Automatic multifunctional infrared smokeless barbecue machine

A multi-functional, infrared technology, applied in the field of barbecue machines, can solve the problems of high labor intensity and low utilization rate of heat energy, and achieve the effect of environmental protection of materials, low cost, and saving operation process and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

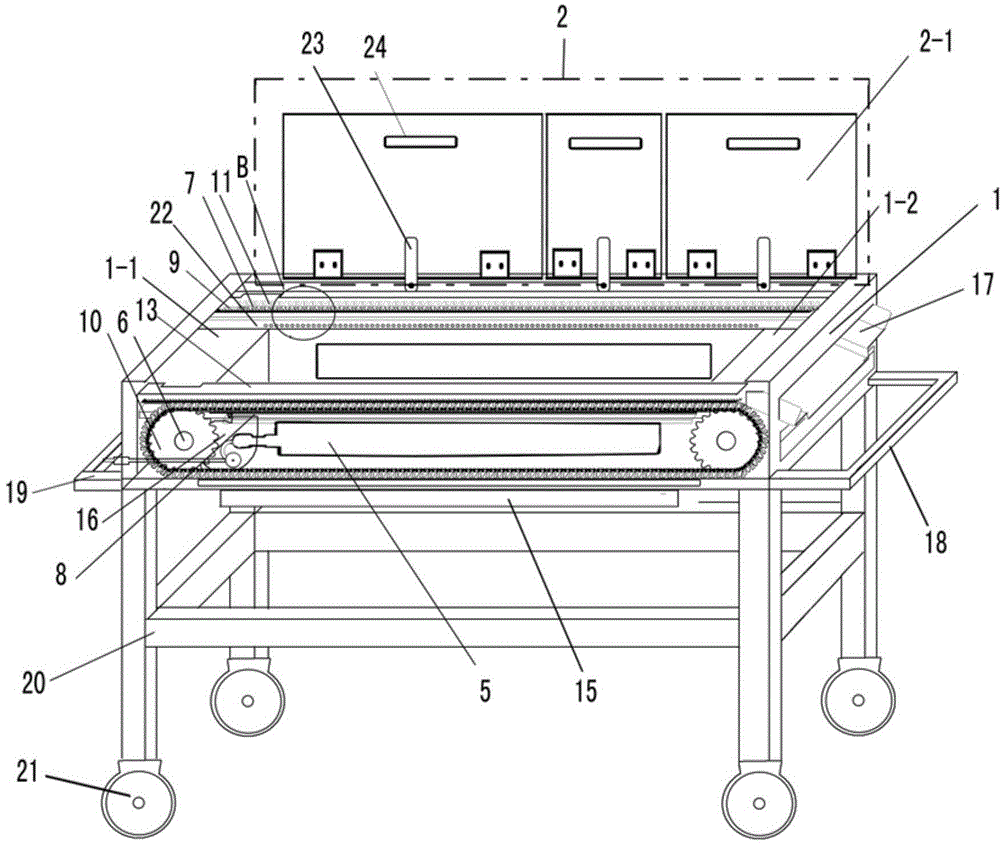

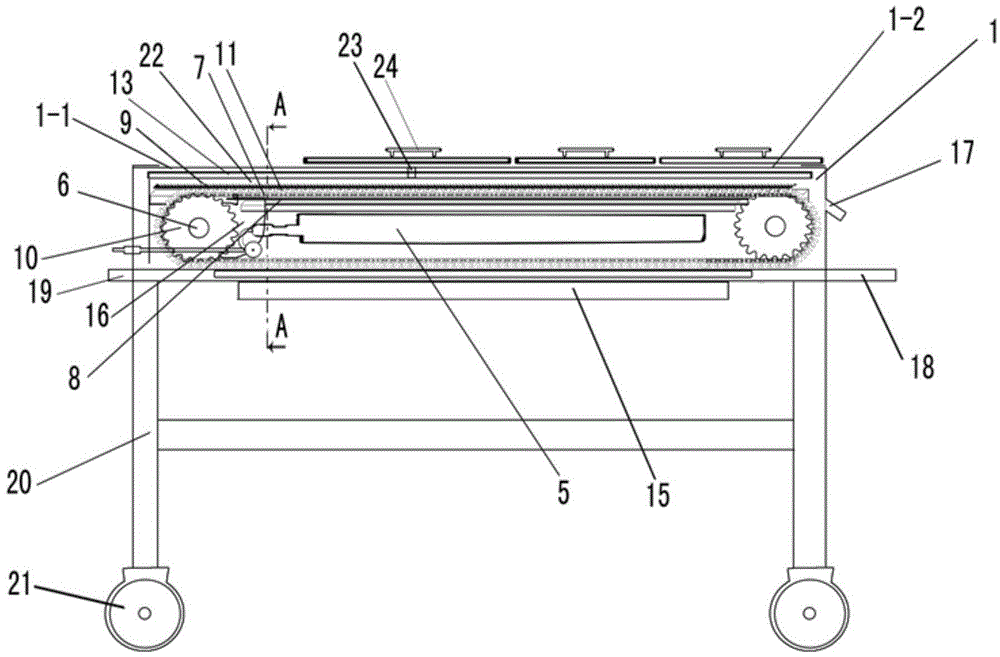

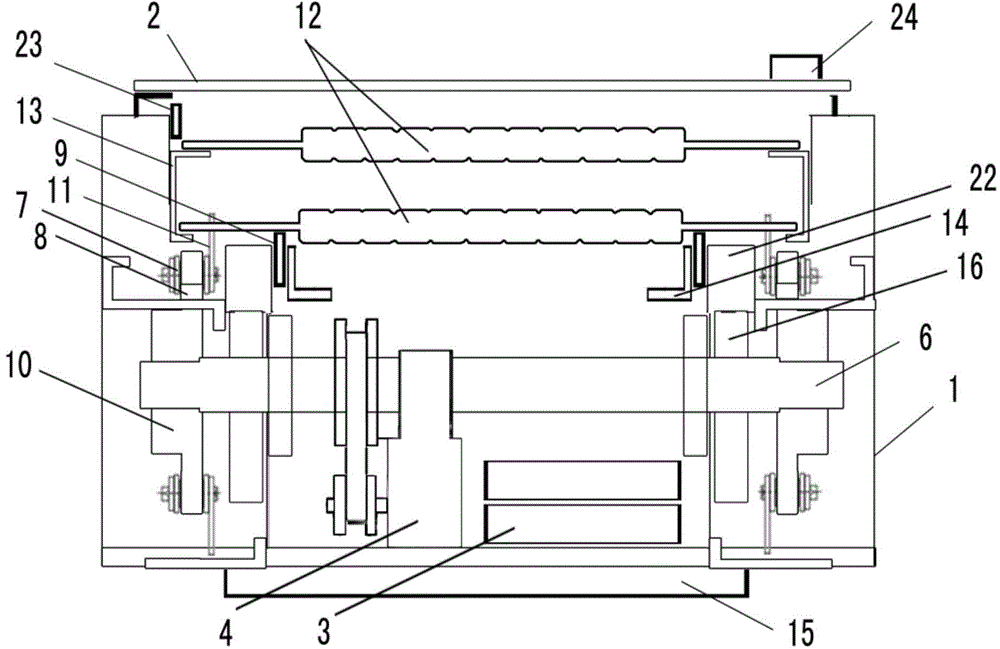

[0011] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Describe this embodiment, an automatic multifunctional infrared smokeless barbecue machine described in this embodiment includes a chassis 1, a tempered glass cover 2, a speed control box 3, a variable speed motor 4, two burners 5, and two transmission shafts 6 and two transmission rotating devices, the tempered glass cover 2 is arranged on the upper end of the case 1, a burner 5 is respectively arranged on the inner wall on both sides of the case 1, and a feed port 1-1 is provided on one side of the upper end surface of the case 1 , the other side of the upper end surface of the cabinet 1 is provided with a discharge port 1-2, two transmission shafts 6 are arranged in parallel at the bottom of the cabinet 1, and the length direction of each transmission shaft 6 is set in line with the width direction of the cabinet 1, and the transmission shaft 6 is connected to the ...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 , figure 2 , image 3 and Figure 4 To illustrate this embodiment, the automatic multifunctional infrared smokeless barbecue machine described in this embodiment further includes two upper grills 13 , one upper grill 13 is arranged above each chain 7 . In this way, the 13 ordinary grills on the upper grill are used to place some difficult-to-cook foods. The time interval for turning these difficult-to-cook foods is long, and they are placed on the upper grill 13, which can make full use of other skewers. 12 The heat energy released during grilling is more energy-saving. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination image 3 and Figure 4 Describe this embodiment, the automatic multifunctional infrared smokeless barbecue machine described in this embodiment also includes two fire baffles 14, the fire baffles 14 are L-shaped plates, the center line of the length direction of the fire baffles 14 is in line with the chassis 1 The center line in the length direction is arranged in parallel, and the fire baffle 14 is fixedly connected with the rack 9 . The grease flowing out from the skewer 12 falls on the burner 5, which is easy to generate thick smoke and even flames. The function of the fire baffle 14 is to prevent the skewer 12 from being polluted by thick smoke and to ensure that the bamboo sticks are not burned by the flames. Bad. Other compositions and connections are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com