Flexible assembling and welding workstation for finned radiator for transformer and production method

A technology for radiators and transformers, applied in applications, household appliances, manufacturing tools, etc., can solve problems such as low production efficiency, inability to weld gooseneck radiators, poor compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

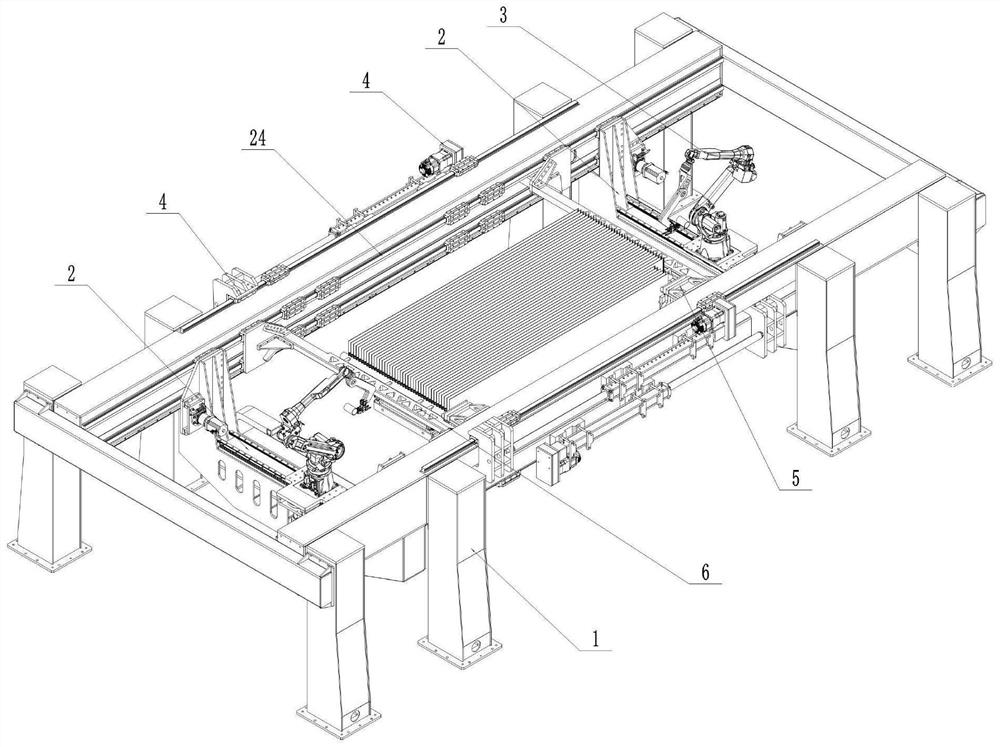

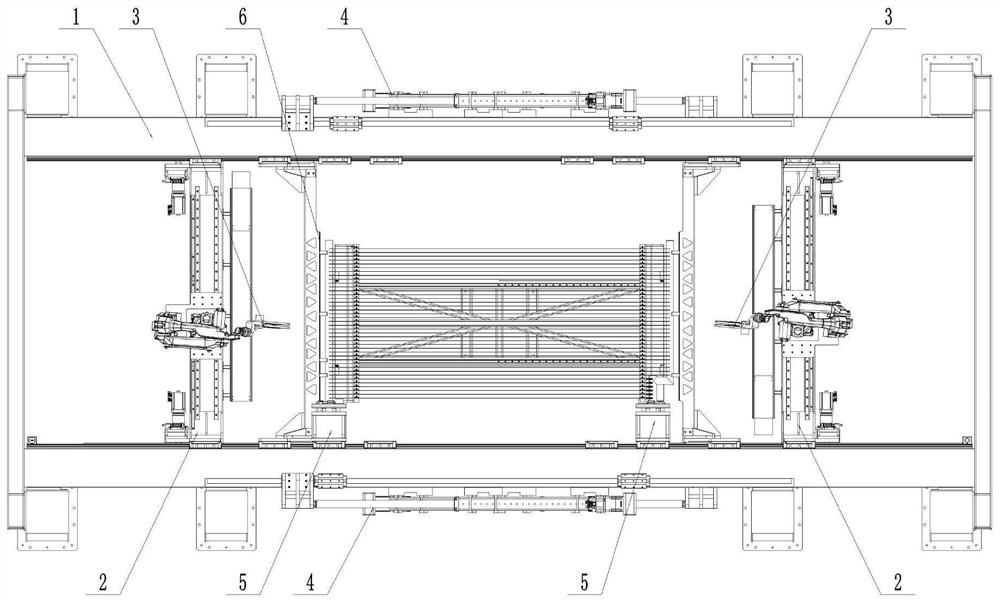

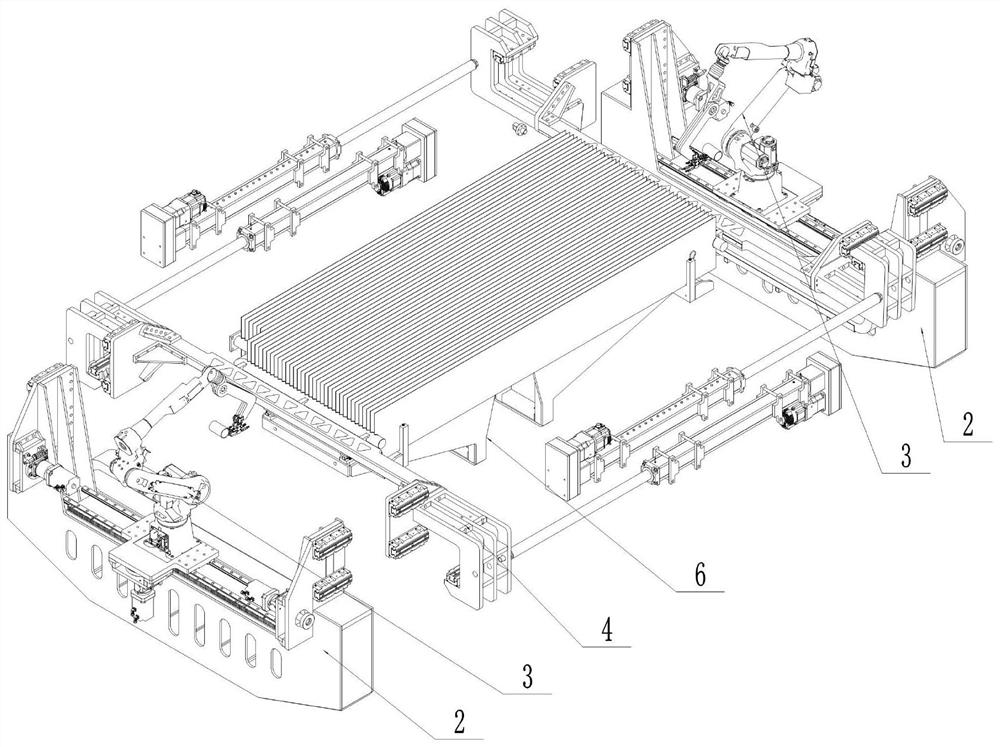

[0051] refer to figure 1 , figure 2 As shown, a flexible assembly and welding workstation for finned radiators for transformers includes a support frame 1, a robot external shaft 2, a welding robot and a welding torch 3, a centering slide 4, a follow-up caliper 5 and a positioning comb 6.

[0052] The support frame 1 includes support columns fixedly connected to the ground and transverse and longitudinal beams forming a frame structure, which are used to provide basic support positioning and partial guiding positioning for other institutions. The support frame 1 described here is broadly defined. The support frame on the frame, any shelf, wall, ground, etc. used for fixing or providing support and positioning in this application belong to the scope of the frame. The invention of the present application is to include the robot external shaft 2 arranged on the support frame 1, the welding robot and welding torch 3 movable on the robot external shaft 2, the centering slide tabl...

Embodiment 2

[0066] It should be noted that the description scheme of this embodiment is only compared with the scheme of the centering slide 4 in Embodiment 1, so the components whose names and reference signs are the same as those of Embodiment 1 above will be omitted here.

