Pump using waste tire

A technology of waste tires and impellers, which is applied to parts, pumps, pump components, etc. of pumping devices used for elastic fluids, and can solve problems such as danger of power generation equipment and pipeline damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Reference is made to the drawings, wherein the same reference numerals are used throughout the different drawings to designate the same or like parts.

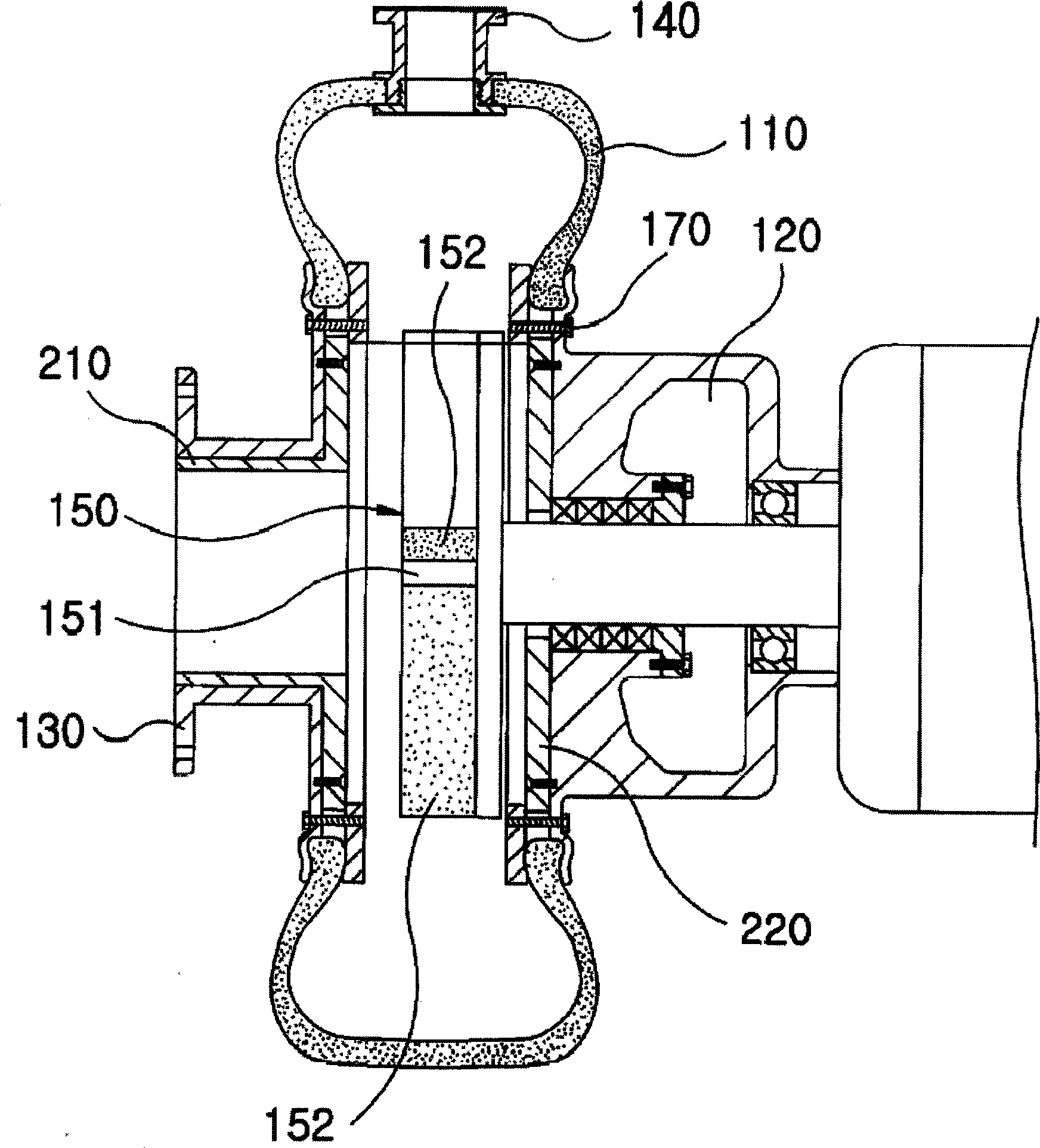

