Automatic assembling mechanism of connector assembly

A connector component and automatic assembly technology, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency and high cost, and achieve the effects of improving production efficiency, high assembly precision, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

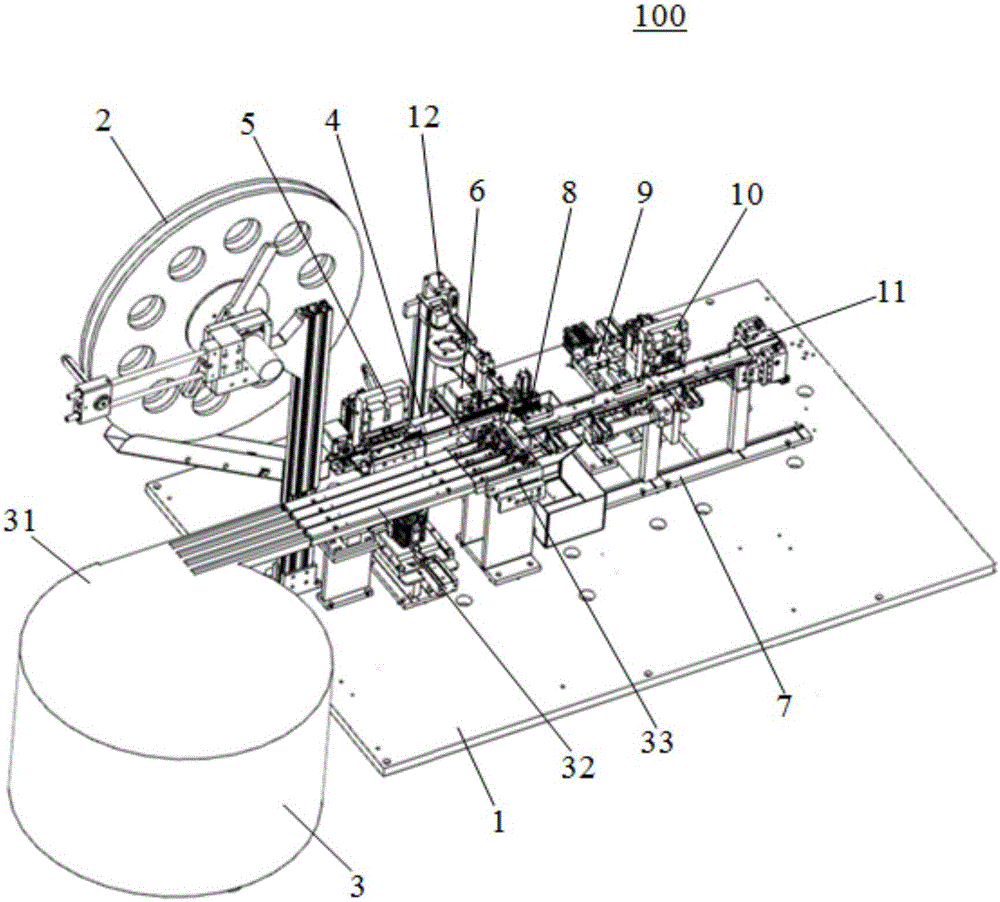

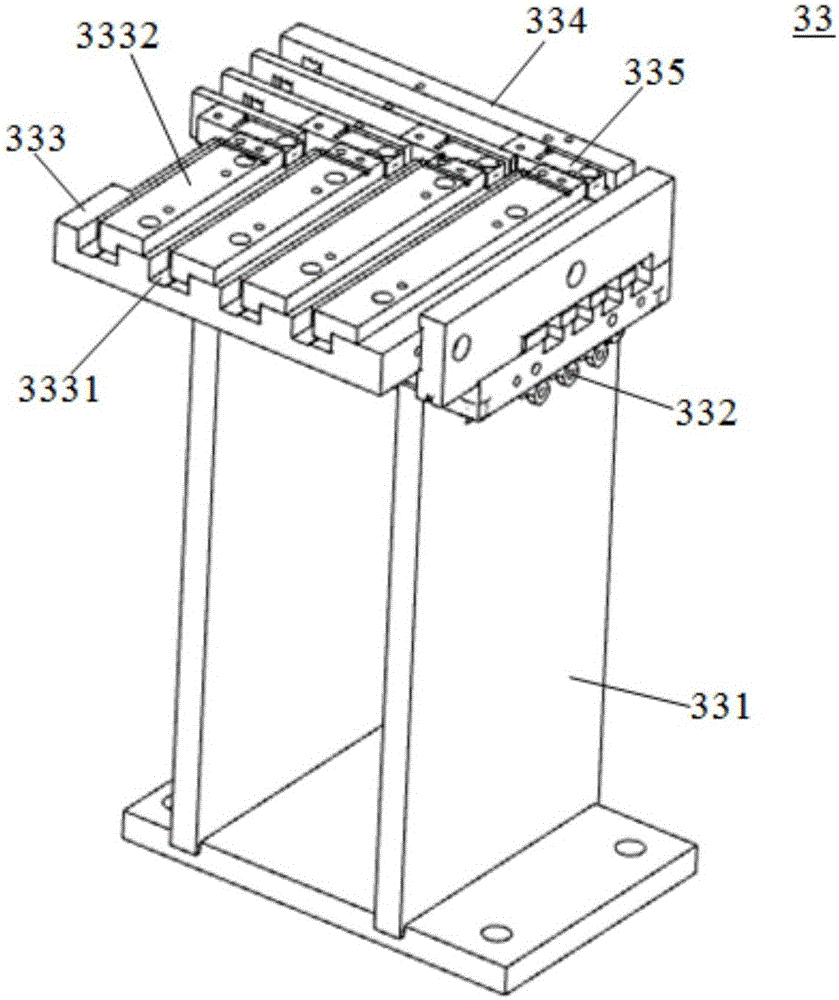

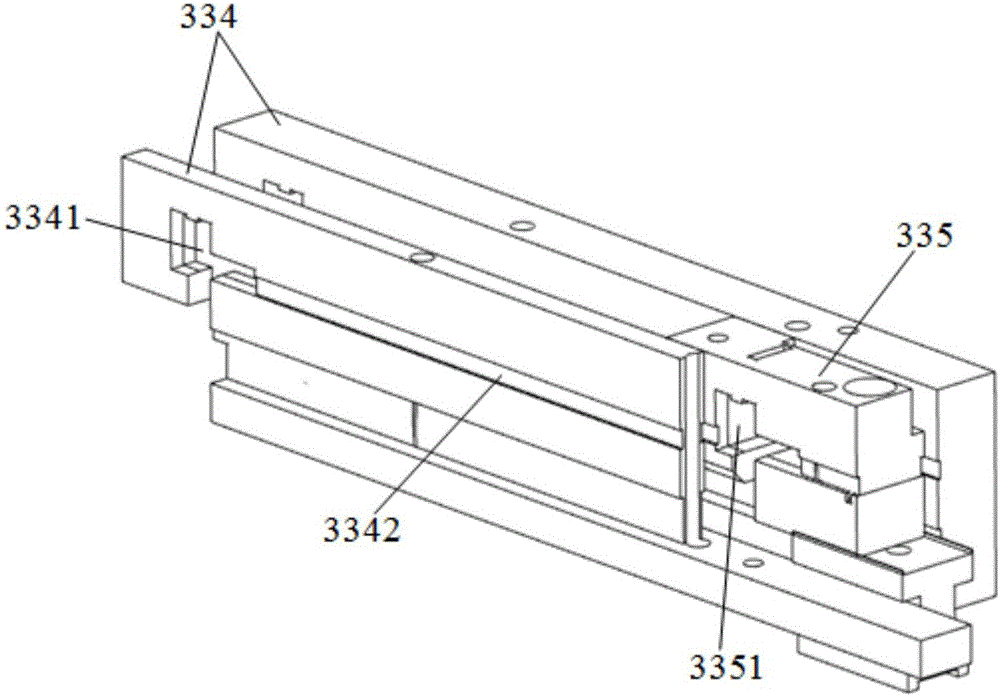

[0045] Please refer to Figure 1-Figure 14, the present embodiment is a connector assembly automatic assembly mechanism 100, which includes a machine base 1, a first feeding device 2 fixed on the machine base 1, and a second feeding device 3 located next to the first feeding device 2 , the feeding track 4 docked with the first feeding device 2, the first cutting device 5 and the second cutting device 6 arranged along both sides of the feeding track 4, the receiving guide rail device 7 docked with the second feeding device 3, The insertion and cutting device 8 , the secondary pressing device 9 , the third cutting device 10 and the turning device 11 are arranged along both sides of the receiving guide rail device 7 . A detection device 12 is arranged between the first cutting device 5 and the second cutting device 6. The detection device 12 is mainly used to detect whether there is a shortage of material in the material tape. If there is a shortage of material in a certain posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com