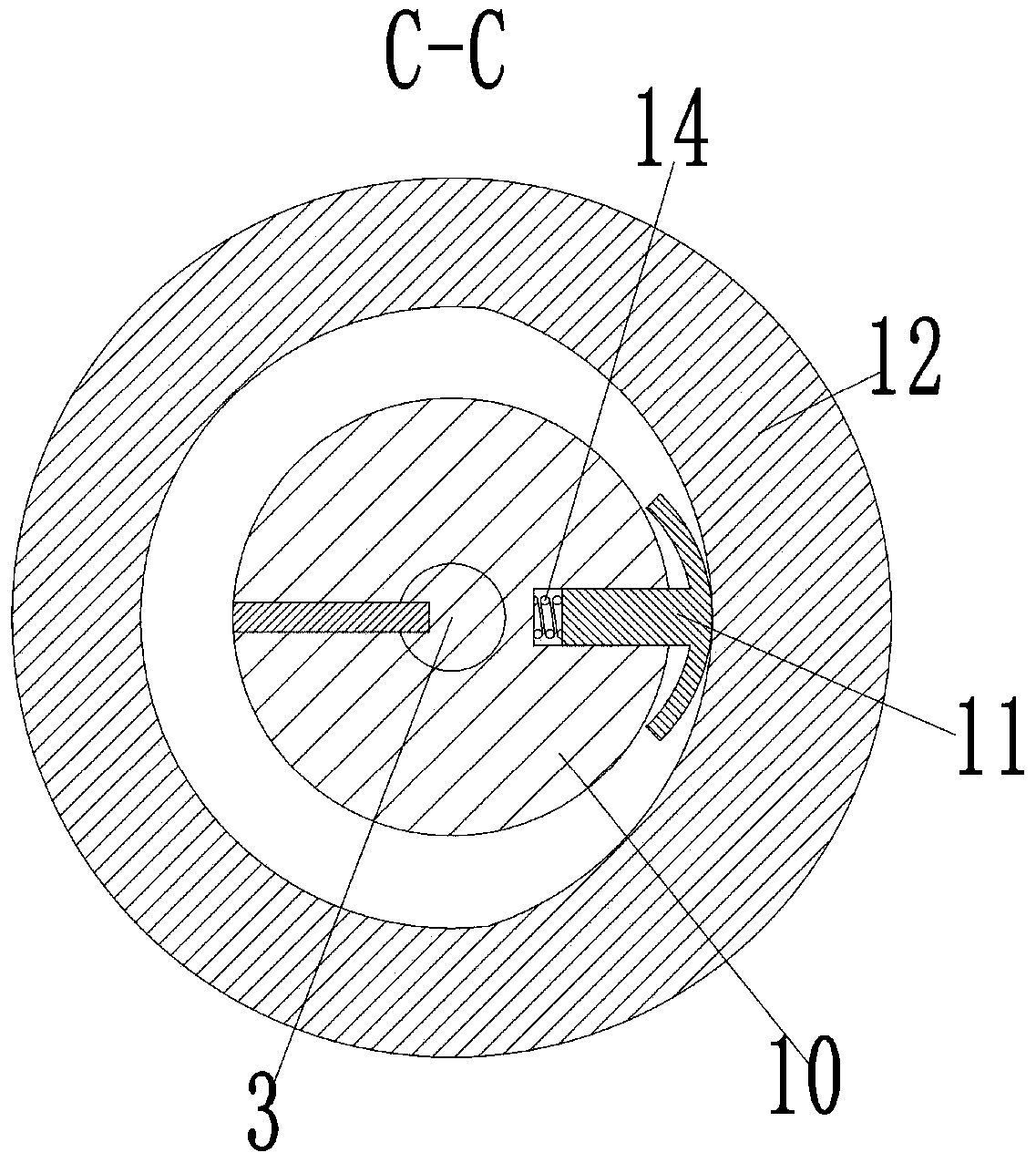

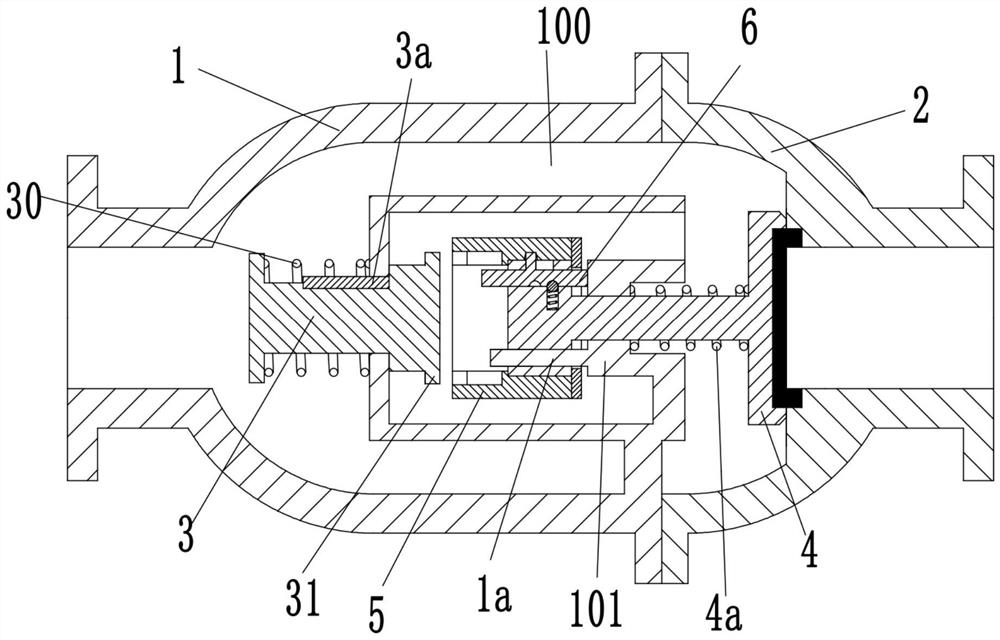

Check valve

ActiveCN111173968AWith flow control functionAvoid damageCheck valvesValve members for absorbing fluid energyEngineeringCheck valve

The invention discloses a check valve comprising a valve body. An upper valve cavity and a lower valve cavity are formed in the valve body. A valve opening used for making the upper valve cavity and the lower valve cavity communicate is formed in the valve body. A port B communicating with the upper valve cavity and a port A communicating with the lower valve cavity are formed in the side face ofthe valve body. An upper end cover is fixedly installed on the portion, at the position of an upper end opening of the upper valve cavity, of the valve body. A lower end cover is fixedly installed onthe portion, at the position of a lower end opening of the lower valve cavity, of the valve body. A rotating shaft is connected in the lower valve cavity in a rotating manner. The lower end cover is provided with a first baffle and a second baffle. The lower valve cavity is divided into a first sealed cavity and a second cavity, communicating with the port A, through the first baffle and the second baffle. A power plate extending into the first sealed cavity is arranged on the circumferential side face of the rotating shaft. A flow regulation assembly is arranged on the upper end cover. A buffer assembly is arranged in the upper valve cavity. The check valve is simple in structure, flow control can be conducted, and furthermore the valve opening can also be slowly closed.

