Sludge preheating device and sludge drying system

A preheating device and sludge technology, applied in dehydration/drying/concentrated sludge treatment, energy wastewater treatment, etc., can solve the problems of energy waste, equipment without heat recovery and utilization, etc., to avoid water hammer and effectively reuse , The effect of minimizing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

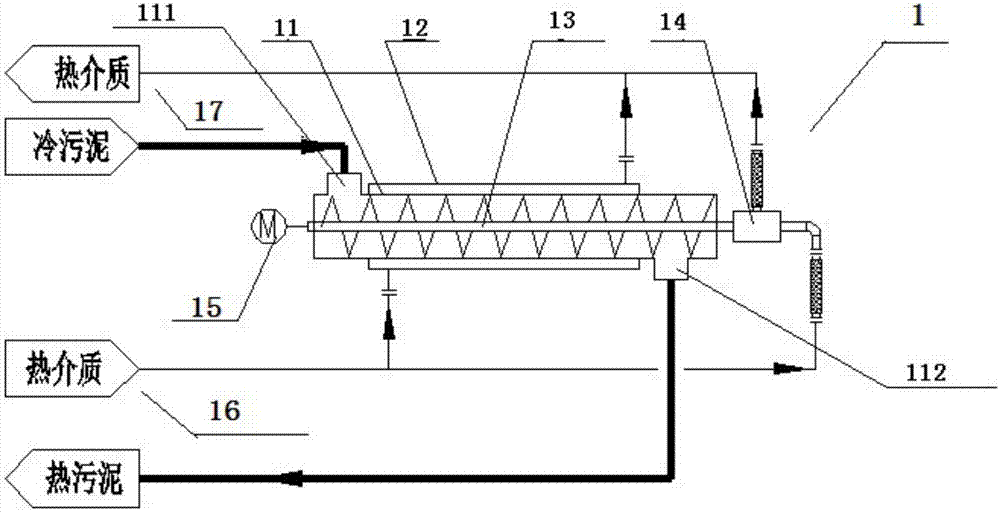

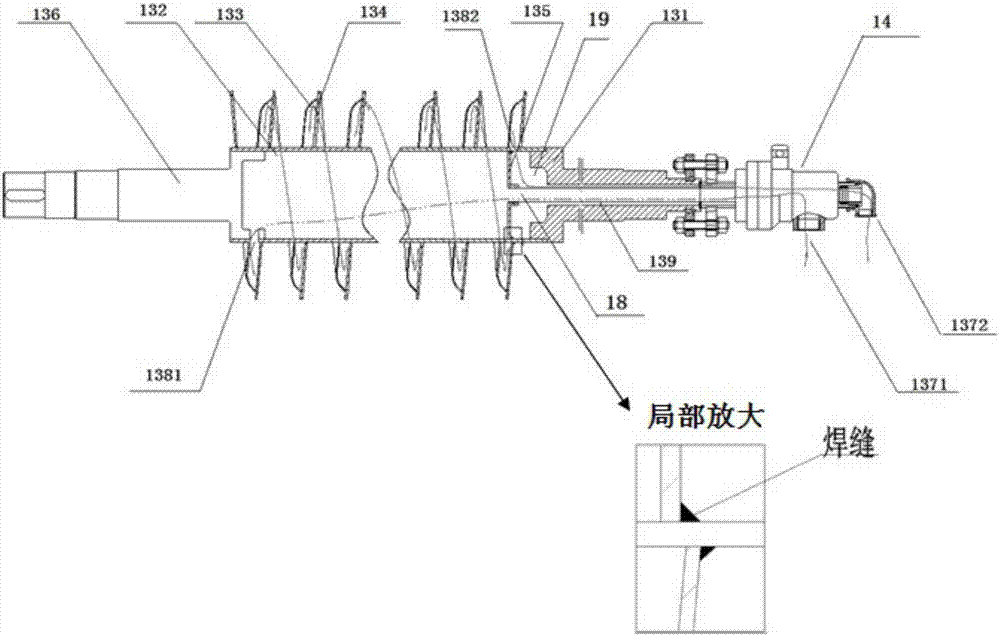

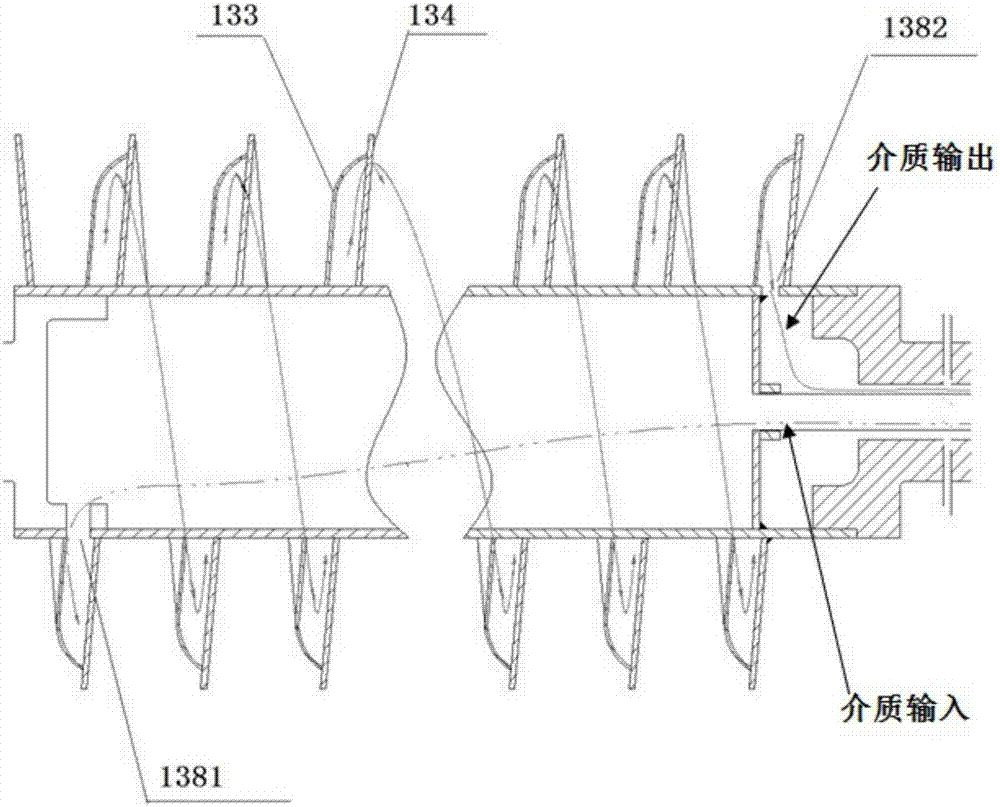

[0036] Such as Figure 1 to Figure 3 As shown, Embodiment 1 discloses a sludge preheater, that is, a hollow spiral sludge preheater 1 (abbreviated as a sludge preheater 1), which includes a housing 11 that sequentially accommodates the passage of sludge, and can be passed into The jacket 12 of the heat medium, the hollow screw shaft 13 that can pass through the medium to heat and push the sludge forward, connects the rotary joint 14 at one end of the hollow screw shaft 13; connects to the other end of the hollow screw shaft 13 and is used to drive the hollow screw shaft 13 rotating drive means 15.

[0037] The housing 11 is provided with a feed port 111 and a discharge port 112. The cold sludge entering the equipment through the feed port 111 is preheated and then comes out from the discharge port 112 to become hot sludge.

[0038] The jacket 12 is sleeved on the outside of the housing 11 and can be connected with the hollow screw shaft 13 and the medium input end 16 through ...

Embodiment 2

[0048] Embodiment 2 discloses a sludge drying system, which includes a sludge preheating device, a sludge drying device, and a heat recovery device.

[0049] Such as Figure 4 As shown, the sludge preheating device adopts the sludge preheater 1 with the structure shown in Example 1, and the cavity of the hollow screw shaft 13 can be fed with heat medium, which can realize material transportation and preheating at the same time.

[0050] The sludge drying device adopts an indirect indirect drying machine 2, and can choose a disc drying machine, a paddle drying machine or a thin layer drying machine and other types of indirect drying machines, which mainly include drying machines Body 21, material inlet 22, material outlet 23, steam trap 24, etc.

[0051] combine Figure 5 As shown, the heat energy recovery device can use a heat energy recovery device 3, which mainly includes a cylinder body 31, a flash steam outlet 32, a condensed water outlet 33, a cylinder body 33, a steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com