A Judgment Method for Slipping and Broken Steel Bar on High-speed Wire Rod

A high-speed wire rod and steel bar technology, which is applied in rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problems of long time, time-consuming and labor-intensive processing of production failures, and reduce the time for processing steel bars and the reduction of troubleshooting. time, the effect of reducing incoming materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

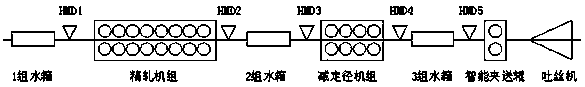

[0022] Embodiment 1: as figure 1 Shown is a judging system for slipping and breaking of steel bars on high-speed wire rods. The judgment system is installed on the production line of the high-speed wire rod workshop. The production line of the high-speed wire rod workshop is composed of a first group of water tanks, a finishing mill, The first group of water tanks, the reducing and sizing unit, the third group of water tanks, the intelligent pinch rollers and the laying machine are sequentially connected. The judgment system is composed of a hot metal detector HMD and a PLC control system. The hot metal detection The detector includes five sets of HMD detectors. The No. 1 HMD detector is installed between the first group of water tanks and the finishing mill, the second HMD detector is installed between the finishing mill and the second group of water tanks, and the No. 3 HMD detector is installed Between the second group of water tanks and the reducing and sizing unit, the No...

Embodiment 2

[0023] Embodiment 2: as figure 1 As shown, the five groups of HMD detectors of the present invention and each equipment on the production line are all connected to the PLC control system via lines, and the PLC control system is AC800PECPLC system. The scanning period of the AC800PECPLC system described in the present invention is 1 ms; the scanning period is short, which facilitates the precise control of the overall production line.

Embodiment 3

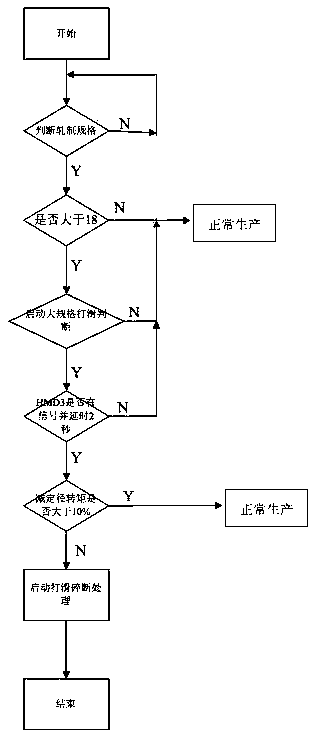

[0024] Embodiment 3: as figure 2 As shown, a method for judging that the steel bar slips and breaks on a high-speed wire rod according to the present invention, the judging method includes the following steps:

[0025] 1) The production line of the high-speed wire rod workshop starts production, and the steel bar specifications are judged by the No. 1 HMD detector, the No. 2 HMD detector and the finishing rolling unit.

[0026] 2) The size of the steel bar is not less than Φ18mm, and the rolling line passes steel normally; the size of the steel bar judged in step 2) of the present invention is Φ18mm~Φ26mm, when the size of the steel bar reaches Φ18mm, it is judged that the steel bar is a large-sized steel bar, and the invention is started control program in the system.

[0027] If the steel bar specification is less than Φ18mm, the PLC control system controls and closes the steps 3) and 4) and proceeds to normal production according to step 5); the steps 3) and 4) of the jud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com