Owner:ZHEJIANG OFILM PETROLEUM EQUIP CO LTD

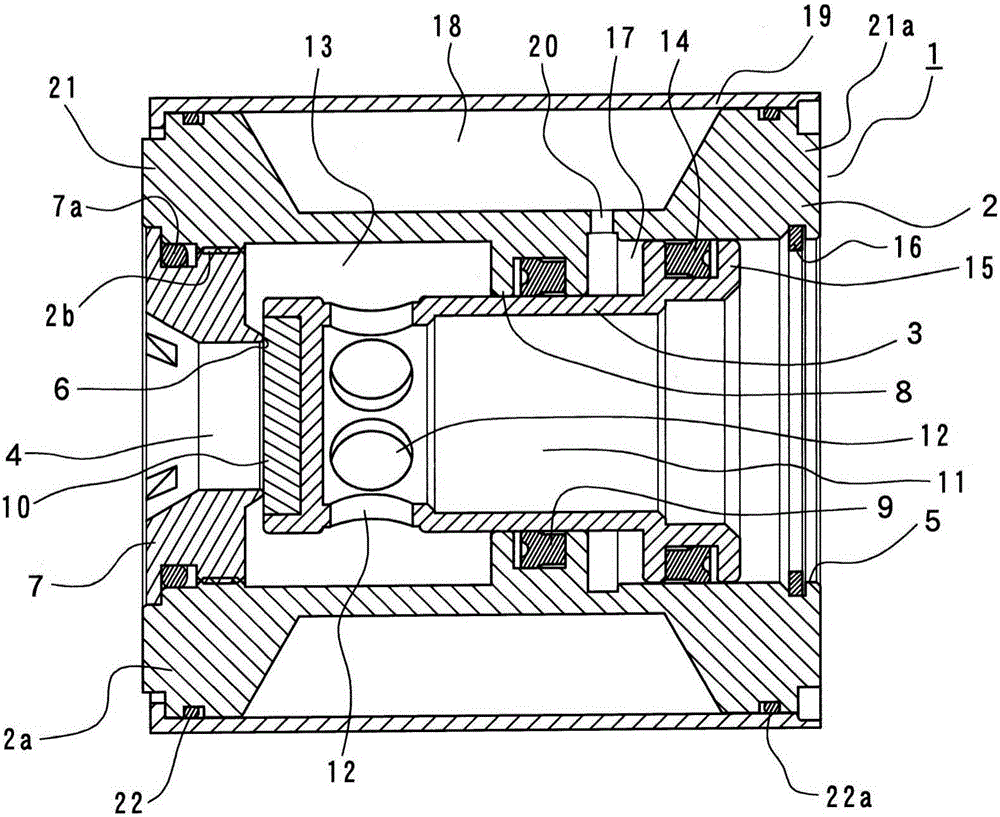

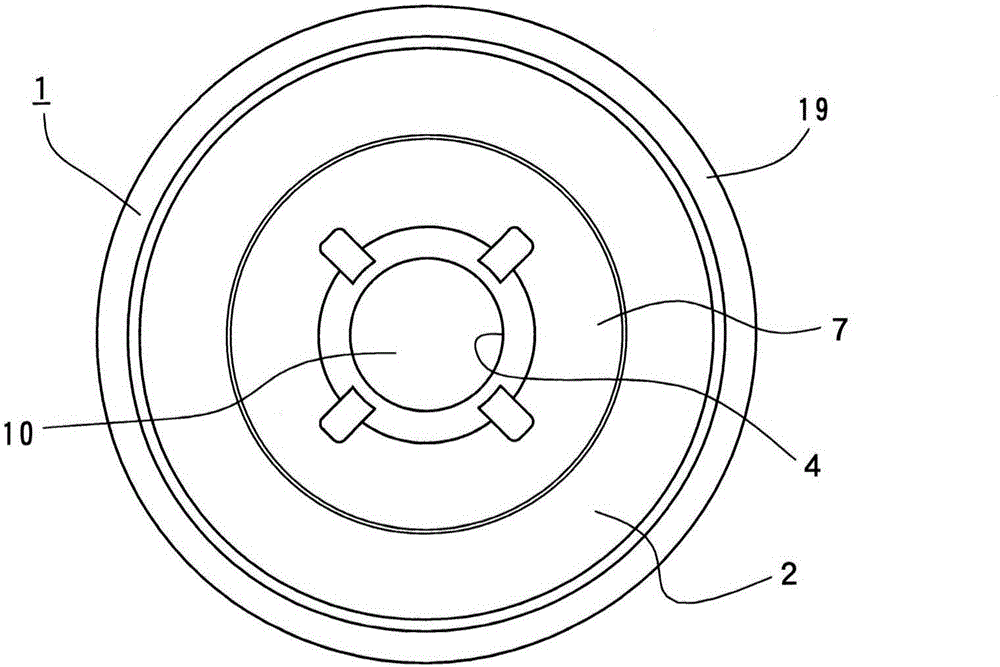

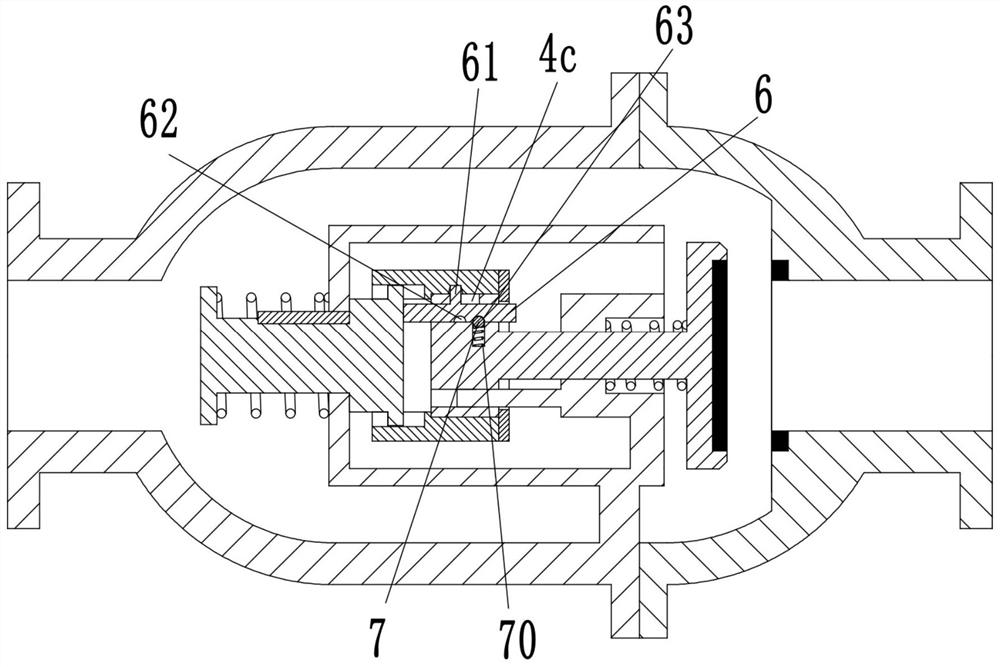

Sealing reversing valve and energy conversion device

ActiveCN111022700AWith pre-boost functionAvoid the quick tap problemValve members for absorbing fluid energyMultiple way valvesWater flowEngineering

The invention belongs to the field of energy conversion control, and relates to a sealing reversing valve which comprises a cylinder body, a reversing piston assembly and an executing mechanism. A pressure boosting hole is formed in the cylinder body, and a pressure relief groove is formed in the reversing piston assembly. According to the sealing reversing valve, the water pressure inside a waterpressure cylinder is boosted in advance through the pressure boosting hole, a low-pressure inlet check valve is slowly closed, and the problem of quick knocking of the low-pressure inlet check valveis solved, and the service life of the check valve is prolonged; high-pressure water flow in the water pressure cylinder is depressurized in advance through the pressure relief groove, water hammeringcaused when large-flow high-pressure concentrated water makes instant contact with low-pressure concentrated water is avoided, equipment vibration is avoided, and equipment operation noise is lowered. The invention further relates to an energy conversion device comprising the sealing reversing valve.

