Method and device for securing a threaded element screwed into a threaded seat, method for mounting at least one balancing weight of a turbine, and a turbine

A technology of threaded components and balance weights, applied in threaded fasteners, blade support components, mechanical equipment, etc., can solve problems such as wear and tear, and achieve the effect of precise plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

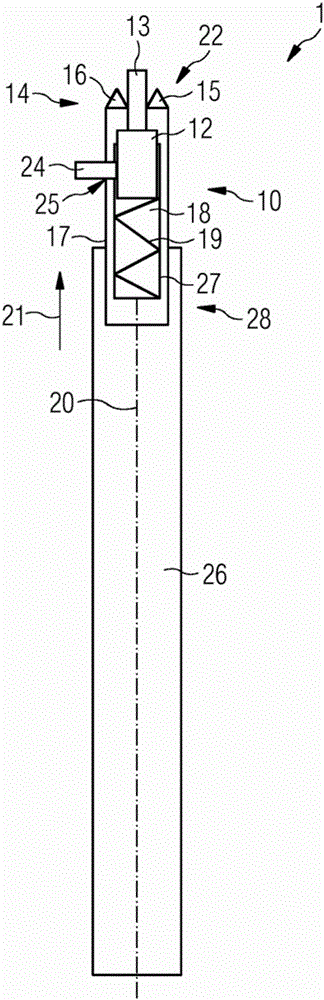

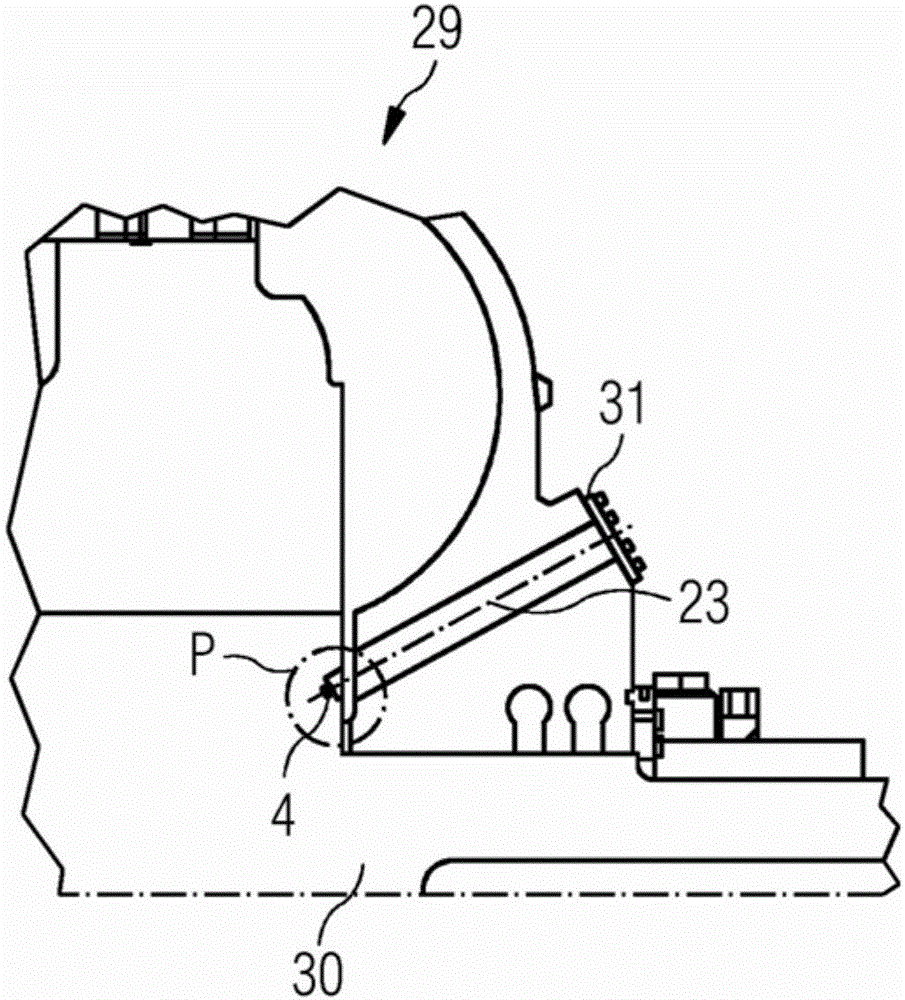

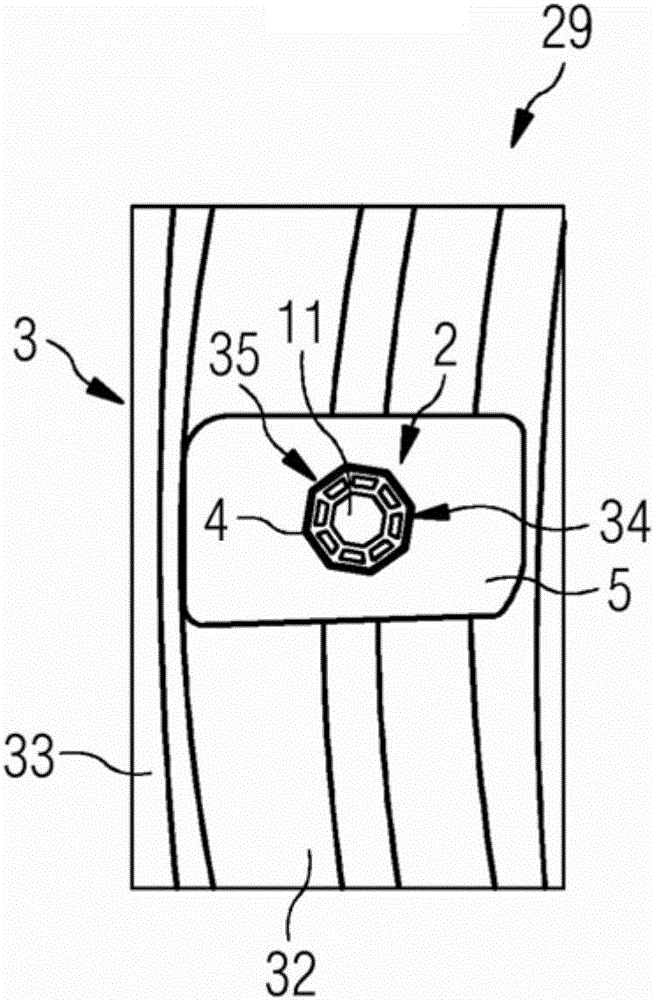

[0052] figure 1 The device 1 shown in this embodiment is constructed in such a way that it is provided for locking screwed into the threaded seat 2 (see figure 2 and 3 ) in the threaded element 3 , which is realized here in the form of a mounting screw 4 of the balance weight 5 .

[0053] To this end, the device 1 is equipped with a tool 10 by means of which at least the threaded socket 2 introduced into the balancing weight 5 and, where appropriate, also the mounting screw 4 can be plastically deformed. Thus, preferably not only the balancing weight 5 but also the mounting screw 4 is plastically deformed by means of the device 1 for the purpose of producing a loss protection for the mounting screw 4 .

[0054] The tool 10 comprises on the one hand a drive receptacle 11 which can be inserted into the threaded element 3 , more precisely the threaded element 3 (see figure 2 ) so that the tool 10 can be placed centrally in front of the threaded element 3 in an operationally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com