Power station boiler heating surface pipe outer diameter creep detector and creep measuring method

A technology of heating surface tubes and power plant boilers, which is applied to measuring devices, instruments, etc., to achieve the effects of easy operation, novel and unique structure, and good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

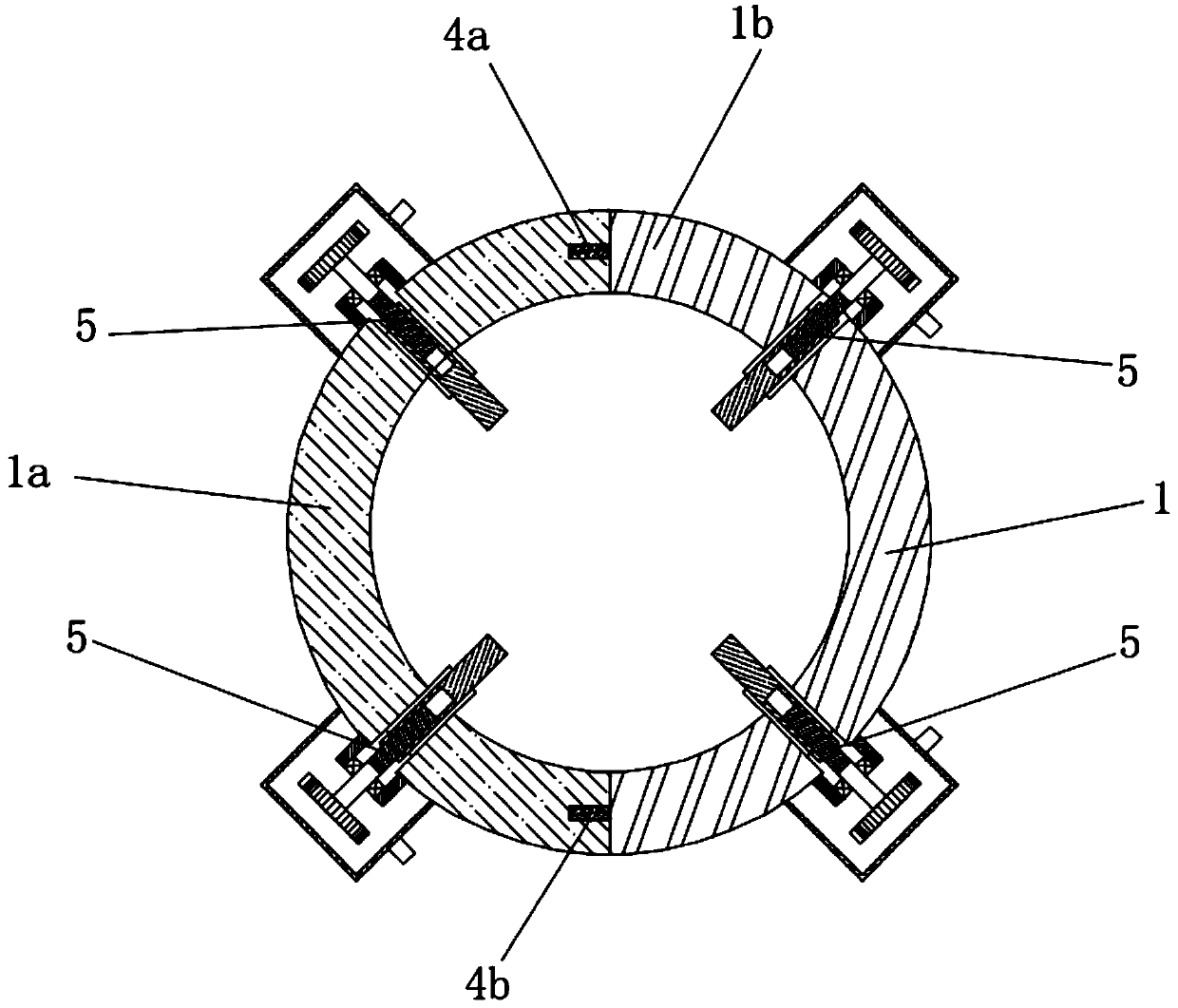

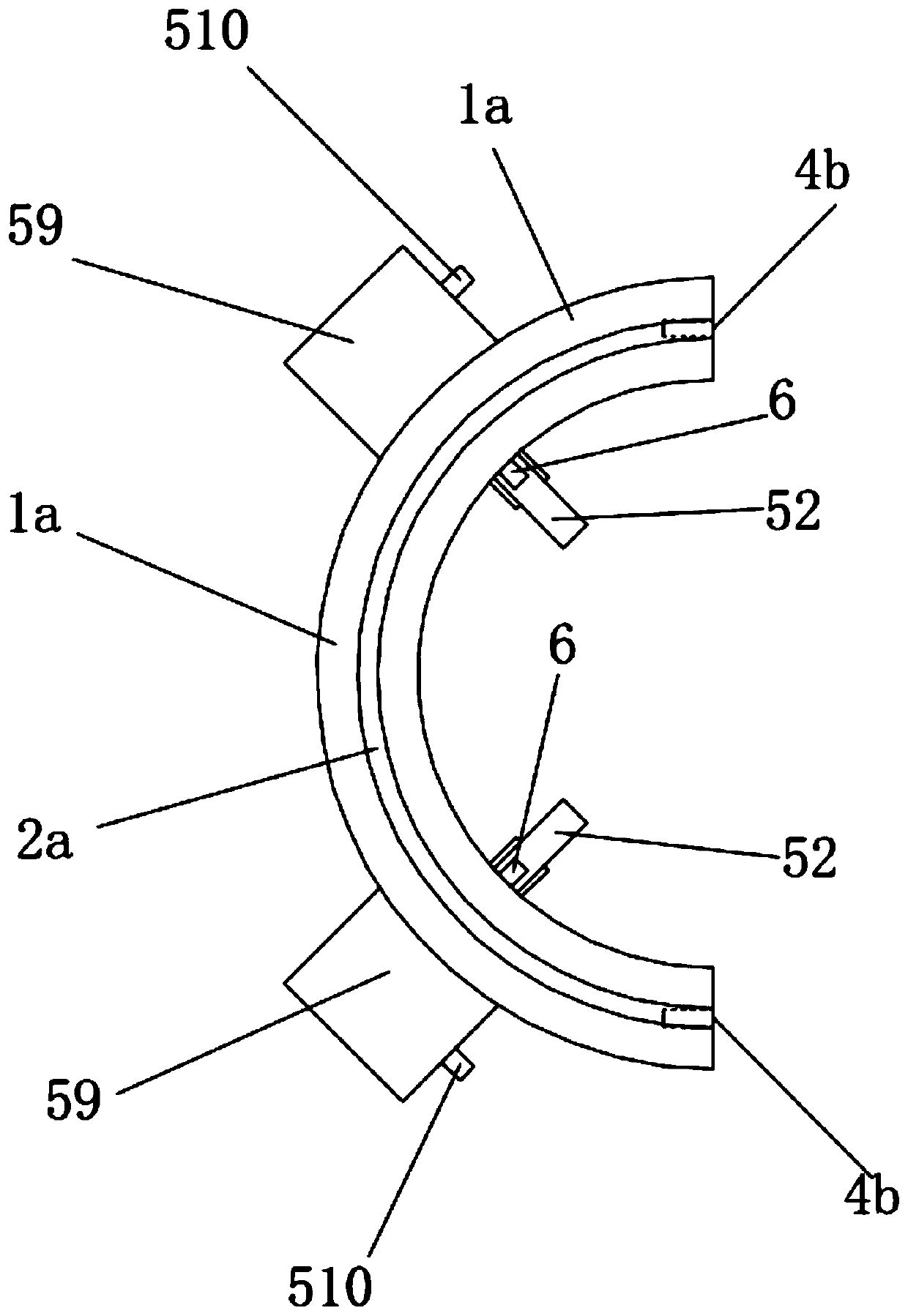

