Method for preparing carbon-silicon composite material by utilizing algae biomass and application of carbon-silicon composite material in lithium ion battery

A lithium-ion battery and composite material technology, which is applied in the field of preparing carbon-silicon composite materials, achieves the effects of wide application prospects, improved production efficiency and safety, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a carbon-silicon (Si@C) composite material, the specific steps of the method are:

[0039] (1) Fully mix and stir 20 g of algae biomass with 500 mL of water and 40 mL of 0.5 mol / L dilute hydrochloric acid, filter, wash with water, and dry to obtain algae biomass without inorganic salts;

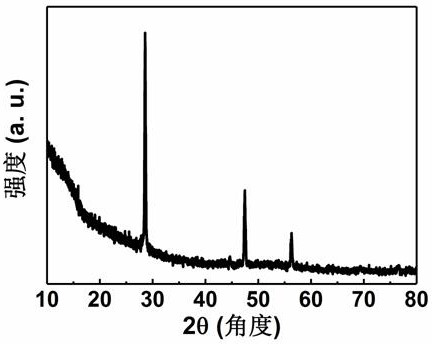

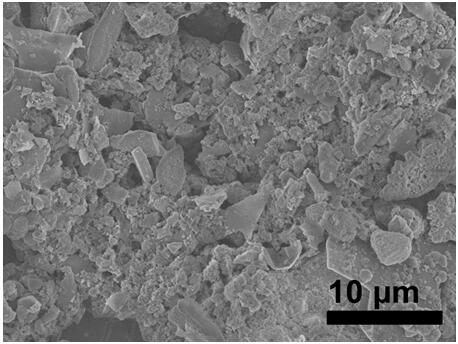

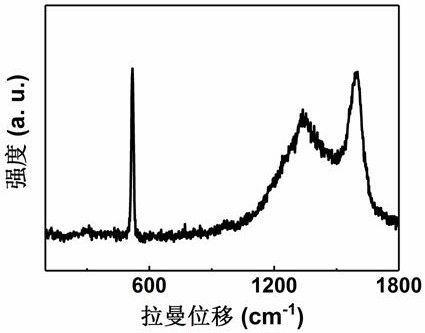

[0040] (2) Crush the above-mentioned algae biomass from which inorganic salts have been removed, and calcinate in a muffle furnace at 450°C for 2 hours in an air atmosphere to obtain a composite of black silica and carbon, and part of the composite of silica and carbon The content of silicon dioxide in the compound of silicon dioxide and carbon is 30.8% by calcining in air to remove carbon;

[0041] (3) Grind the composite of silica and carbon obtained in step (2) into powder, according to silica: magnesium metal powder: AlCl 3 Molten salt according to the molar ratio of 1:2.2:50, adding magnesium metal powder and anhydrous AlCl 3 Molten salt, and grind evenly ...

Embodiment 2

[0045] A method for preparing a carbon-silicon (Si@C) composite material, the specific steps of the method are:

[0046] (1) Fully mix and stir 20 g of algae biomass with 500 mL of water and 40 mL of 0.5 mol / L dilute hydrochloric acid, filter, wash with water, and dry to obtain algae biomass without inorganic salts;

[0047] (2) Crush the above-mentioned algal biomass from which inorganic salts have been removed, and calcinate it in an air atmosphere at 500°C for 2 hours in a muffle furnace to obtain a composite of black silica and carbon, and part of the silica and carbon The compound is calcined in air to remove carbon to obtain a content of 33.4% of silicon dioxide in the compound of silicon dioxide and carbon;

[0048] (3) Grind the product obtained in step (2) into powder, according to silica: magnesium metal powder: ZnCl 2 Molten salt according to the molar ratio of 1:2.2:50, adding magnesium metal powder and anhydrous ZnCl 2 Molten salt, and grind evenly in an inert a...

Embodiment 3

[0052] A method for preparing a carbon-silicon (Si@C) composite material, the specific steps of the method are:

[0053] (1) Fully mix and stir 20 g of algae biomass with 500 mL of water and 40 mL of 0.5 mol / L dilute hydrochloric acid, filter, wash with water, and dry to obtain algae biomass from which inorganic salts have been removed;

[0054] (2) Crush the above-mentioned algal biomass from which inorganic salts have been removed, and calcinate it in an air atmosphere at 500°C for 3 hours in a muffle furnace to obtain a composite of black silica and carbon, and part of the composite of silica and carbon The content of silicon dioxide in the compound of silicon dioxide and carbon is 30.7% by calcining in air to remove carbon;

[0055] (3) Grind the product obtained in step (2) into powder, according to silica: aluminum metal powder: AlCl 3 Molten salt according to the molar ratio of 1:1.8:50, adding aluminum metal powder and anhydrous AlCl 3 Molten salt, and grind evenly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com