Owner:国能朗新明环保科技有限公司

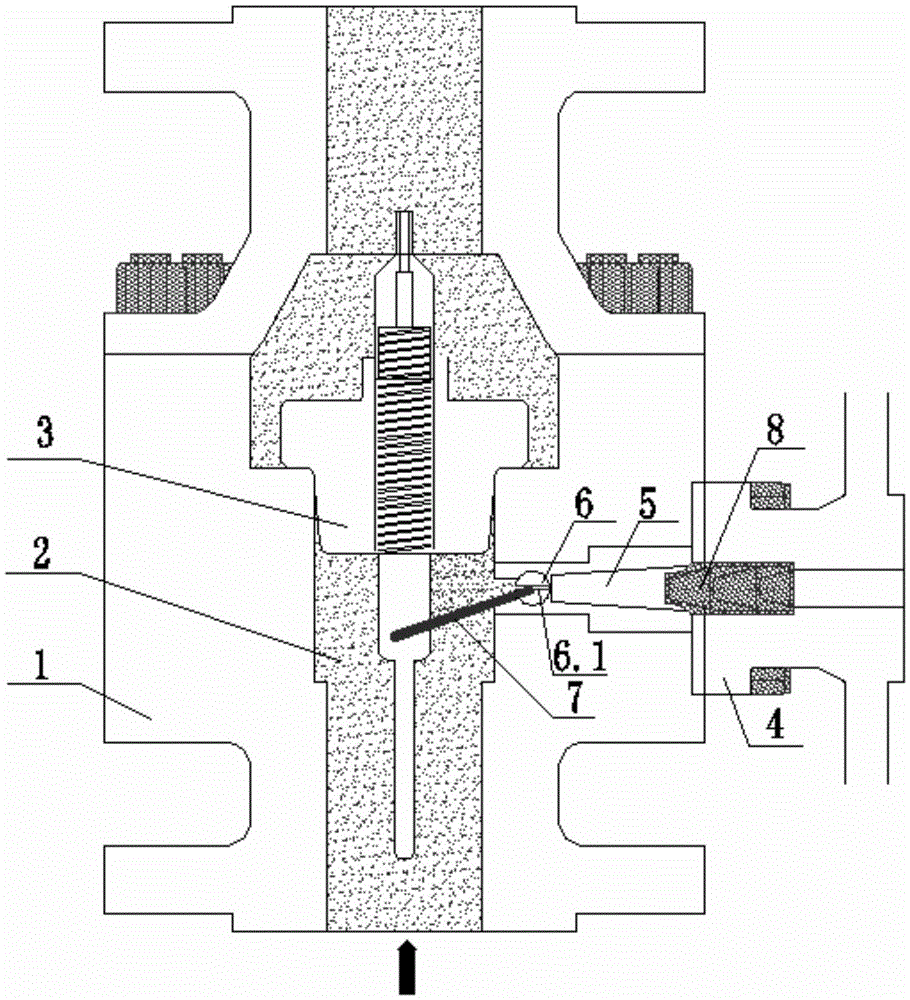

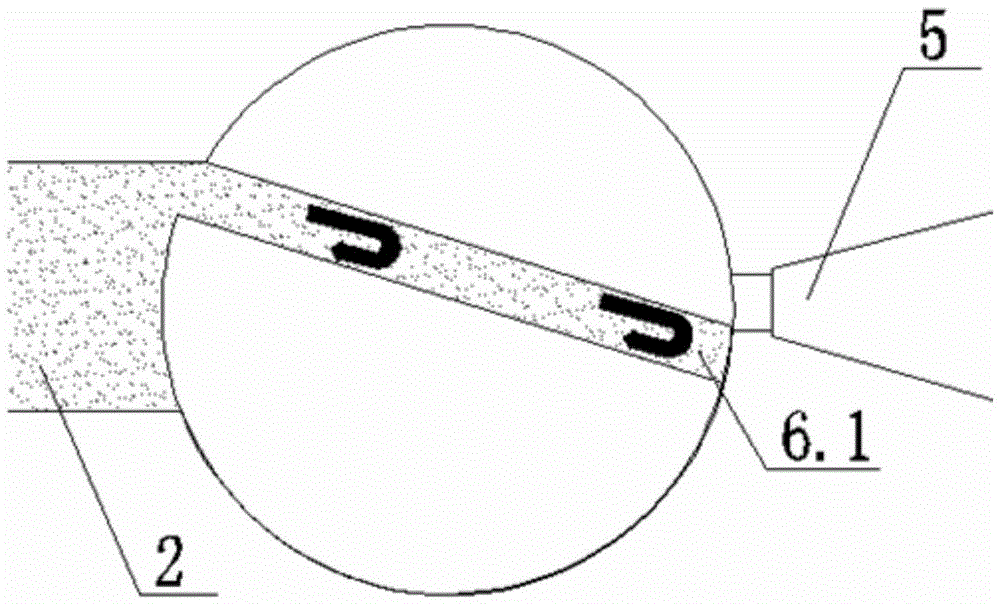

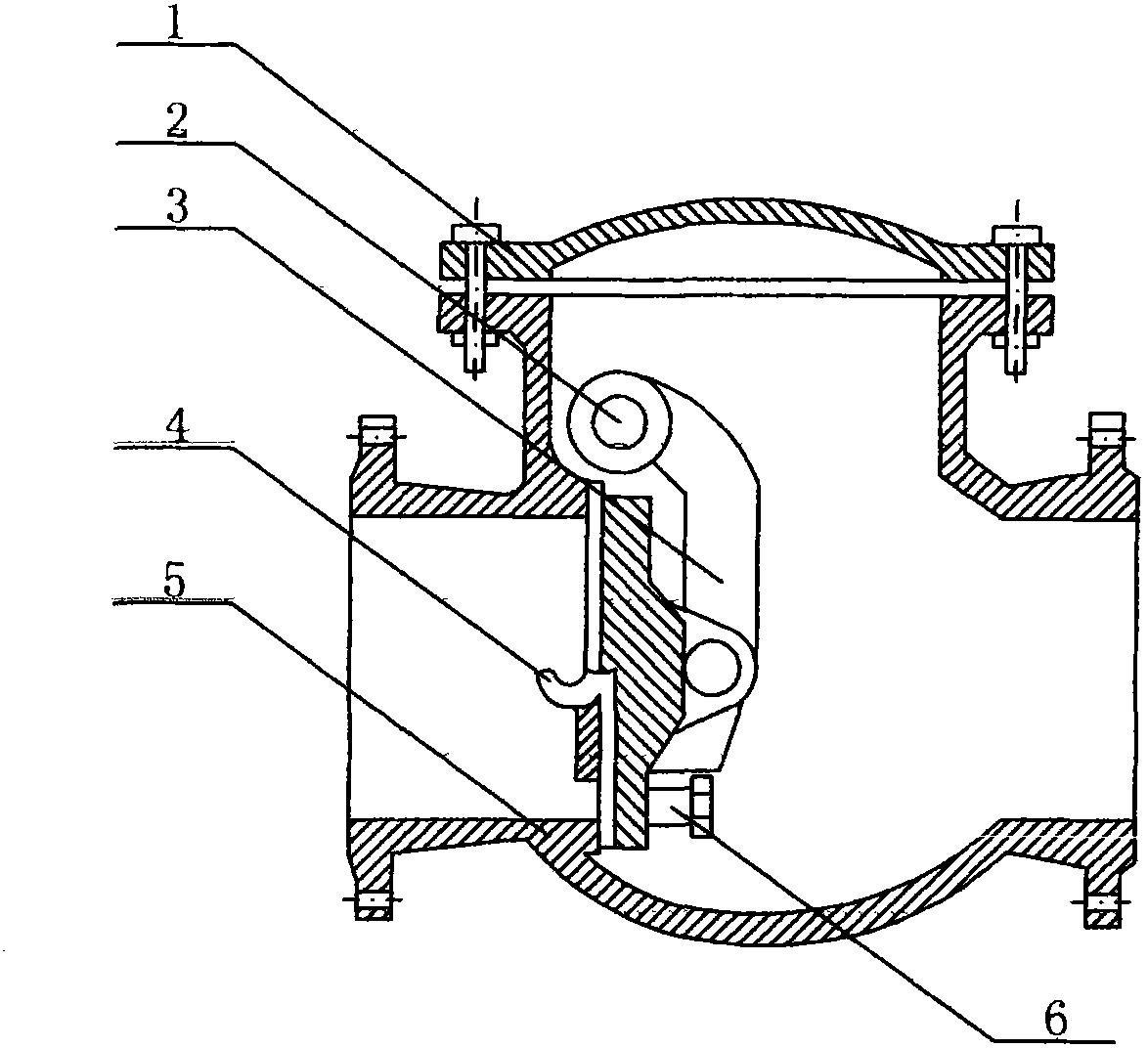

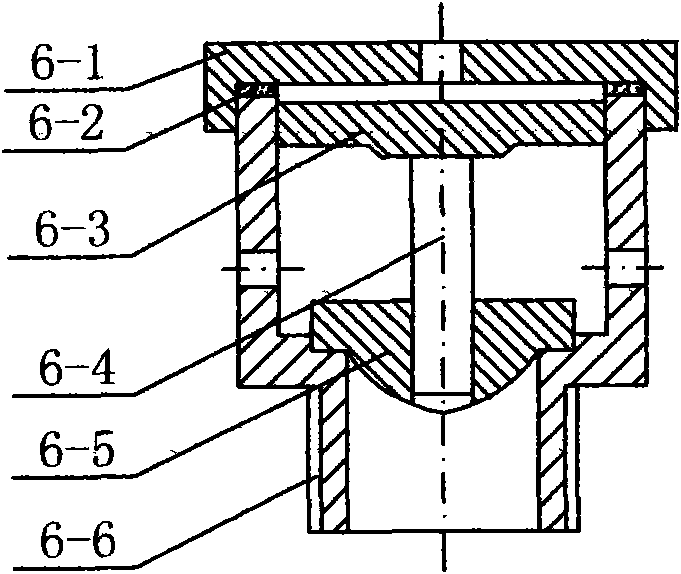

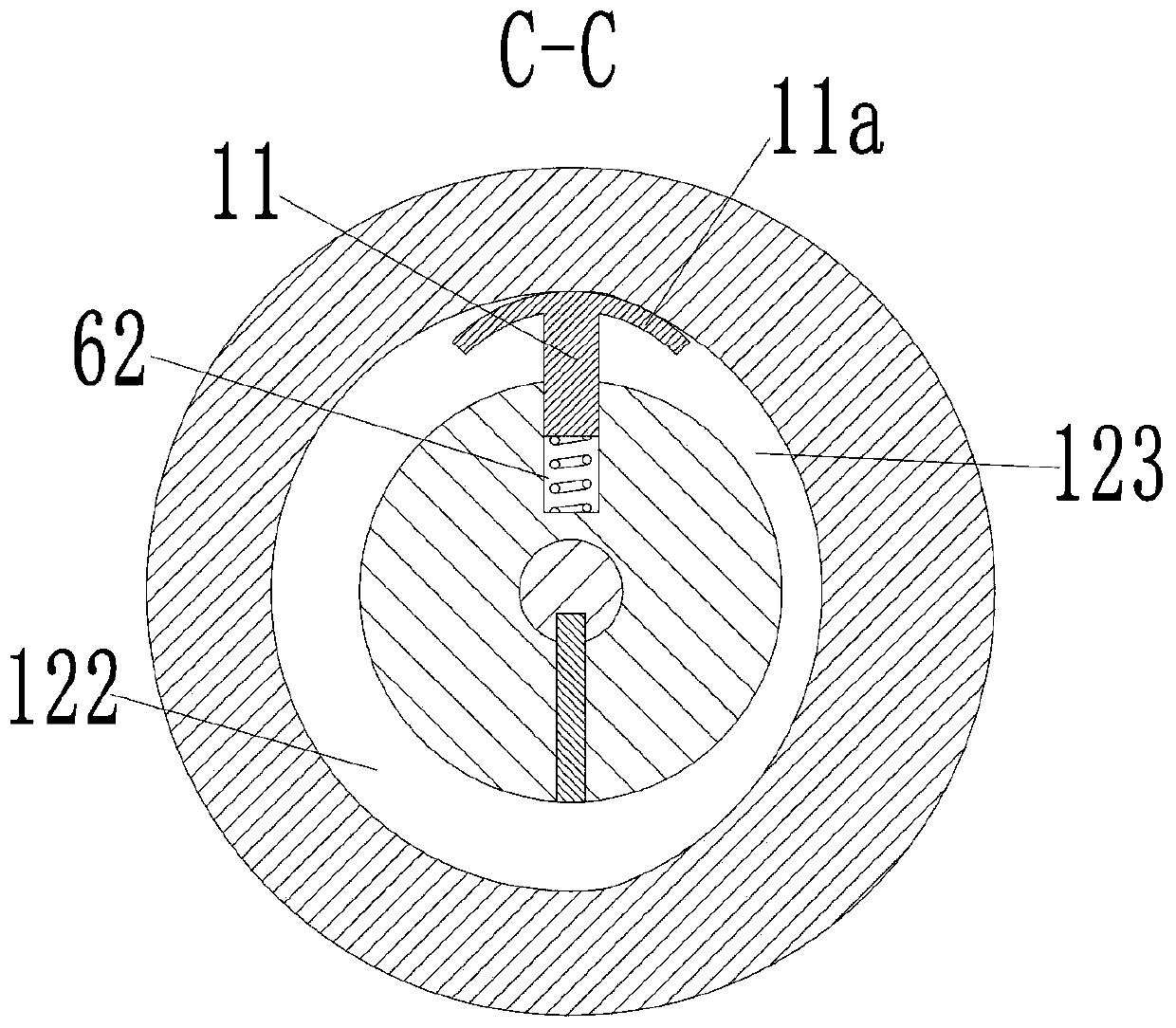

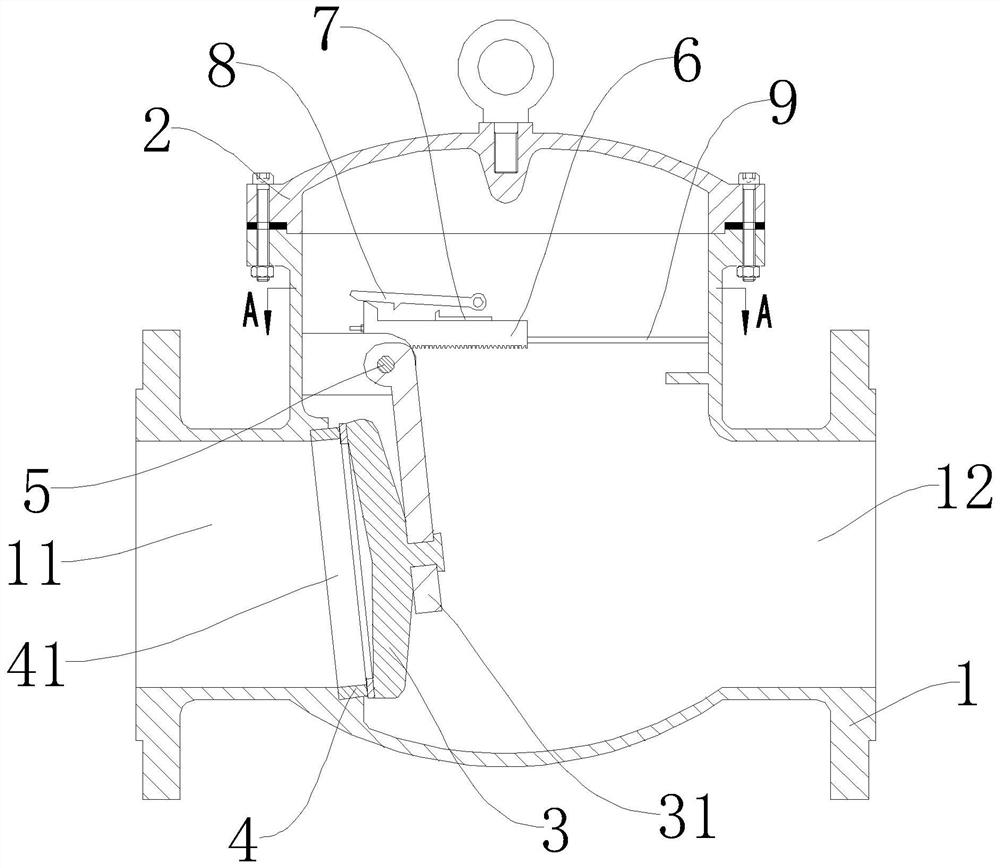

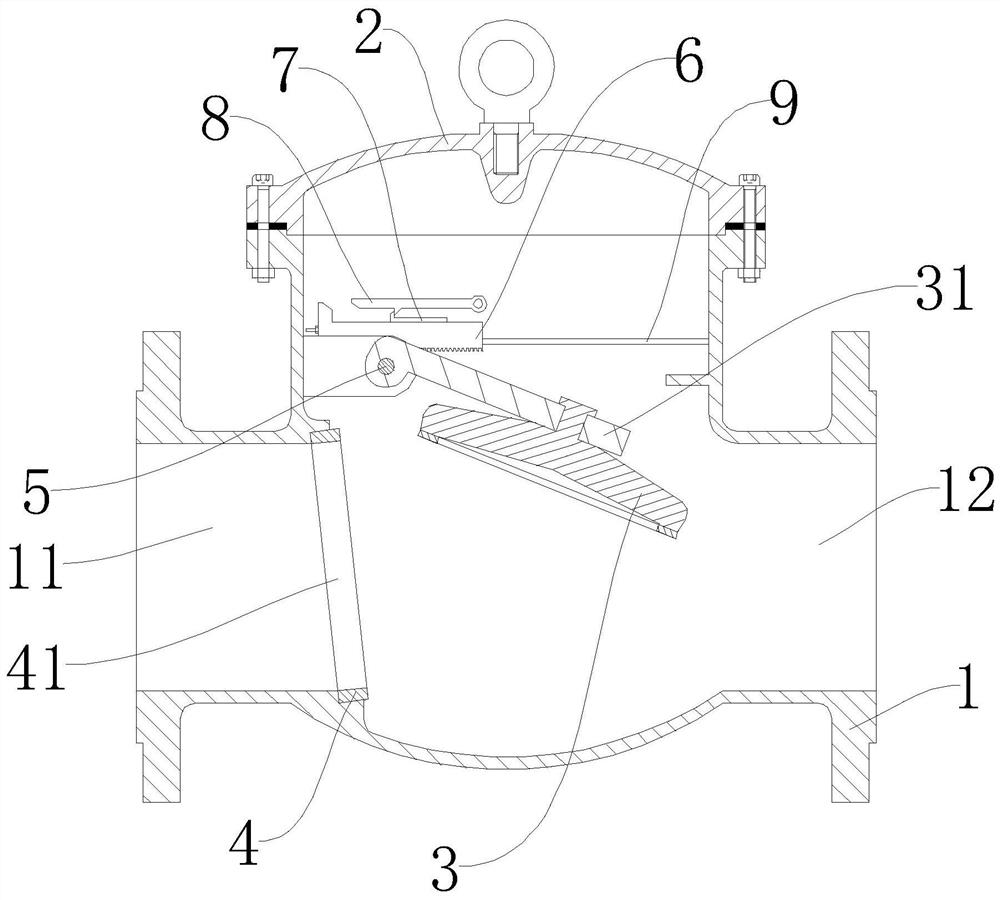

Rotary starting type check valve of water hammer prevention mechanism for pipelines

InactiveCN105135005AReduce impact forceExtended service lifeCheck valvesValve members for absorbing fluid energyCheck valveWater hammer

The invention relates to a rotary starting type check valve of a water hammer prevention mechanism for pipelines. The rotary starting type check valve comprises a valve body, wherein a valve part and a valve base are mounted in the valve body; the valve part is mounted in the valve body through a swing arm and a lifting plate; the lifting plate is n-shaped, and is mounted in the valve body through a support plate; the support plate is transversely placed in an inner cavity of the valve body, and is fixedly connected with the inner side wall of the valve body; the swing arm is arranged at the lower end of the lifting plate, and is fixed on the lifting plate through a pin shaft; the lower end of the swing arm is fixedly connected with the valve part; and the pin shaft is coated with a compression spring. The rotary starting type check valve has the following advantages: as the internal compression spring is added, preopening force is provided to the valve part when a medium normally flows, the valve is quickly opened, and the flow resistance is reduced; and when the medium flows back, slow closing force is provided to the valve part at the moment of closing the valve part, so that the closing speed is slowed down, the collision force of the valve part to a sealing surface is reduced, the water hammer phenomenon can be effectively prevented, the safe operation of the pipelines is guaranteed, and the service life of the pipelines is prolonged.

