Leakage testing device

A test device and tester technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, can solve the problems of low safety module test efficiency and inability to meet the needs of modern industrial production, and achieve rapid detection and good accuracy , Guarantee the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the implementations shown in the drawings, but it should be noted that these implementations are not limitations of the present invention, and those of ordinary skill in the art based on the functions, methods, or structural changes made by these implementations Equivalent transformations or substitutions all fall within the protection scope of the present invention.

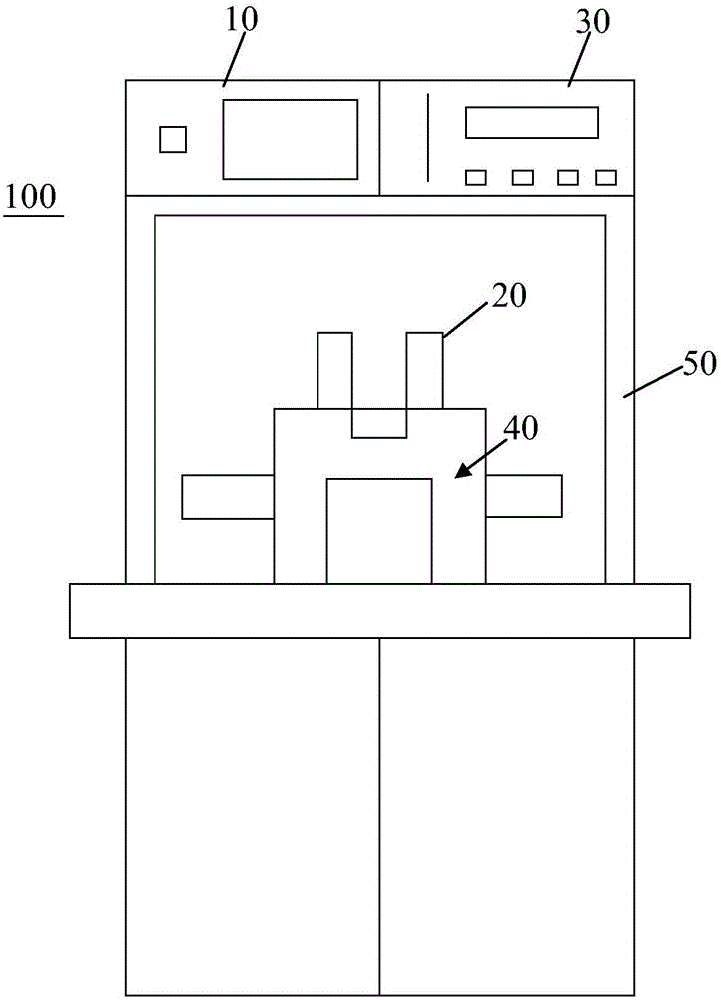

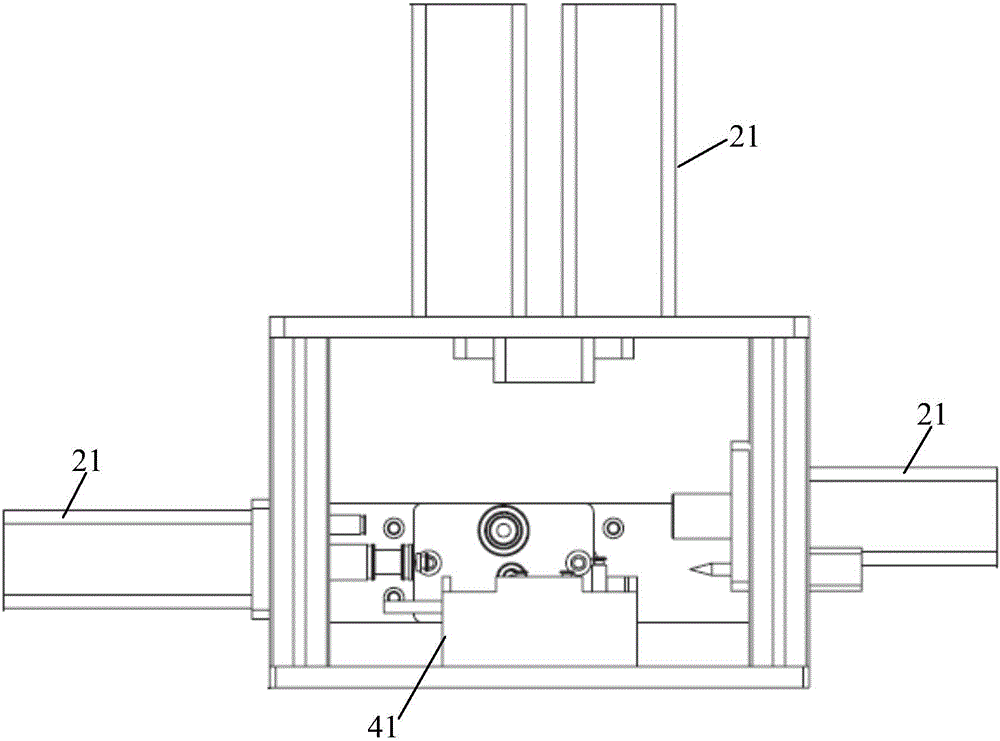

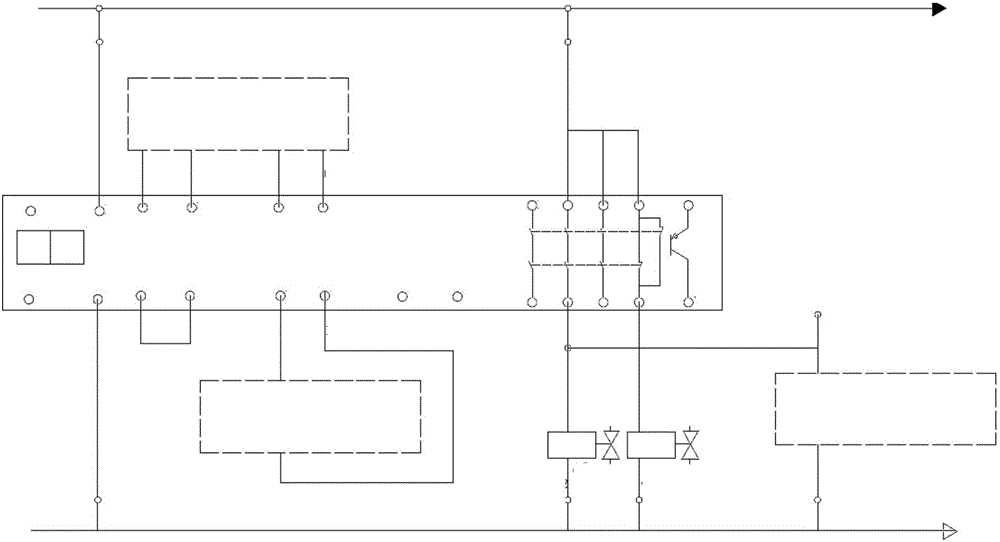

[0026] Such as figure 1 , 2 As shown, the leak test device 100 of the present invention includes: a control unit 10 , a pneumatic unit 20 , a control panel 30 , a test unit 40 and a frame 50 . The control unit 10, the pneumatic unit 20, the control panel 30, and the test unit 40 are integrally installed on the frame. Preferably, the frame 50 is an aluminum alloy profile, and its length, width and height dimensions are: 630mm×800mm×1700mm.

[0027] The control unit 10 is installed on the top of the frame, and the control unit 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com