Leakage sensor automatic shut-off valve

A technology of automatic cut-off and valve body, applied in the direction of valve details, valve devices, fluid distribution valves, etc., can solve the problems of low cost, inconvenient replacement by users, and easy moisture desorption and water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

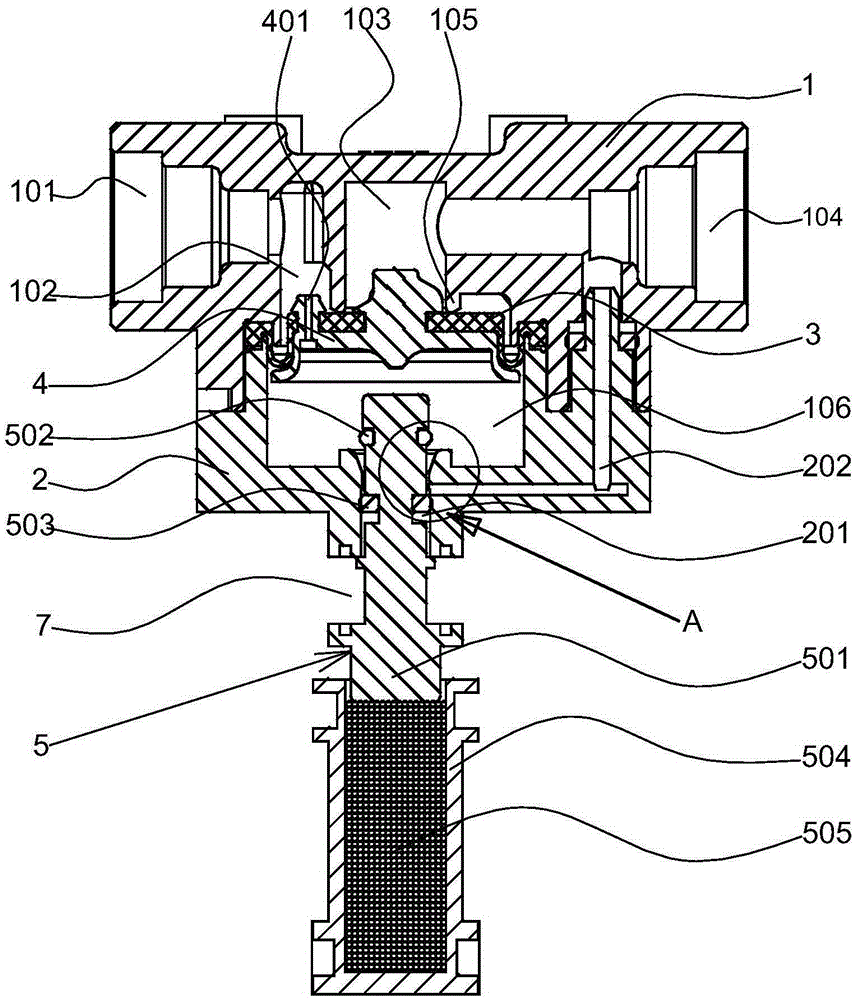

[0021] A water leakage sensing automatic cut-off valve, the valve body 1 has a water inlet 101, a water supply chamber 102 connected to the water inlet, a water outlet chamber 103 and a water outlet 104 connected to the water outlet chamber, and the valve body is provided between the water supply chamber and the water outlet chamber. There is a valve seat 105, a valve cover 2 is connected to the valve body, a back pressure cavity 106 is formed between the valve body and the valve cover, a diaphragm 3 for opening and closing the valve seat is arranged on the valve body, and a diaphragm plate is embedded on the diaphragm 4. The back pressure chamber and the valve seat are separated by the diaphragm 3 and the diaphragm plate 4. The diaphragm and the diaphragm plate are provided with a side hole 401 communicating with the water supply chamber. The valve cover is provided with a piston hole 201 and a diversion channel 202. The piston hole The inner port is connected to the back pres...

