Novel swing check valve

A swing-type, check valve technology, applied in the direction of valve details, control valves, valve devices, etc., to achieve the effect of expanding the scope of use and facilitating use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

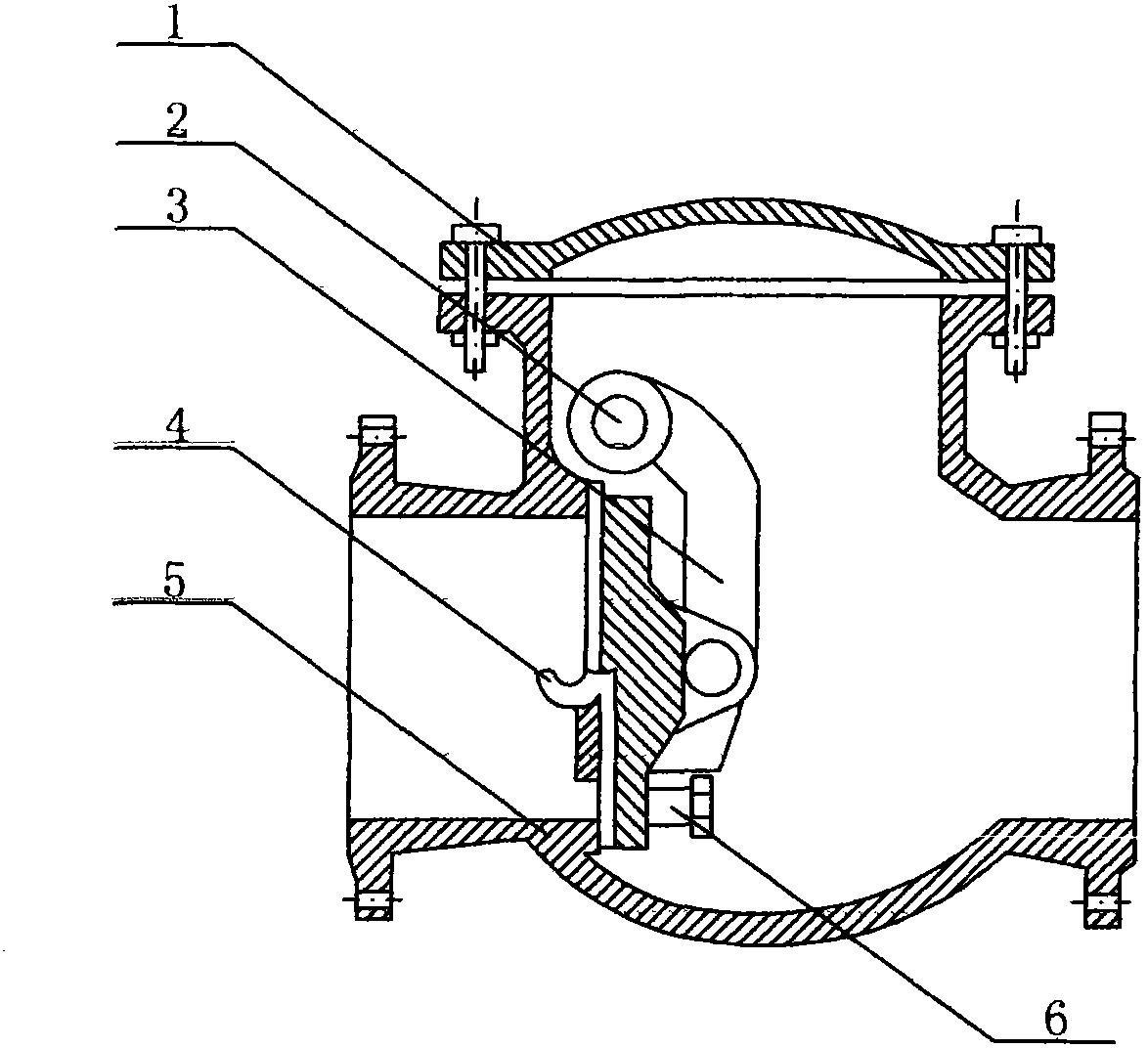

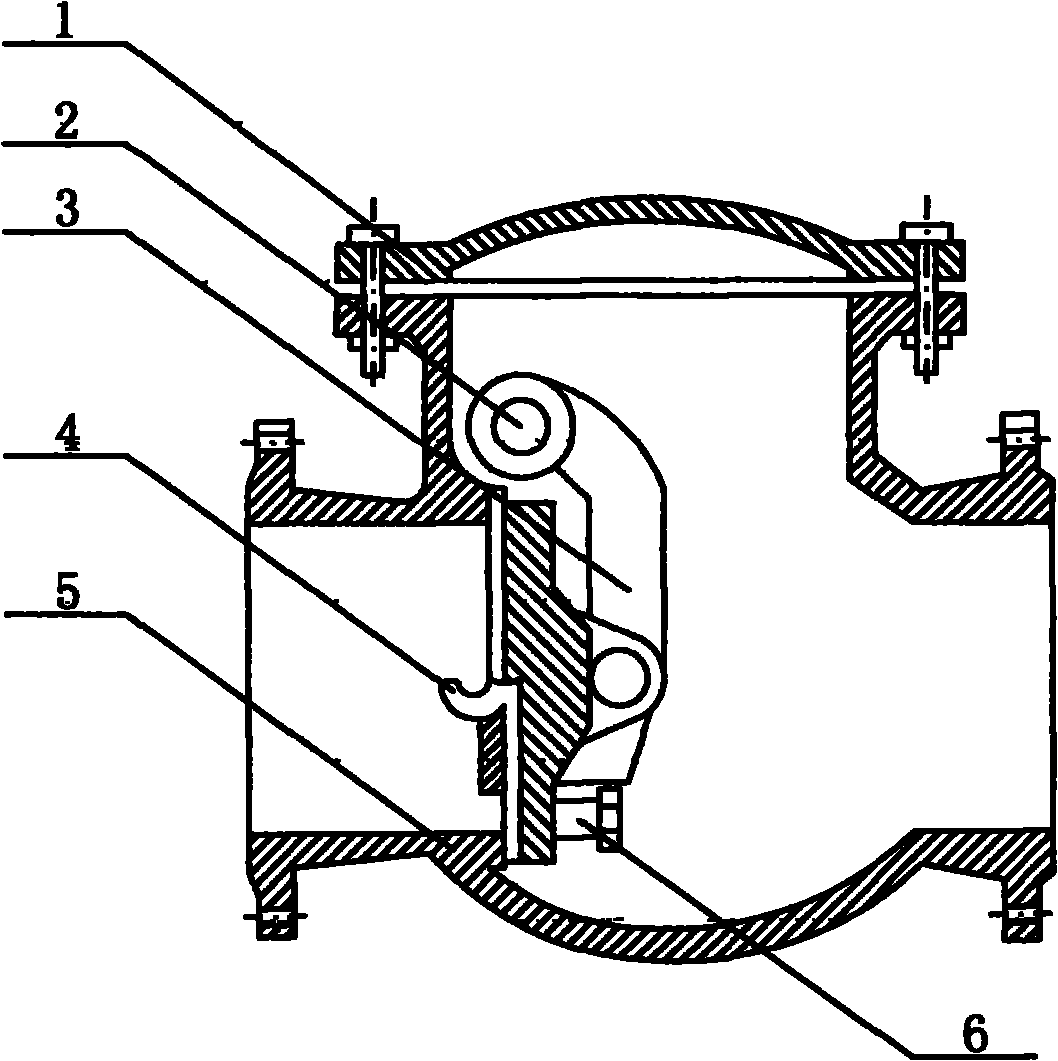

[0009] refer to Figure 1-2 , the specific embodiment adopts the following technical scheme: it is composed of valve cover 1, pin shaft 2, rocker 3, valve disc 4, valve body 5 and auxiliary valve 6, valve cover 1 is arranged on the upper end of valve body 5, pin shaft 2 is arranged at the upper end inside the valve body 5, the rocker 3 is connected with the pin