Patents

Literature

94results about How to "Realize processing and manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

3D laser printing system and method based on robot

InactiveCN105499573AImprove processing efficiencyRealize processing and manufacturingAdditive manufacturing apparatusIncreasing energy efficiencyShielding gasEngineering

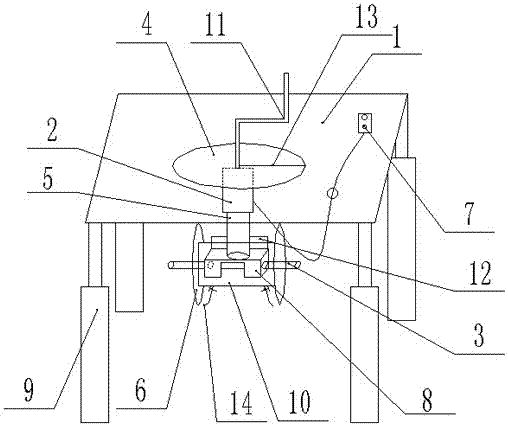

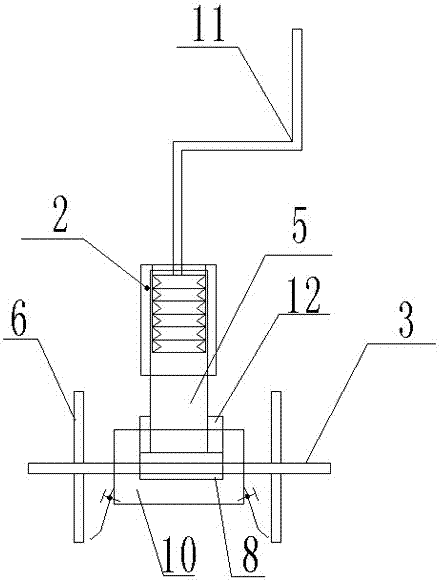

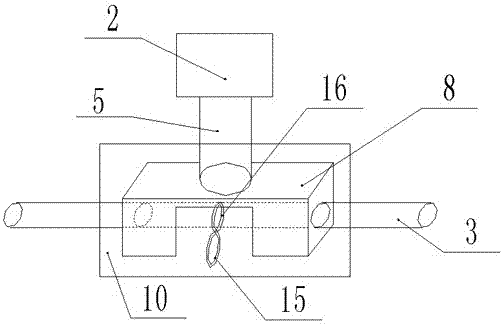

The invention relates to a 3D laser printing system and method based on a robot. A mechanical arm is utilized for driving a laser printing head unit for 3D printing, and comprises a machine base, a horizontal rotating disc, an arm joint, an upper arm, an elbow joint, a lower arm, a wrist joint, a robot wrist, a connecting disc, a protection gas supply pipeline, and a powder supply pipeline connected with a powder stock bin. The connecting disc is connected with the laser printing head unit, the connecting disc drives the laser printing head unit to rotate, and the protection gas supply pipeline and the powder supply pipeline are fixed to the upper arm and the lower arm through fixing rings. The end of the protection gas supply pipeline and the end of the powder supply pipeline are connected with the laser printing head unit. The 3D laser printing system and method have the advantages that metal parts, especially stainless steel alloy parts, in any shape can be directly machined and manufactured, and the machining and manufacturing efficiency of the metal parts, especially the stainless steel alloy parts, in the complex shapes is greatly improved. Adopted metal powder is directly sprayed according to the shapes of the parts, and little powder is left, and can be recycled and reused.

