Full automatic double-head word pressing machine for clamping piece

A type press, full-automatic technology, applied in the field of type presses, can solve problems such as danger, punch presses, unsafety, etc., and achieve the effects of high production efficiency, reduced safety problems, and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

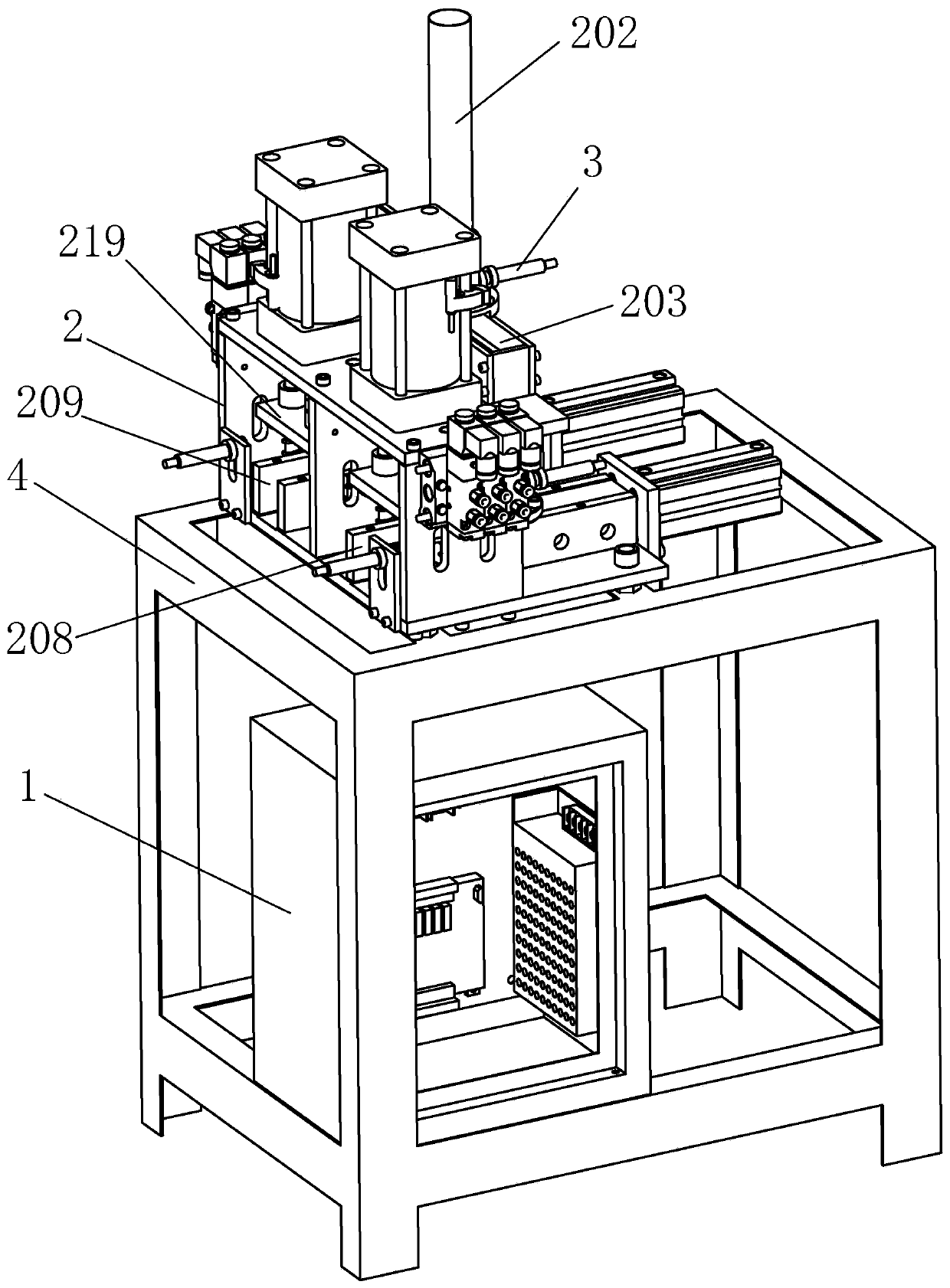

[0025] A full-automatic double-head embossing machine with clips, including a support frame, a double-head embossing mechanism, an electric box, and a sensor. The press mechanism and the sensor are respectively connected with the electric box.

