Biomass recycling and recovering equipment

A recovery device and biomass technology, applied in the field of biomass recycling and recovery devices, can solve the problems of wasting resources, occupying space, and not fully utilizing it, and achieve the effect of saving costs and reducing input into use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

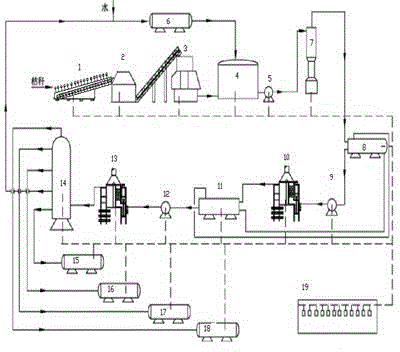

[0016] A biomass recycling recovery device, characterized in that the device includes a biomass roller screening cleaning machine 1, a cutter 2, a chain wood grinder 3, a high-concentration pulper 4, a slurry pump 5, and a water purification system 6. High-concentration slag remover 7, waste heat exchanger 8, slurry high-pressure pump 1 9, supercritical hydrolysis liquefaction reactor 10, intercooler 11, slurry high-pressure pump 2 12, subcritical hydrolysis liquefaction reactor 13, Distillation and rectification equipment 14, storage tank 1 15, storage tank 2 16, storage tank 3 17, storage tank 4 18, operation control center 19, and the above devices are connected in sequence, wherein the inlet and outlet of fluid mechanical material pipelines are equipped with electromagnetic valves.

[0017] Further, the biomass roller table cleaning machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com