Owner:CANGZHOU DWAYA LASER TECH CO LTD

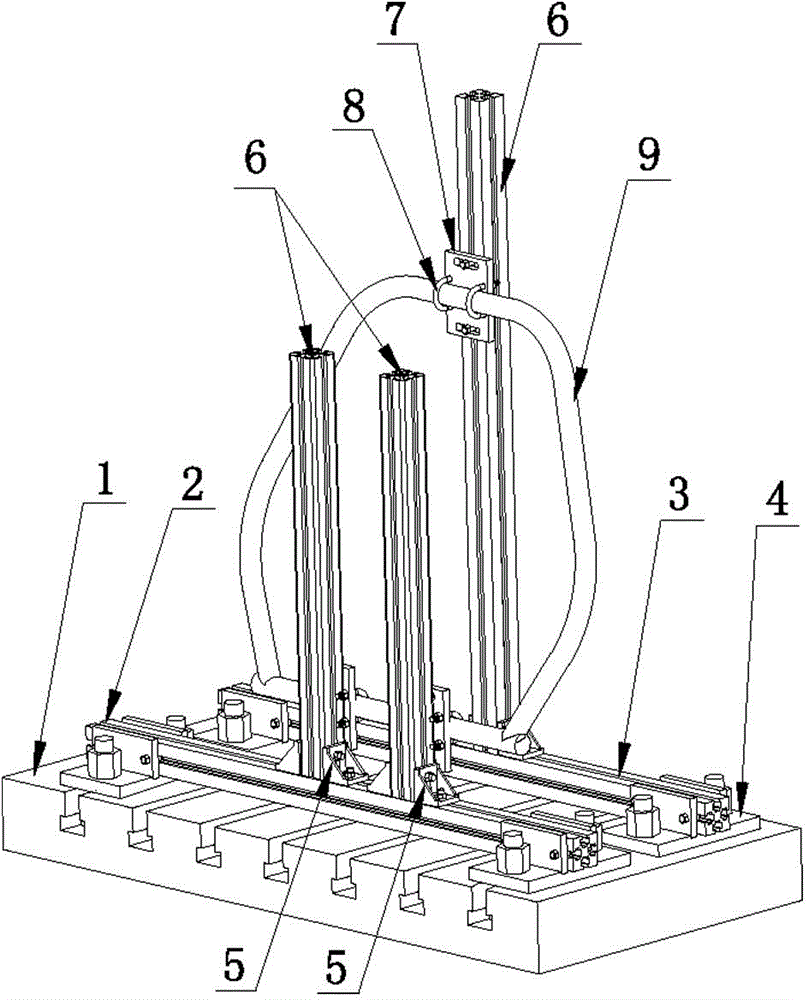

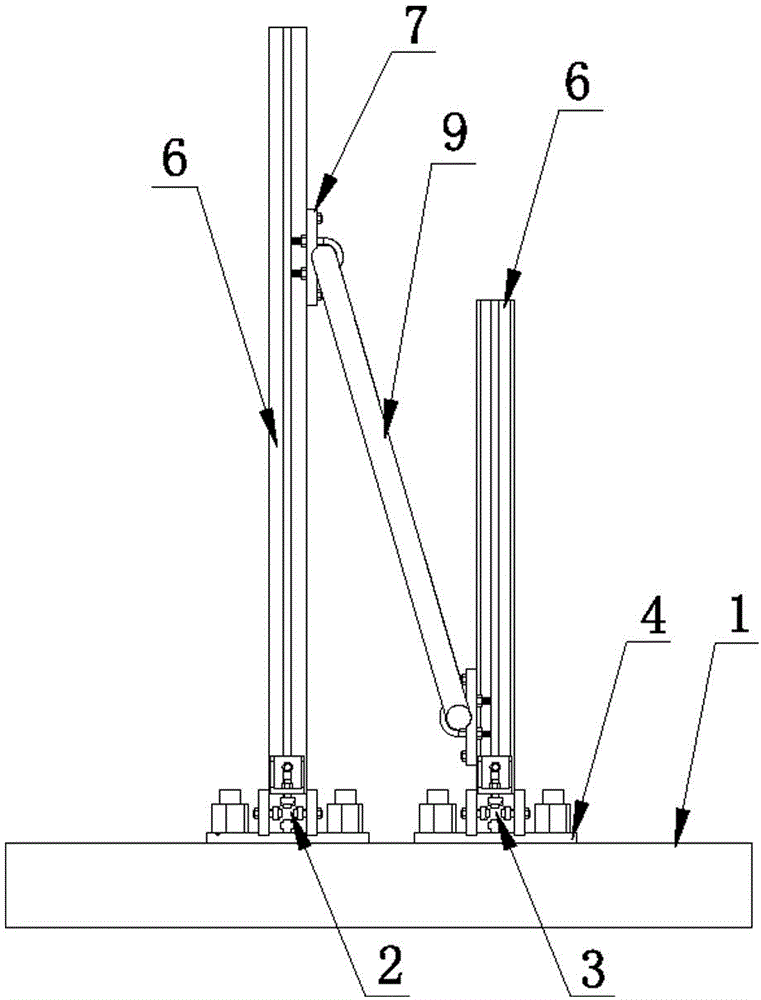

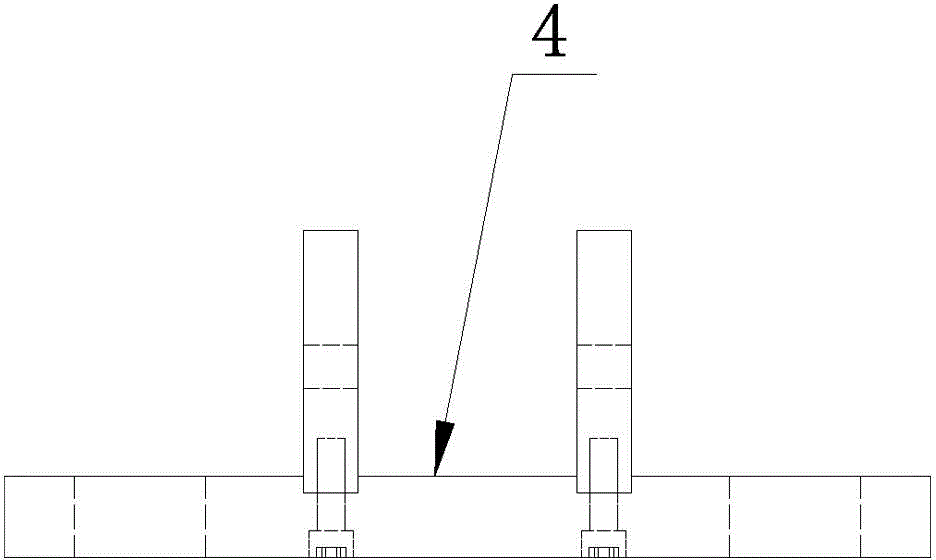

Racing automobile frame welding jig

InactiveCN104439851AAvoid deformationEasy to buildWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention provides a racing automobile frame welding jig which comprises a platform. Inverted T-shaped grooves are formed in the platform. Horizontal 4040 aluminum profiles are arranged on the faces of the inverted T-shaped grooves of the platform. The two ends of each horizontal 4040 aluminum profile are fixedly connected with the platform through T-shaped fixing clamping plates respectively. L-shaped corner joint plates are oppositely arranged on each horizontal 4040 aluminum profile. A vertical 4040 aluminum profile is vertically clamped between every two opposite L-shaped corner joint plates. An arc-shaped groove fixing clamping plate is arranged on one vertical 4040 aluminum profile and is composed of an arc-shaped groove fixing plate and U-shaped bolts. In the use process, a frame steel pipe is clamped and fixed through the arc-shaped groove fixing clamping plate. By means of the jig, all parts of a frame can be fixed and welded independently, overall welding is conducted after residual stress is eliminated, and therefore the stability of the frame is ensured, and the racing automobile machining and manufacturing are smoothly achieved; meanwhile, all the components of the jig are low in price, and the jig is convenient to detach, capable of being repeatedly used, long in service life and capable of greatly reducing the competition cost.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