Owner:NANTONG POWER STATION VALVE

Axial-flow type check valve

ActiveCN112161090AAct as a resistance bufferExtended service lifeCheck valvesValve members for absorbing fluid energyStructural engineeringCheck valve

The invention discloses an axial-flow type check valve. The axial-flow type check valve comprises a valve body. A valve cavity is formed in the valve body. A valve deck is fixedly installed at the position, on an opening in the right end of the valve cavity, of the valve body. An outlet pipe communicating with the valve cavity is arranged on the left side of the valve body, and an inlet pipe communicating with the valve cavity is arranged in the valve deck. A valve element cylinder with an opening in the right end is arranged on the inner side wall of the valve cavity, a mounting block is arranged on the inner side wall of the valve element cylinder, a valve rod is connected in the mounting block in a sliding manner, and a valve element block used for controlling on-off of the inlet pipe is arranged at the right end of the valve rod. A protruding block is arranged at the left end of the valve rod, and a rotation stopping rod stretching into the protruding block is arranged on the leftside of the mounting block. The valve rod is sleeved with a first spring between the mounting block and the valve element block, and the first spring is used for forcing the valve element block to press the inlet pipe. A buffer assembly is arranged at the left end of the valve element cylinder, and a locking assembly is arranged on the protruding block. The check valve is simple in structure and can be slowly closed, and the water hammer phenomenon is prevented.

Owner:邯郸市宏晨金属制品有限公司

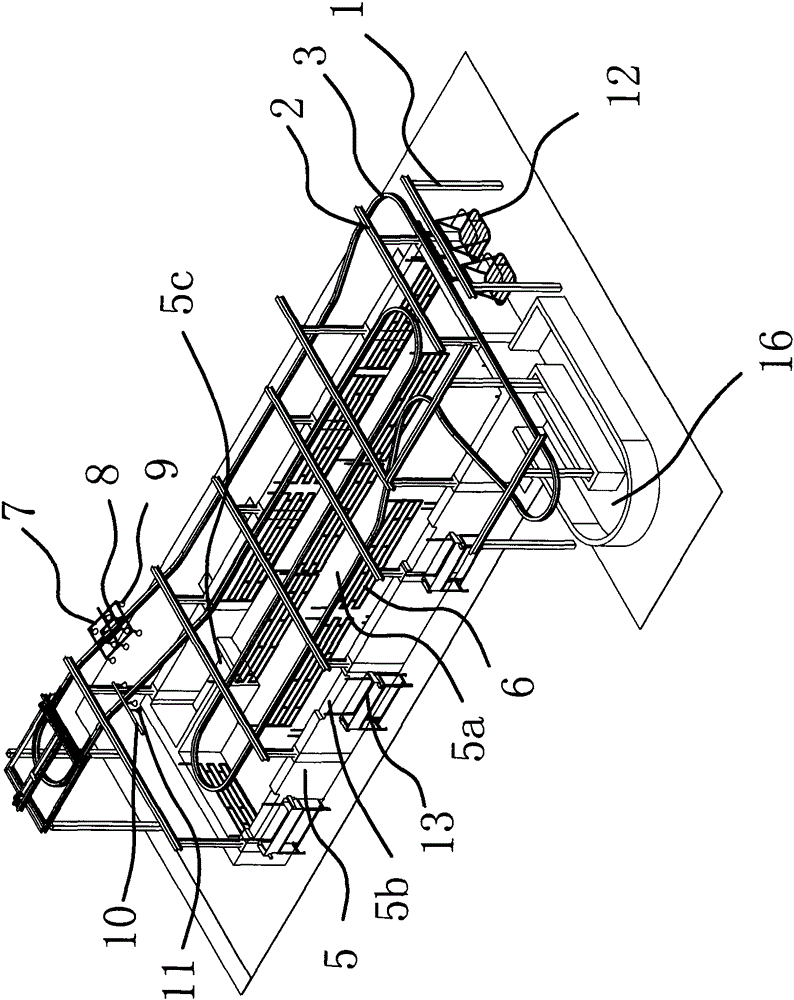

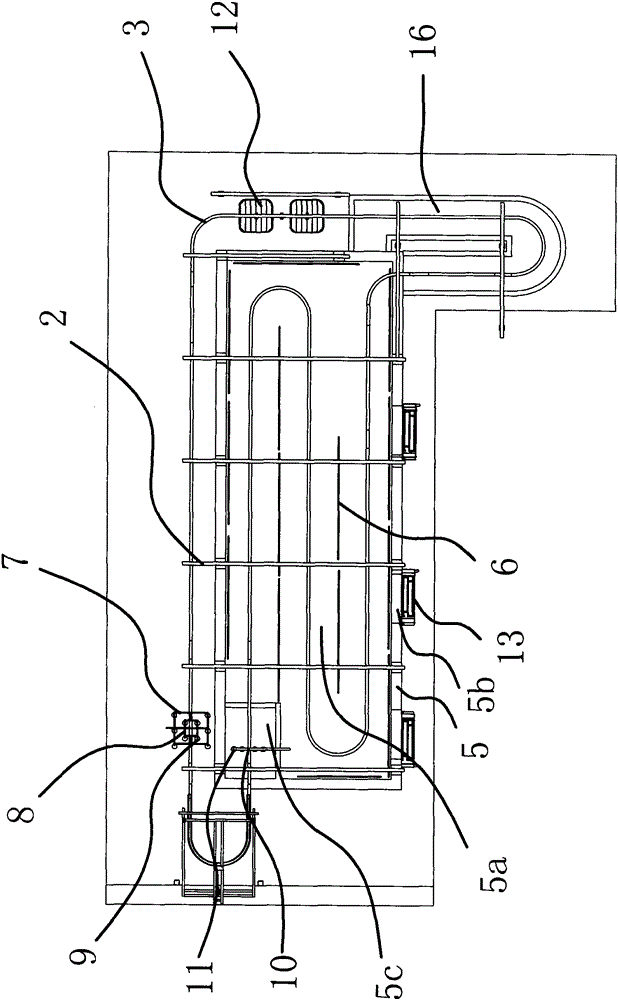

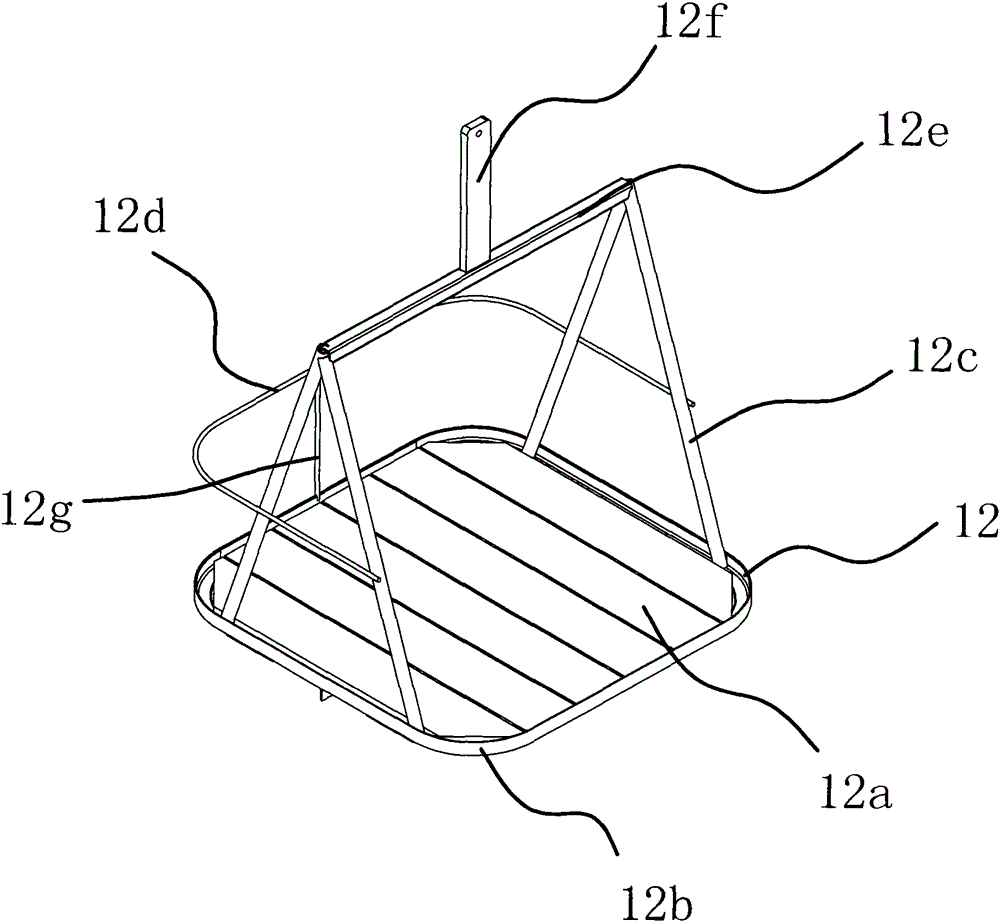

Lost Wax Line

InactiveCN102909318BAvoid problems with impuritiesAvoid enteringFoundry mouldsFoundry coresFoundryWax

