Toothed wheel

A technology of gears and teeth, applied in the body field, can solve the problems of increasing the output of broken dangerous waste products, and achieve the effects of good compactability, good stability, and good demoldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] At the outset, it should be pointed out that the same reference numerals or the same component designations are used for the same components in different embodiments, wherein the disclosure contained in the entire description can be referred to the components with the same reference numerals or the same component designations. Likewise, selected position indications such as above, below, side, etc. in the description relate to the direct description as well as to the illustrated figures and in the event of a change of position they are automatically transferred to the new position.

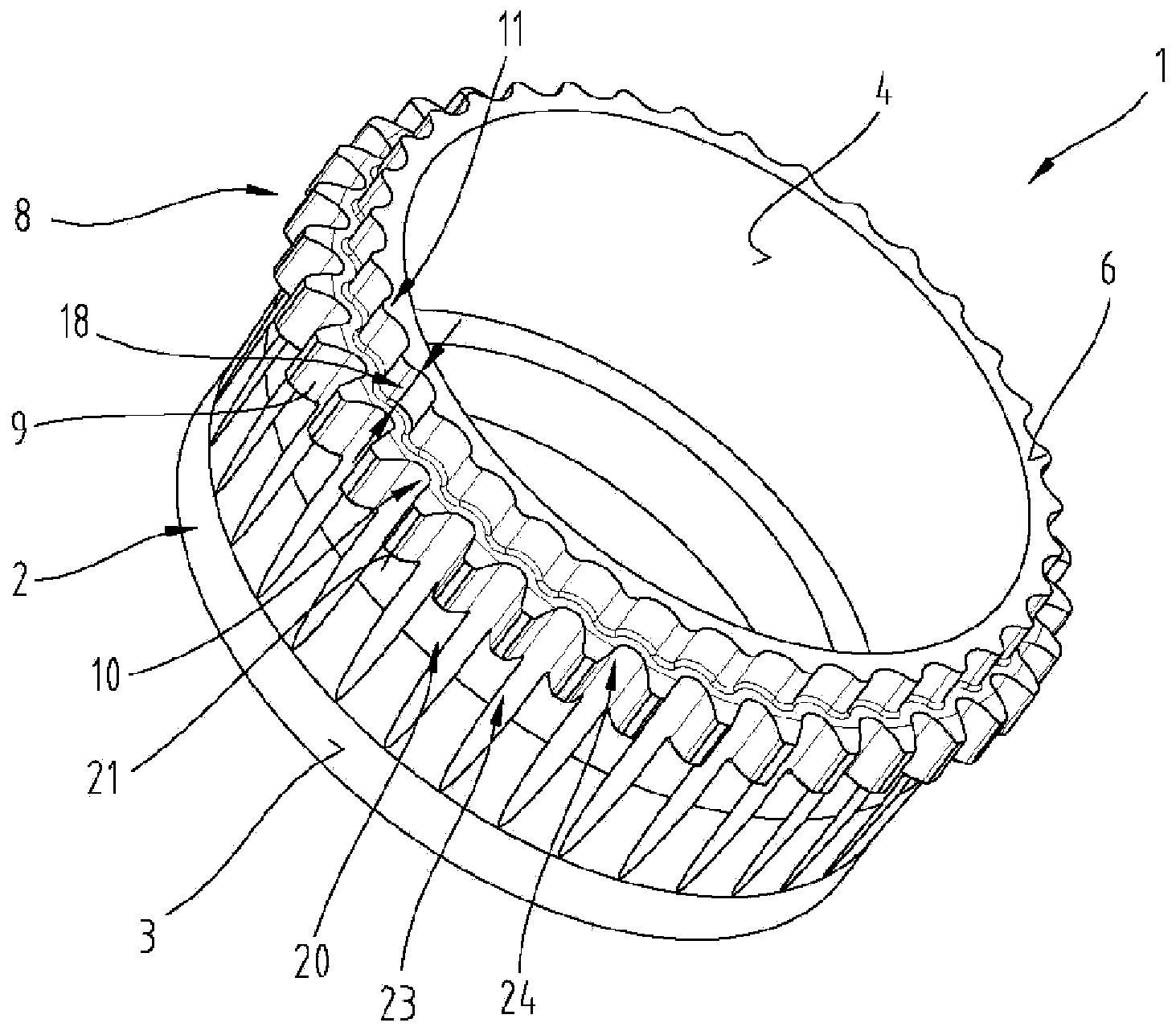

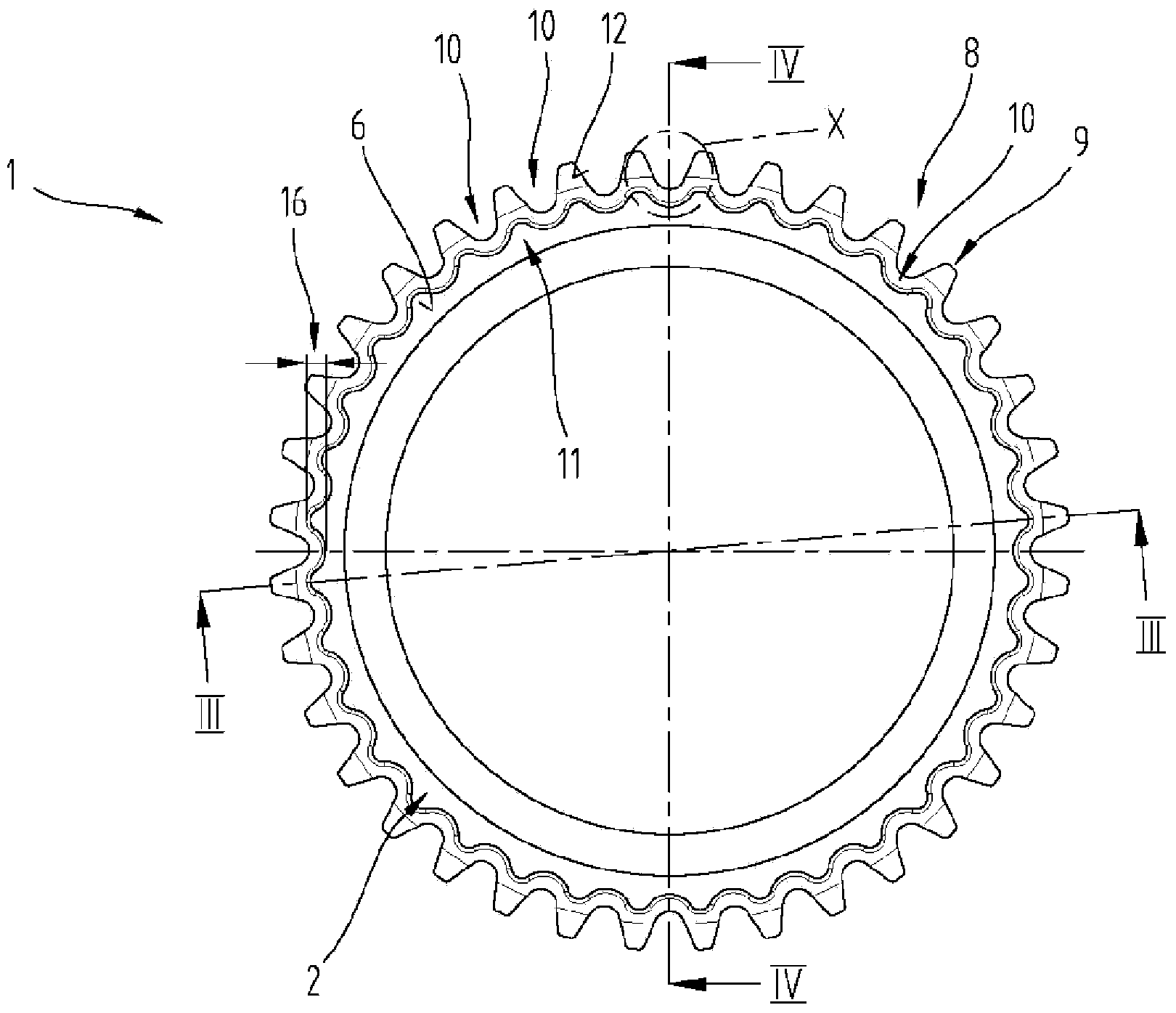

