Rotary valve type pump protecting device

A protection device, rotary valve technology, applied in non-variable-capacity pump, pump control, machine/engine, etc., can solve the problems of unadjustable bypass fluid pressure, increase investment, etc., achieve simple structure, prevent "water hammer". Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

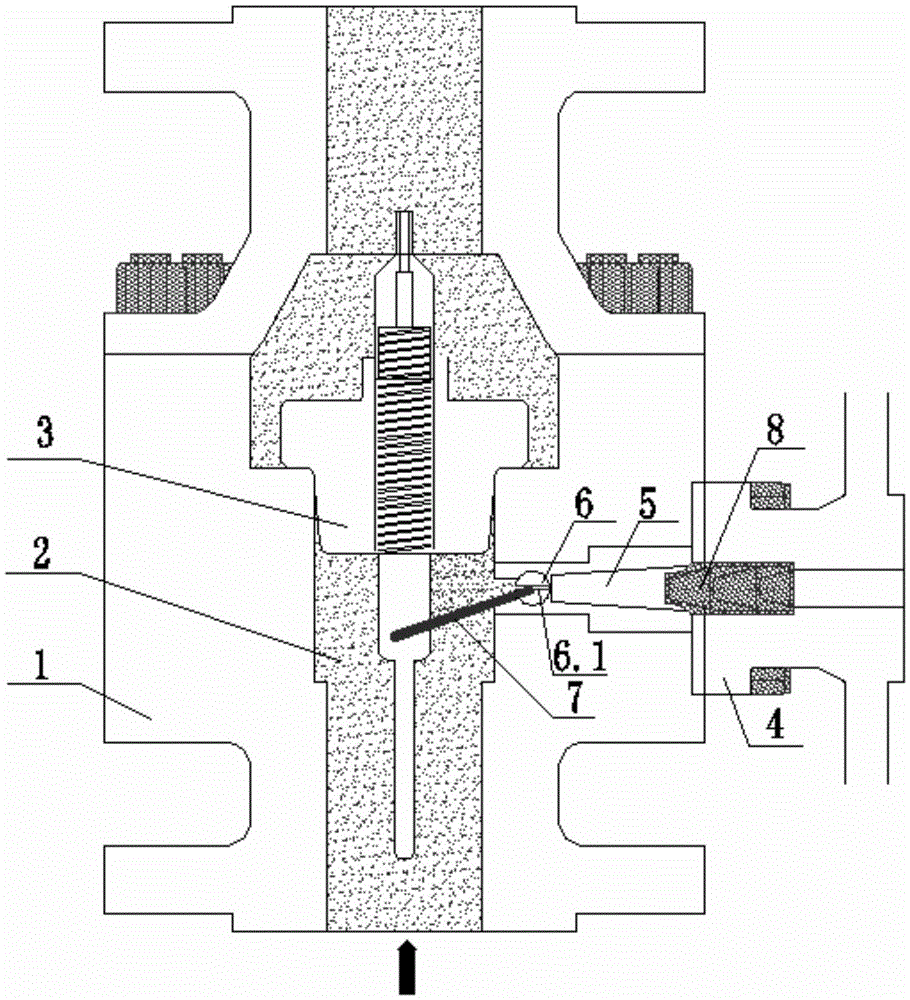

[0013] Below in conjunction with accompanying drawing, the present invention will be further explained:

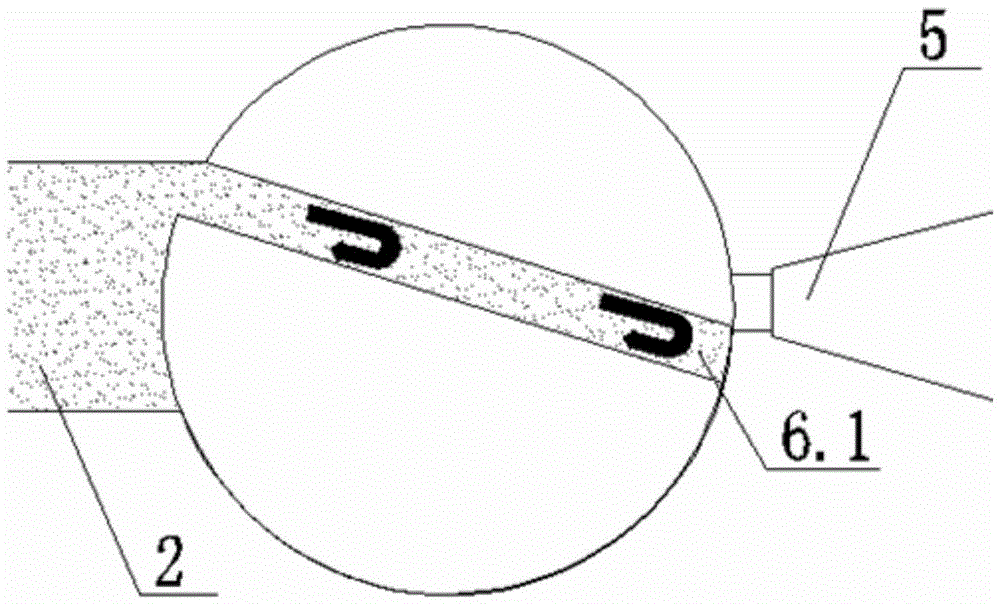

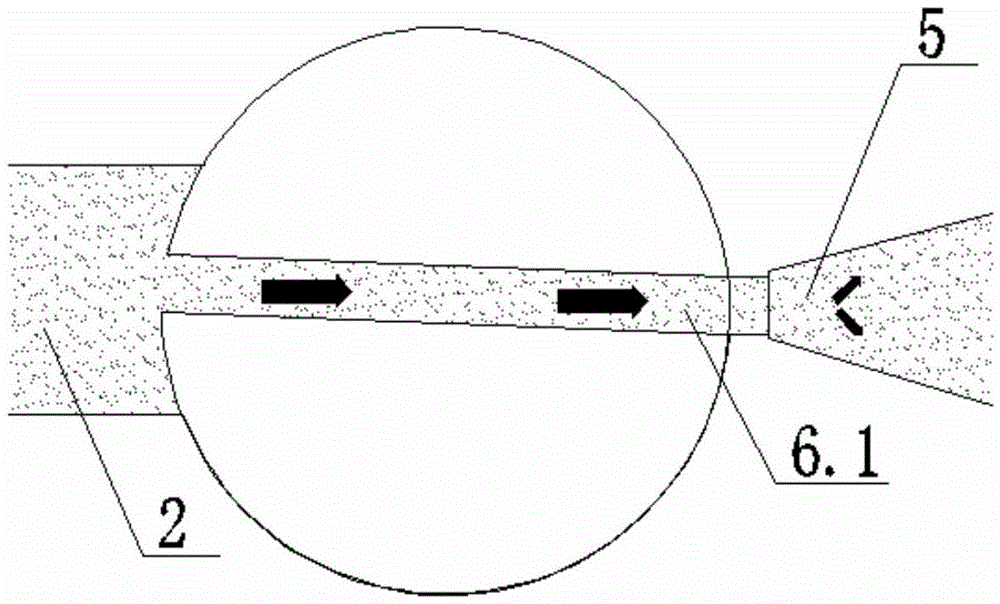

[0014] see figure 1 , the outlet of the centrifugal pump (not shown in the figure) is provided with a sealing valve body 1, and a check valve 3 is provided in the first flow channel 2 inside the sealing valve body 1, and the first flow channel below the check valve 3 The channel 2 communicates with the second flow channel 5 through the flow hole 6.1 of the ball valve 6; the second flow channel 5 is located in the bypass valve body 4, the ball valve 6 is fixedly connected to one end of the guide rod 7, and the guide rod The other end of 7 is hinged with check valve 3. When check valve 3 is displaced, one end of guide rod 7 can drive ball valve 6 to rotate by pulling the other end of guide rod 7. A multi-stage throttling orifice 8 is also provided in the second flow channel 5 .

[0015] working principle:

[0016] When the centrifugal pump starts, the downstream flow cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com