The invention provides a dewaxing assembly line, belongs to the technical field of foundry machinery, and solves the problems that impurities are mixed into wax recovered by the existing dewaxing assembly line formwork when the wax is molten, and grains of sand are attached inside the formwork. The dewaxing assembly line comprises a frame and a pool; a chain track is fixed on the frame and a hanging box moving along the chain track is arranged on the chain track; a cold water shower device and a hot water shower device are arranged on the frame; the cold water shower device is arranged at the outer side part of the pool; the hot water shower device is arranged above the inlet end of the pool; the cold water shower device, the hot water shower device and the pool are orderly arranged clockwise or anticlockwise; the hanging box can be driven to pass through the cold water shower device, the hot water shower device and the pool through the chain track; a plurality of heating sheets connected with a hot steam source are vertically arranged inside the pool, and the heating sheets partition the pool into a plurality of S-shaped channels connected in series. The dewaxing assembly line is simple in structure, good in wax melting effect, high in work efficiency and high in yield of the formwork.

Owner:宁波创二代机械科技有限公司

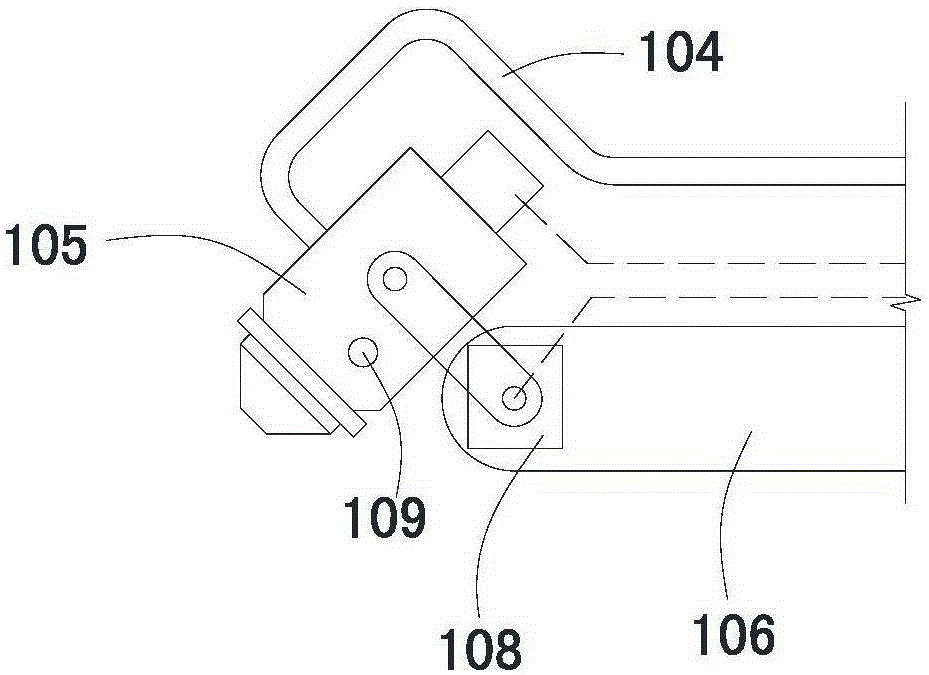

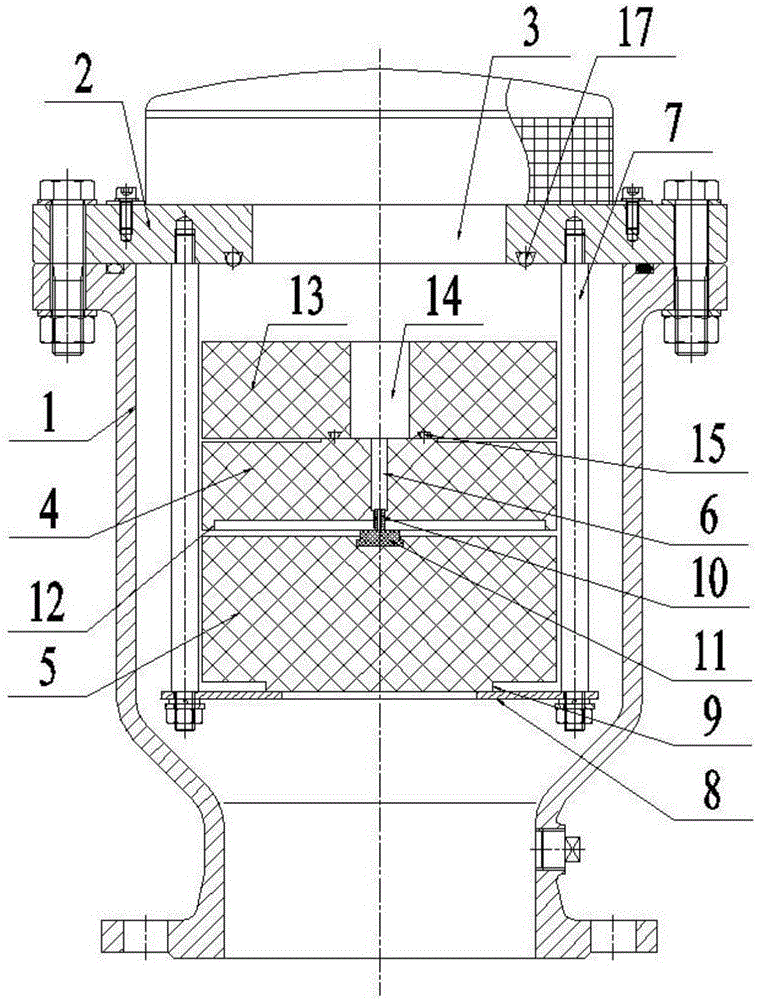

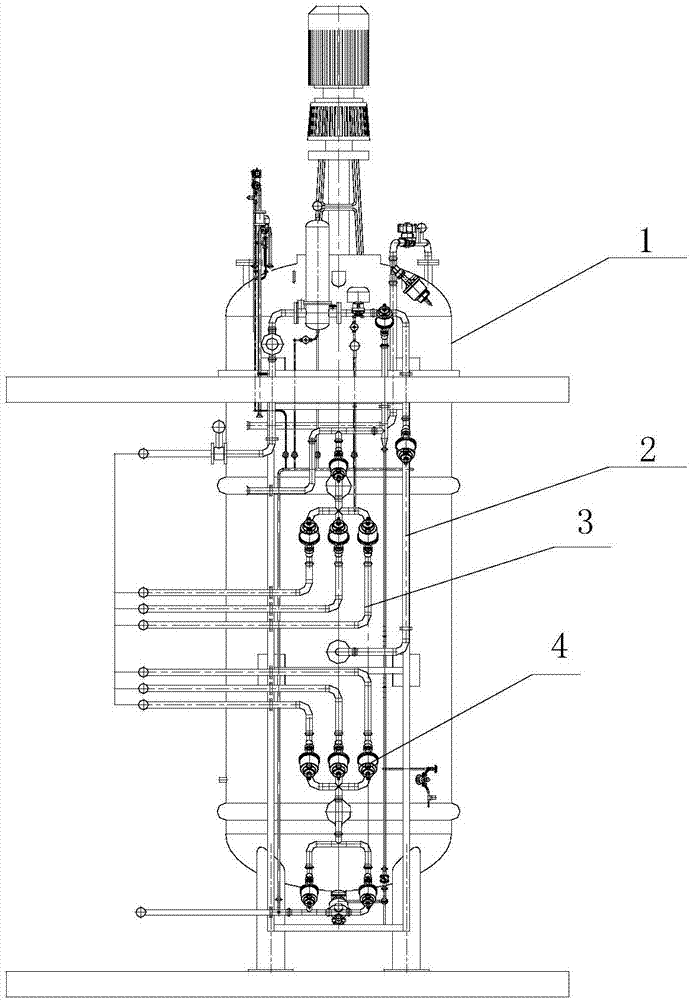

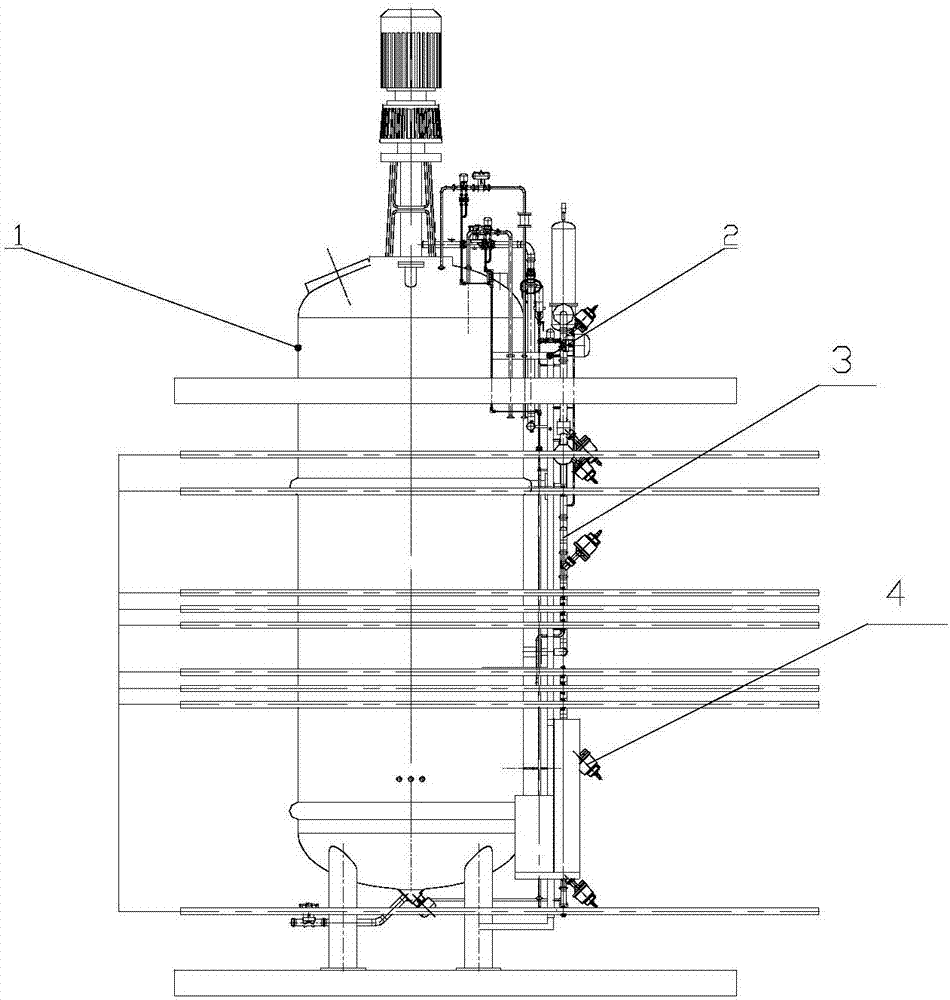

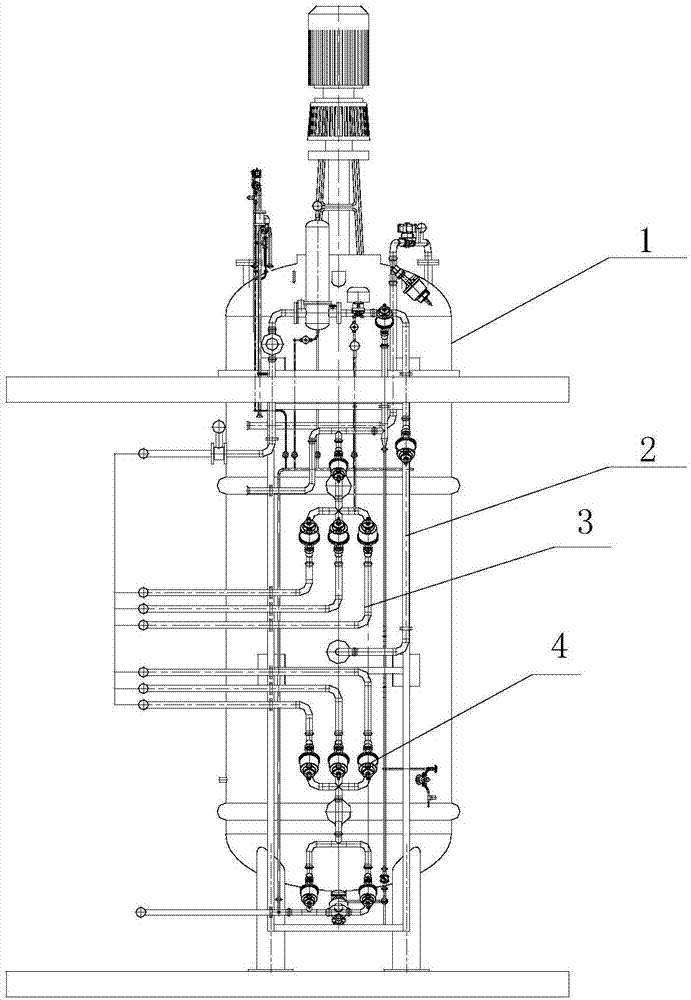

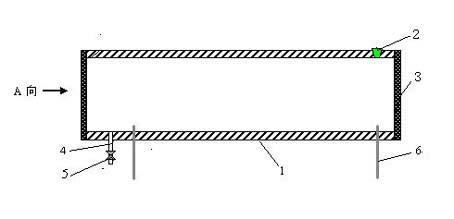

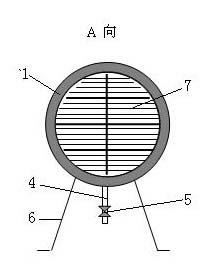

Large vertical fermentation tank with integrated pipe layout and pipe layout method thereof

ActiveCN108004120ASimple and reasonableReduced installation effortBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringControl valves

The invention provides a large vertical fermentation tank with integrated pipe layout. The fermentation tank comprises a vertical tank body, wherein a vertical pipe frame is arranged on one side of the vertical tank body; a mounting space is formed between the vertical pipe frame and the vertical tank body; corresponding process pipelines connected with various interfaces of the vertical tank bodyare fixed on the vertical pipe frame; a corresponding control valve is mounted on each of the process pipes. In the fermentation tank, the layout of the pipes connected to the fermentation tank is simple and reasonable; the large fermentation tank can be manufactured, transported and mounted more conveniently, so that the delivery period of a client is shortened; cooling water in jackets (row pipes) can be conveniently ensured to be exhausted; the production efficiency of the large vertical fermentation tank can be improved, and the cost of equipment investment of the client is lowered.

Owner:ZHENJIANG FENGZE BIOTECH EQUIP MFG

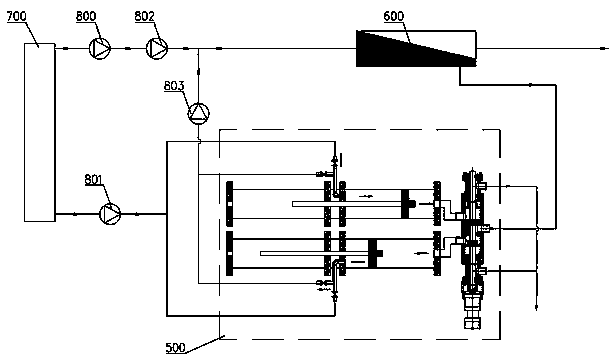

Energy conversion system for desulfurization wastewater zero discharge

ActiveCN111039358AReduce headReduce construction costsGeneral water supply conservationSpecific water treatment objectivesReverse osmosisPiston Guide

The invention belongs to the technical field of desulfurization wastewater treatment, and specifically relates to an energy conversion system for desulfurization wastewater zero discharge. The systemcomprises a raw water supply device, an energy conversion device, a reverse osmosis device, a pump and the like, wherein the energy conversion device comprises a water pressure cylinder, a check valveset and a sealing reversing valve, the water pressure cylinder comprises a water pressure cylinder body, a water pressure cylinder piston and a water pressure cylinder piston guide rod, the water pressure cylinder piston is arranged in the water pressure cylinder body and can reciprocate, the water pressure cylinder piston guide