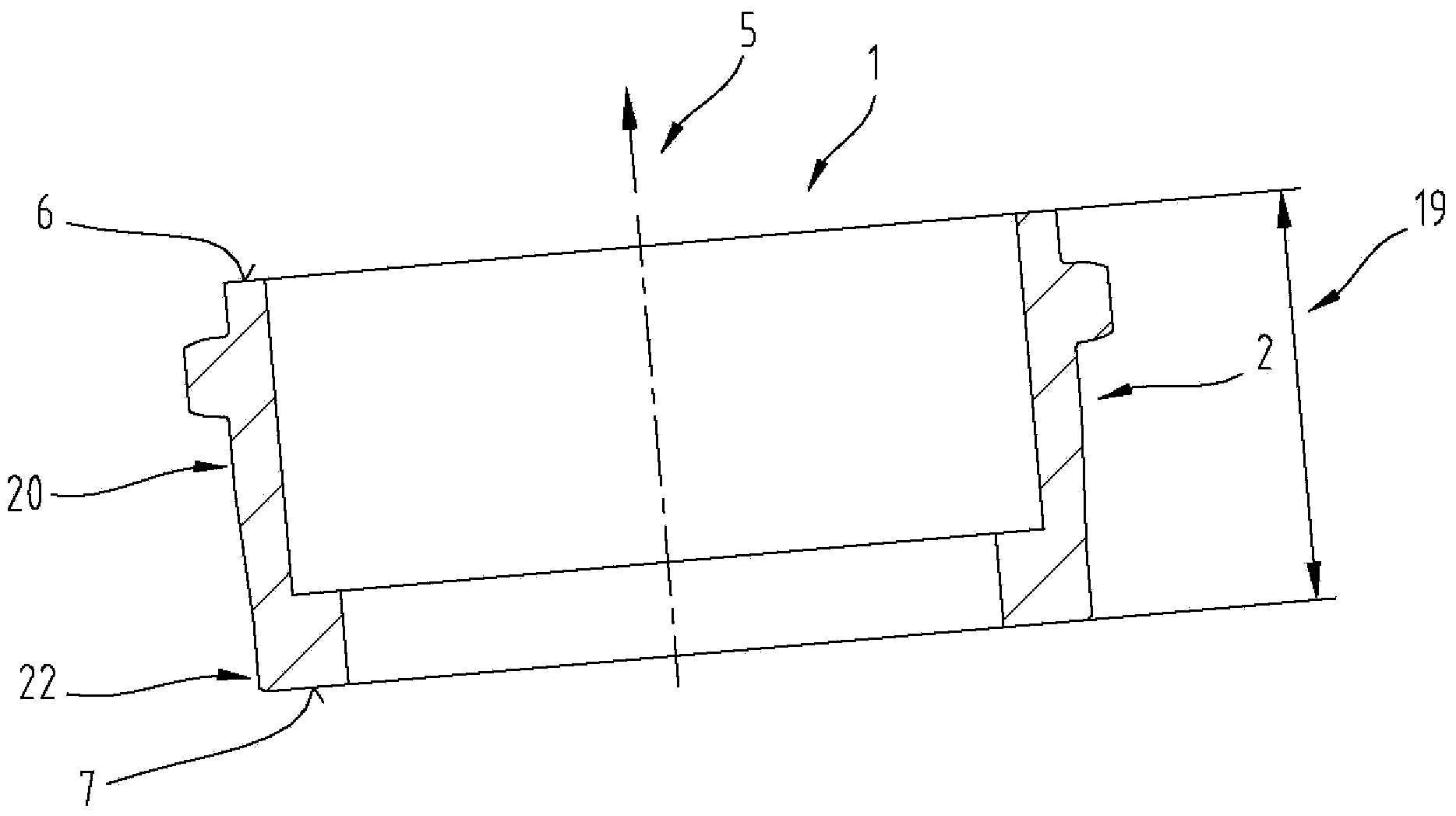

[0026] Figures 1 to 4 Different views of a first embodiment of the gear 1 , in particular of the sprocket, are shown.

[0027] according to Figures 1 to 4 Gear 1 is used in a so-called variable valve timing (VVT) system. according to Figures 1 to 4 The gear 1 is especially configured as a stator for a VVT system.

[0028] Such a stator, as described in DE 10 2010 034 014 A1 mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com