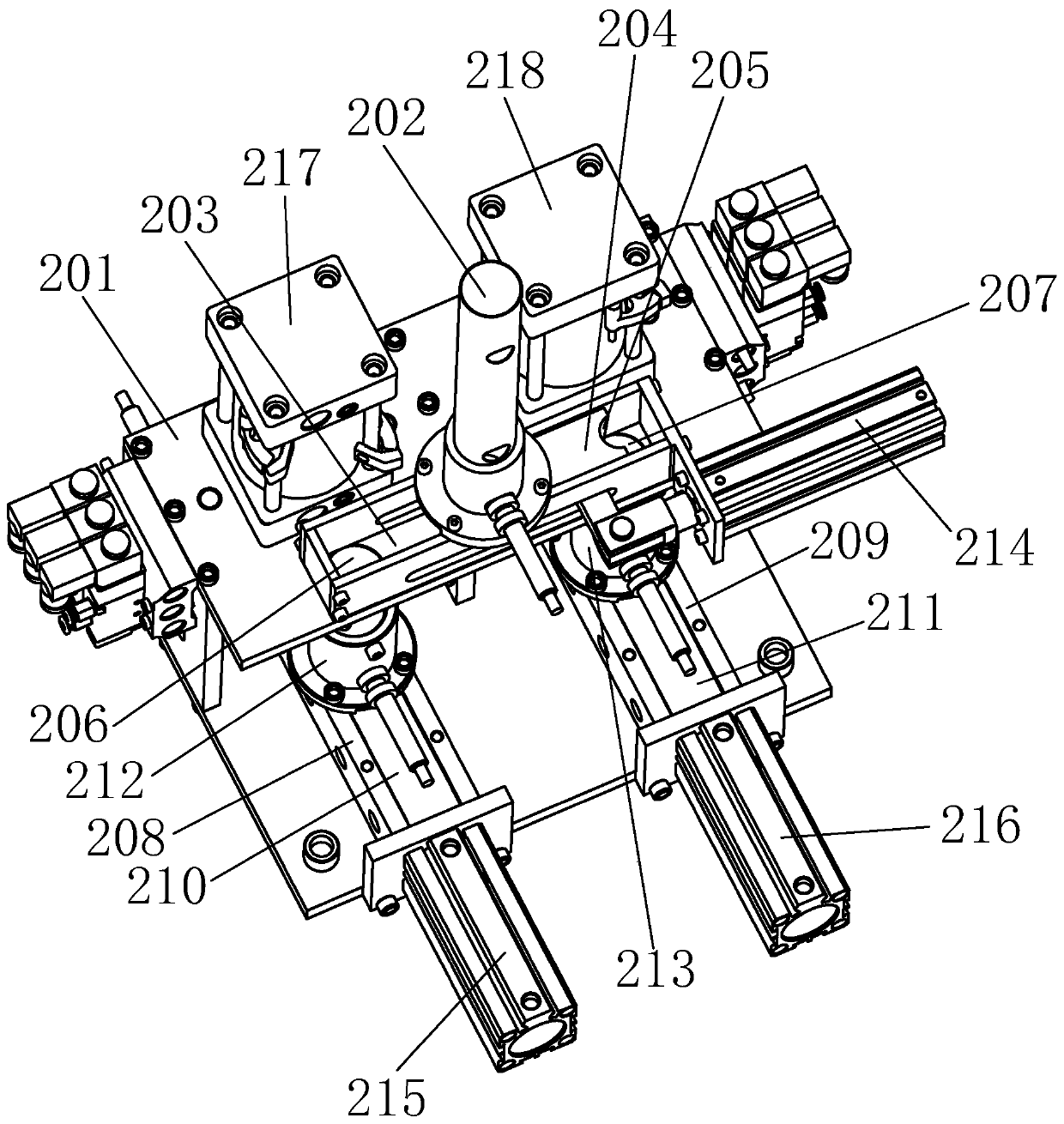

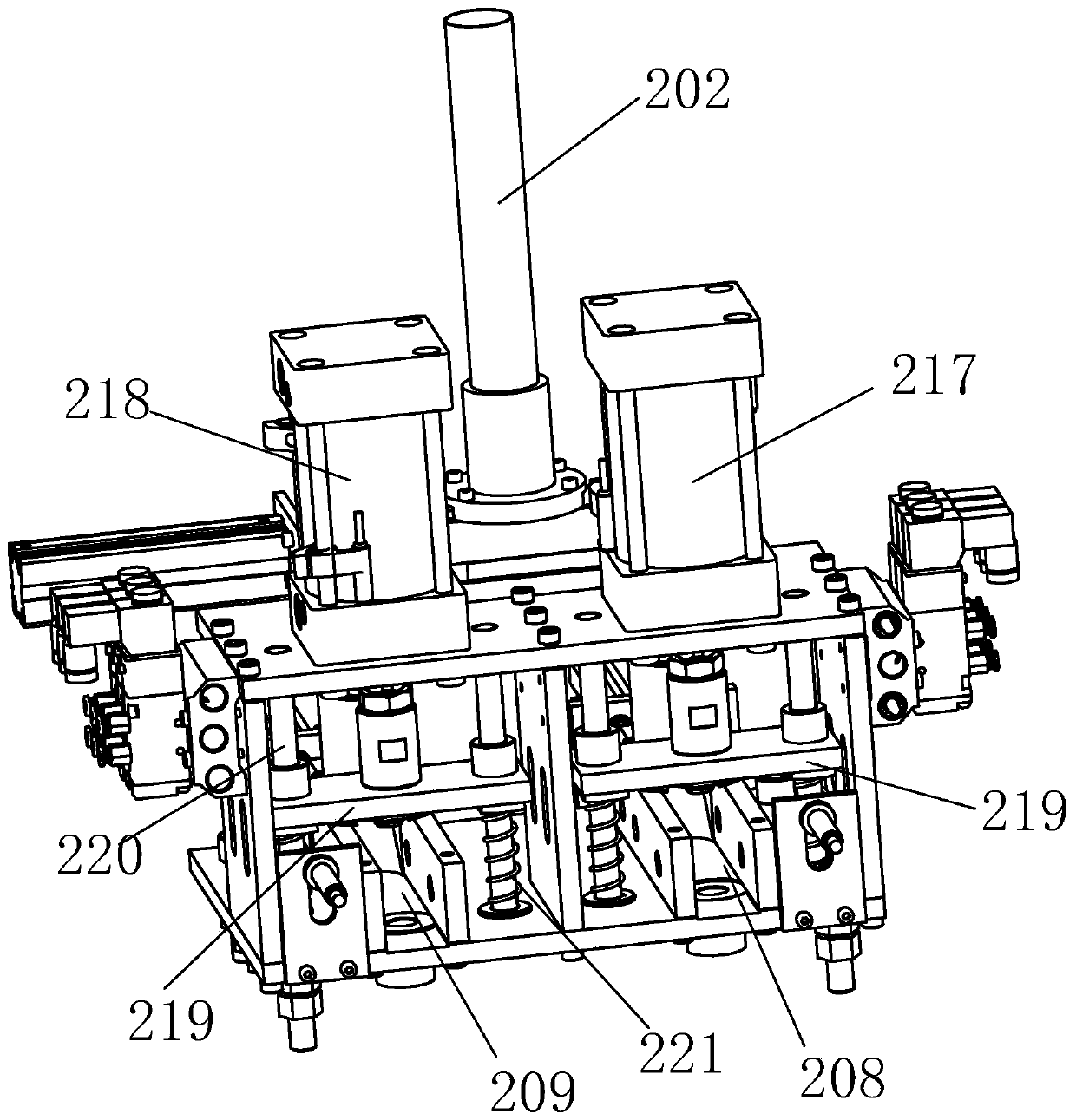

[0026] The double-head embossing machine mechanism includes a fixed frame, a feeding pipe, a guide groove, a pushing plate, a guiding pipe, a pushing block, a letterpress and a cylinder, and the described feeding pipe, the guiding groove, the pushing plate, The guide pipe, the pushing block, the pressure plate and the cylinder are arranged on the fixed frame respectively, and the guide groove includes guide groove I, guide groove II and guide groove III, and the guide groove II and guide groove III are respectively located in the guide groove Below I, the two ends of the bottom plate of guide groove I are respectively provided with blanking holes, and the two blanking holes are respectively connected with guide groove II and guide groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com