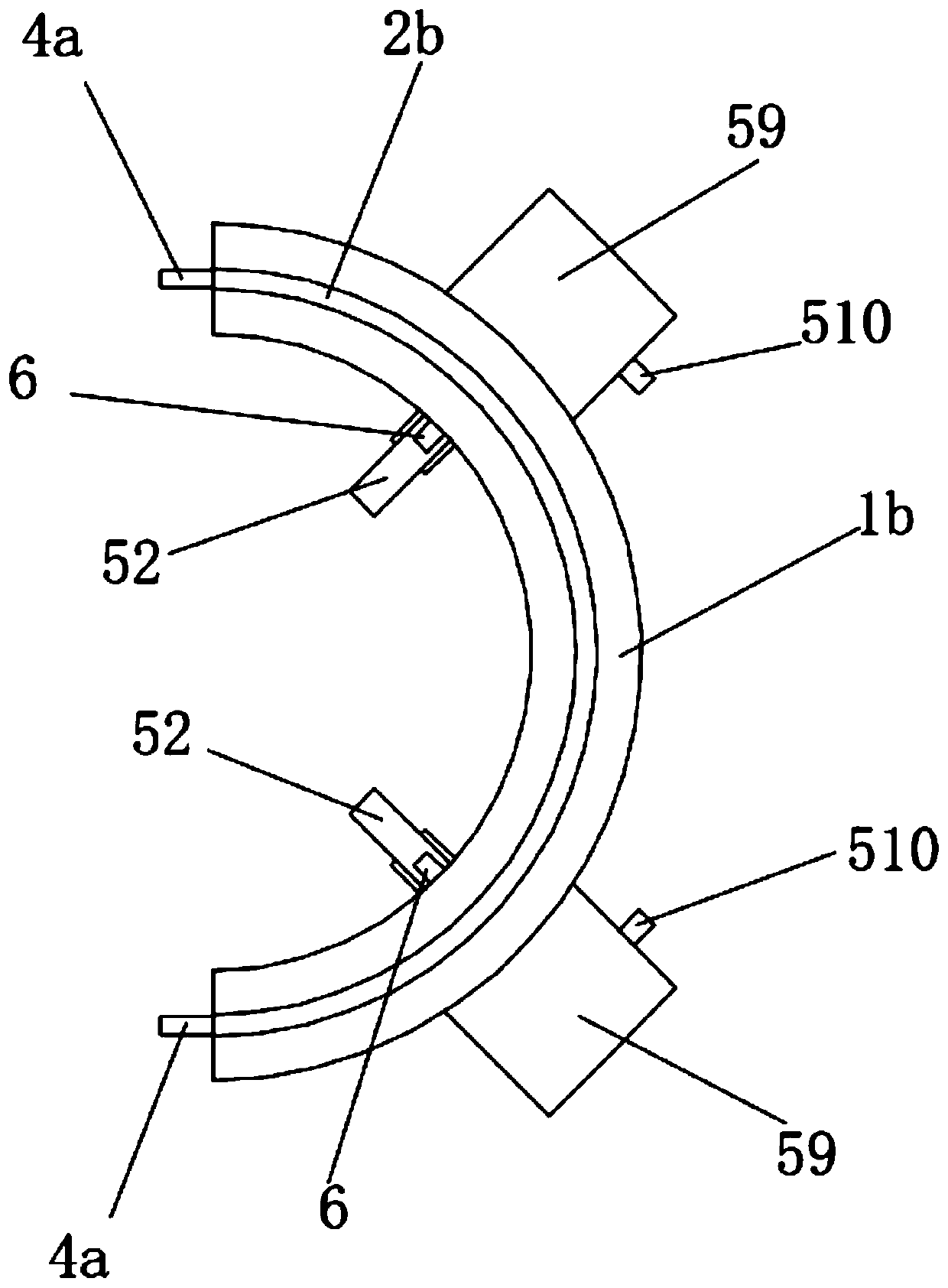

[0029] Depend on Figure 1-11 Given, the present invention includes a positioning sleeve 1 and a measuring sleeve 3. The positioning sleeve 1 is composed of a left semi-annular sleeve 1a and a right semi-annular sleeve 1b to form a circular tubular hollow structure, positioned along the same height There are four positioning mechanisms uniformly distributed in the circumferential direction of the sleeve for adjusting the position of the axis of the positioning sleeve. Each positioning mechanism includes a push rod 52 that expands and contracts radially along the positioning sleeve and a motor 511 that drives the push rod to expand and contract. The distance measuring sensor 6 for measuring the distance between the inner wall of the positioning sleeve and the outer wall of the pipeline to be measured is fixed on the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com