Screwing opening type check valve capable of balancing pressure automatically

An automatic balance and swing-type technology, applied in the direction of valve details, control valves, valve devices, etc., can solve problems such as increased hydrostatic pressure, water hammer in the pipeline system, and long backflow time, so as to improve life and solve problems. High temperature resistance, the effect of protecting the safety of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

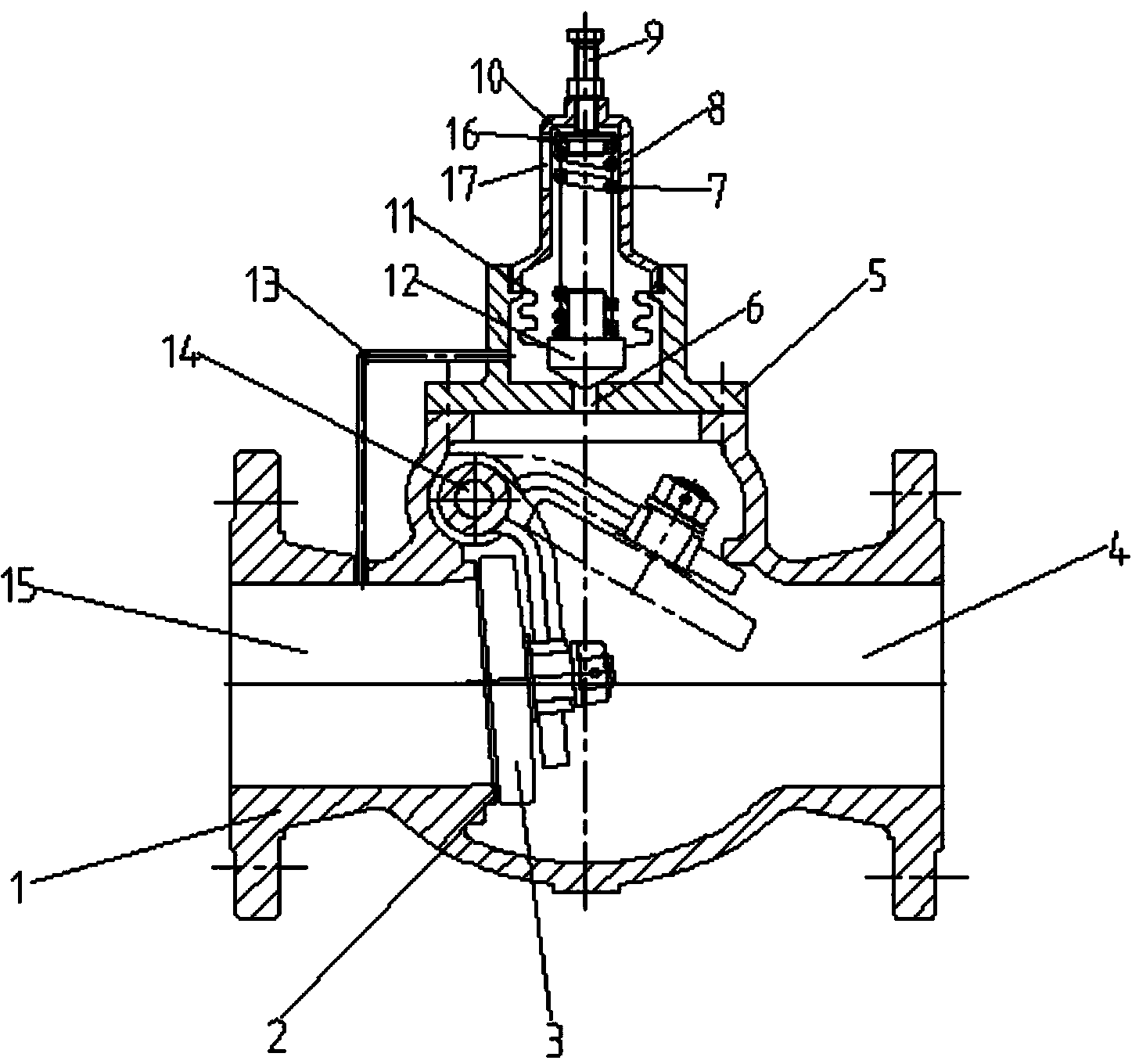

[0020] A swing check valve with automatic pressure balance, its structure is as follows: figure 1 As shown, it mainly includes a valve body 1, a valve cover 5, a spring cover 8, a spring 7, a valve core 12, a bellows 11, and a connecting pipe 13. There are inlet 15 and outlet 4 whose axes are on the same horizontal line at both ends of the valve body 1. There is a valve seat 2 on the side facing the outlet 4 in the valve body 1. There is a horizontal plane perpendicular to the axis of the inlet and outlet above the valve seat 2 in the valve body 1. The valve shaft 14 is hinged with the valve disc 3 matching with the valve seat 2 in the valve body 1 and on the valve shaft 14 , and the valve cover 3 is arranged on the upper side of the valve body 1 . There is a drainage hole 6 at the center position of the bottom of the valve cover 3, and a spring cover 8 is connected on the top of the valve cover 5. One side above spring cover 8 has U-shaped mouth 17, is provided with spring 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com