Inclined type water turbine with adjustable jetting angles and multiple nozzles

One-type turbine and multi-nozzle technology, applied in impact engine, hydroelectric power generation, mechanical equipment, etc., can solve the problems of reducing turbine efficiency, unstable water resources, unstable turbine operation, etc., to improve flow and output, energy efficiency Maximize and improve the effect of the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

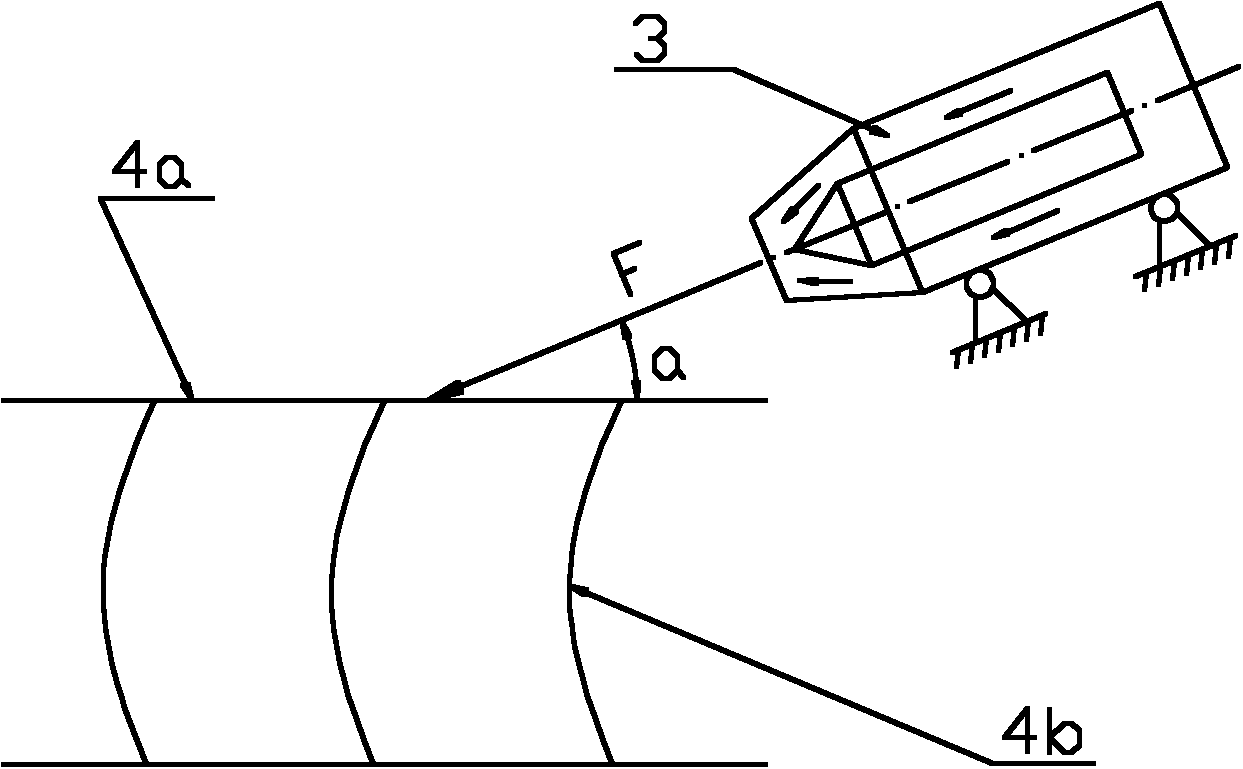

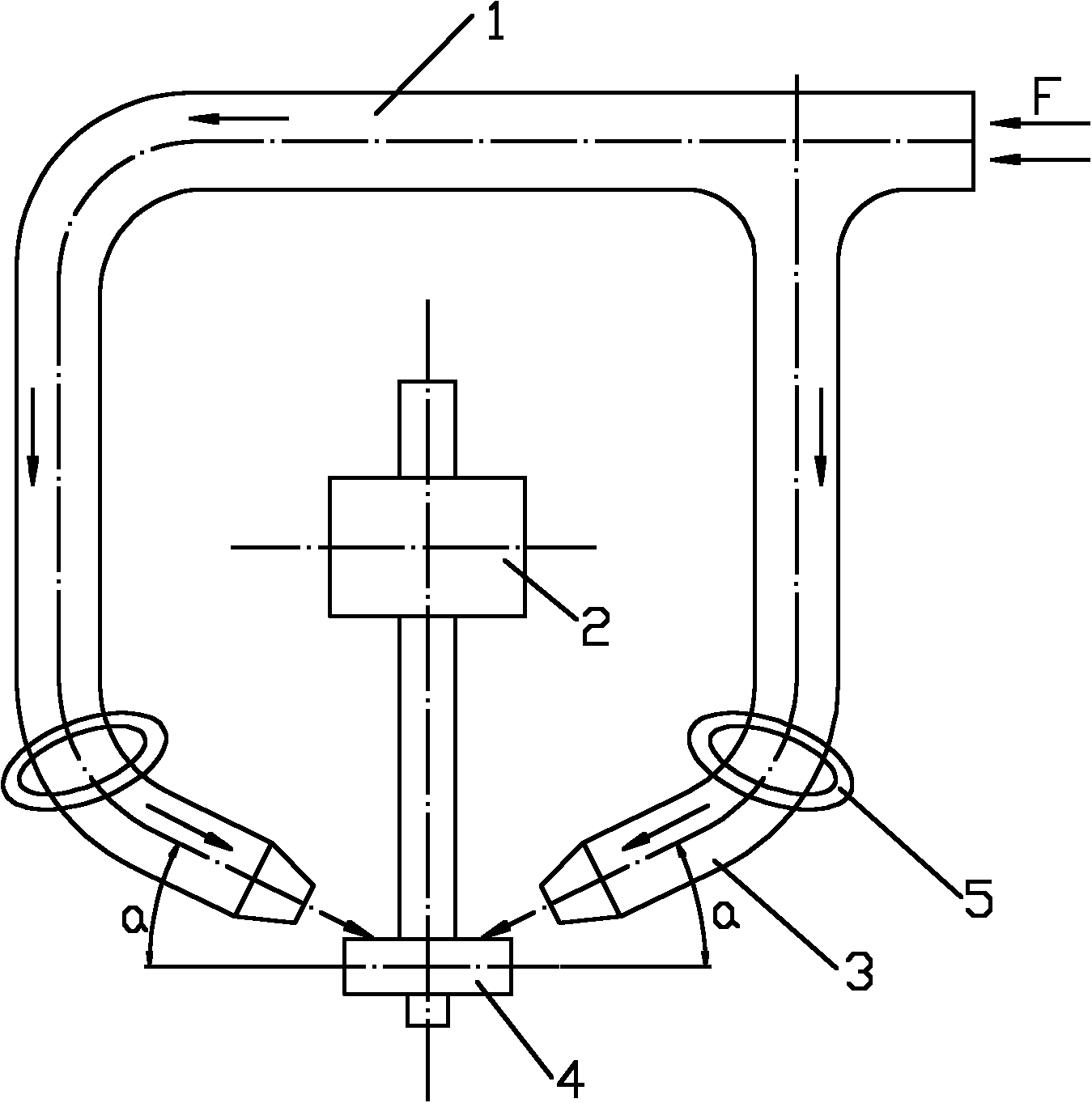

[0035] In this example, the multi-nozzle slanting water turbine with adjustable jet angle includes a water diversion pipe 1, a plurality of nozzles 3 connected with the water diversion pipe 1 and a runner 4, and the nozzles 3 are rotatable. The rotation angle b of the nozzle 3 is 5.5 degrees to 6.5 degrees, and the included angle a between the water jet direction F of the nozzle 3 and the horizontal plane 4a of the runner 4 is 17 degrees to 25 degrees.

[0036] Usually, 2 to 6 nozzles 3 can be arranged, and they are evenly and symmetrically arranged above the circular plane of the runner 4. When the turbine is running, the angle a between the water jet direction F of each nozzle 3 and the horizontal plane 4a of the runner 4 is the same , and rotate at the same time or synchronously; according to the size of the running water, different numbers of nozzles 3 can be opened. When opening, the symmetrical position of the nozzles 3 should be opened as much as possible. The angle a b...

