Low-resistance slow-closure type check valve

A check valve, low resistance technology, applied in valve details, control valves, valve devices, etc., can solve problems such as large head loss, abnormal noise, damage to system pipelines and testing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

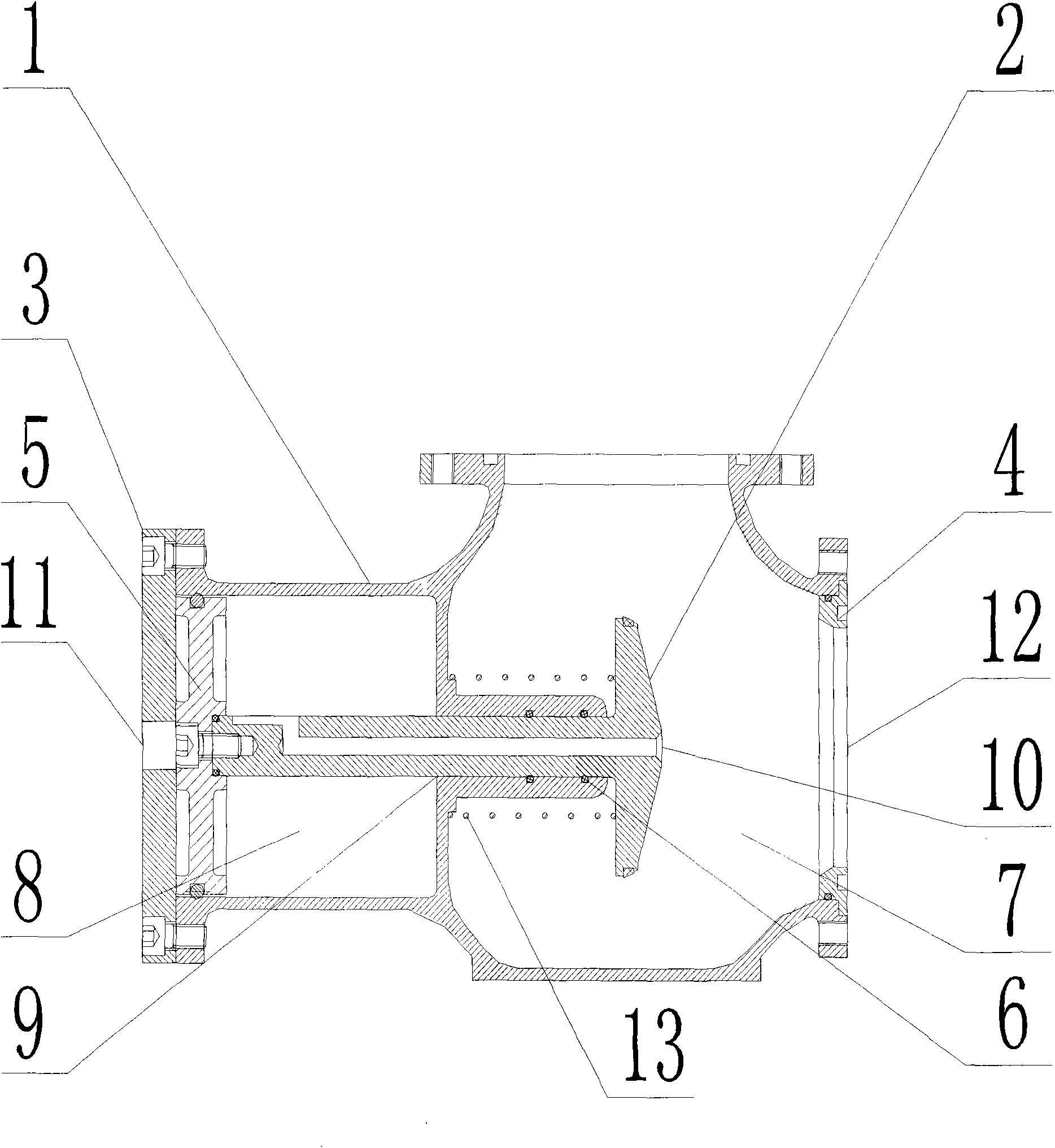

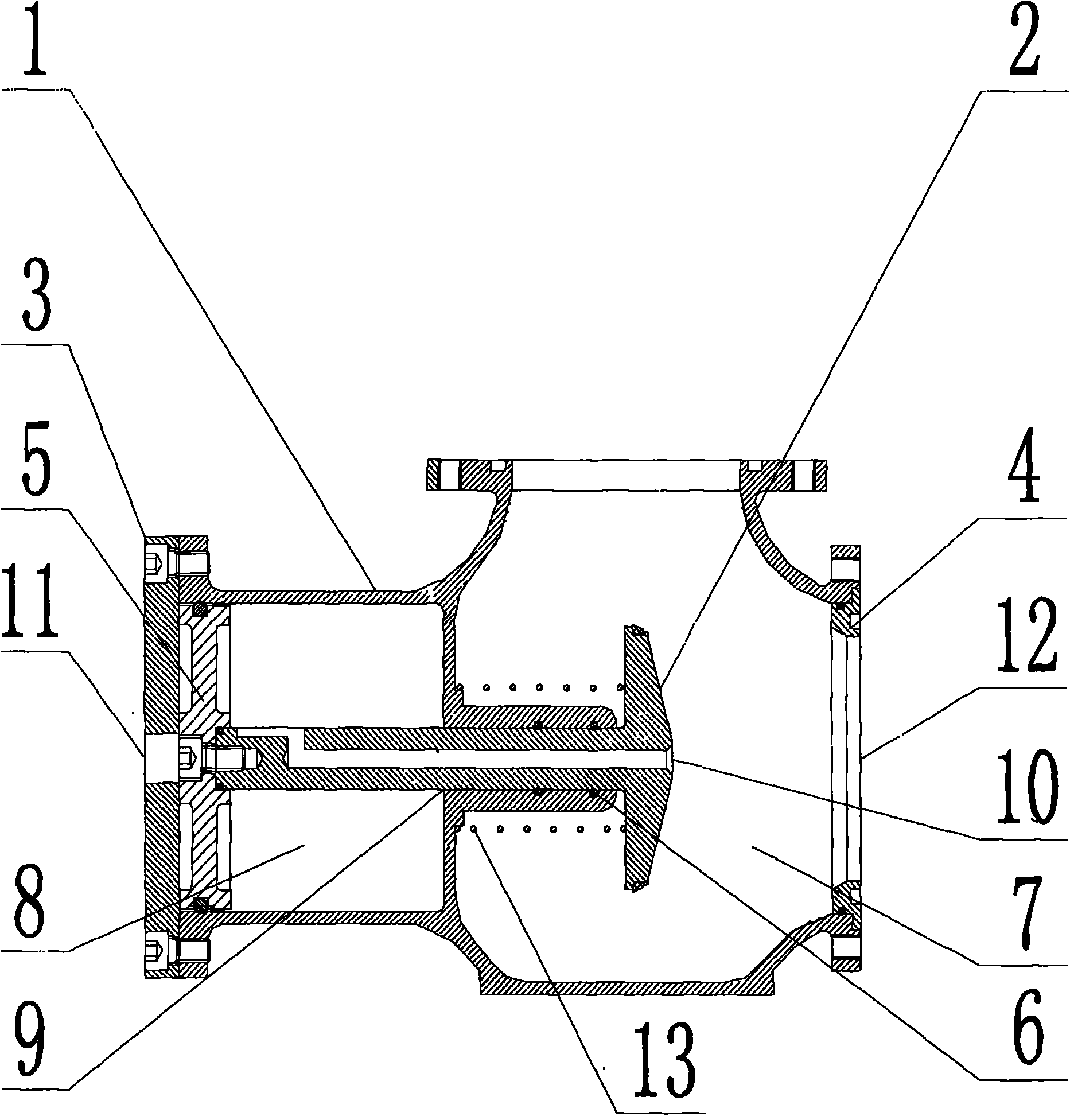

[0007] Low-resistance slow-closing check valve, including: valve body 1, valve disc 2, back cover 3, seal ring 4, piston 5, seal ring 6, valve body 1 is divided into flow chamber 7 and piston chamber 8, flow chamber 7 There is a connection hole 9 between the cavity 7 and the piston cavity 8, the shaft of the valve disc 2 can enter the piston cavity 8 through the hole 9, the shaft of the valve disc 2 enters the piston cavity 8 and connects with the piston 5, and the piston 5 The seal ring 6 is installed on the shaft of valve disc 2, and the seal ring 4 is installed at the water inlet 12, which solves the sealing problem. When the check valve is closed to supply water to the system, because there is a hole 10 on the disc 2, the high-pressure water will now enter the piston chamber 8 through the hole 10. There is an air circulation hole 11, so that the high-pressure water in the piston chamber 8 pushes the valve disc 2 to move forward, so that the water inlet 12 of the low-resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com