Stir friction welding method for hollow aluminum extruded section splicing arc plate

A technology of friction stir welding and friction stir, which is applied in the direction of welding equipment, non-electric welding equipment, workpiece edge, etc., can solve the problems of reducing welding quality, increasing the gap between workpieces, exceeding the allowable requirements of the process, etc., and reaching the size The effect of control effect and improvement of weld seam quality, reduction of incoming materials and assembly precision requirements, and saving of manpower and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings.

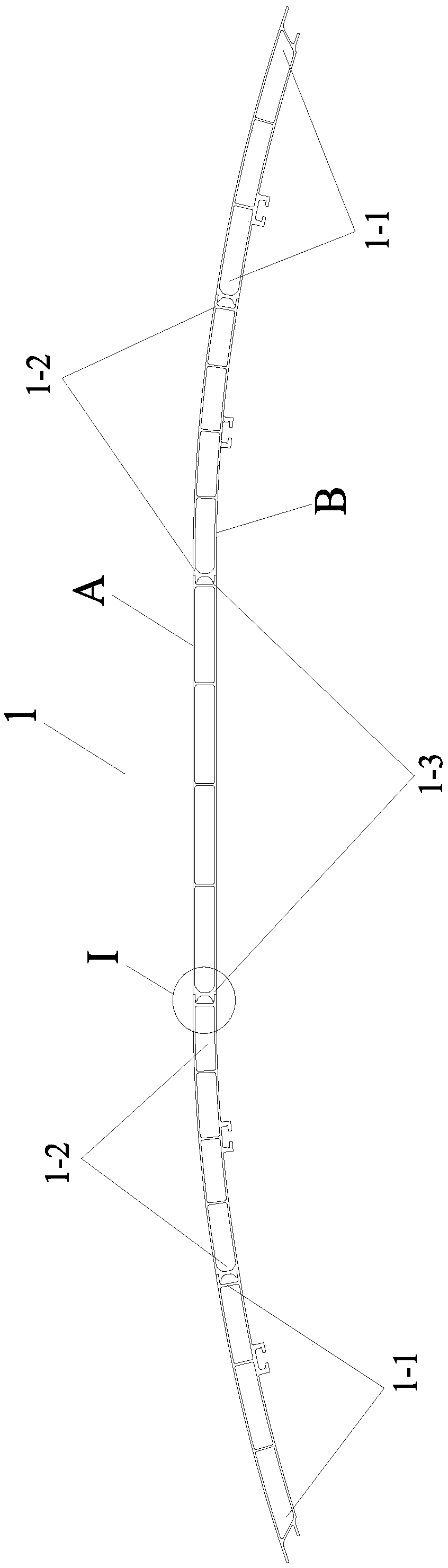

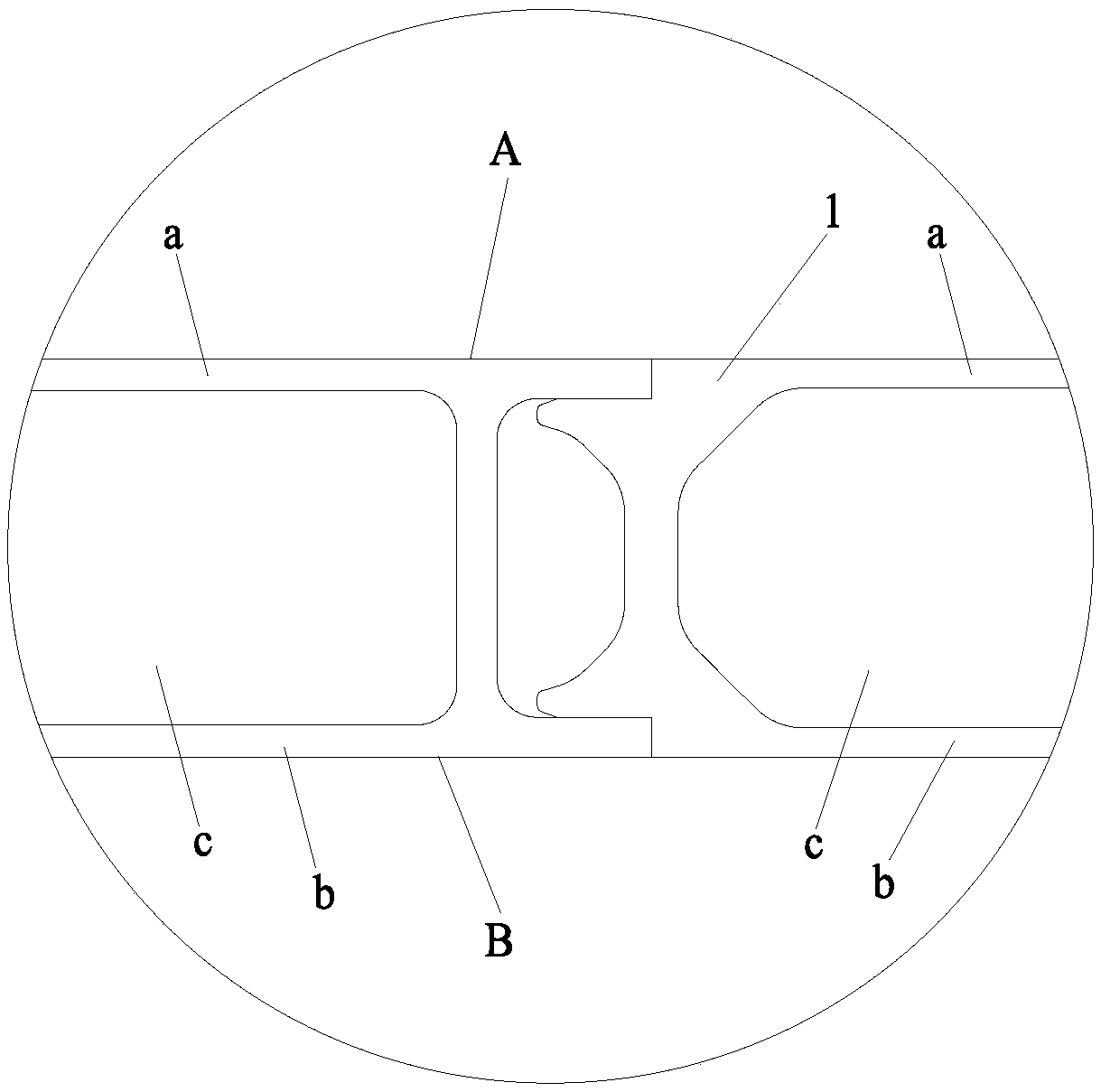

[0054] Such as Figure 10 to Figure 17 Shown, the friction stir welding method of the hollow aluminum section bar of the present invention splicing circular-arc plates is characterized in that: the method comprises the steps:

[0055] Step 1: Pre-set the workpiece and tooling, which specifically includes the following sub-steps:

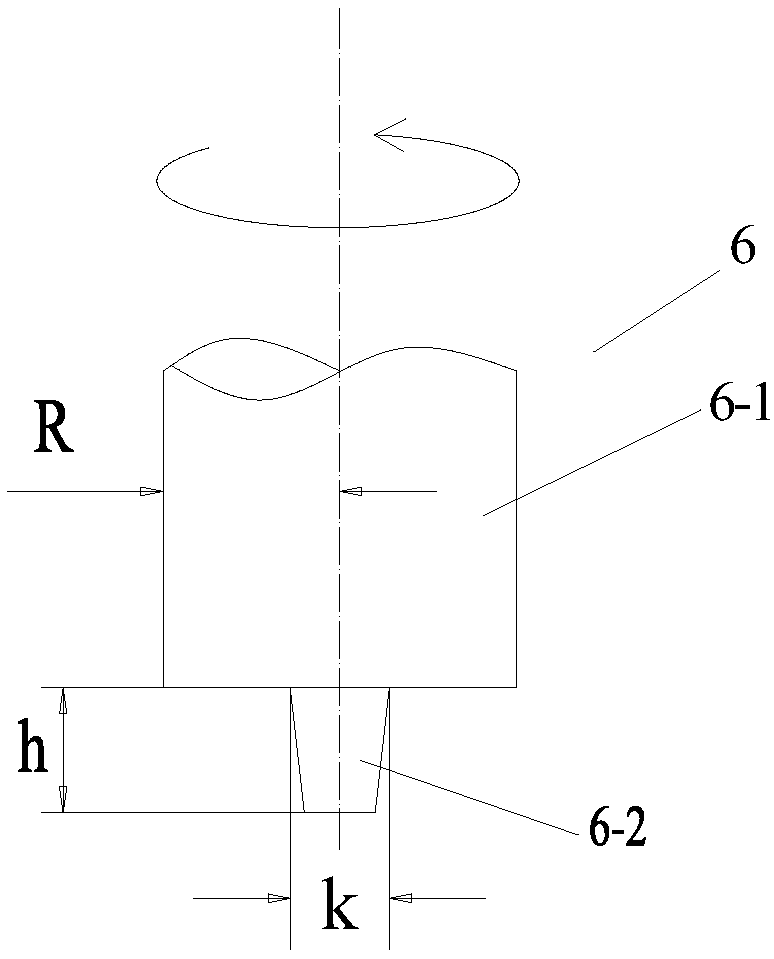

[0056] Step 1.1: Set up the raised structure of the hollow aluminum profiles of the five roof arc plates used to form the outer end surface A of the integral arc plate that arches upwards, so that the total of the new raised structure 8 after each welding seam is assembled The width value N is 95% to 105% of the root diameter k of the stirring needle 6-2 of the stirring head 6, and the height value D of the new raised structure 8 is in the range of 0.3-0.5mm;

[0057] Step 1.2: Design special friction stir welding formal tooling a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com