Embodiment 2

[0044] Same as Embodiment 1, the multi-nozzle slanting impact water turbine with adjustable jet angle includes a water diversion pipe 1, a plurality of nozzles 3 communicated with the water diversion pipe 1 and a runner 4, and the nozzles 3 are rotatable. The rotation angle b of the nozzle 3 is 5.5 degrees to 6.5 degrees, and the included angle a between the water jet direction F of the nozzle 3 and the horizontal plane 4a of the runner 4 is 17 degrees to 25 degrees.

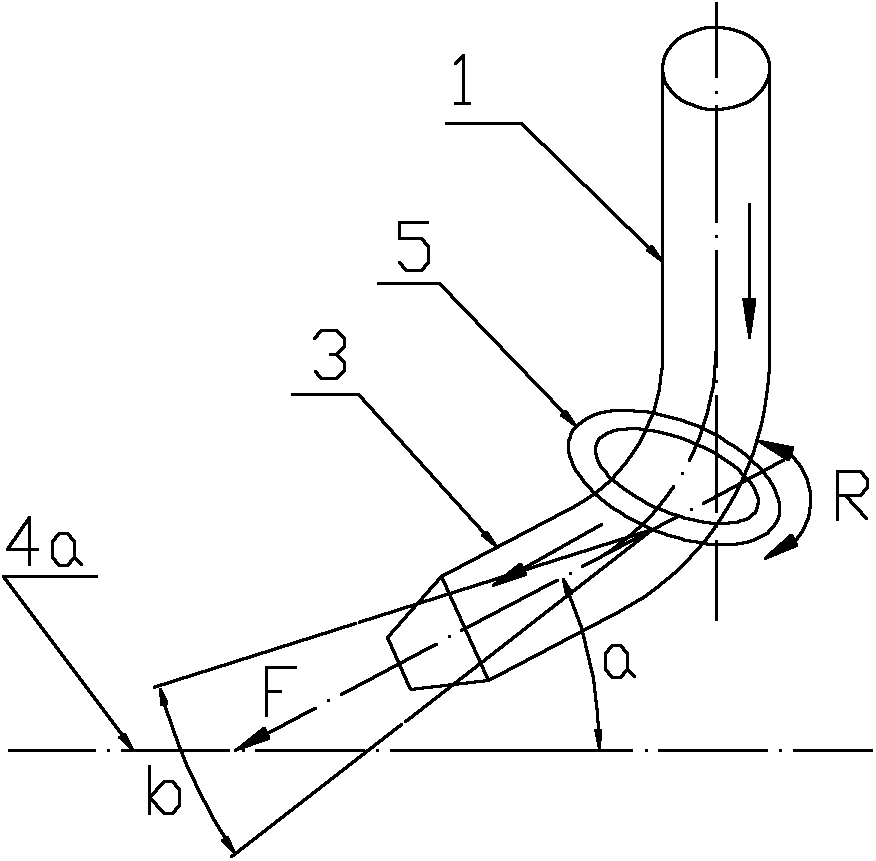

[0045] This example adopts the flange rotation connection structure, and the rotation connection 5 is set at the connection position between the water diversion pipe 1 and the nozzle 3. Usually, the runner 4 is connected with the motor 2 in the design of a water turbine. In this example, the connection 5 between the water diversion pipe 1 and the nozzle 3 is arranged at On the road, and through the flange connection, the flange connection has the usual sealing and other structures, in order to realize the rotatio...

Embodiment 3

[0048] Same as Embodiment 2, the multi-nozzle slanting impact water turbine with adjustable jet angle includes a water diversion pipe 1, a plurality of nozzles 3 communicated with the water diversion pipe 1 and a runner 4, and the nozzles 3 are rotatable. The rotation angle b of the nozzle 3 is 5.5 degrees to 6.5 degrees, and the included angle a between the water jet direction F of the nozzle 3 and the horizontal plane 4a of the runner 4 is 17 degrees to 25 degrees.

[0049] This example adopts the embedded sliding sleeve rotating connection structure, and the rotating connection 5 is set at the connection position between the water diversion pipe 1 and the nozzle 3. Usually, the runner 4 is connected to the motor 2 in the design of a water turbine. In this example, the nozzle 3 and the water diversion pipe 1 are extended and connected Form the same bend as in Example 2. The straight pipe at the connection end is embedded in the water diversion pipe 1 and can rotate axially ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com