Building cement platform roof crack leak repairing method

A building and cement technology, which is applied in the field of leakage repair, can solve the problems of short service life, waste of materials, and increase the pressure on the roof top surface, etc., and achieve the effect of good leakage prevention effect, long service life and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

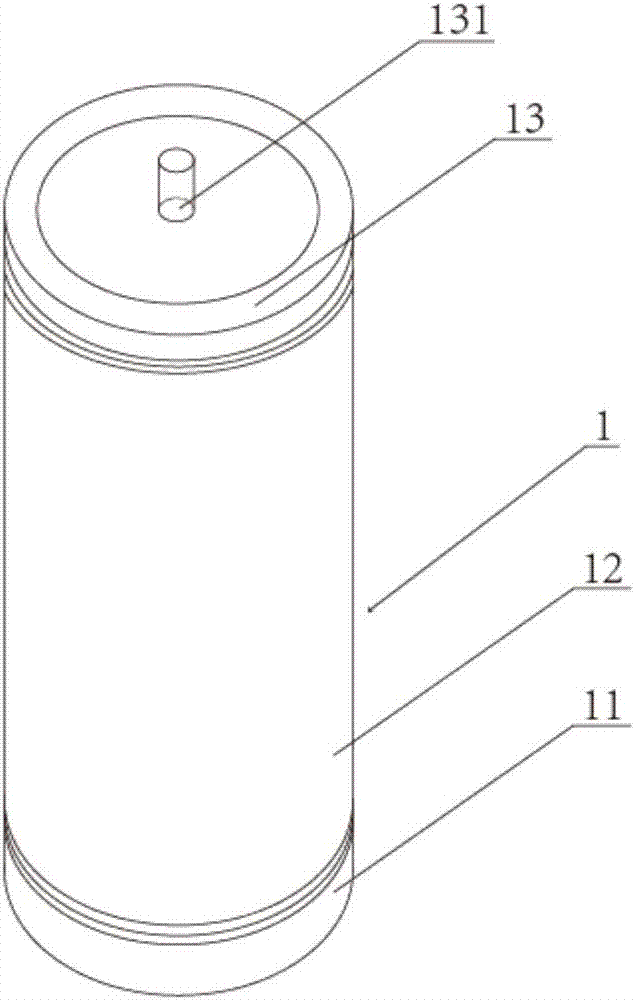

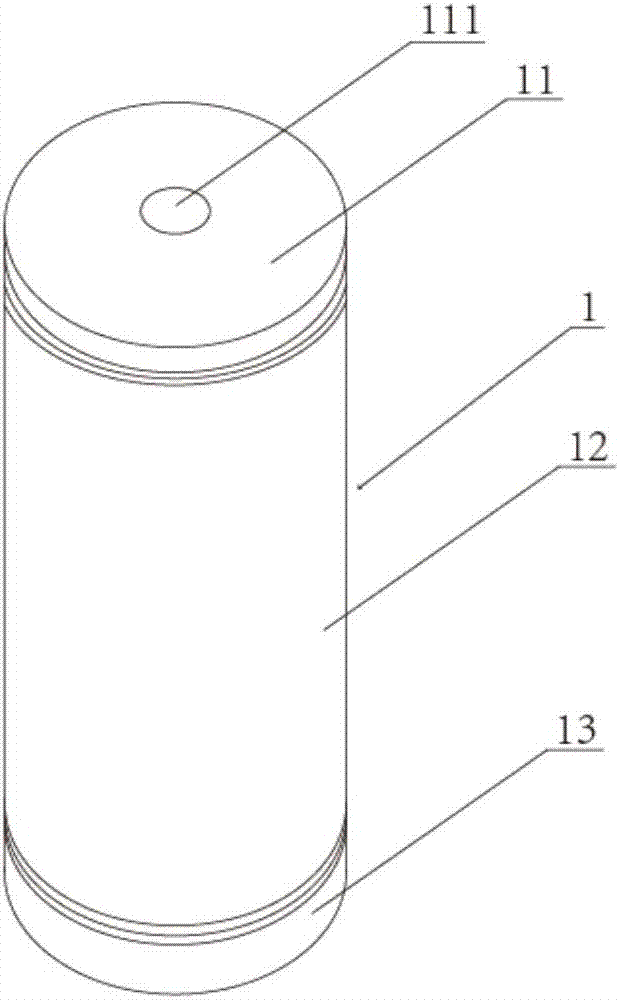

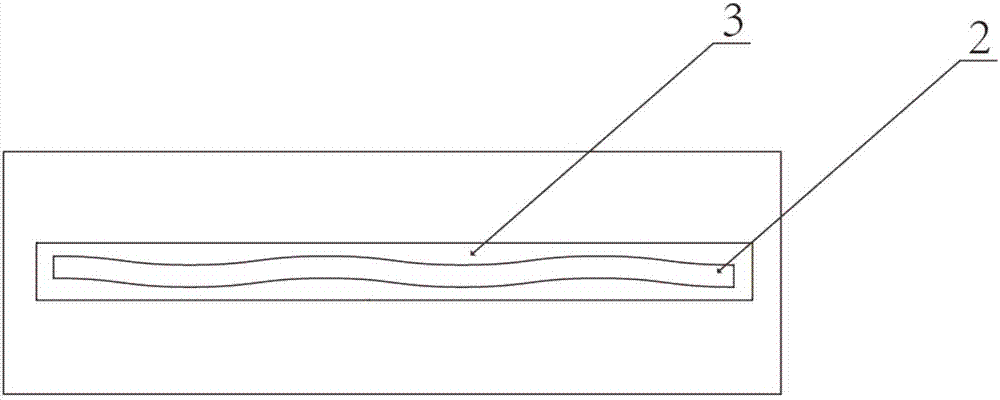

[0027] The present invention will be further elaborated below in conjunction with accompanying drawing, wherein, the direction of the present invention is with figure 1 as standard.

[0028] Such as Figure 1 to Figure 6 As shown, the leakage repairing glue injection device 1 adopted for implementing the leakage repairing method for building cement platform roof cracks of the present invention comprises a rubber cartridge holder 11, a rubber cartridge 12, a rubber cartridge cover 13 and an air pump, wherein the leak repairing device 1 is vertically arranged , the rubber cartridge fixing seat 11 is arranged at the bottom of the rubber cartridge 12, and the rubber cartridge fixing seat 11 and the rubber cartridge 12 are detachably connected in an airtight manner through threaded cooperation. The glue port 111 and the glue cartridge 12 are used to store the prepared and mixed AB glue. The glue cartridge 12 is made of transparent plastic material with high compressive strength, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com