Frequency conversion type intelligent type valve actuator

A valve execution and intelligent technology, applied in the direction of valve details, valve devices, mechanical equipment, etc., can solve the problems of application limitations, motor temperature rise, precision distortion, etc., achieve high-precision position continuous detection, simplify the structure of the actuator, The effect of continuously adjustable running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

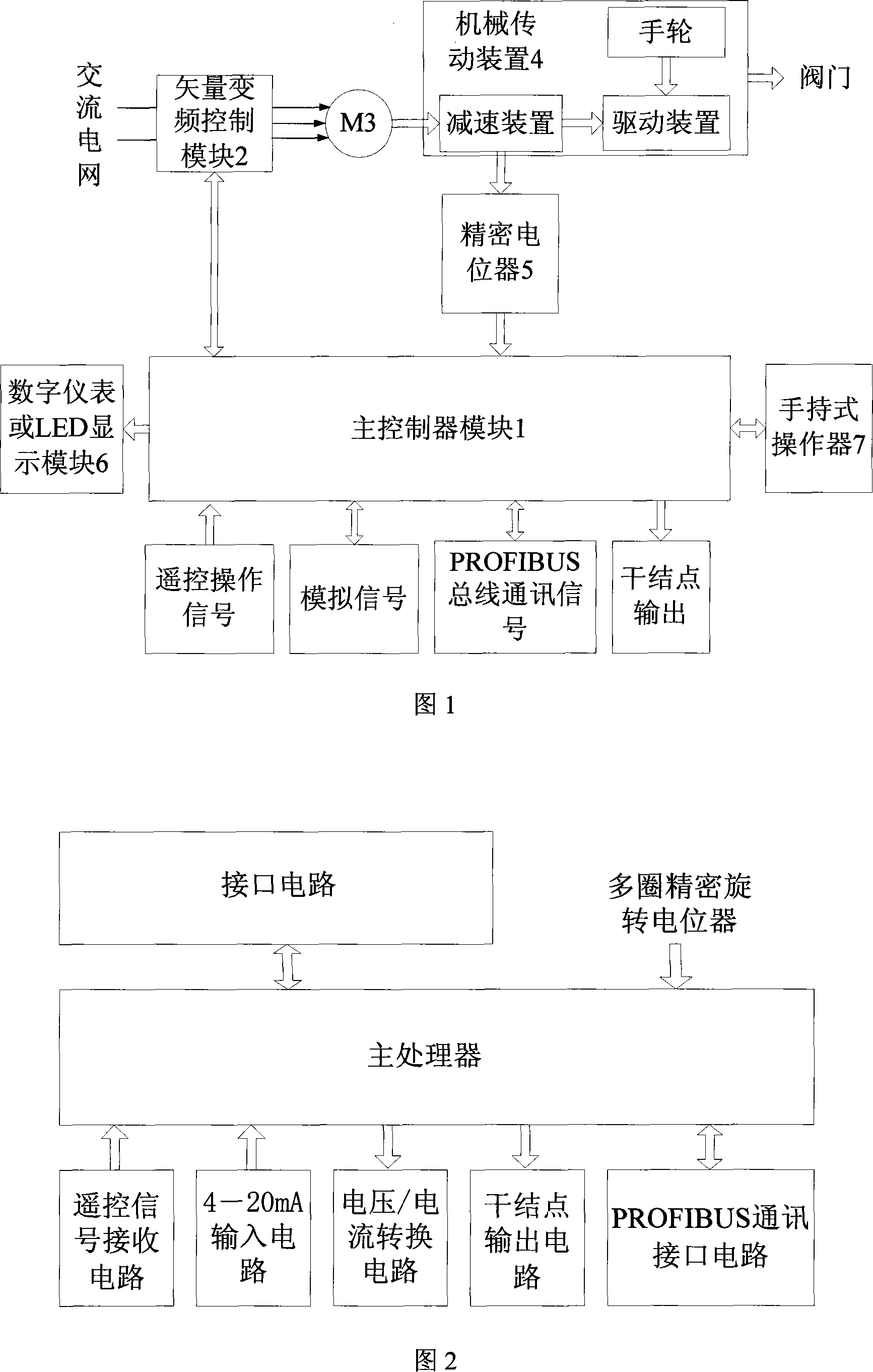

[0026] Referring to Fig. 1, this embodiment includes a main controller module 1, a vector frequency conversion control module 2, an asynchronous motor 3, a mechanical transmission device 4, a multi-turn precision rotary potentiometer 5, a display module 6 and a hand-held operator 7, and the vector frequency conversion control The input end of module 2 is connected to the AC power grid, the output end is connected to the asynchronous motor 3, the shaft end of the asynchronous motor 3 is connected to the mechanical transmission device 4, the output end of the mechanical transmission device 4 is connected to the valve, and the 5th shaft end of the multi-turn precision rotary potentiometer is connected to the mechanical transmission device Device 4 is connected.

[0027]The vector frequency conversion control module 2 is connected with the main controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com