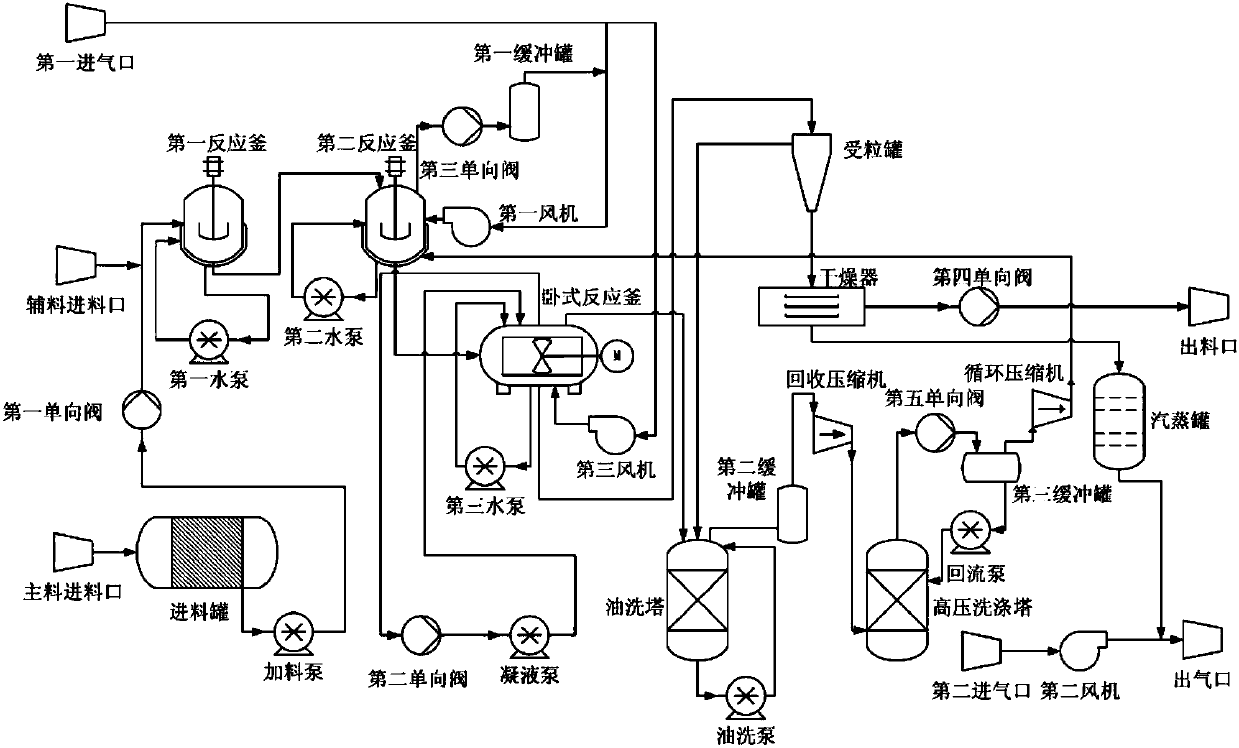

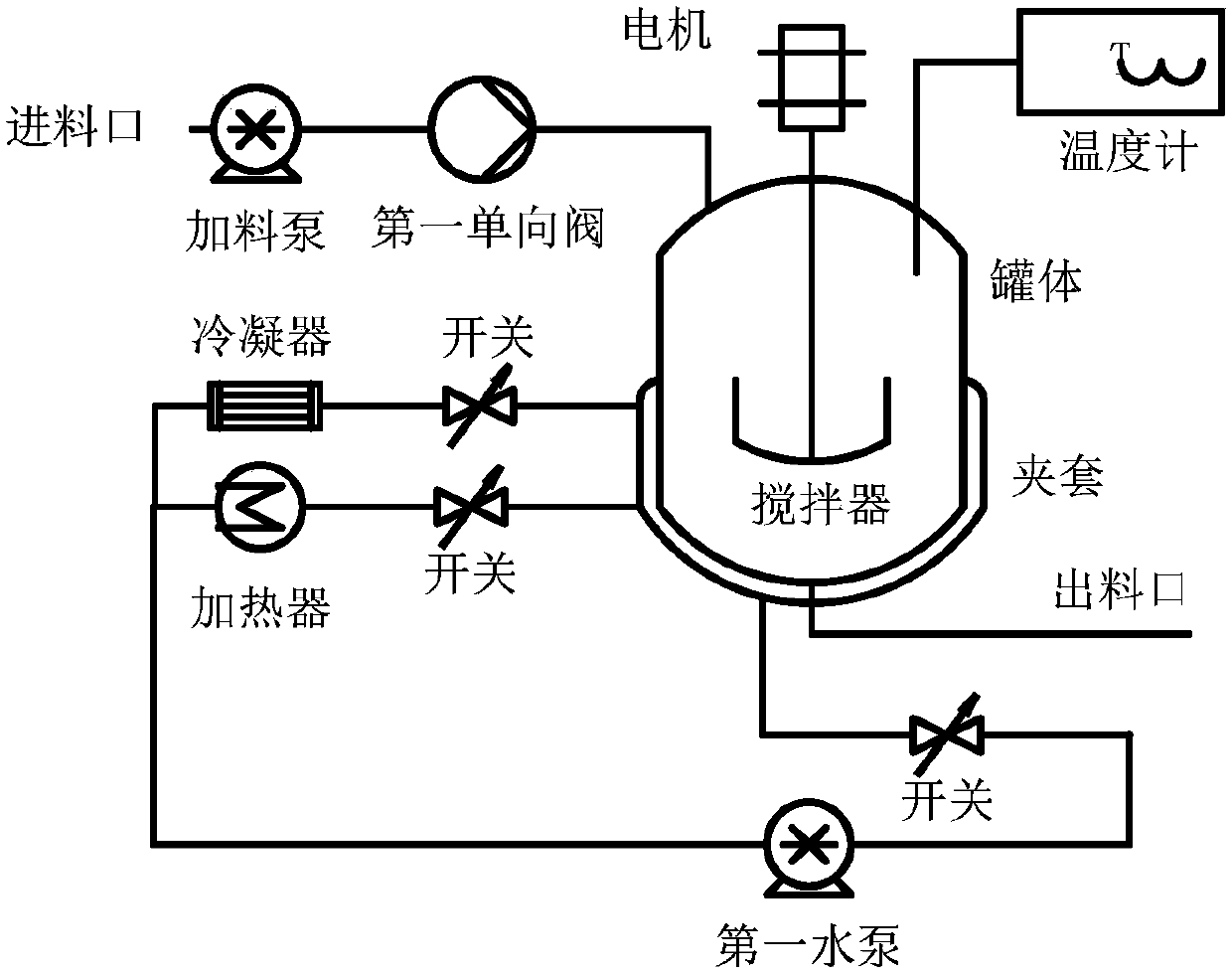

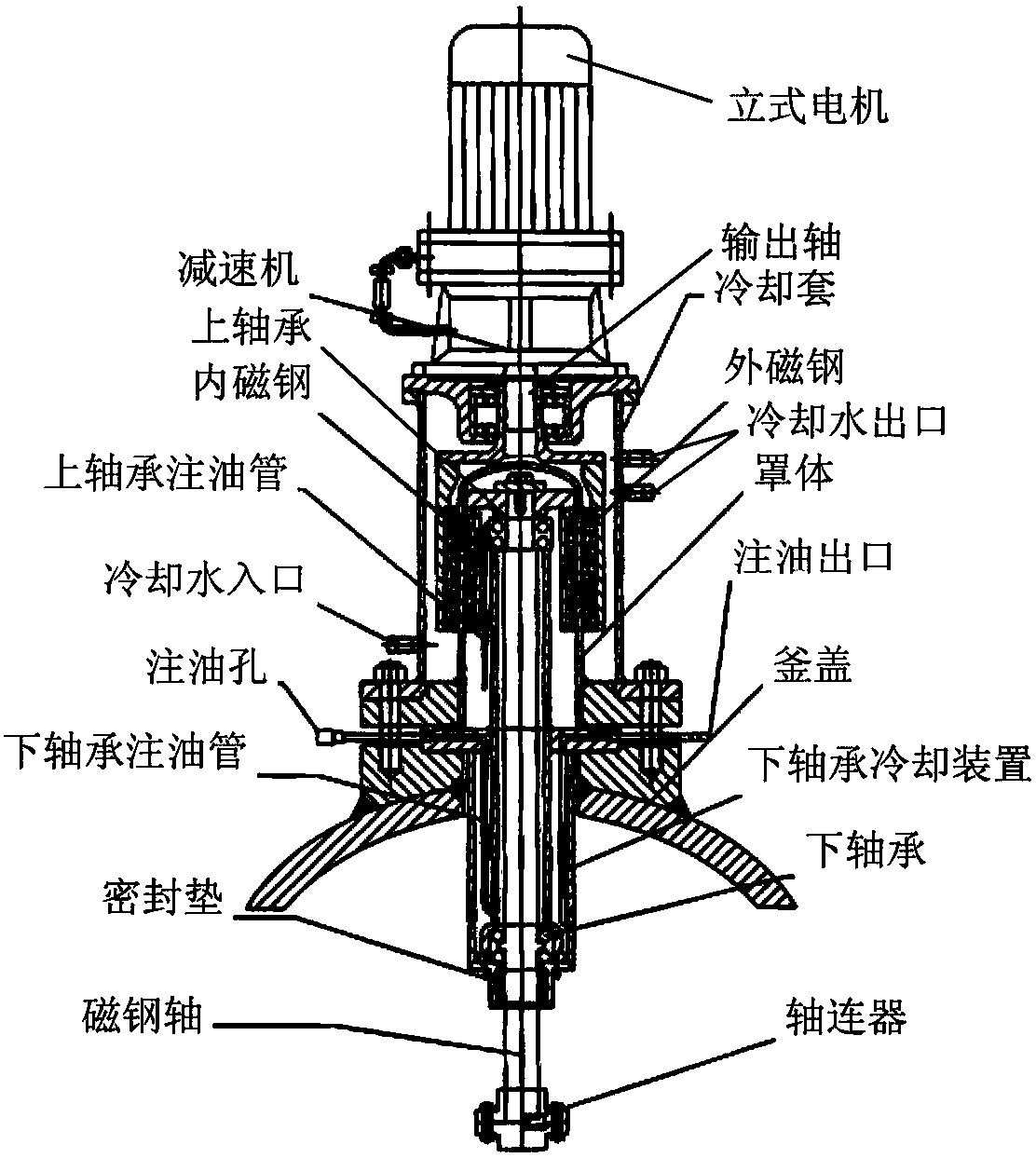

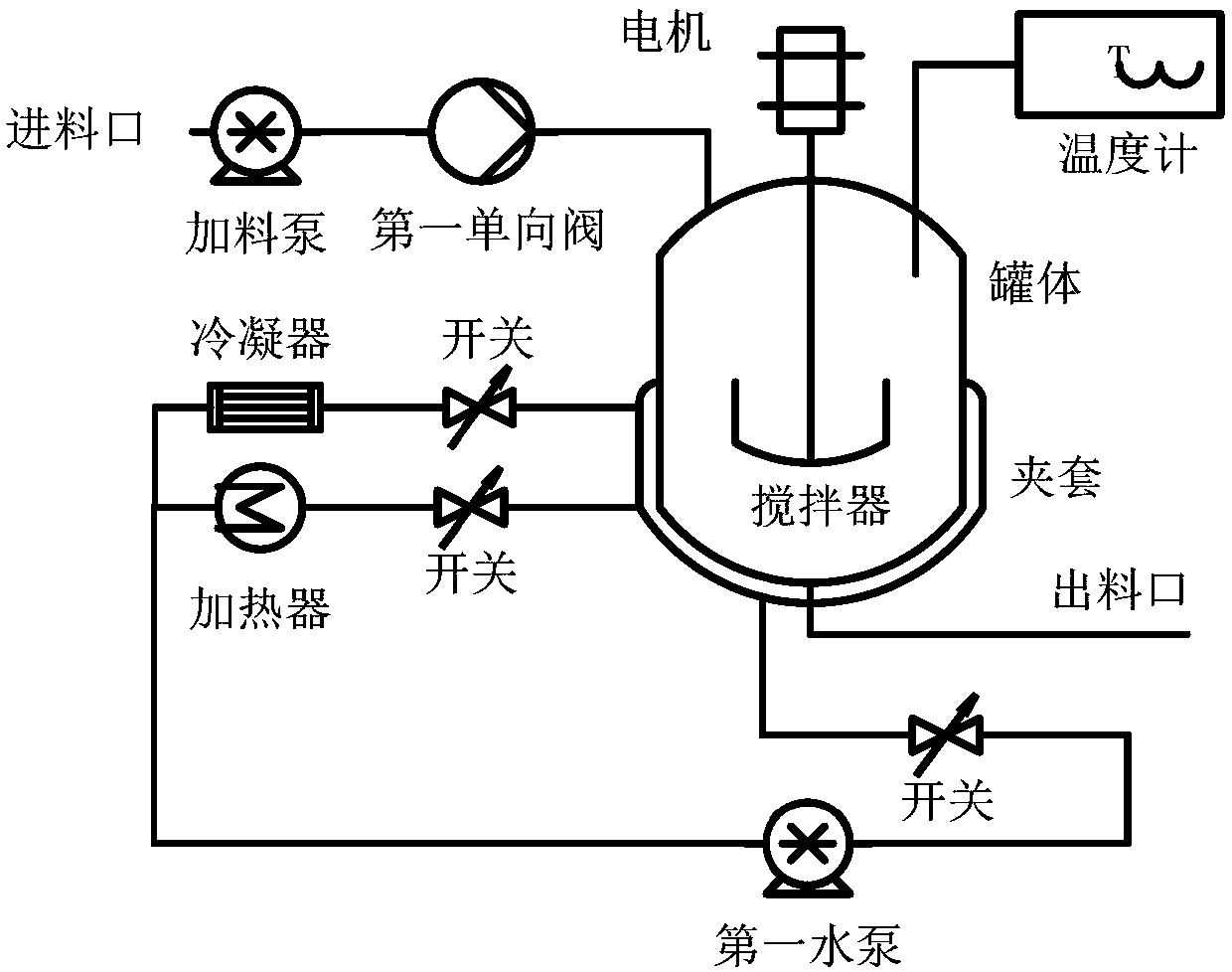

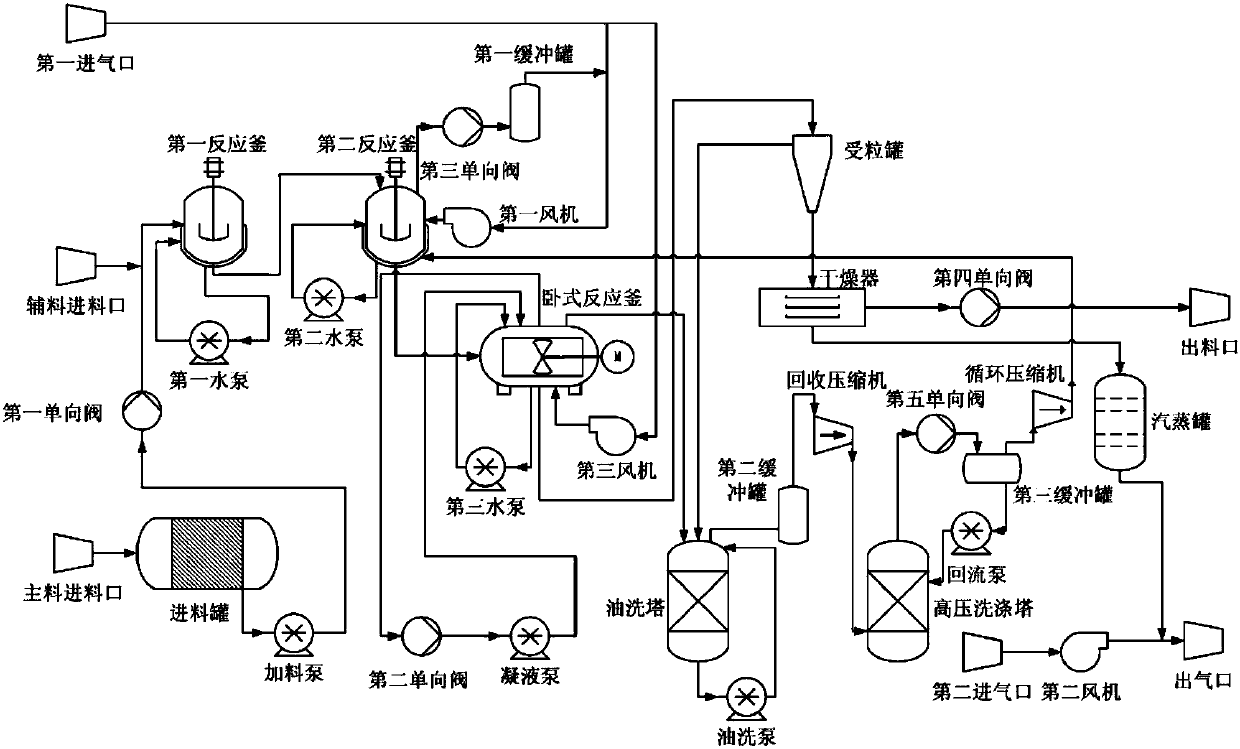

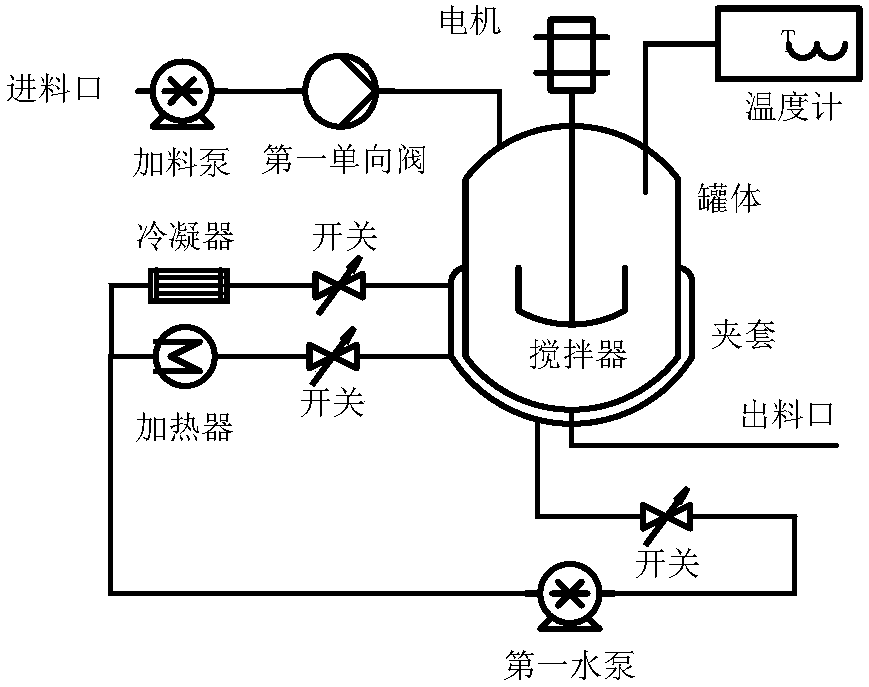

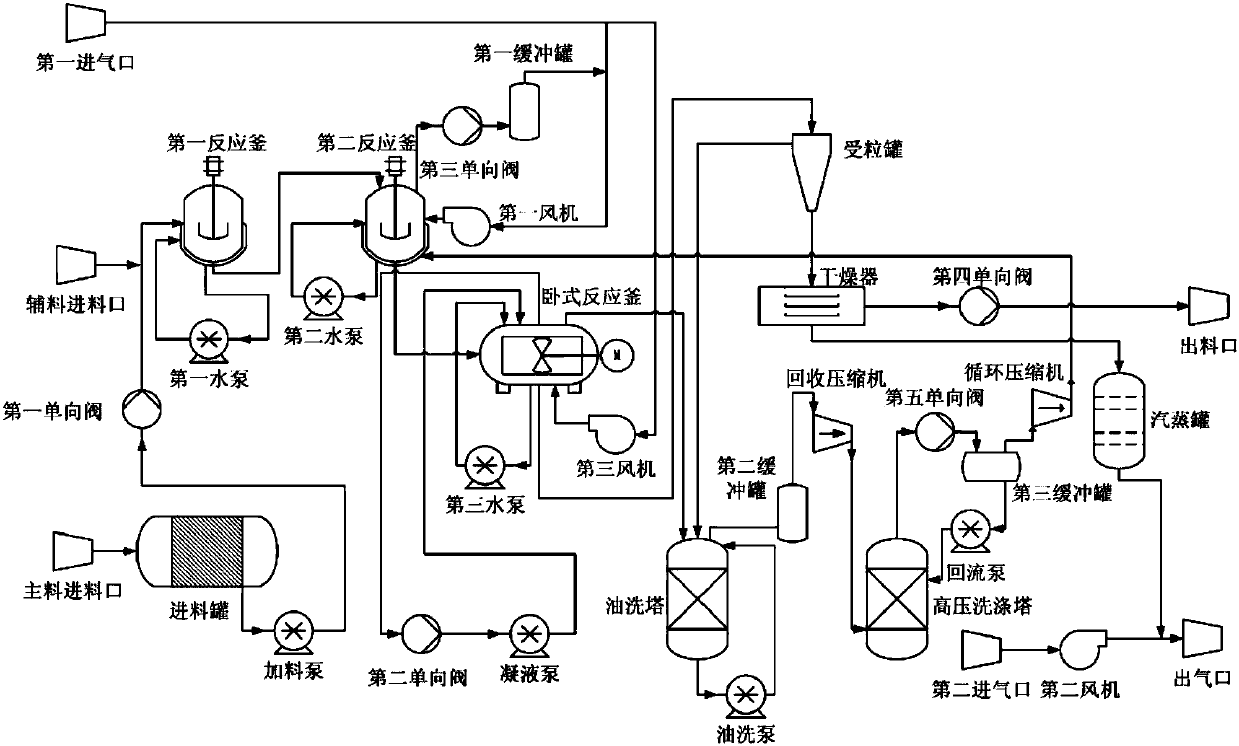

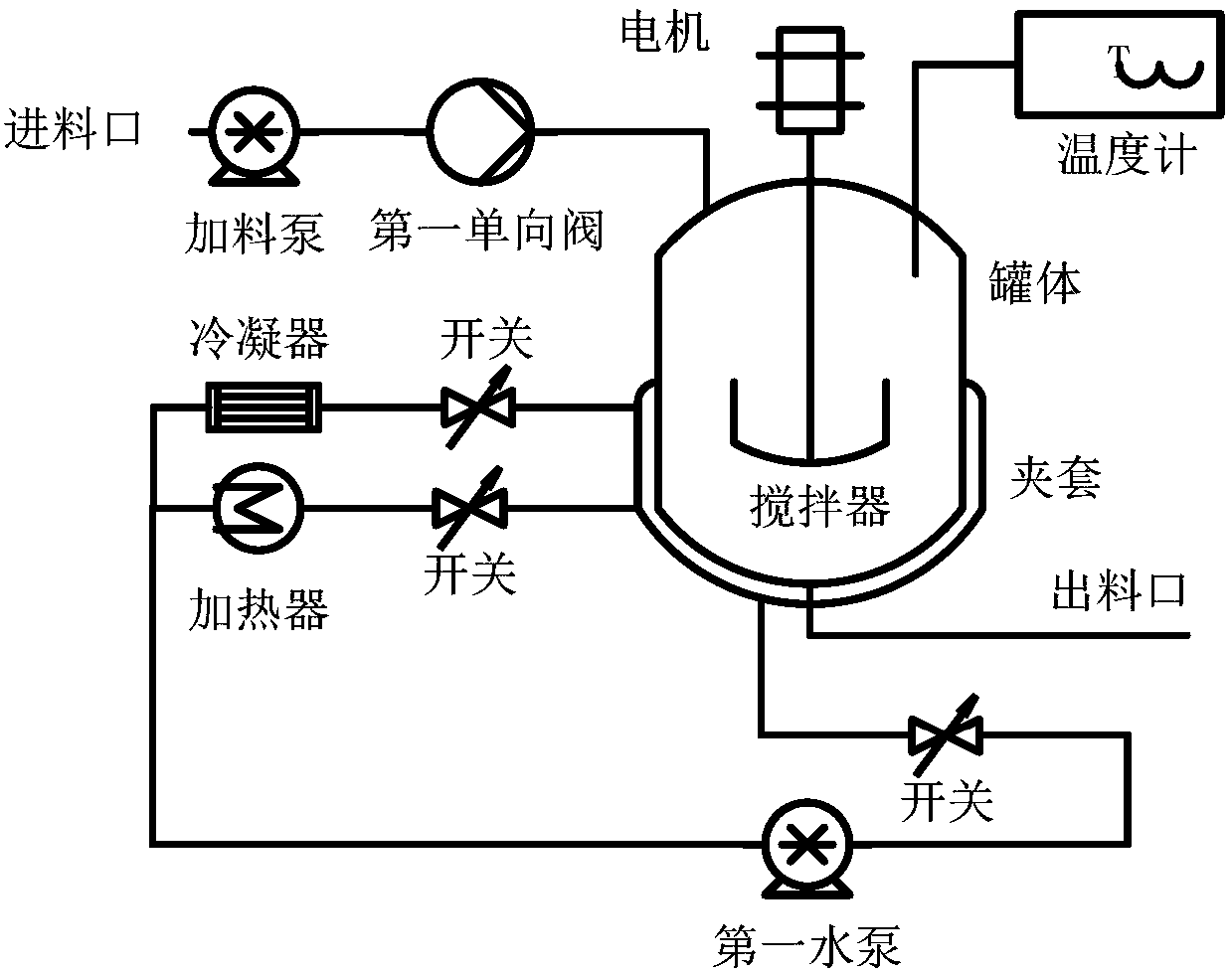

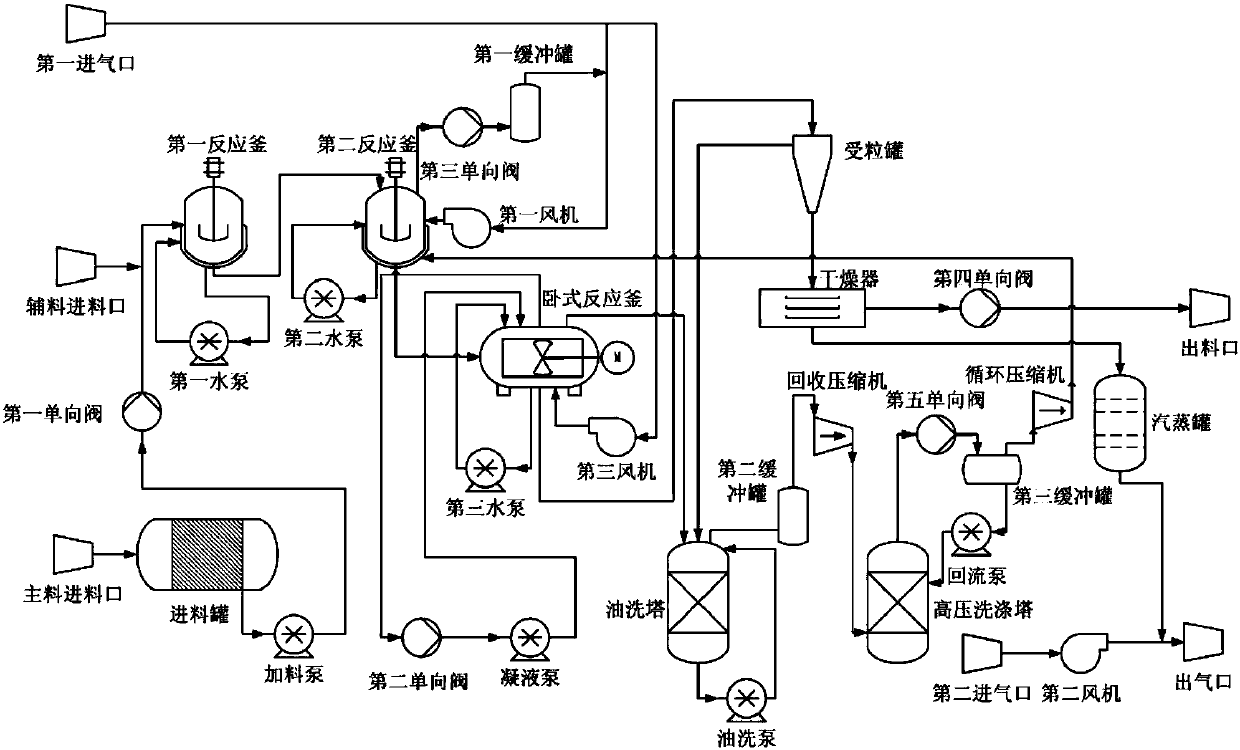

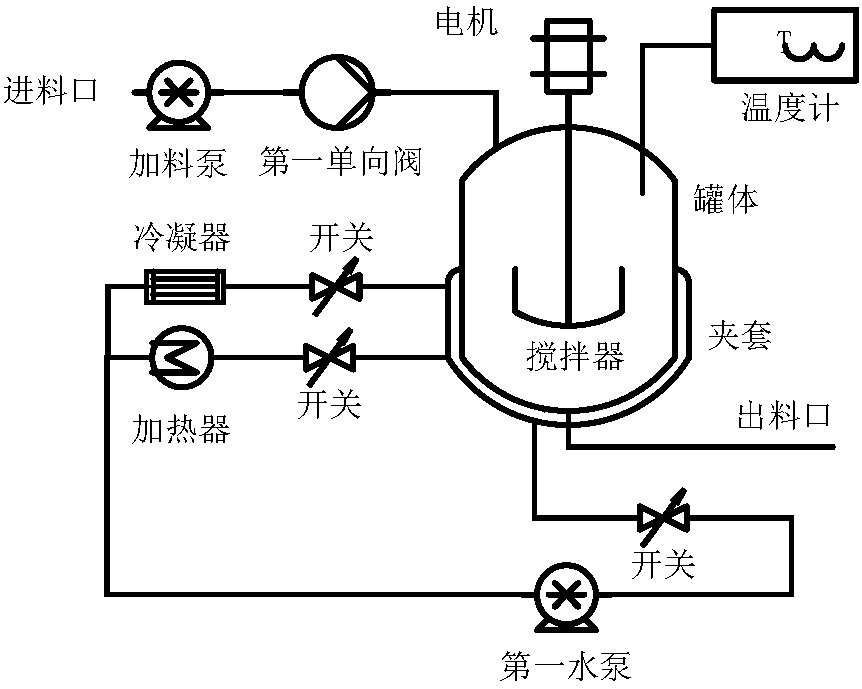

Chemical machinery system using vertical reactor

ActiveCN107670613APrevents the formation of fibrous and lumpy materialsReduce vibration transmissionProcess control/regulationCombination devicesCompound (substance)Mechanical system

The invention discloses a chemical machinery system using a vertical reactor. A first reactor is a vertical reactor and comprises a vertical tank, a vertical mixer and a vertical jacket. The verticaljacket is arranged in the middle-lower part of the vertical tank. The vertical jacket and the vertical tank form an enclosed concave interlayer. The