Bionic blade on basis of shark surface drag reduction technologies

A blade and technology technology, applied in the field of bionic blades, can solve the problems of reducing the thickness of the boundary layer on the surface of the fan blade, reducing the friction of the blade surface, ignoring the impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

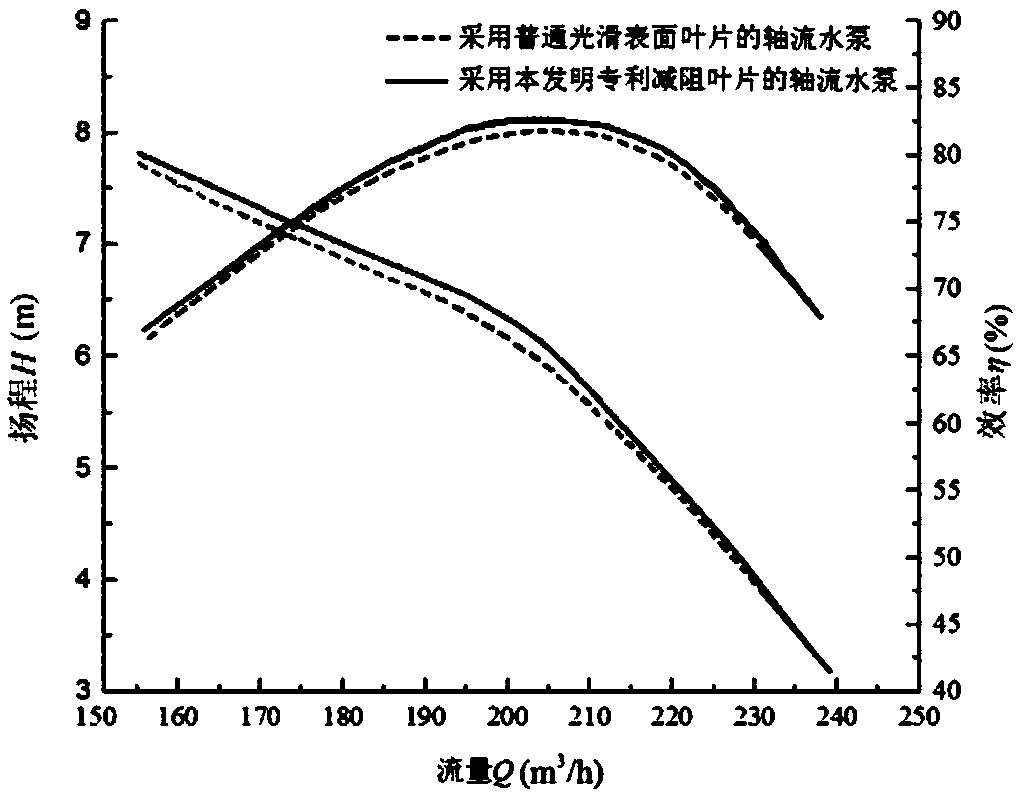

[0022] An axial flow water pump with a specific speed of 650, its design parameters are: design flow Q d =200m 3 / h, head H=6m, rotational speed n=2900r / min, impeller diameter 150mm, chord length at blade rim l 0 =83.64mm, chord length l at the hub 01 =63.46mm.

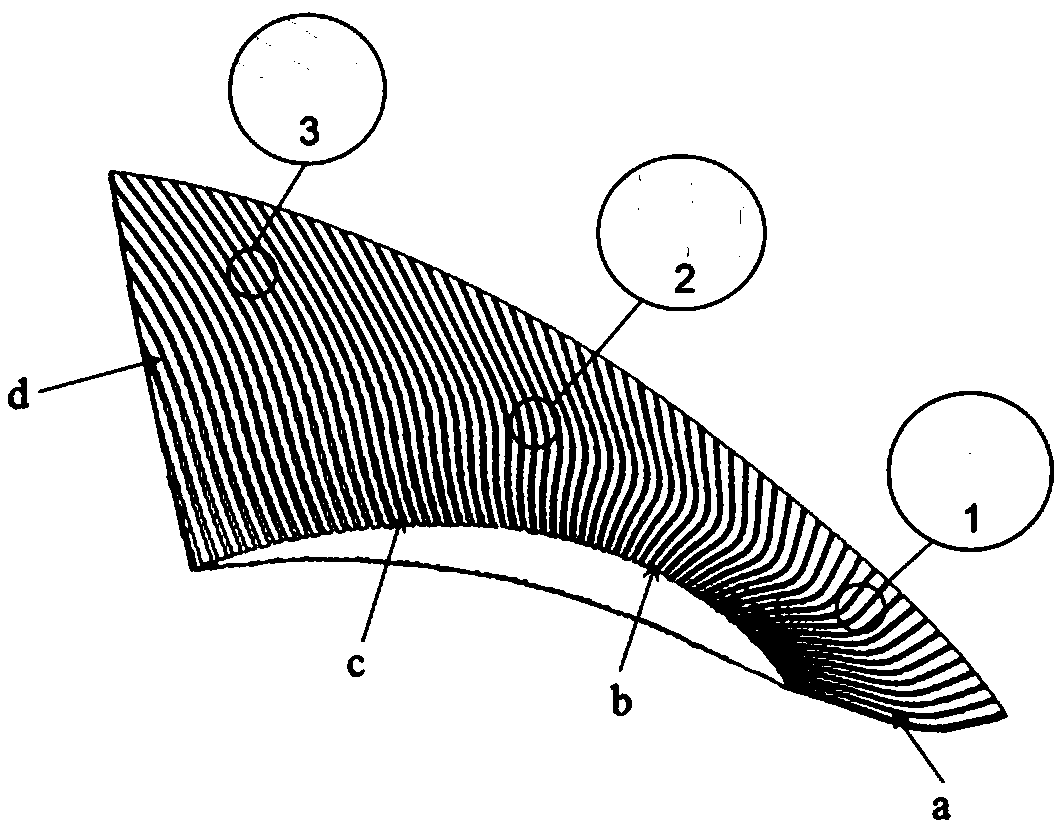

[0023] Blade rim inlet placement angle β 1 =11.5°, outlet placement angle β 2 =13.4°; Angle of attack at the blade rim α 1 =3°; the placement angle at the inlet of the blade hub β 12 =21.3°, exit placement angle β 22 =39.8°; Angle of attack at the blade hub α 2 = 1°; the parameters of the transition section from the rim to the hub adopt a linear transition.

[0024] The drag reducing section at the leading edge is the working surface of the blade with scalloped drag reducing grooves, and the scalloped drag reducing grooves are smaller.

[0025] According to the calculation of the average velocity v of the flow field in the drag reduction section of the leading edge 1 =20.18m / s, the surrounding humidity c on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com