Embodiment 2

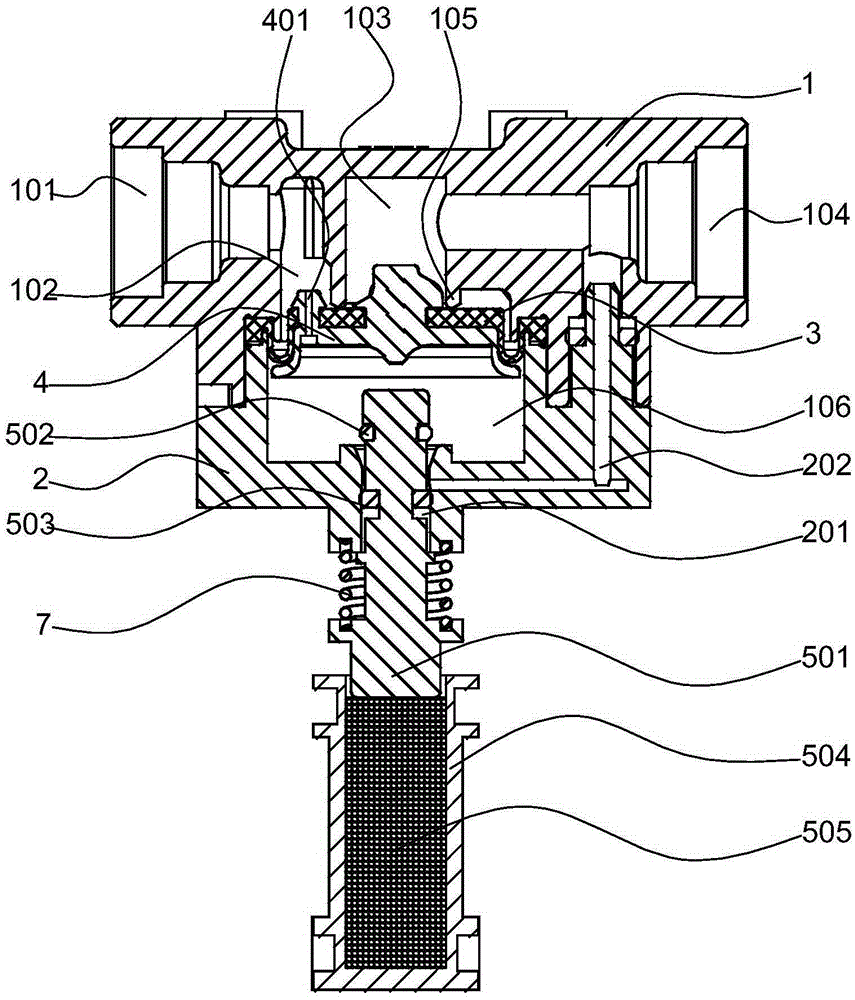

[0027]The difference between this example and the previous example is that the inner opening of the piston hole is formed with a bell mouth-shaped sealing socket 203 , so that the sealing member A moves down and sits on the socket, which can seal the flow channel 2011 more reliably. Other constructions are the same as the above example.

Embodiment 3

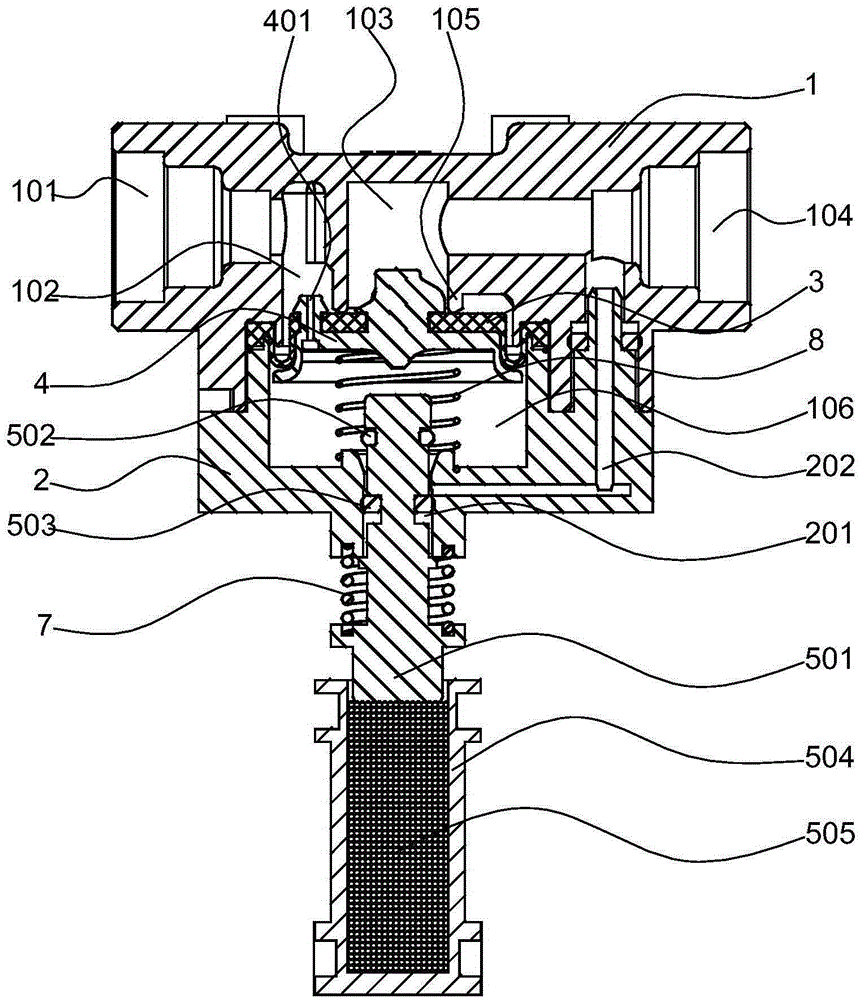

[0029] This example is different from Example 2 in that the piston rod is sheathed with a spring A7, the upper end of the spring A is placed in the peripheral area of the outer opening of the piston hole of the valve cover, and the lower end of the spring A is placed on the radially outwardly expanded step of the piston rod. In this way, after the water-soluble solid dissolves, the piston rod can move down more reliably to cut off the waterway. Other structures are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com