side of the vertical jacket is provided with two water inlets. The bottom wall of the vertical jacket is provided with a water outlet. The water outlet is connected to a first water pump through a switch.

Owner:QINGDAO UNIV

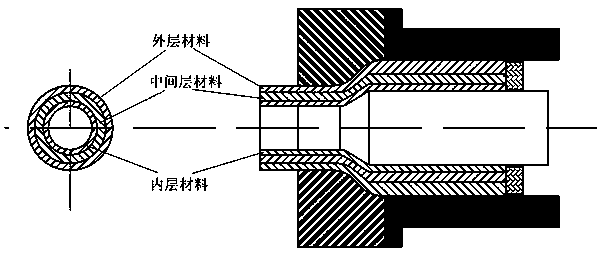

Semi-solid forming method of composite pipe

The invention relates to a semi-solid forming method of a composite pipe, and belongs to the technical field of semi-solid forming of metal. The semi-solid forming method comprises the following steps: at first, pouring a three-layered material by a centrifugal casting machine to obtain a composite pipe blank (at first, pouring an outer-layer easy-to-plastic deformation material, then pouring the middle-layer difficult-to-plastic deformation material, and at last, pouring an inner-layer easy-to-plastic deformation material); then, heating the composite pipe blank to the solid-liquid temperature interval of the difficult-to-plastic deformation material to enable the composite pipe