rod can act along with the water pressure cylinder piston, the contact area between the water pressure cylinder piston and high-pressure raw water is smaller than the contact area between the water pressure cylinder piston and high-pressure concentrated water, a waterpressure cylinder piston boss is arranged on the end surface, facing the opening of the water pressure cylinder end cover, of the water pressure cylinder piston, and part or all of the water pressurecylinder piston boss can enter the opening of the water pressure cylinder end cover, so that the impact force between the water pressure cylinder piston and the water pressure cylinder end cover whenthe water pressure cylinder piston is out of control in operation can be reduced so as to effectively protect the water pressure cylinder piston.

Owner:国能朗新明环保科技有限公司

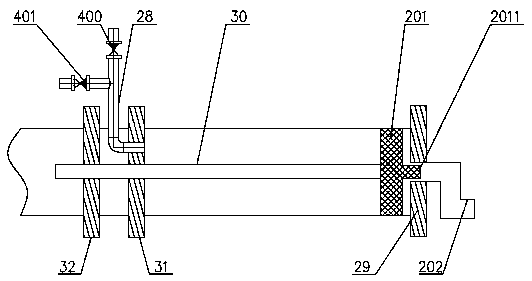

Exhaust butterfly valve

PendingCN110645361APrevent water hammerAvoid damageOperating means/releasing devices for valvesLift valveRubber ringEngineering

The invention discloses an exhaust butterfly valve. The exhaust butterfly valve comprises a valve body and a water-sealing valve arranged in the valve body. A sealing rubber ring is connected to the water-sealing valve. A valve handle, a first fixing plate and a second fixing plate are connected above the valve body, wherein the valve handle is fixed by the first fixing plate and the second fixingplate. An exhaust handle is embedded in the valve handle. The valve handle is connected with the water-sealing valve through a hollow pipe. Rotation of the water-sealing valve is controlled through rotating the valve handle, and thus the purpose of controlling the water route can be achieved. The exhaust handle is connected with an exhaust pipe. The exhaust pipe is nested in the hollow pipe. Theexhaust pipe can rotate in the hollow pipe. An external exhaust hole and an internal exhaust hole which are matched with each other are formed respectively in the portions, close to the top of the inner wall of the valve body, in the pipe walls of the hollow pipe and the exhaust pipe. An exhaust port communicating with the internal cavity of the exhaust pipe is formed in the top of the exhaust handle. The exhaust butterfly valve has the following advantages that the phenomenon of water hammer can be effectively prevented from occurring in a pipeline, and damage to the pipeline and the valve isprevented; and the cost is lowered, and there is no need for installing other exhaust devices additionally.

Owner:大禹节水(天津)有限公司

Surface cooler

PendingCN111306961AAvoid damageImprove work efficiencySafety devices for heat exchange apparatusStationary conduit assembliesWater flowOutfall

The invention discloses a surface cooler which comprises a water inlet pipe, a water outlet pipe and a heat exchange pipe. A water inlet is formed in the water inlet pipe, a water outlet is formed inthe water outlet pipe, and the two ends of the heat exchange pipe communicate with the water inlet pipe and the water outlet pipe correspondingly so thatwater flow can enter from the water inlet and passes through the water inlet pipe, the heat exchange pipe and the water outlet pipe sequentially, and the water flow is discharged from the water outlet; and exhaust ports are formed in the water inlet pipe and the water outlet pipe correspondingly, and a flow-guiding structure is arranged on the water inlet pipe and used for enabling the water flow to be in a turbulent state, so that bubbles inthe water flow are separated from water and discharged from the exhaust ports. By means of the surface cooler, the water flow can be controlled, bubbles in the water are quickly separated from the water flow to be discharged, the water hammer phenomenon is avoided, the heat exchange effect is improved, and the surface cooler is advantageously prevented from being damaged.

