Remote variable-frequency constant-pressure pump set for construction and control method thereof

A variable frequency constant pressure, variable frequency water pump technology, applied in water supply installations, buildings, water supply mains and other directions, can solve problems such as prominent dust problems, unfavorable energy conservation and environmental protection, and increased equipment failure rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

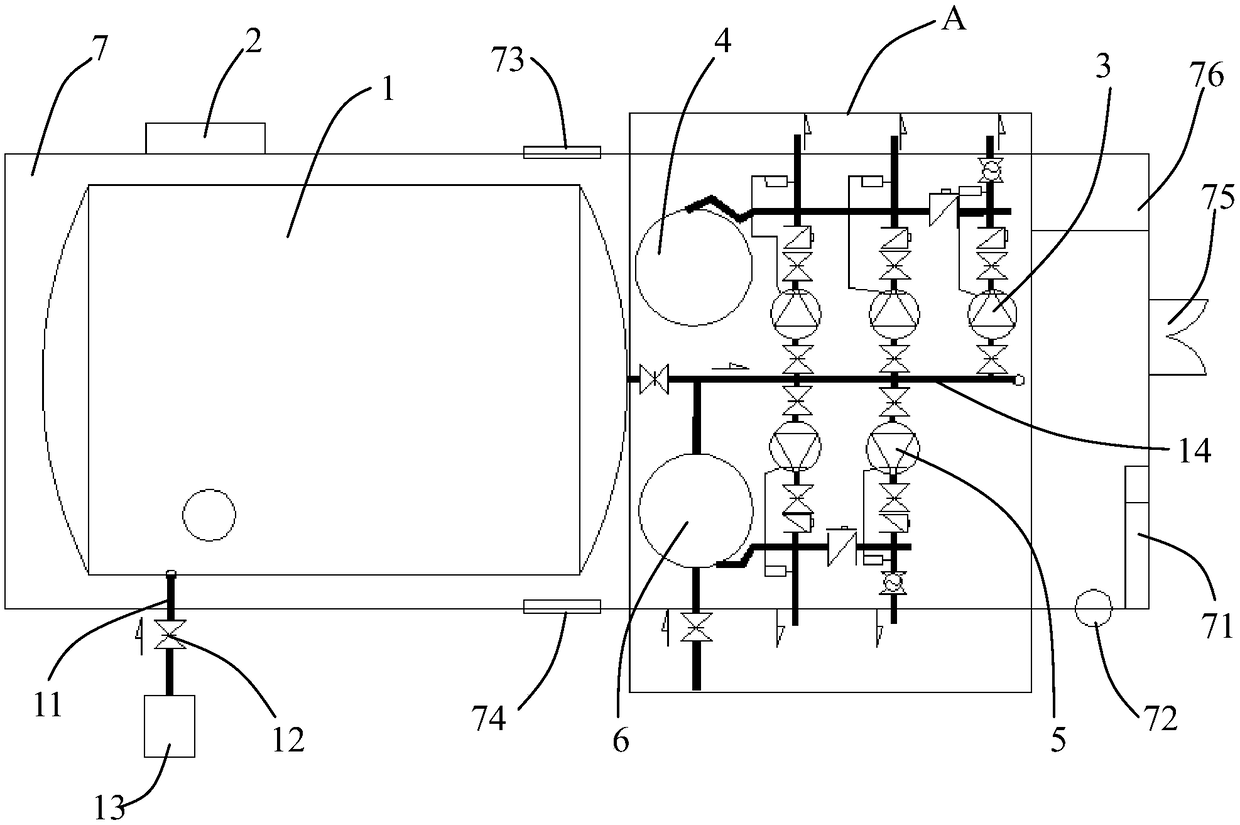

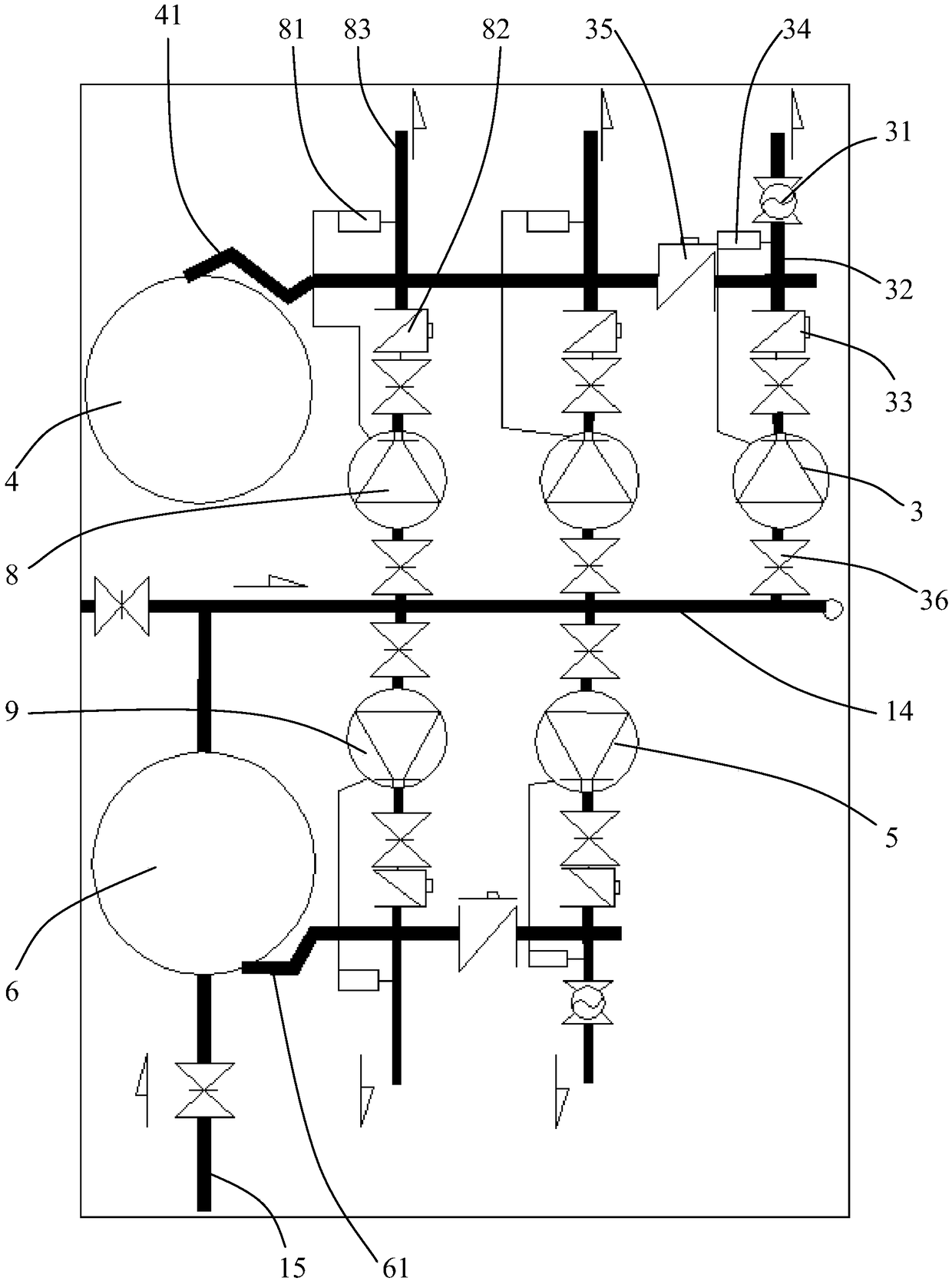

[0040] In the present invention, the remote frequency conversion constant pressure pump set for construction can be specifically divided into a high-area pump set and a low-area pump set, which supply water to the high-altitude area and the low-altitude area respectively, and the water supply operation is divided, saving electric energy; specifically as figure 2As shown: the pump set in the high area includes a first frequency conversion water pump 3, two second frequency conversion water pumps 8 and a surge tank 4, the first frequency conversion water pump 3 is a frequency conversion water pump for high-altitude dust suppression, and the two second frequency conversion water pumps 8 are respectively The frequency conversion water pump for fire fighting and the frequency conversion water pump for maintenance, the water inlet end of the surge tank 4 is connected to the output ends of the first frequency conversion water pump 3 and the second frequency conversion water pump 8 thr...

Embodiment 2

[0045] In the present invention, the remote frequency conversion constant pressure pump group for construction includes a temperature sensor 71, a humidity sensor 72, an exhaust fan 73 and a warm fan 74, and the temperature sensor 71, the humidity sensor 72, the exhaust fan 73 and the warm fan 74 are all installed on the inner wall of the box structure 7 . When the temperature in the box structure 7 was high, the exhaust fan 73 was turned on to cool down, in case the temperature was too high and the equipment circuit was damaged; When the temperature is low, the parts in the equipment will freeze and crack, become hard and brittle, and are easily damaged.

[0046] Wherein, the temperature sensor 71 and the humidity sensor 72 are both electrically connected to a third controller (not shown in the figure), and the third controller is used to control the start and stop of the exhaust fan 73 and the heater fan 74 respectively. Specifically, the third controller is used to control...

