Antibacterial pipe and preparation method thereof

A technology of pipes and antioxidants, applied in the field of antibacterial pipes and their preparation, can solve the problems of harming health, easy to cause chronic poisoning, and poor mechanical properties of antibacterial pipes, and achieve less environmental pollution, protect skin health, antibacterial and antibacterial Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A preparation method for any one of the antibacterial tubing described above, said method comprising the following steps:

[0036] (1) 60-70 parts of polypropylene resin, 20-30 parts of linear low-density polyethylene resin, 0.5-1.5 parts of modified tetraacicular zinc oxide whiskers, 5-10 parts of chitosan, 0.2-30 parts of antioxidant Mix 0.5 parts with 0.2-0.5 parts of dispersant, extrude and granulate at 170-180°C to obtain chitosan-zinc ion composite antibacterial masterbatch; combine chitosan-zinc ion composite antibacterial masterbatch, color masterbatch and polypropylene resin Mix according to the weight ratio as the inner layer material;

[0037] (2) mixing polypropylene resin, basalt fiber, compatibilizer, lubricant and antioxidant according to the weight ratio as the middle layer material, and mixing polypropylene resin and color masterbatch according to the weight ratio as the outer layer material;

[0038] (3) Add the inner layer material, the middle layer ...

Embodiment 1

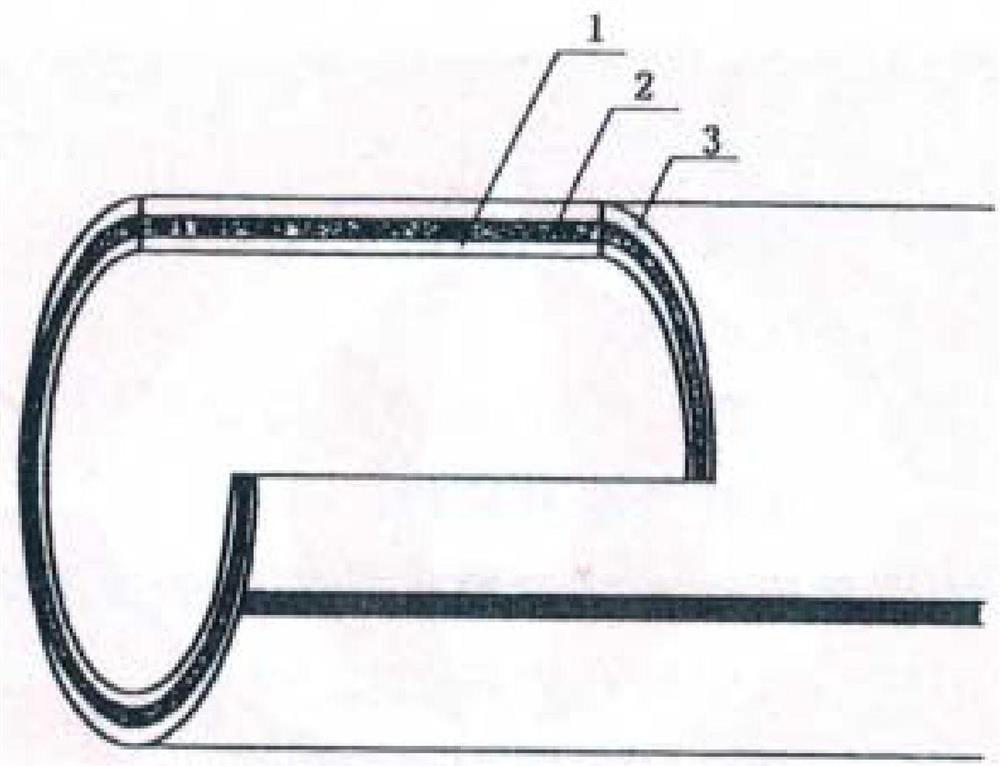

[0040] As an antibacterial pipe according to an embodiment of the present invention, the antibacterial pipe includes an inner layer, a middle layer and an outer layer. The thickness of the outer layer of the pipe is 1.0mm, the thickness of the middle layer is 1.0mm, and the thickness of the inner layer is 0.8mm. The specification of the antibacterial pipe is S3.2 -20×2.8;

[0041]The inner layer is extruded from 100 parts by weight of polypropylene resin, 2 parts by weight of white masterbatch and 2 parts by weight of chitosan-zinc ion composite antibacterial masterbatch, and the chitosan-zinc ion composite antibacterial masterbatch is made of polypropylene 70 parts by weight of resin, 30 parts by weight of linear low-density polyethylene resin, 1 part by weight of surface-modified tetraacicular zinc oxide whiskers, 8 parts by weight of chitosan, 0.4 parts by weight of antioxidant and 0.4 parts by weight of calcium stearate Part extrusion granulation is made, and described ant...

Embodiment 2

[0049] As a kind of antibacterial pipe material of the embodiment of the present invention, the only difference between this embodiment and Embodiment 1 is that the inner layer is made of 100 parts by weight of polypropylene resin, 20 parts by weight of basalt fiber, and 6 parts by weight of maleic anhydride grafted polypropylene. 0.4 parts by weight of calcium stearate and 0.4 parts by weight of antioxidant are extruded, and the antioxidant is a mixture of antioxidant 1010 and antioxidant 168 with a weight ratio of 1:1, wherein the Basalt fibers accounted for 15.77% by weight of the middle layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com