Owner:PANYU BRANCH GUANGZHOU JETEX LLOYDS MACHINERY

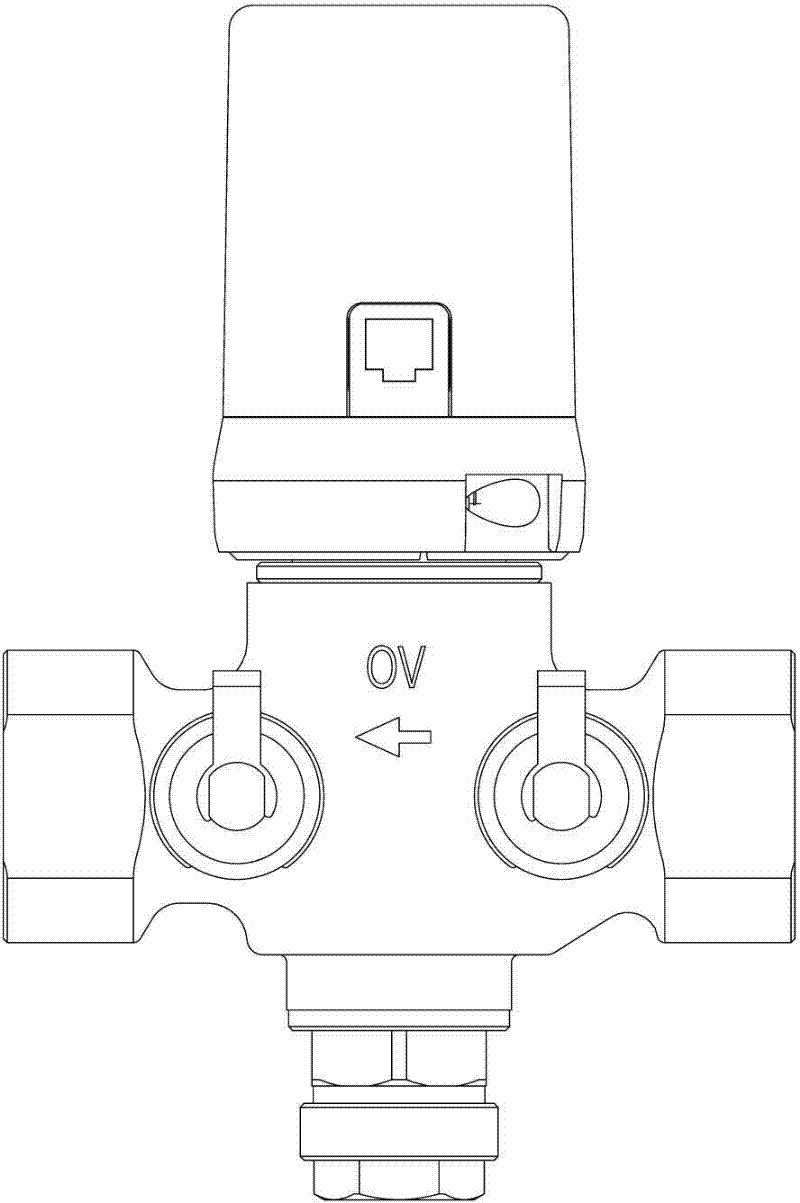

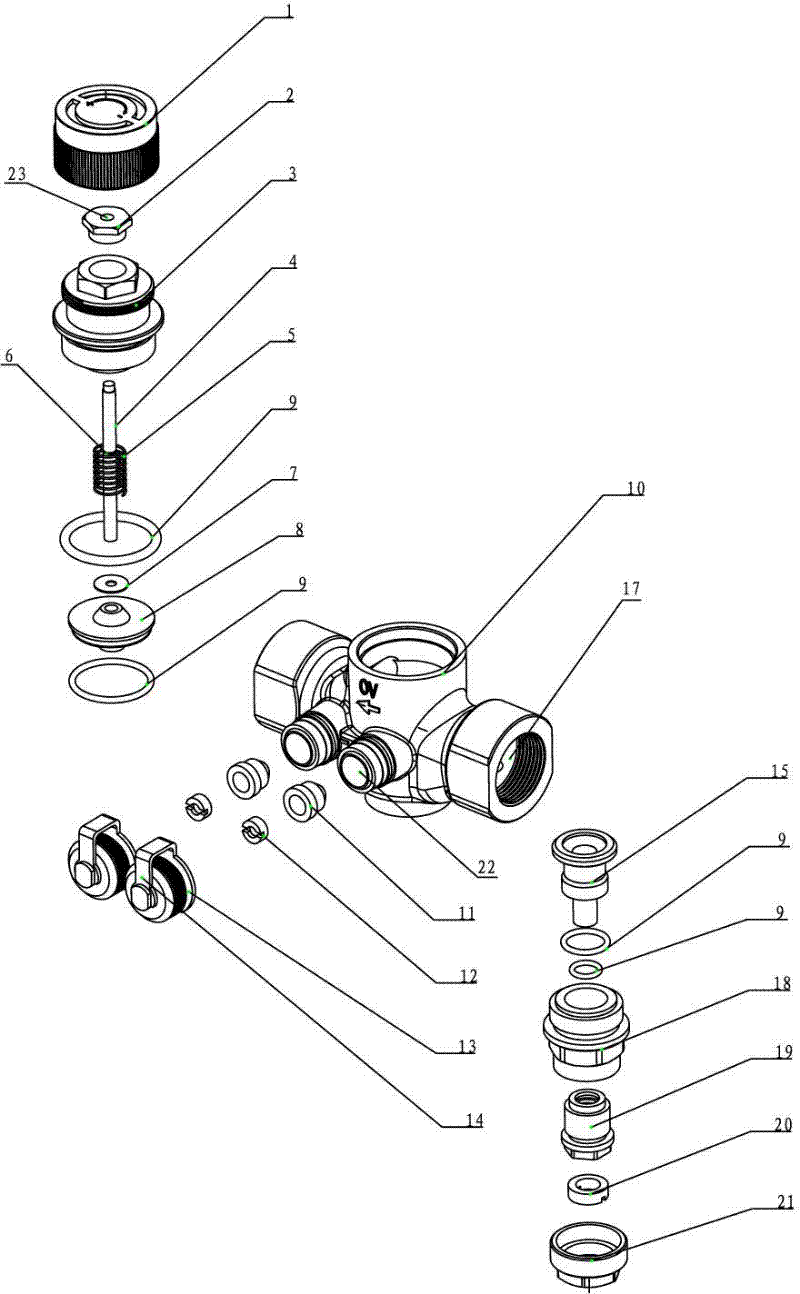

Static balance type dual-source type time on/off area heat metering system and method

InactiveCN102331316AIdeal heating temperatureEnsure balanceOperating means/releasing devices for valvesApparatus for hiring articlesElectrothermal actuatorHeating temperature

The invention relates to a static balance type dual-source type time on / off area heat metering system and method. The system comprises a client and a management end, wherein the client comprises a static balance on / off control valve arranged on a heat supply pipeline, an electric heating executor for controlling the static balance on / off control valve to open and close, an IC (Integrated Circuit)card type heat metering temperature controller and a user charging IC card, wherein the IC card type heat metering temperature controller is connected with the electric heating executor and is used for realizing temperature control; the user charging IC card is used for charging the IC card type heat metering temperature controller; and the management end comprises a charger and a computer. According to the static balance type dual-source type time on / off area heat metering system and method disclosed by the invention, on the basis of ensuring the static hydraulic balance, the hot water flow of each user is adjusted in advance according to the heat load of the user at the tail end so as to ensure that each user can acquire ideal heating temperature. The heat user prepays in a heat supply unit for purchasing the heating time; and the heat is generated by consuming the heating time.

Owner:OVENTROP VALVES & SYST BEIJING

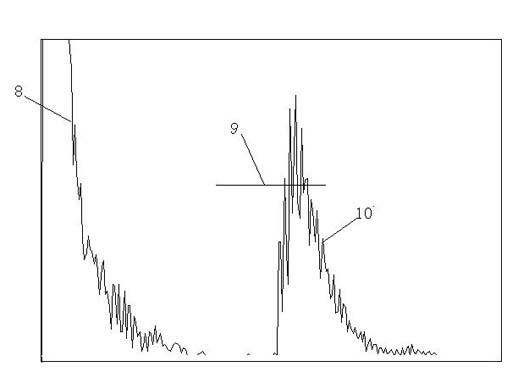

Water-hammer-preventing ultrasonic water level detection method

ActiveCN102680055AHigh sensitivityImprove detection accuracyMachines/enginesLevel indicatorsReflected wavesWater level

The invention relates to a water-hammer-preventing ultrasonic water level detection method, comprising the following steps of: (1) selecting an A type pulse reflection type ultrasonic flaw detector with a work frequency range of 0.5 MHz-10 MHz; (2) selecting a probe; (3) selecting a straight pipe which is the same as a detected pipe in specification and material as a comparing test block; (4) adjusting the detection sensitivity of the ultrasonic flaw detector; (5) determining a part to be detected of a pipeline; polishing until a metal luster can be observed and coating a coupling agent; (6) placing the probe on the part to be detected of the pipeline and starting an instrument to detect; (7) comparing a wave outputting position with a detection reference reflecting wave position; and (8) if the wave outputting position is in front of a reference reflecting wave, determining that a water level is lower than a threshold value; and after the wave outputting position is behind the reference reflecting wave, determining that the water level exceeds the threshold value. The water-hammer-preventing ultrasonic water level detection method accurately judges whether the water level of the pipeline exceeds the highest allowable water level value or not so as to provide technology supports to the operation and manipulation in time and avoid a water hammer phenomenon; and the water-hammer-preventing ultrasonic water level detection method is good for safe production and operation, and reducing and avoiding personnel damages and economical losses, which are caused by the water hammer.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

