Energy-saving method and system for underground mine double-slurry inputting and discharging

A slurry and mine technology, which is applied to the energy saving of double slurry input and discharge in underground mines, realizes the system field of the method, and achieves the effects of avoiding fatigue damage, low operation and maintenance costs, and light wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

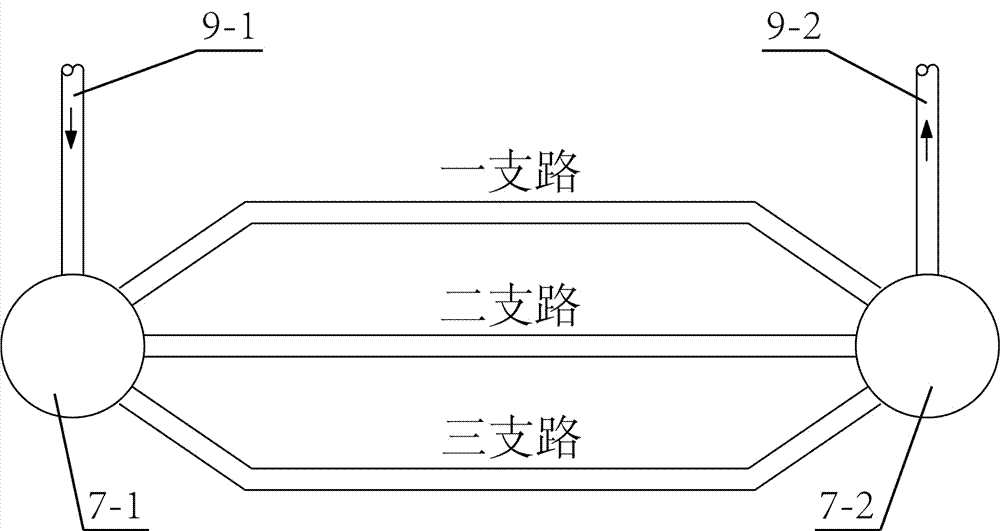

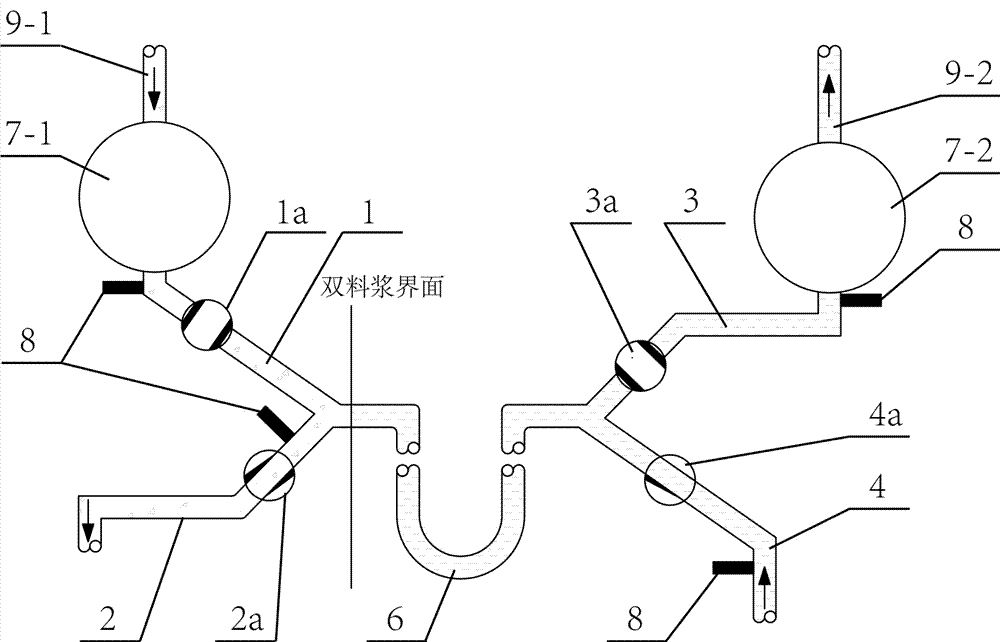

[0038] The first embodiment of the system branch to realize the energy-saving method of double slurry input and discharge in underground mines of the present invention is as follows: figure 2 , the branch includes a buffer pipe 6, and the left end of the buffer pipe 6 is respectively connected with a feed high-pressure pipe 1 provided with a feed high-pressure valve 1a and a feed low-pressure pipe 2 provided with a feed low-pressure valve 2a. The right end of the buffer pipe 6 is respectively connected with a discharge high pressure pipe 3 provided with a discharge high pressure valve 3a and a discharge low pressure pipe 4 provided with a discharge low pressure valve 4a. Wherein, the front end of the high-pressure feed pipe 1 has a filler inlet and is provided with a pressure sensor