blank to be in the semi-solid state, and reducing the diameter and the wall thickness of the composite pipe blank through high-speed extrusion, so as to obtain a pipe with a certain length; and at last, heating the hot extrusion pipe, so as to obtain a composite pipe with different mechanical properties. The semi-solid forming method solves the problem that a difficult-to-deformation pipe is difficult to process and manufacture, long in forming cycle, and high in product cost, and expands the application field of a semi-solid forming technology.

Owner:KUNMING UNIV OF SCI & TECH

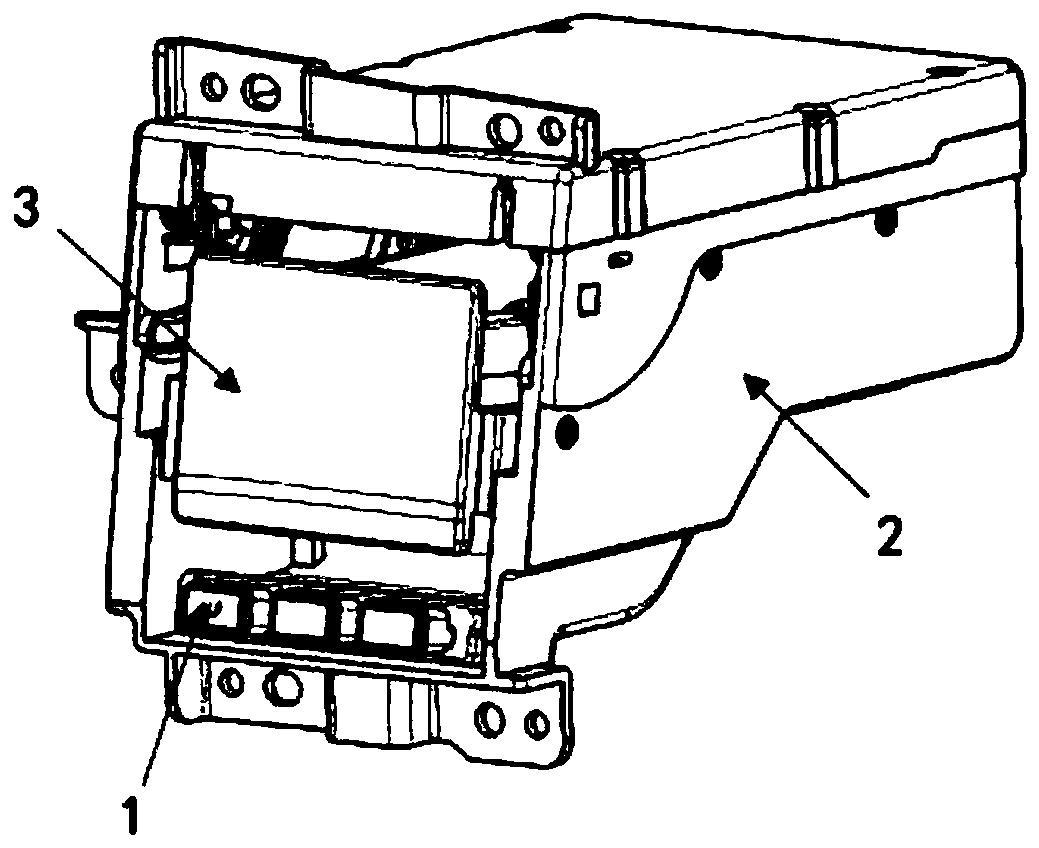

Electric mobile phone support, automobile instrument panel and automobile

The invention discloses an electric mobile phone support, an automobile instrument panel and an automobile. The electric mobile phone support comprises a shell which is internally connected with a mobile phone fixing support capable of stretching out of the shell; a guide rod and guide groove limiting mechanism and a transmission driving mechanism which are used for driving the mobile phone fixingsupport to move and overturn relative to the shell are arranged between the shell and the mobile phone fixing support; when the mobile phone fixing support is located in the shell under the effects of the guide rod and guide groove limiting mechanism and the transmission driving mechanism, the mobile phone fixing support is in a horizontally-stored state; and when the mobile phone fixing supportis located outside the shell under the effects of the guide rod and guide groove limiting mechanism and the transmission driving mechanism, the mobile phone fixing support is in a vertically-used state. The mobile phone fixing problem can be solved under the premise that the air blowing property of an air outlet and the driving visual field of a driver are not sacrificed, automatic operation in the whole journey can be achieved, meanwhile electric hiding is achieved, and the appearance effect is good.