shaft 2, and the auxiliary valve 6 is arranged at the lower side of the valve disc 4, and the valve disc 4 is connected with the rocker 3.

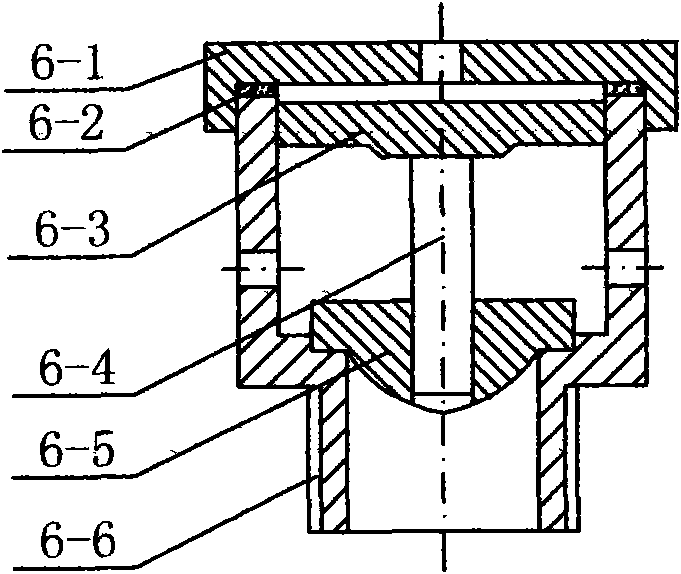

[0010] Described auxiliary valve 6 is made up of auxiliary valve cover 6-1, sealing ring 6-2, piston 6-3, piston rod 6-4, auxiliary valve disc 6-5 and auxiliary valve body 6-6, auxiliary valve cover 6-1 is arranged on the upper end of the auxiliary valve body 6-6, a sealing ring 6-2 is arranged between the auxiliary valve cover 6-1 and the auxiliary valve body 6-6, and the piston 6-3 is arranged on the side of the auxiliary valve body 6-6. At the inner upper end, the piston rod 6-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com