Large vertical fermentation tank with integrated pipe layout and pipe layout method thereof

A technology for fermentation tanks and vertical tanks, which is applied in the field of vertical large-scale fermentation tanks with integrated pipeline arrangement and its pipeline layout, which can solve the problems of increased pipeline stroke, complicated pipeline direction, and incomplete sterilization, etc., and achieves The effect of improving production efficiency, moving towards simplicity and rationality, and reducing the workload of pipeline installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

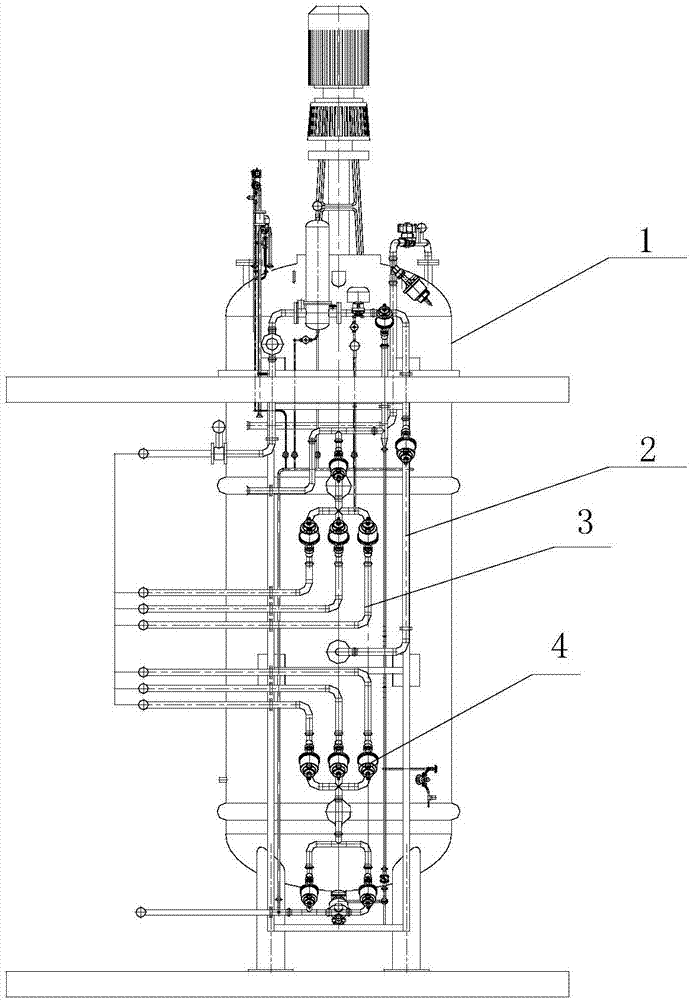

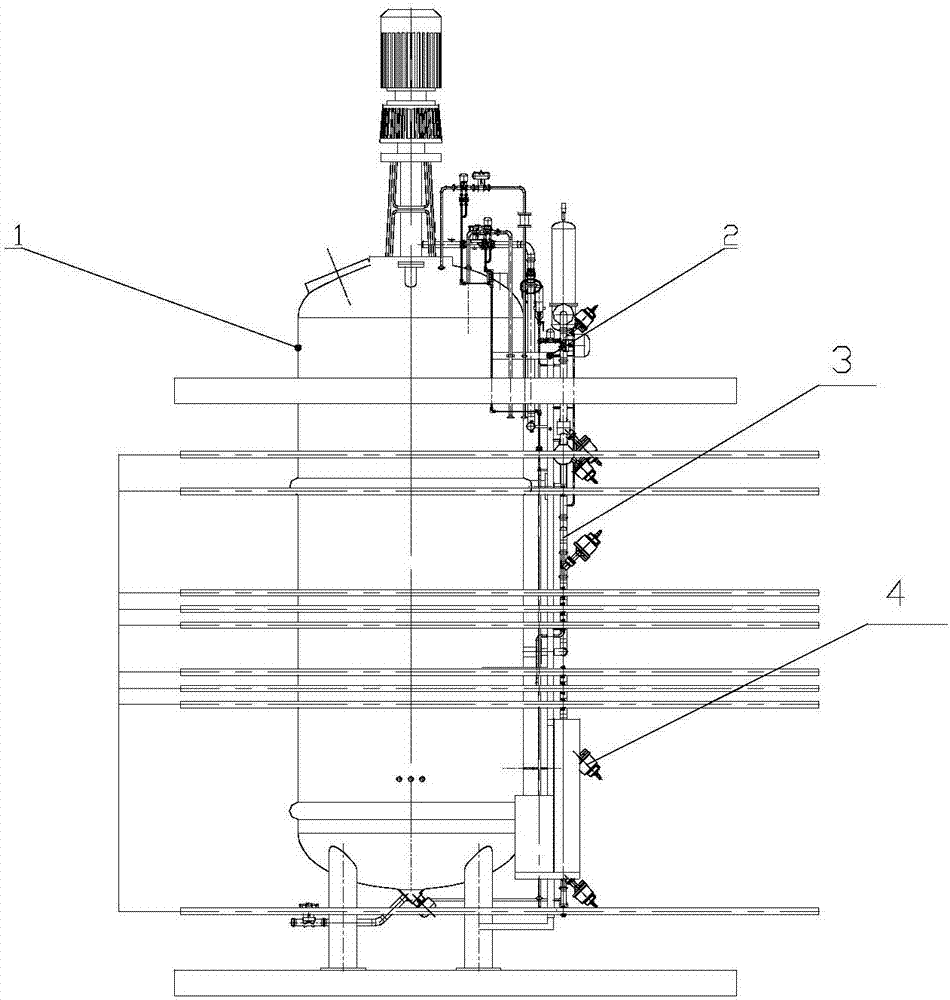

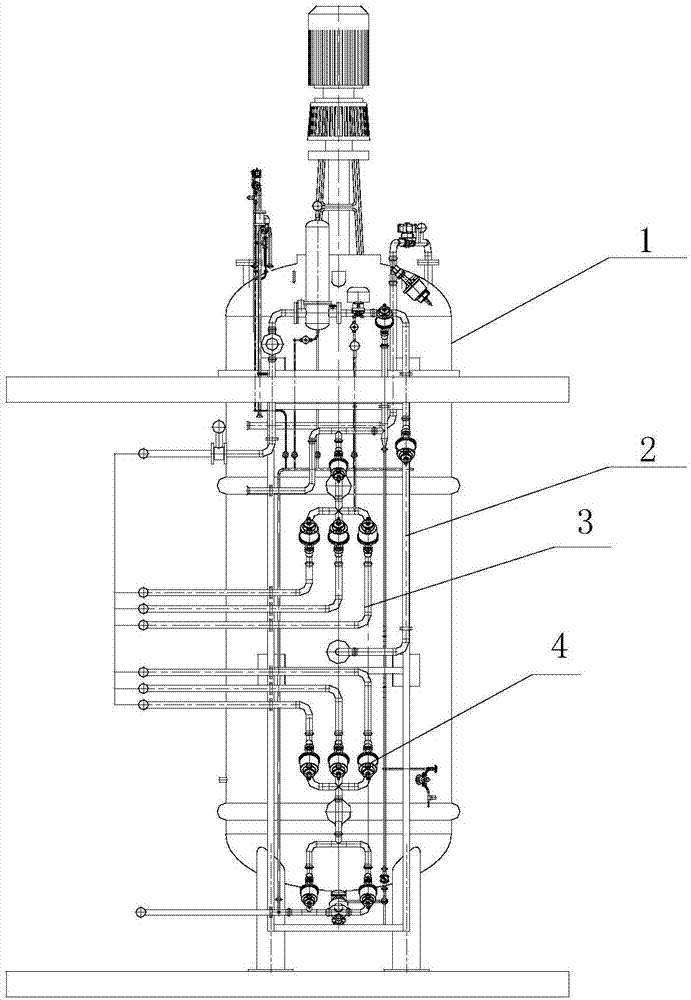

[0026] This embodiment is a vertical large-scale fermentation tank with an integrated pipeline arrangement, which is a fermentation tank with a volume of more than 5000L, and the structure is as follows figure 1 with figure 2 As shown, it includes a vertical tank body 1, and a vertical pipe frame 2 is provided on one side of the vertical tank body. There is an installation space between the vertical pipe frame 1 and the vertical tank body 2, and the vertical tank body has a Corresponding process pipelines 3 connected with various interfaces are fixed on the vertical pipe frame, and corresponding control valves 4 are installed on each process pipeline.

[0027] The vertical pipe rack in this embodiment includes a vertical frame and a horizontal support, one end of the horizontal support is fixedly connected to the vertical frame, and the other end is fixedly connected to the vertical tank body. The vertical frame is connected by square tubes to form a rectangular frame, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com