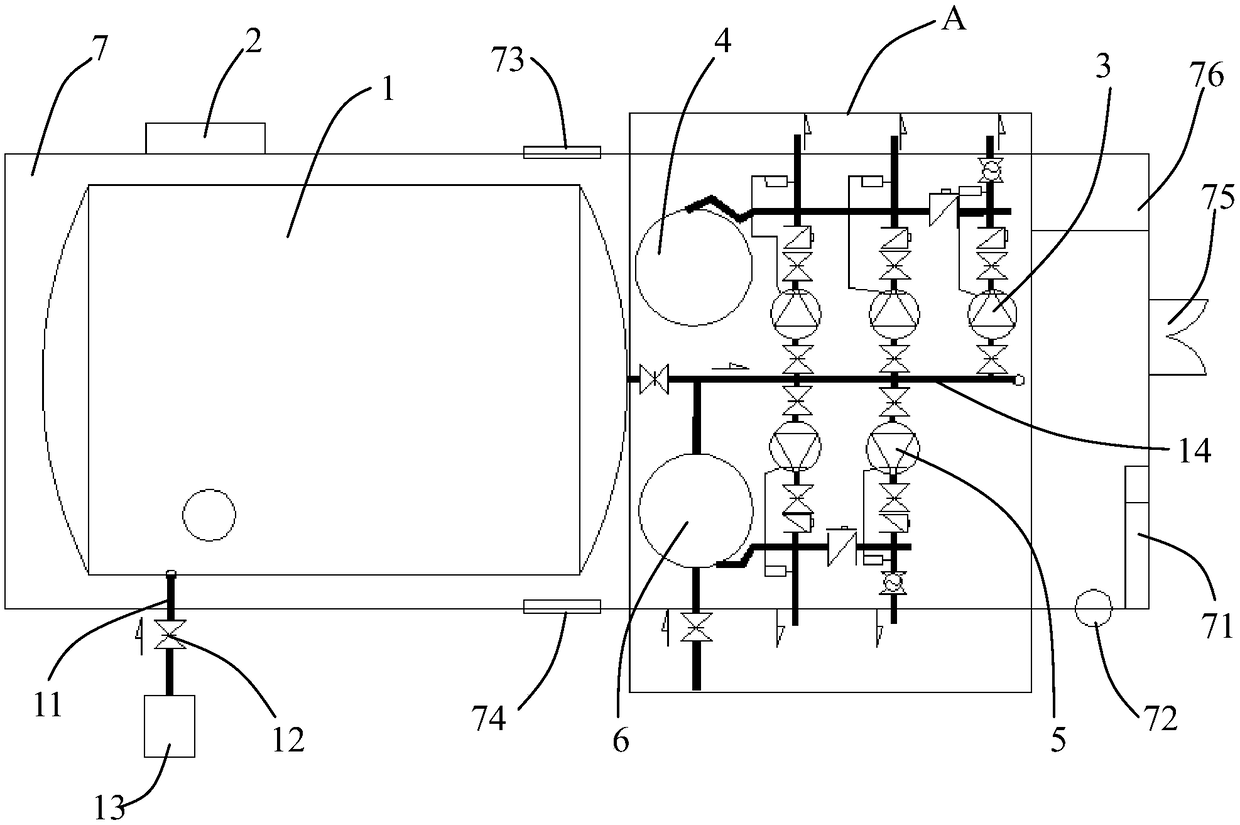

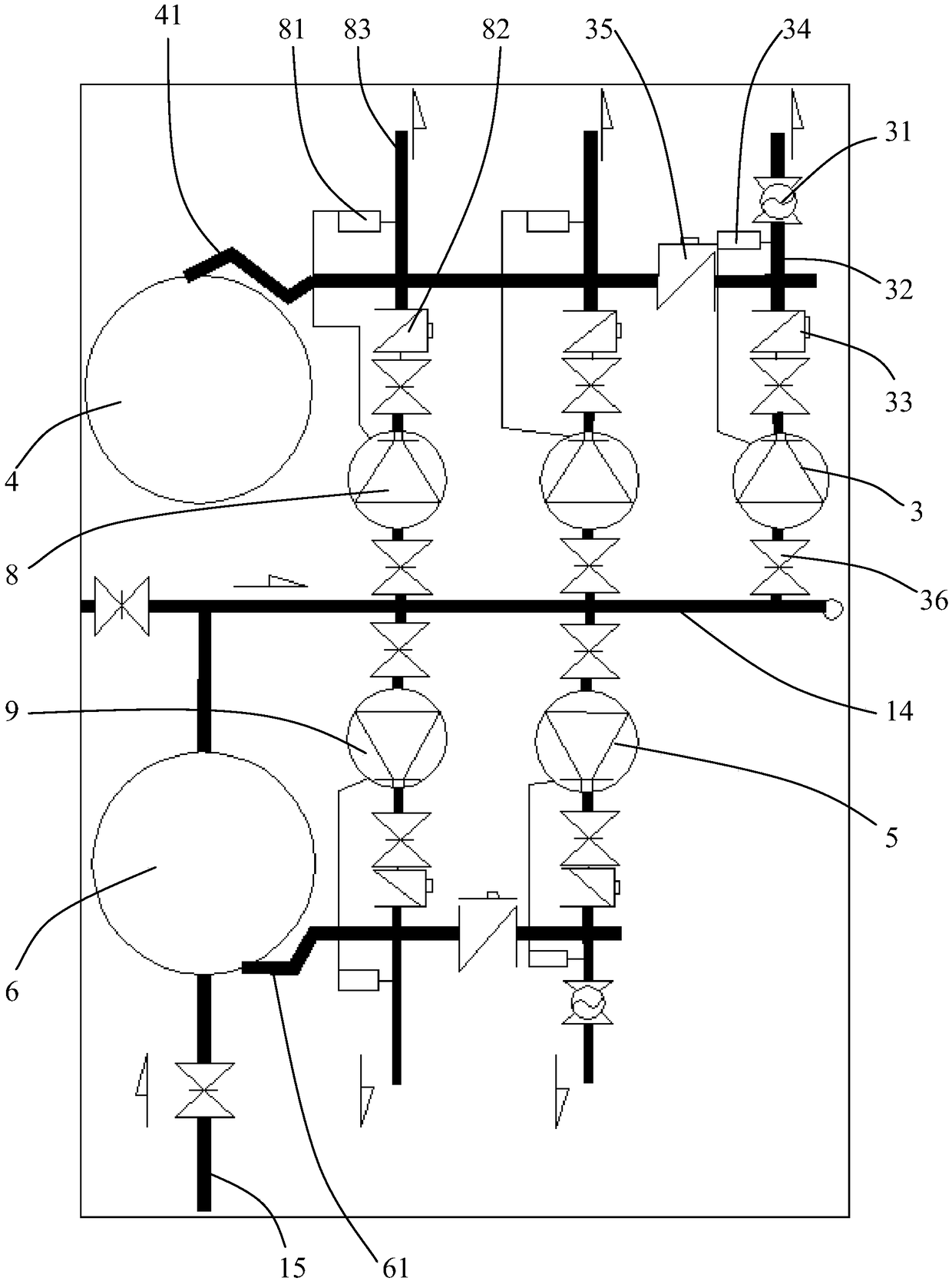

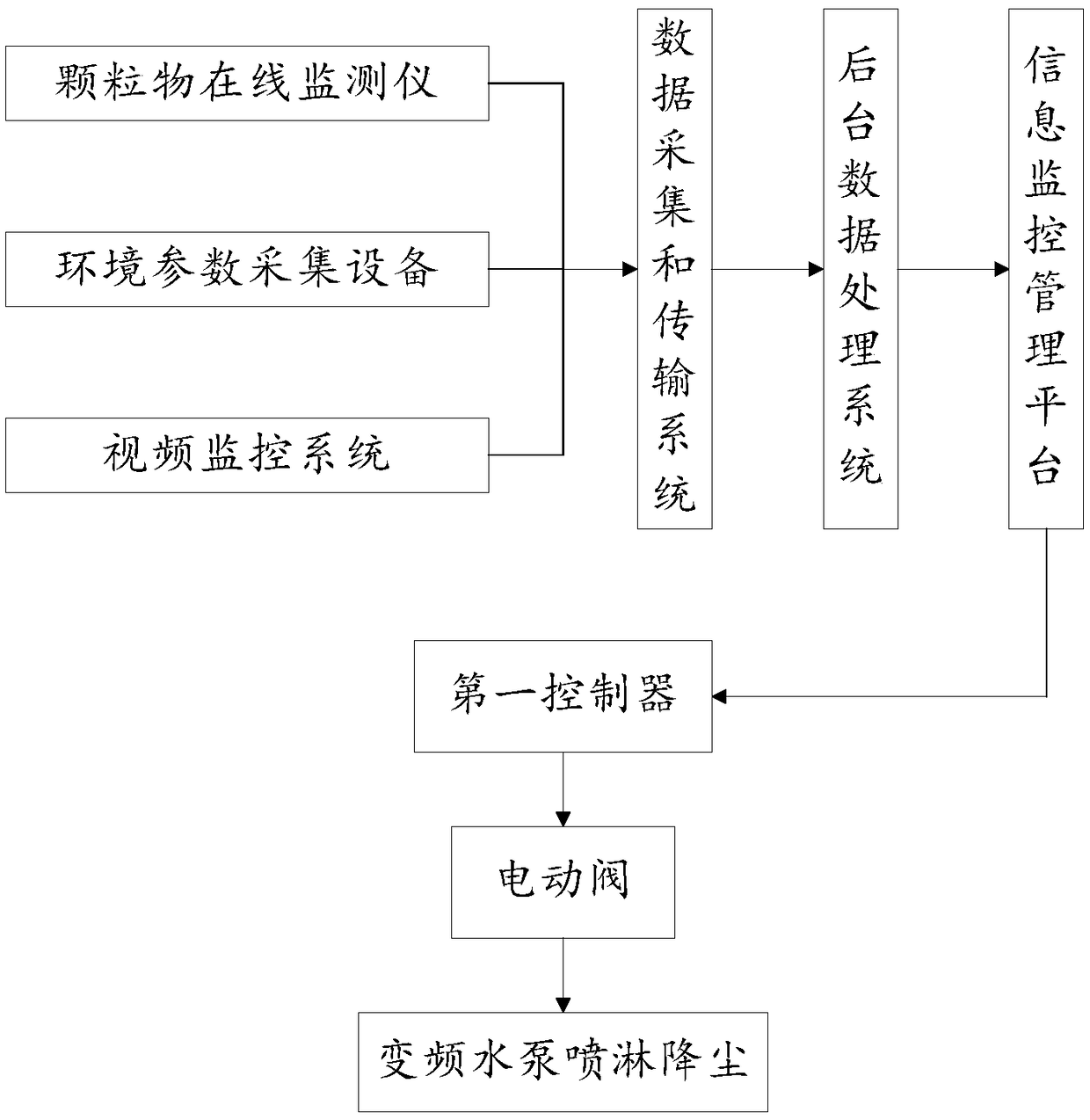

Remote variable-frequency constant-pressure pump set for construction and control method thereof

PendingCN108729504AAchieve conductionRealize spray dust reductionService pipe systemsWater mainsElectricitySurge tank

The invention provides a remote variable-frequency constant-pressure pump set for construction and a control method thereof, the remote variable-frequency constant-pressure pump set for construction comprises a water storage tank, a water outlet main pipe, variable-frequency water pumps, electrically-operated valves, surge tanks, and a flying dust monitoring device; the water storage tank is provided with a water outlet, the water outlet main pipe is communicated with the water outlet, the variable-frequency water pumps are communicated with the water outlet main pipe through pipelines, the electrically-operated valve is communicated with the output end of the first variable-frequency water pump through a first water pipe, the water inlet end of the surge tank is communicated with a firstwater pipe through a second water pipe, and the flying dust monitoring device is electrically connected to the electrically-operated valves. By utilizing the remote variable-frequency constant-pressure pump set for construction in the invention, when the flying dust concentration of a construction site is higher than or equal to a preset concentration, the electrically operated valves are opened,so that the first water pipes connected to the variable-frequency water pumps are opened, and thereby the variable-frequency water pumps carry out dust suppression spray operation, the structure is simple, and the remote variable-frequency constant-pressure pump set for construction is convenient to operate.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Swing check valve

InactiveCN112361036AAvoid quick shutdownAvoid damageCheck valvesValve members for absorbing fluid energyEngineeringCheck valve

The invention relates to a swing check valve. The swing check valve comprises a valve body and a valve deck arranged at the upper end of the middle of the valve body, wherein an inlet flow channel andan outlet flow channel are formed in the valve body, a valve seat is arranged at the position, located at the outlet end of the inlet flow channel, in the valve body, a fluid channel communicating with the inlet flow channel is formed in the valve seat, a valve clack matching with the valve seat is arranged in the valve body, and the swing check valve further comprises a speed reducing mechanismused for reducing the closing speed of the valve clack when the valve clack is closed. The swing check valve has the beneficial effects that by arranging the speed reducing mechanism, the valve clackis prevented from being closed quickly when a medium flows reversely, so that the phenomenon that a sealing surface is damaged due to too large impact force is prevented, the service life of the checkvalve can be prolonged, the water hammer phenomenon can be prevented, the check valve is protected, and the swing check valve is prevented from being suffering other harmful conditions such as damage.

Owner:段井胜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com