Zr element-toughened WC-Ni3Al hard alloy and preparation method thereof

A technology of cemented carbide and its manufacturing method, which is applied in the field of cemented carbide materials and its preparation, and can solve problems such as performance degradation and poor toughening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

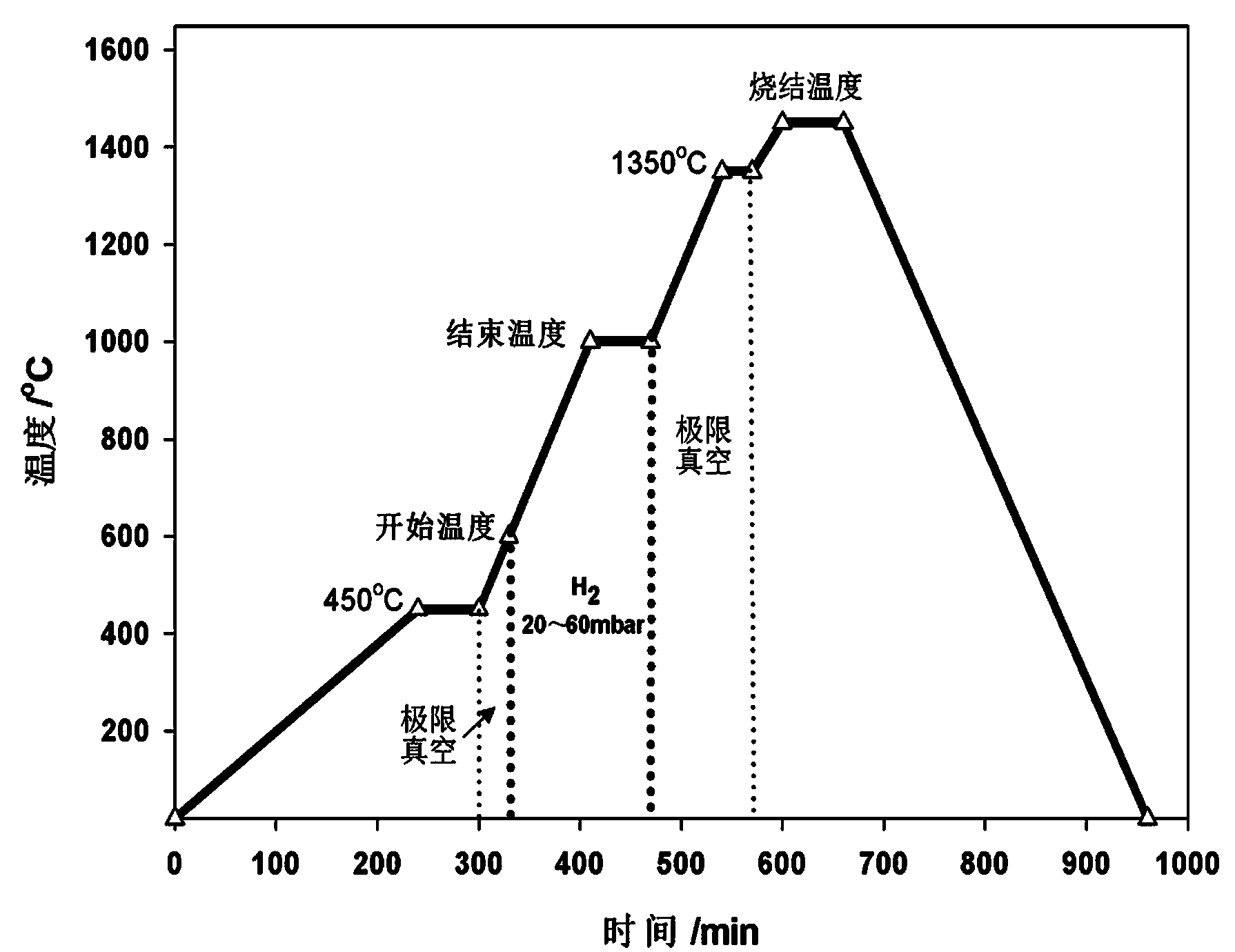

[0022] Embodiment 1: be 0.005% ZrH by mass percent 2 After the powder is pre-wet milled for 1 hour, the remaining WC+Ni 3 Al pre-alloyed powder (Ni 3 The mass percentage of Al in the pre-alloyed powder is 5.04%) and wet grinding together to obtain a wet grinding mixture; the wet grinding mixture is spray-dried and pressed to form a green compact; The speed is raised from normal temperature to 450°C, kept for 1 hour, and pumped to the ultimate vacuum of 4×10 -3 Below Pa, then continue to heat up to 650°C, start from the initial temperature of 650°C, feed 20mbar low-pressure hydrogen, and increase the temperature at a rate of 1°C / min to the end temperature of 1000°C, and then evacuate again to 4×10 -3 Pa and keep it warm for 1 hour to complete the low-pressure hydrogen treatment of the compact; then follow the conventional sintering curve, heat up to the sintering temperature of 1550°C, and obtain Zr-toughened WC-Ni after low-pressure liquid phase sintering 3 Al cemented carb...

Embodiment 2

[0026] Embodiment 2: the ZrH that mass percent is 0.026% 2 After the powder is pre-wet milled for 1.5 hours, the remaining WC+Ni 3 Al pre-alloyed powder (Ni 3 The mass percentage of Al in the pre-alloyed powder is 5.04%) added together for wet grinding to obtain a wet-milled mixture; the wet-milled mixture is spray-dried and pressed to form a green compact; The speed is raised from normal temperature to 450°C, kept for 1.5 hours, and pumped to the ultimate vacuum of 4×10 -3 Below Pa, then continue to heat up to 550°C, start from the initial temperature of 550°C, feed 40mbar low-pressure hydrogen, and increase the temperature at a rate of 3°C / min to the end temperature of 1100°C, and then evacuate again to 4×10 -3 Pa and keep it warm for 1.5 hours to complete the low-pressure hydrogen treatment of the compact; then follow the conventional sintering curve, heat up to the sintering temperature of 1550°C, and obtain Zr-toughened WC-Ni after low-pressure liquid phase sintering 3...

Embodiment 3

[0027] Embodiment 3: the ZrH that mass percent is 0.051% 2 After the powder is pre-wet milled for 2 hours, the remaining WC+Ni 3 Al pre-alloyed powder (Ni 3 The mass percentage of Al in the pre-alloyed powder is 5.04%) added together for wet grinding to obtain a wet-milled mixture; the wet-milled mixture is spray-dried and pressed to form a green compact; The speed is raised from normal temperature to 450°C, kept for 2 hours, and pumped to the ultimate vacuum of 4×10 -3 Below Pa, start from the initial temperature of 450°C, pass in 60mbar low-pressure hydrogen, and raise the temperature to the end temperature of 1200°C at a rate of 5°C / min, and then evacuate again to 4×10 -3 Pa and keep it warm for 2 hours to complete the low-pressure hydrogen treatment of the compact; then follow the conventional sintering curve, heat up to the sintering temperature of 1550°C, and obtain Zr-toughened WC-Ni after low-pressure liquid phase sintering 3 Al cemented carbide, where the binder ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com