Proportional pressure reducing valve for waterworks

The technology of a constant ratio pressure reducing valve and a water pipe is applied in the field of constant ratio pressure reducing valve, which can solve problems such as large leakage and achieve the effect of preventing water hammer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

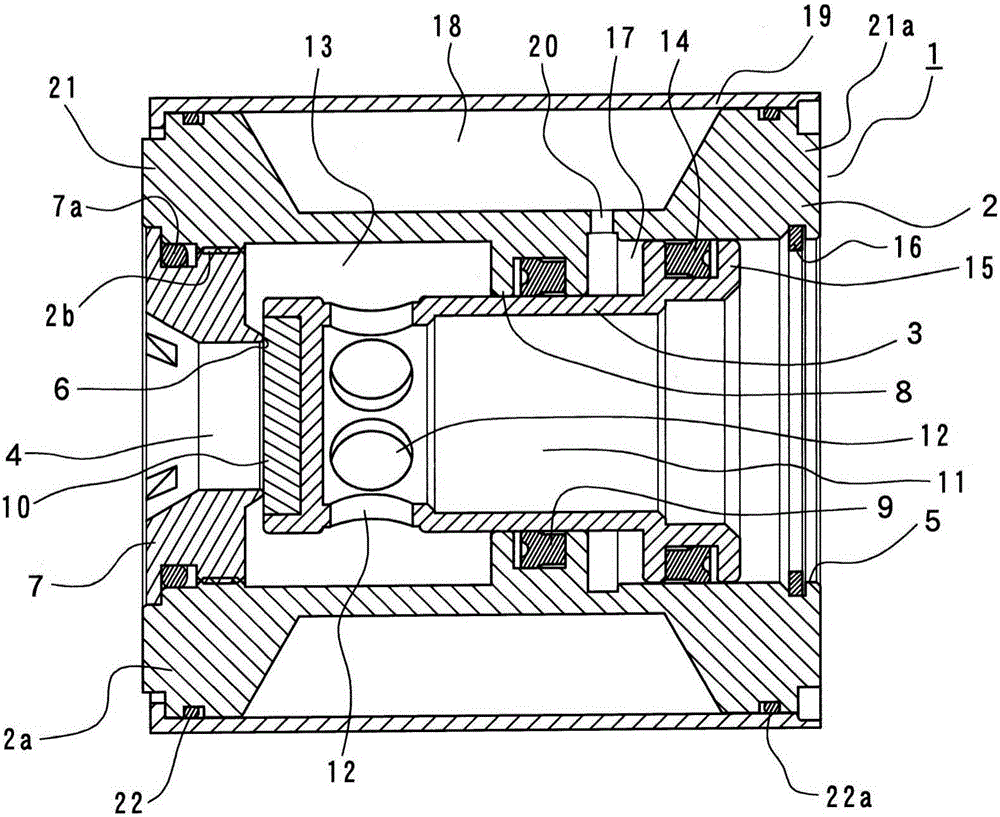

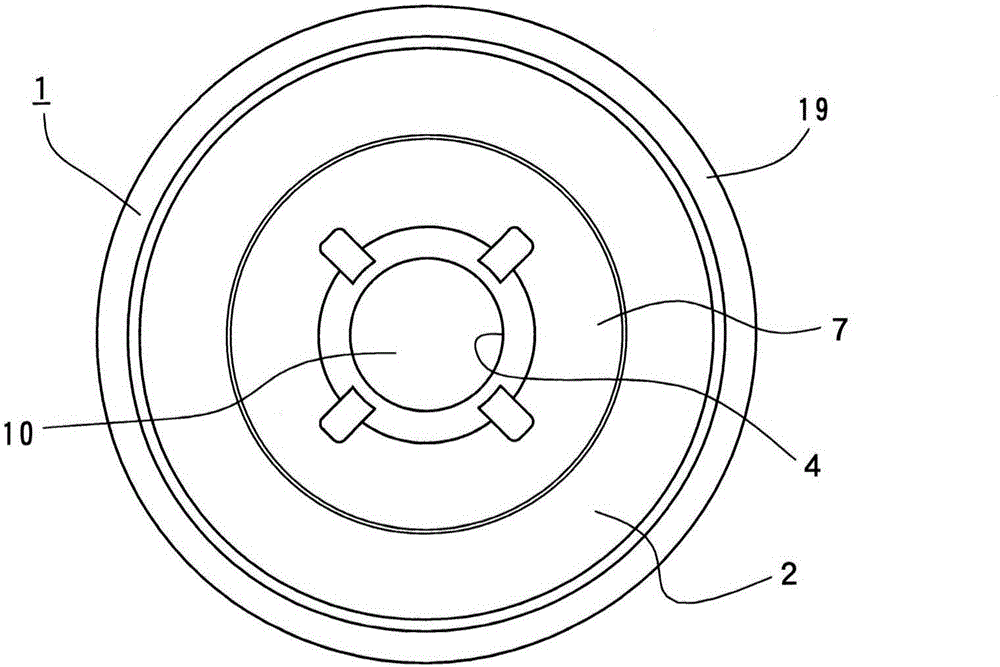

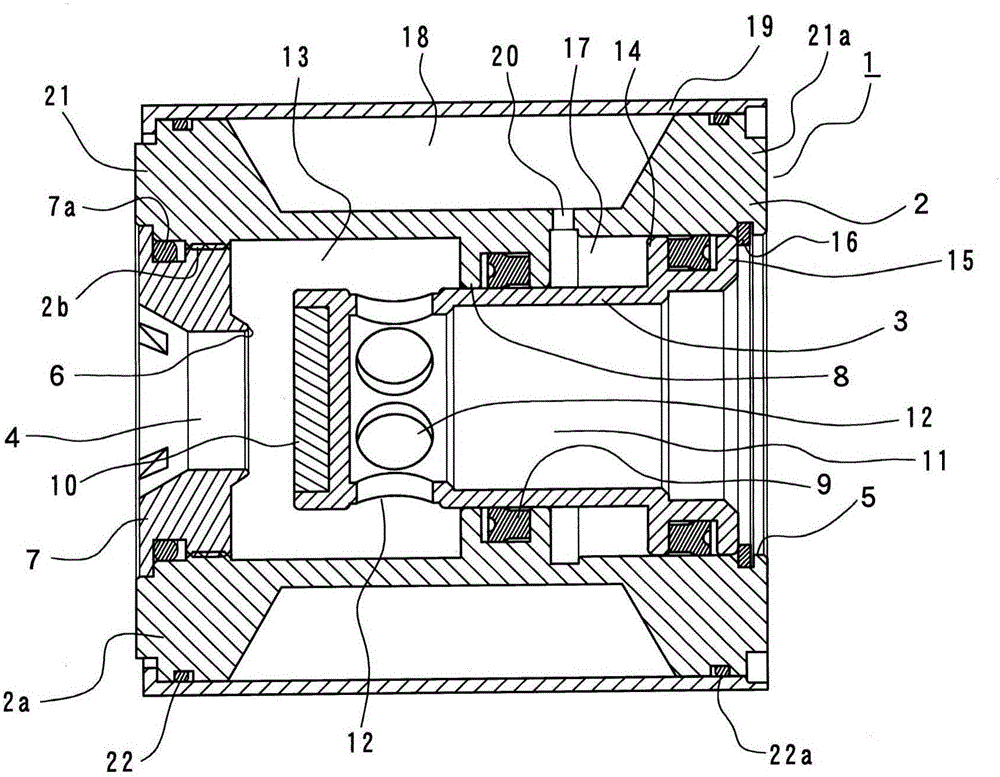

[0029] Hereinafter, an embodiment of the present invention will be explained based on the drawings.

[0030] 1 is a built-in fixed-ratio pressure reducing valve for tap water pipes. The fixed-ratio pressure reducing valve 1 is mainly composed of its valve body 2, and a piston 3 built into the valve body 2. By clamping the valve body 2 in the figure, Use bolts and nuts to fasten the pipe flanges to each other between the pipe flanges for the tap water pipe shown in the figure, thereby arranging the pipes.

[0031] Regarding the valve body 2, its side wall 2a is formed in a thick cylindrical shape, and an inflow port 4 is opened on the front end surface, and an outflow port 5 is opened on the rear end surface, thereby forming a straight line between the inflow port 4 and the outflow port 5. In the flow path, the outflow port 5 is set to have a larger diameter than the inflow port 4, and a valve seat 6 is protrudingly provided on the periphery of the secondary side opening of the infl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com