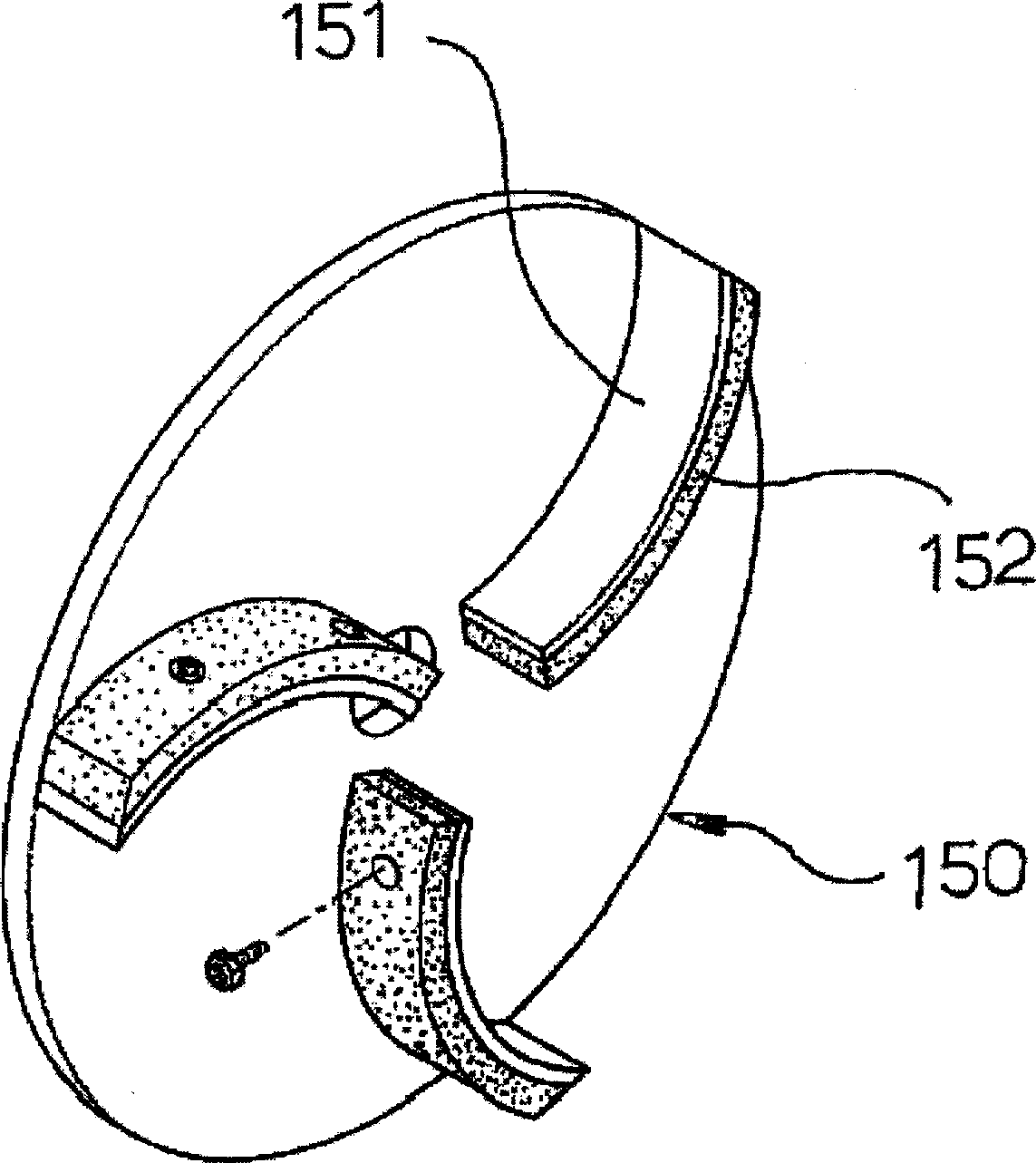

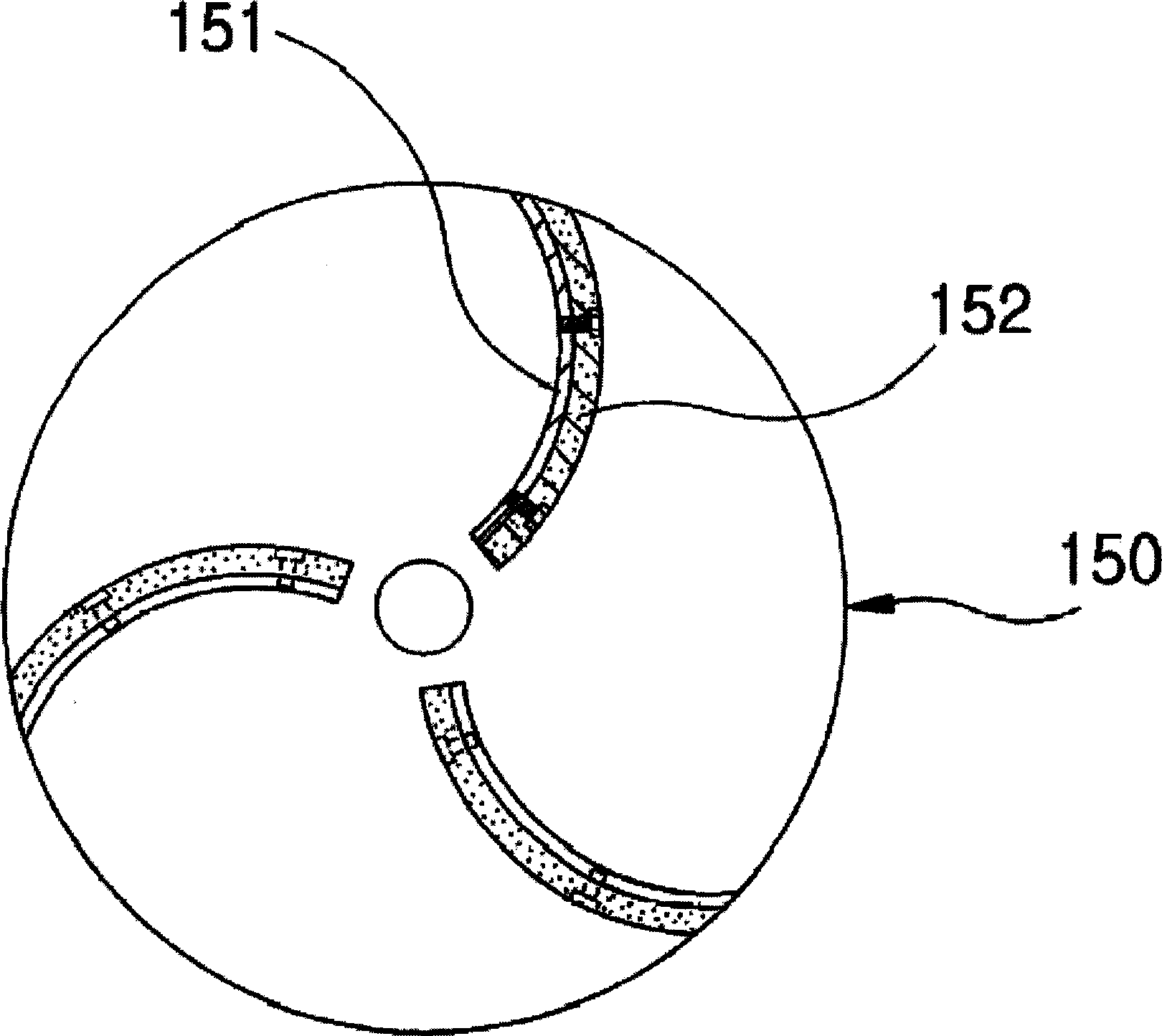

[0027] figure 1 is a sectional view of a pump according to a first embodiment of the present invention. Figure 2a with Figure 2b Respectively, a perspective view and a front view of the impeller of the present invention.

[0028] As shown, the pump of the present invention includes a housing 120 having an impeller 150 and a casing body 110 having an inlet and an outlet. In this case, the casing main body 110 is made of scrap tires that maintain their original shape. The inlet unit 130 is hermetically installed at the first opening at one side of the waste tire so as to function as an inlet of the casing main body 110 . The casing 120 is hermetically installed at the second opening opposite to the first hole on the other side of the waste tire, so that the impeller 150 is fixed inside the casing main body 110 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com