[0067] The synchronous transmission mode of the centering slide 4 adopts the synchronous toothed belt mode in this embodiment, and the synchronous toothed belt is built into the profile of the support frame 1, and the C-shaped bracket 26 is replaced by a flange butt joint In the form of throwing guide components, linear guides and sliders are used. Therefore, the synchronous toothed belt and the linear guide rail are arranged inside the profile of the support frame 1, the slider group on the linear guide rail is connected and fixed with a pair of symmetrically arranged flange plates, and the flange connector is connected to the load-bearing beam of embodiment 1. The connecting brackets 32 are combined into the same ...

Embodiment 3

[0070] It should be noted that in this embodiment, the seventh shaft transmission part of the welding robot is arranged at the bottom of the positioning comb 6 to move, so the names and reference numbers of the components are the same as those of the above-mentioned embodiment 1, and the description is omitted here.

[0071] refer to figure 1As shown, the scheme of this embodiment is to set the seventh axis of the external shaft 2 of the welding robot at the bottom of the positioning comb 6, thus, the production and positioning method of this embodiment is changed as follows: the external shaft 2 of the robot is equipped with the first embodiment The eighth axis of the robot external axis 2 is set on the base of the positioning comb plate 6, and is fixed together with the positioning comb plate 6 at the center of the workstation; the welding robot and welding torch are arranged on the external axis 2 of the robot On the robot mounting base 18, the external axis 2 of the robot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com