Hot spray process to form alloy coating on the surface of oil pumping polished AOC alloy rod

A technology for sucking polished rods and surface alloys, applied in metal material coating process, coating, melt spraying and other directions, can solve the problems of complex processing technology, peeling of polished rods, and high cost, achieve reasonable control of the process flow, and facilitate the process flow , The effect of saving alloy powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

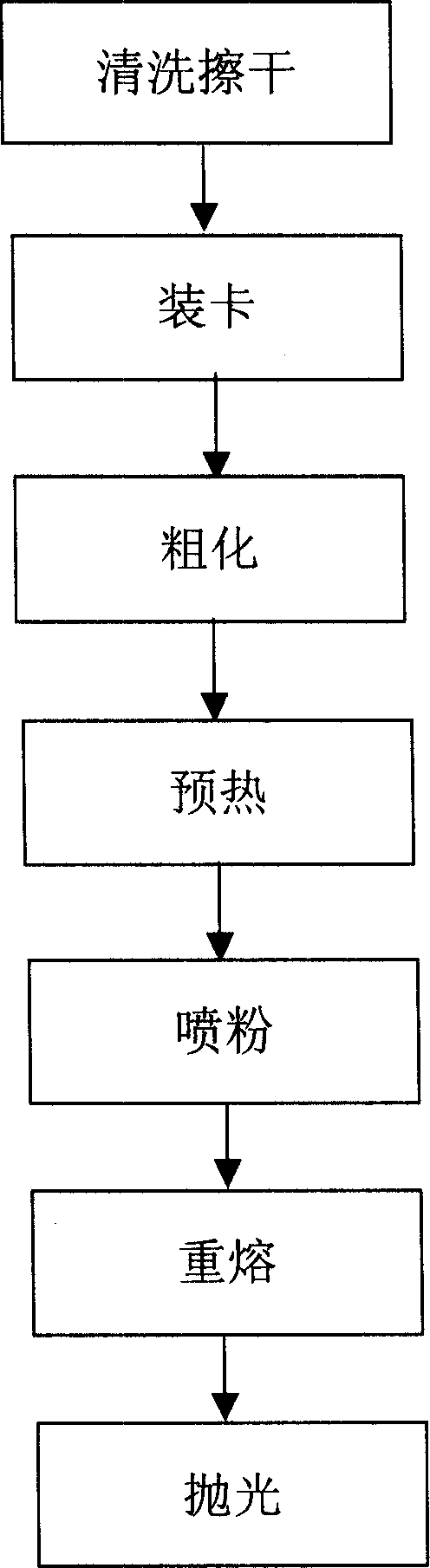

[0009] The thermal spraying process of alloy coating on the surface of AOC alloy oil pumping rod is carried out according to the following procedures:

[0010] 1. Degreasing treatment

[0011] Clean the polished rod blank with kerosene or gasoline to remove surface oil.

[0012] 2. Coarsening treatment

[0013] Install the polished rod on the quenching machine tool, and polish the surface with a 50-100# abrasive belt during the process of advancing and rotating, with a feed rate of 5-15 μm to make the surface roughness 0.8-3.2 μm.

[0014] 3. Preheat

[0015] Preheat the polished rod to 200-300°C for 5 minutes.

[0016] 4. Spraying

[0017] The dynamic balance spraying method is adopted to ensure the rotation speed of the polished rod is 100-300r / min, the traveling speed is 0.2-5m / min, the gas pressure is controlled at 0.5-0.8Mpa, the spraying distance is 200-1000mm, and the spraying angle is 0-90° from the horizontal. The number of spraying can be set according to the ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com