Water-hammer-preventing ultrasonic water level detection method

A water level detection, ultrasonic technology, applied in the direction of measuring devices, engine lubrication, liquid/fluid solid measurement, etc., can solve the problems of ineffective prevention of water hammer, inability to measure pipeline water level, etc., to achieve the benefit of safe production and operation, The effect of reducing personal injury and economic loss and avoiding personal injury and economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

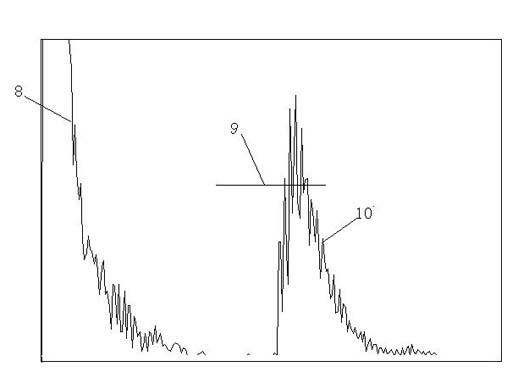

[0030] The process of the ultrasonic water level detection method of the waterproof hammer of the present invention is as follows figure 1 shown, including the following steps:

[0031] ⑴ Choose A-type pulse reflection ultrasonic flaw detector, the instrument model is CTS-9002Plus, and the working frequency range is 0.5MHz~10MHz. The instrument is linearly displayed at least 80% of the full scale on the fluorescent screen, and has a continuously adjustable attenuator above 80dB, and the step level is not greater than 2dB per step.

[0032] ⑵The specification of the pipeline to be tested is Φ51×5mm, the material is 12Cr1MoV, and the pipe diameter is small, so the 5P10mm probe is selected.

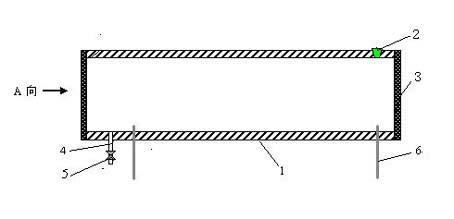

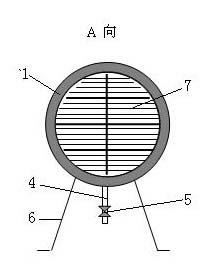

[0033] (3) Select a straight tube with the same specification and material as the tested tube as a comparison test block. Such as figure 2 , image 3 As shown, the comparison t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com