Rope arranging detection device used for multi-rope winding type elevator

A detection device and hoist technology, used in elevators, transportation and packaging, etc., can solve the problems of asynchronous wire ropes, lack of detection devices, etc., to achieve the effect of not easy to block, ensure sensitivity, flexible and reliable rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

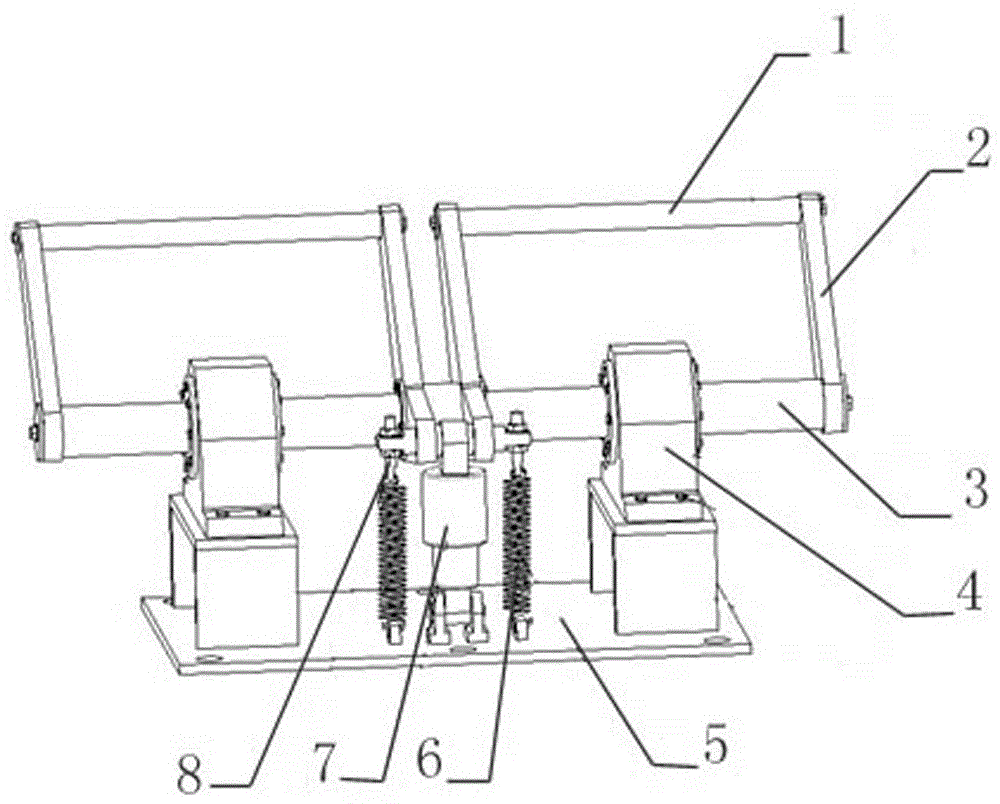

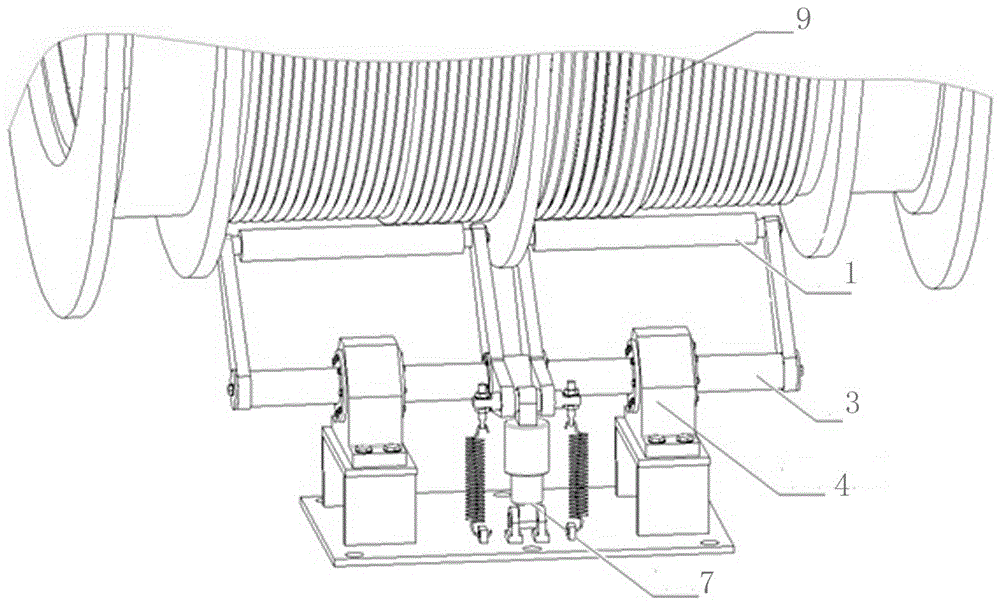

[0020] Embodiment 1: As shown in the figure, a rope detection device for a multi-rope winding hoist, the bottom 5 is installed on the machine room foundation below the hoist drum 9 with expansion bolts, and the bottom 5 is installed on the base 5. There is a pair of rolling bearings 4, a hydraulic cylinder 7 is arranged between the rolling bearings 4, the bottom of the hydraulic cylinder 7 is set on the base 5 through the rotation of the pin shaft, and the support composed of the rotating shaft 3, the connecting rod 2 and the pressing rod 1 is set on the rolling bearing 4, Wherein, the rotating shaft 3 is fixed on the inner ring of the rolling bearing 4, and is fixedly connected with two pressing rods 1 parallel to the rotating shaft 3 through the connecting rod 2 perpendicular to the rotating shaft 3, and the two ends of the pressing rod 1 are connected to the connecting rods 2 respectively. , there is a certain gap between the two pressure rods 1, and the body of the pressure...

Embodiment 2

[0022] Embodiment 2: On the basis of Embodiment 1, this structure can be used in all the specifications of the multi-rope winding hoist, but the lengths of the pressure rods used in different specifications are different. For example: JKD-4×1.9, the diameter of the drum is 4m, the diameter of the wire rope is 45mm, the length of the connecting rod of the rope detection device is 300mm, and the adjusted length of the hydraulic cylinder is 200mm. Then it can be known by calculation that the distance between the pressure bar in the detection device and the outermost steel wire rope or the outer layer rope lining of the drum needs to be adjusted to be 22.5 mm; each additional layer of the drum steel wire rope requires a rotation angle of At this time, when the first layer is wound, it is necessary to set the adjustment amount of the oil cylinder to 200sin4.3=15mm; when the second layer is wound, it is necessary to set the adjustment amount of the oil cylinder to 215sin4.3=16.1mm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com