LED bulb lamp assembling system

An LED bulb lamp and assembly system technology, applied in the field of automation, can solve the problems of poor assembly accuracy, lack of continuity, and low assembly efficiency of LED bulb lamps, and achieve the effect of high assembly efficiency and good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the embodiments shown in the drawings, but it should be noted that these embodiments are not a limitation of the present invention, and those of ordinary skill in the art make functional, method, or structural improvements based on these embodiments. Equivalent changes or substitutions fall within the protection scope of the present invention.

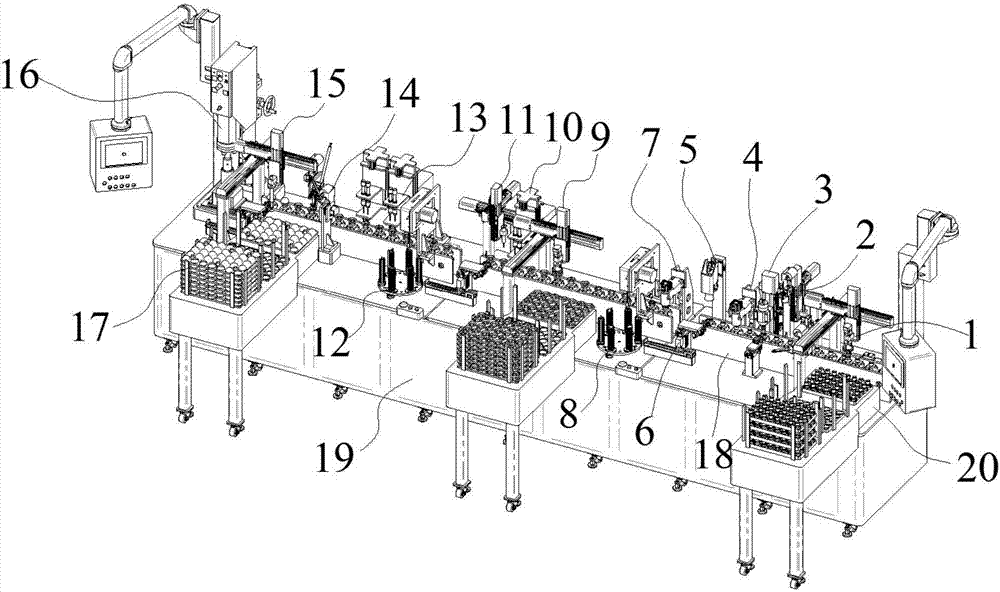

[0024] Such as figure 1 As shown, the LED bulb lamp assembly system of the present invention includes: automatic feeding station 1, screw welding station 2, mouth metal fixing station 3, polishing station 4, inspection station 5, turning and handling station 6, Repositioning station 7, radiating plate assembly station 8, lower lampshade assembly station 9, first screw assembly station 10, glue injection station 11, lamp board assembly station 12, second screw assembly station 13, The wire management welding station 14, the upper lampshade assembly station 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com