Permanent magnet coupling

A technology of permanent magnetic coupling and permanent magnetic block, which is applied in the direction of permanent magnetic clutch/brake, electric brake/clutch, electrical components, etc., and can solve problems such as sparks, steel plate heating, and permanent magnetic coupling burning , to achieve active use, reduce operating temperature, and improve heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

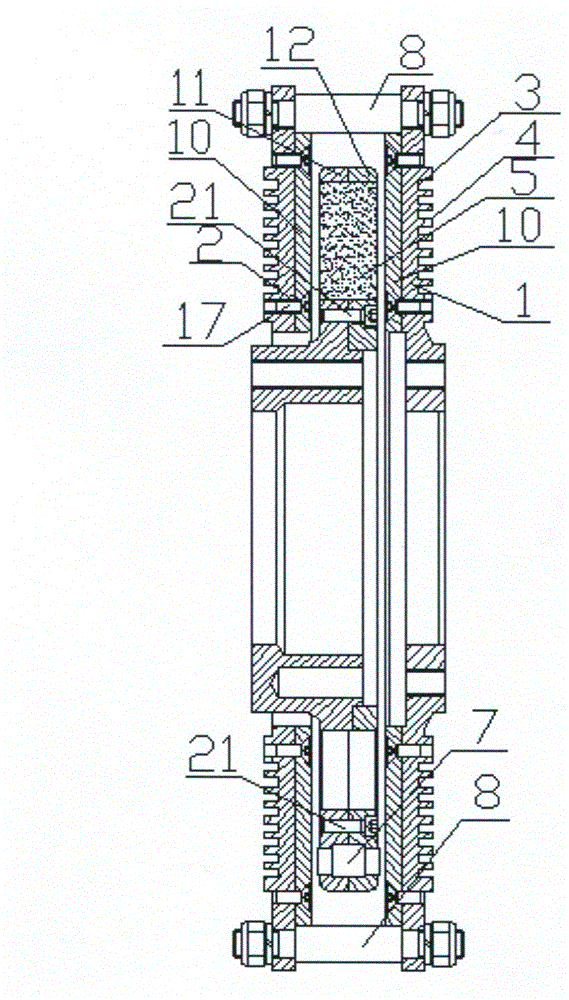

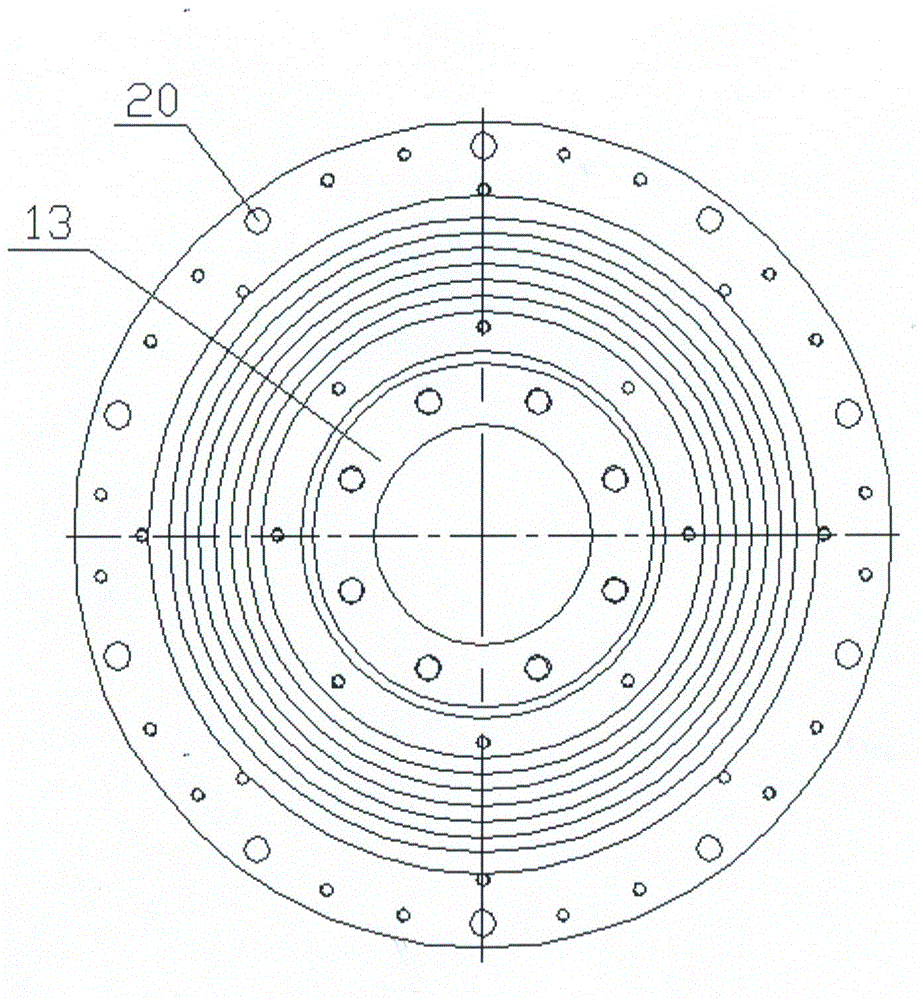

[0024] Referring to the accompanying drawings, figure 1 The main drawing (designated as the accompanying drawing of the abstract of the specification), figure 1 The left side is the load side, which is connected with the reducer, and the right side is the motor side. A plurality of neodymium-iron-boron permanent magnet blocks 5 of the permanent magnet coupling are made into a trapezoidal shape, and are embedded in the trapezoidal groove 18 on the disk. Compared with the existing rectangular permanent magnet block, the trapezoidal permanent magnet block 5 can fully Utilizing the area of the disk improves the utilization rate of the effective area of the disk, and has the effect of obviously increasing the area of the permanent magnet block and increasing the magnetic flux.

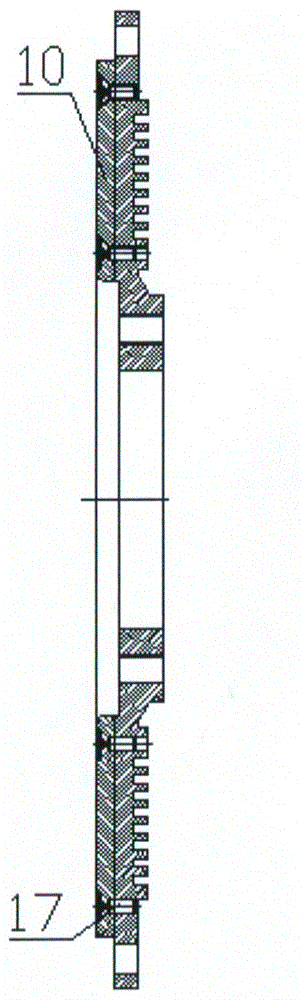

[0025] The main disk 11 and the auxiliary disk 12 are fastened and assembled, and are fastened by cylindrical head screws 21 to form a permanent magnet rotor; the main disk 11 is provided with a main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com