or a pressure gauge 8, and the low-pressure feed pipe 2 has a filler outlet and is provided with a pressure sensor or a pressure gauge 8 at the front end. The rear end of the high-pressure pipe 3 ...

Embodiment 2

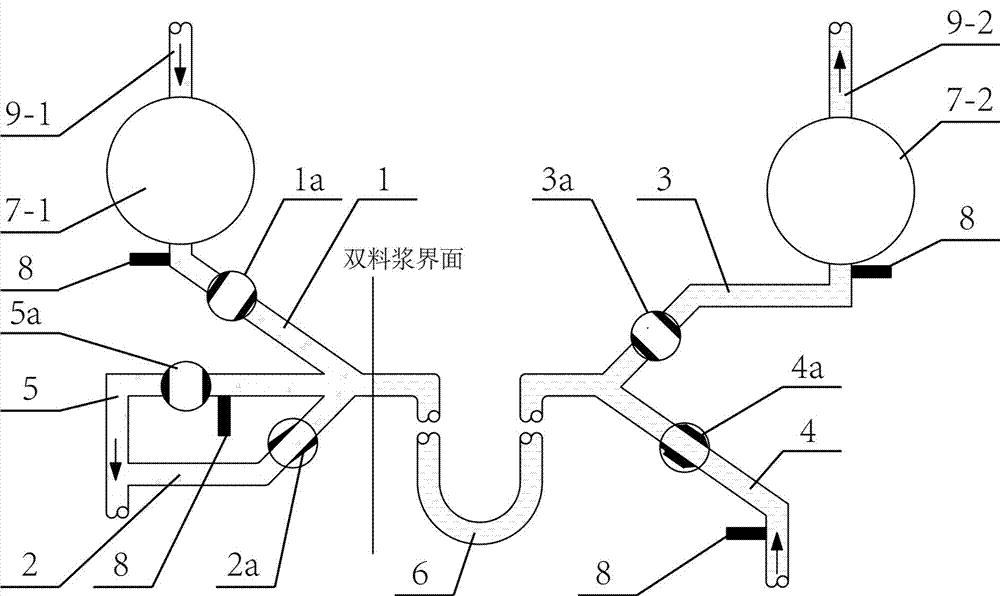

[0040] The second embodiment of the system branch to realize the energy-saving method for double slurry input and discharge in underground mines of the present invention is as follows: image 3 , the branch includes a buffer pipe 6, the left end of the buffer pipe 6 is respectively connected with a feed high pressure pipe 1 provided with a feed high pressure valve 1a, a feed low pressure pipe 2 provided with a feed low pressure valve 2a and a pressure reducing valve The decompression pipe 5 of 5a. The right end of the buffer pipe 6 is respectively connected with a discharge high pressure pipe 3 provided with a discharge high pressure valve 3a and a discharge low pressure pipe 4 provided with a discharge low pressure valve 4a. The front end of the high-pressure feed pipe 1 is provided with a filler inlet and a pressure sensor or pressure gauge 8, the front end of the low-pressure feed pipe 2 is provided with a filler outlet, and the front end of the decompression pipe 5 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com