Embodiment 3

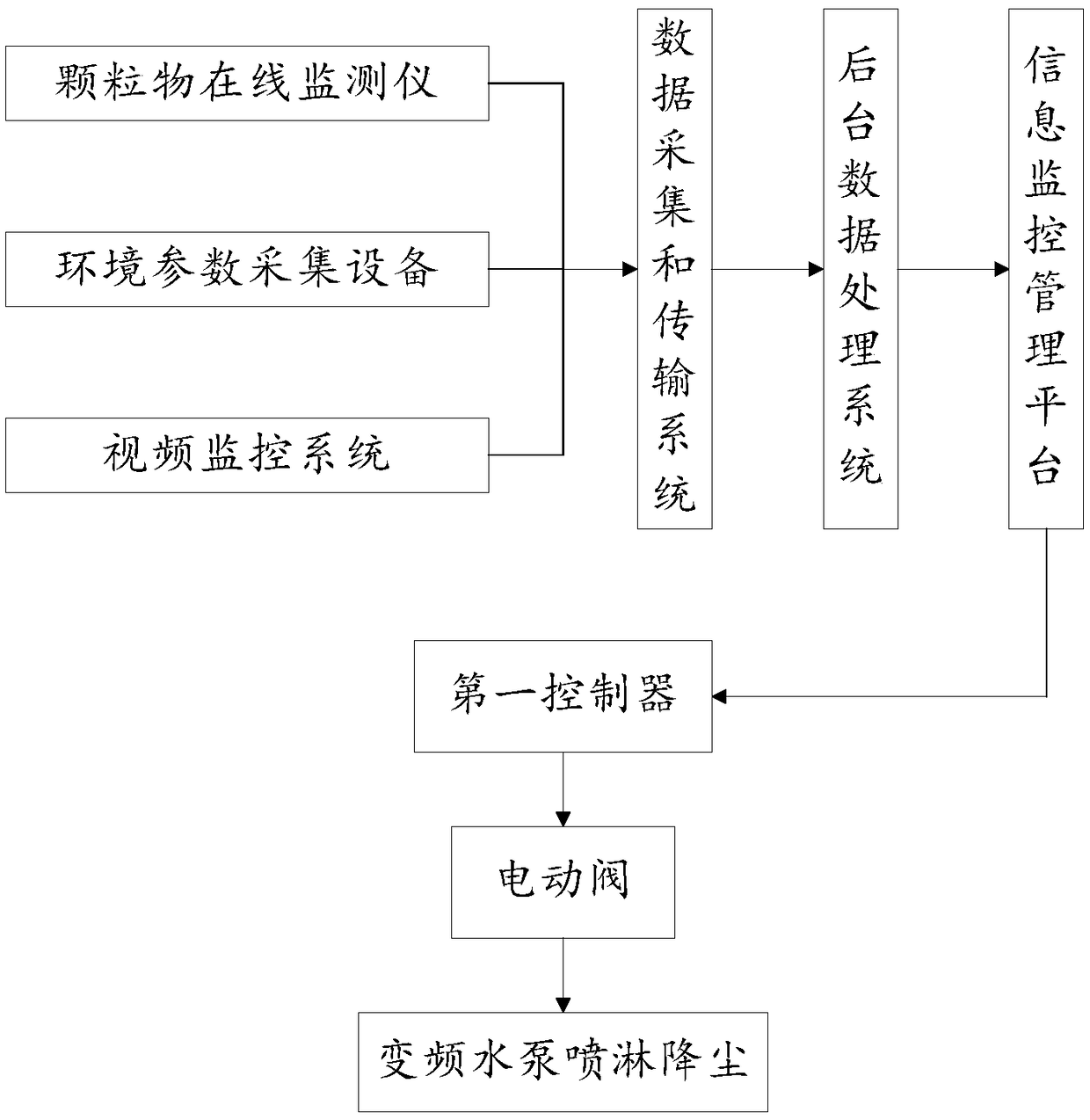

[0048] In this application, the dust monitoring device 2 can not only realize dust monitoring, but also measure wind speed, wind direction, temperature, humidity, light intensity, carbon dioxide, PM2.5, PM10 and other environmental data; figure 2 As shown, the dust monitoring device 2 is mainly composed of a particle monitor (including monitor), environmental parameter collection device, data collection and transmission system, video monitoring system, background data processing system and information monitoring management platform. Specifically, light scattering monitors, 360° spherical cameras, meteorological five-parameter acquisition equipment and data transmission equipment are used to realize real-time, remote and automatic monitoring of particle concentration; data can be transmitted on smart mobile platforms, desktop PCs, etc. through network transmission. Multi-terminal access; the monitoring platform also has a variety of statistics and high-concentration alarm funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com