Method for designing centrifugal impeller splitter blade

A splitter vane and design method technology, applied to components of pumping devices for elastic fluids, mechanical equipment, non-variable pumps, etc., can solve the two halves that cannot be equal, lack of theoretical support, and splitter vane structural form Insufficient design methods and other problems, to achieve the effect of increasing head and efficiency, reducing hydraulic loss, and improving velocity distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

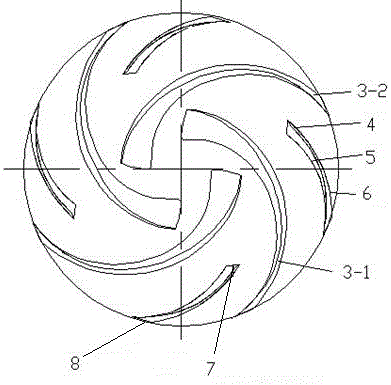

[0018] see figure 1 , the splitter blade 4 in the centrifugal impeller is between two adjacent long blades, the splitter blade 4 is composed of the working surface 5, the back side 6, the inlet side 7, and the outlet side 8, and the working surface 5 is facing the center of the centrifugal impeller The side of the axis Z, the back 6 is the side opposite to the working surface 5 away from the central axis Z, the inlet edge 7 is close to the end of the central axis Z, and the outlet edge 8 is away from the end of the central axis Z.

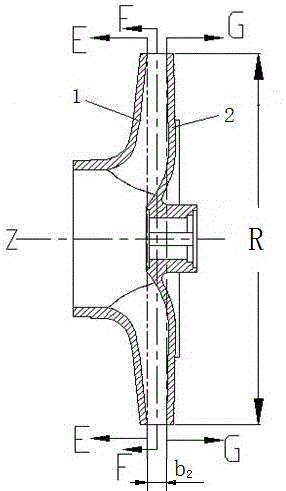

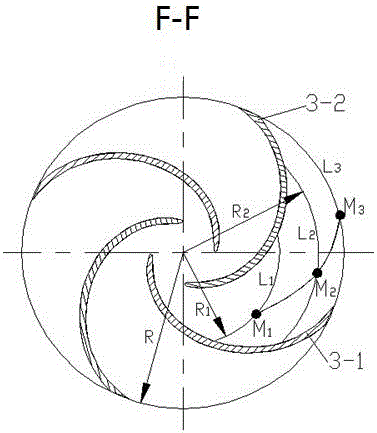

[0019] see figure 2 , The exterior of the centrifugal impeller is composed of a front cover 1 and a rear cover 2, and the splitter blade 4 is located between the front cover 1 and the rear cover 2. In the axial direction of the impeller, the long blades and splitter blades 4 are connected to the front shroud 1 and the rear shroud 2 respectively. In the centrifugal impeller, it is determined that there are three radial cross-sections perpendicula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com