Vertical Hopkinson pressure rod test device and test method

A technology of Hopkinson pressure bar and test device, which is applied in the direction of measuring device, instrument, scientific instrument, etc., can solve the problems of low wave impedance material dynamic mechanical performance test, etc., achieve good social and economic benefits, easy experimental method, and protection environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

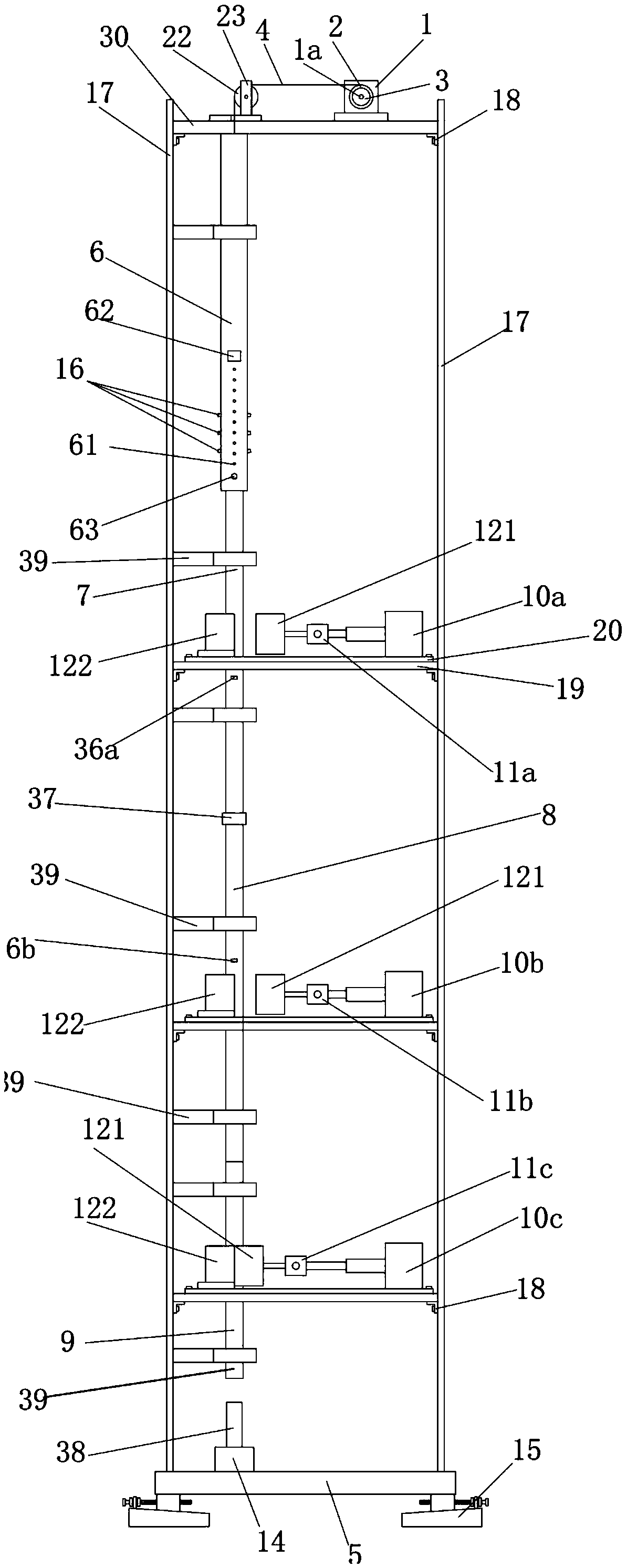

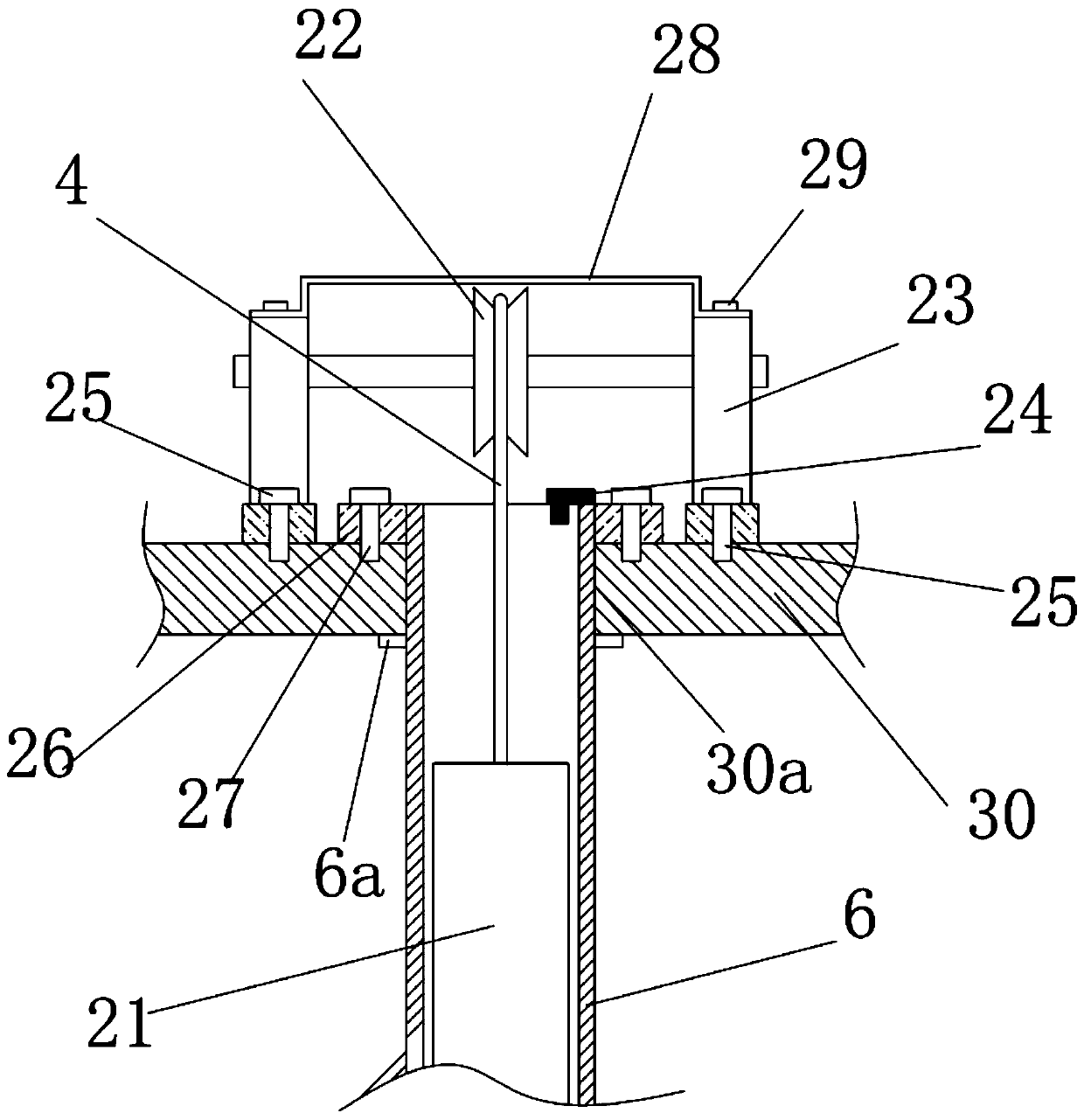

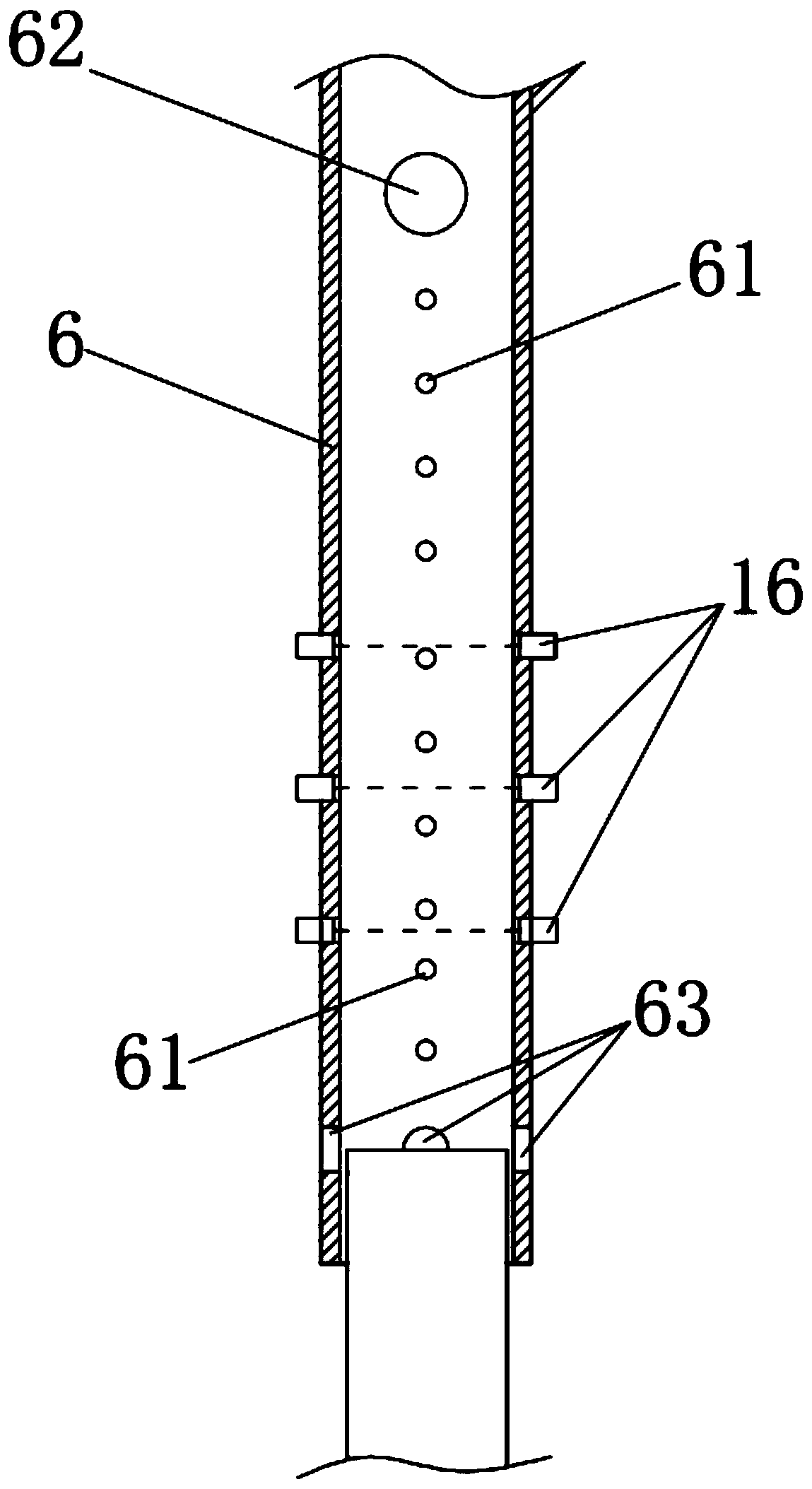

[0046] Depend on Figure 1-13 Given, the vertical Hopkinson compression bar test device of the present invention includes a guide cylinder 6, an incident rod 7, a transmission rod 8, a buffer rod 9 and a bullet 21, and the vertical Hopkinson compression bar test device also includes a base 5, Base 5 both sides symmetrically is equipped with the lateral support plate 17 that vertically is arranged upwards, the first horizontal support plate 30 of level is equipped with on the top between the lateral support plates of both sides, below the first transverse support plate 30, on both sides Three groups of horizontal second transverse support plates 19 are sequentially installed between the lateral support plates on the side. The first transverse support plate 30 is provided with a guide cylinder installation hole 30a that pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com