Owner:DONGFENG MOTOR CORP HUBEI

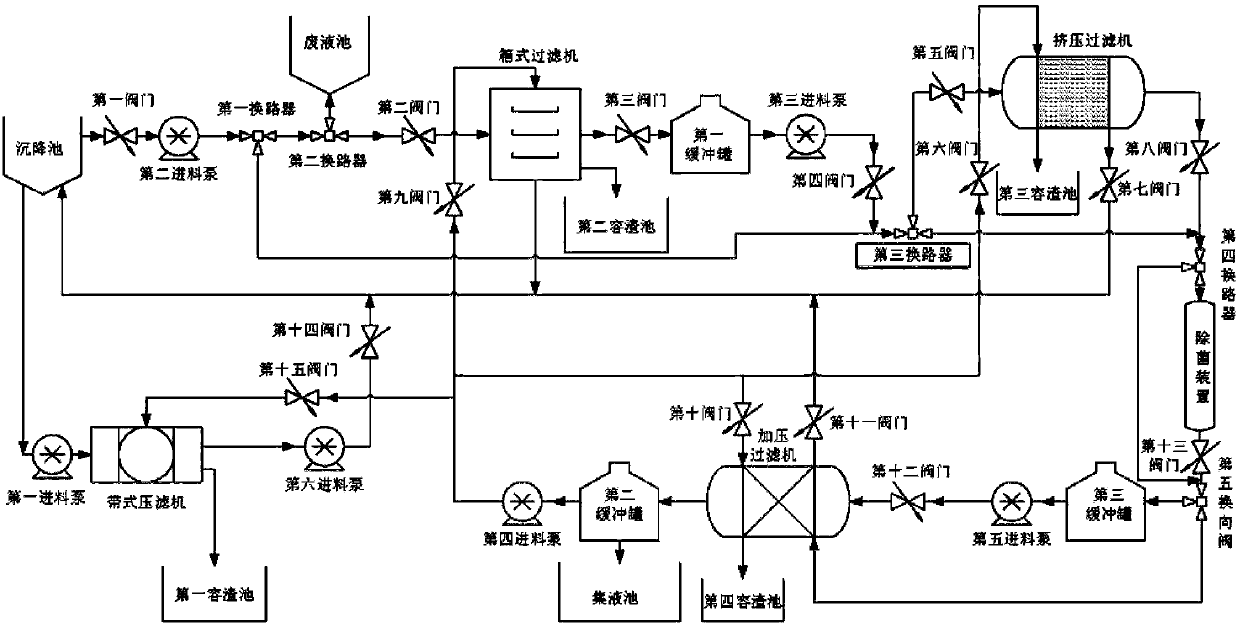

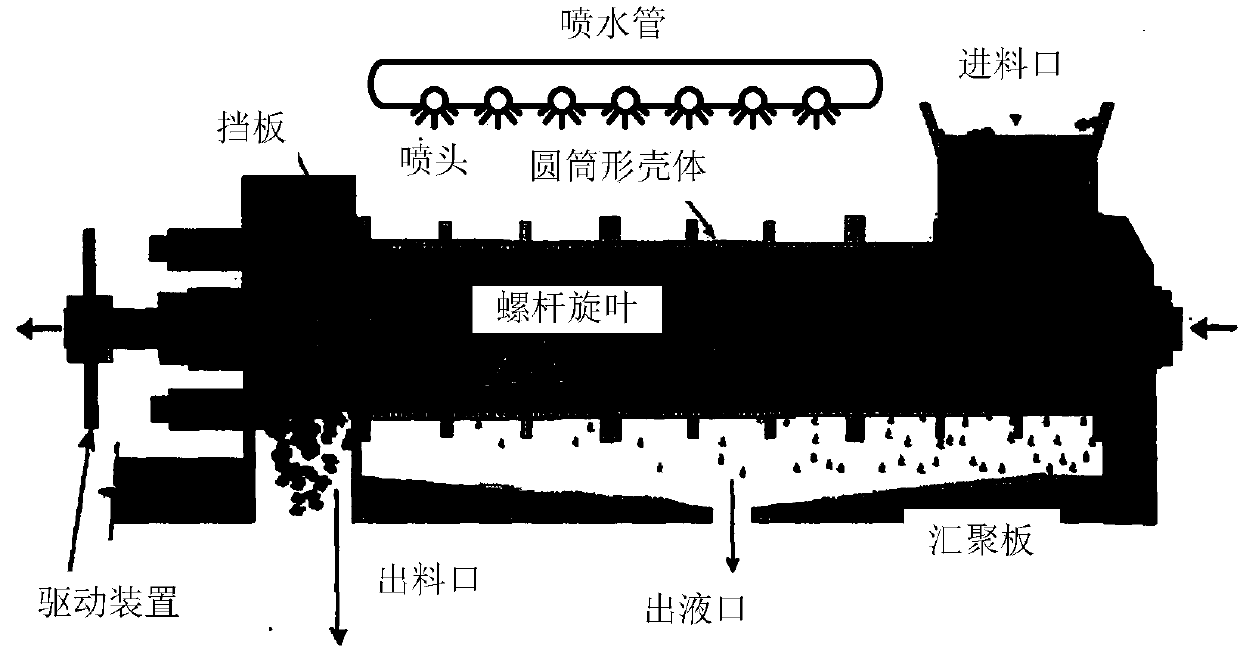

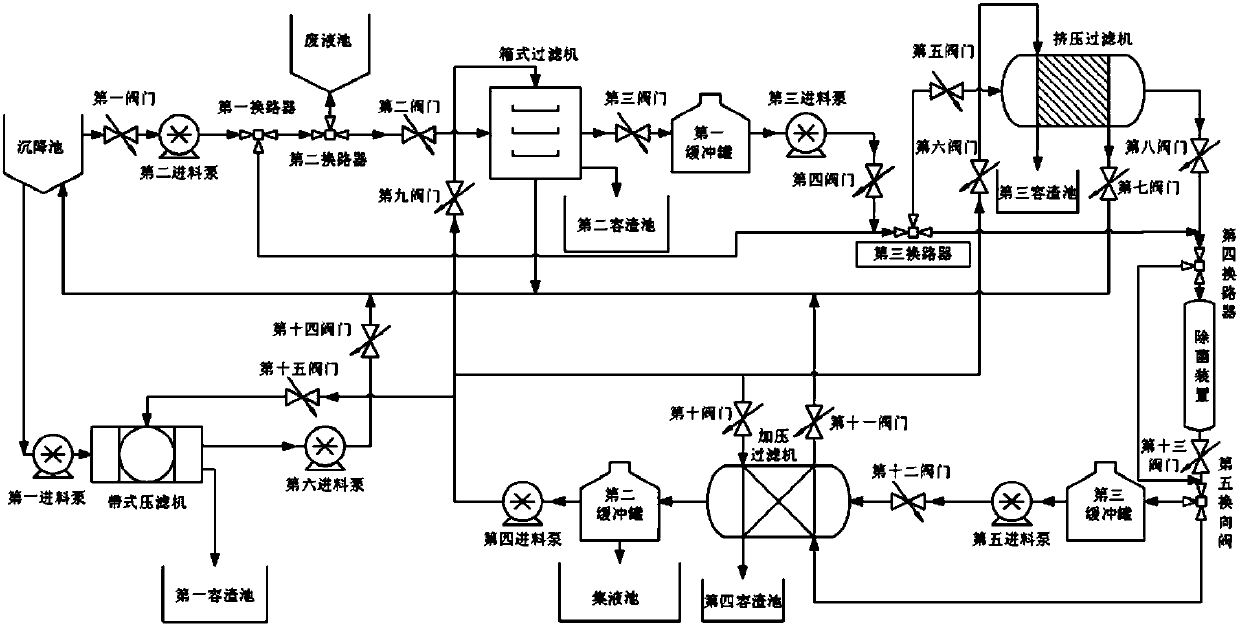

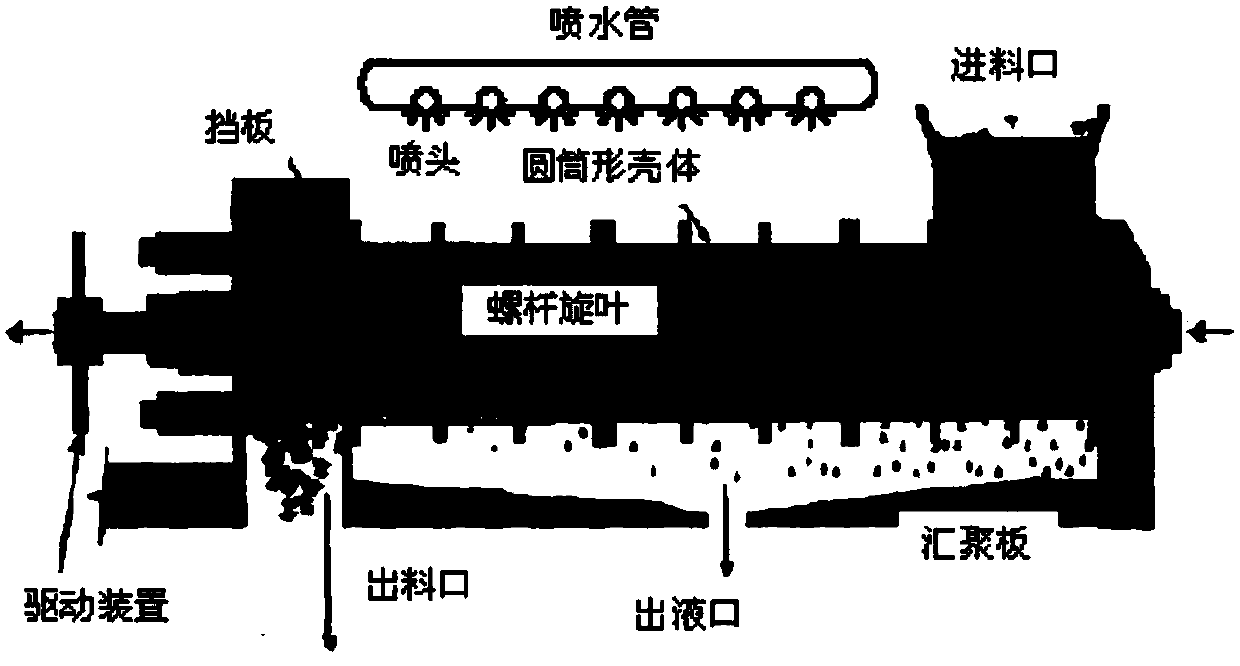

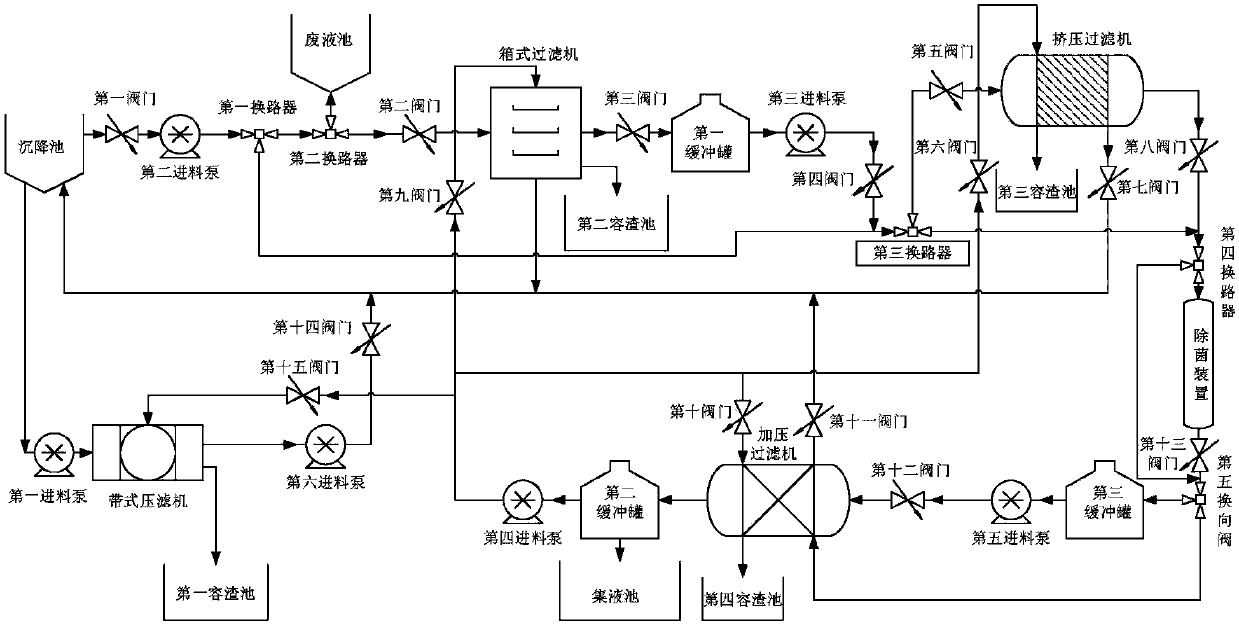

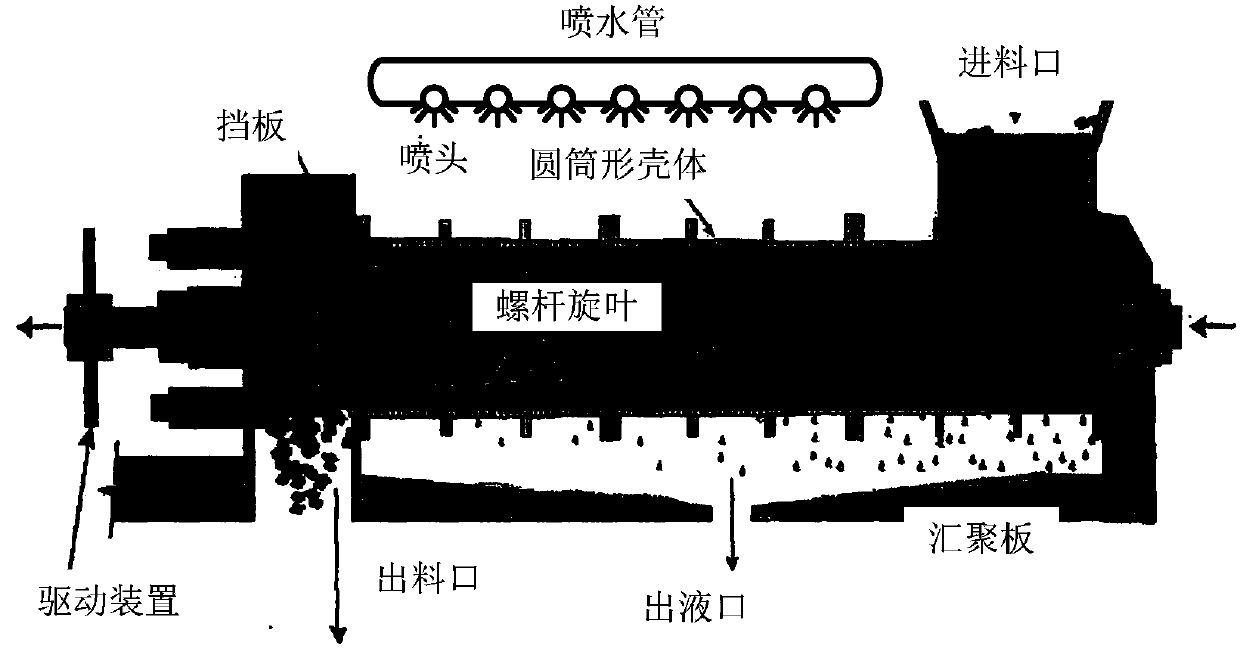

Chemical slurry squeezing filtration system

ActiveCN107670385ARealize processing and manufacturingFilter thoroughlyWater treatment parameter controlSpecific water treatment objectivesSlagFiltration

The invention discloses a chemical slurry squeezing filtration system. The system comprises one belt filter press, one box filter, one pressure filter, one squeezing filter, one sterilization device,one sedimentation tank, one waste liquid pool, one liquid collection pool, four slag storage tanks, three buffer tanks, six feeding pumps, five circuit switches and fifteen valves. The squeezing filter comprises a waster spray pipe, a cylindrical housing, screw vanes, a driving motor and a gathering plate. The screw vanes are arranged at intervals.

Owner:山东辰安化学有限公司

Performance verification method of high-fluidity concrete of steel shell

ActiveCN107656037AImprove qualityRealize processing and manufacturingMaterial testing goodsValidation methodsMaterials science

The invention relates to a performance verification method of high-fluidity concrete of a steel shell, which is characterized by including steps of designing multiple models with different sizes; orderly selecting corresponding models from small to big, and carrying out the test of the high-fluidity concrete. Specific to the construction technique requirement of the high-fluidity concrete of the steel shell, the method applies multiple models orderly to verify the influences of the concrete matching ratio, pouring method, pouring speed and other technical parameters on the concrete filling state one by one, evaluate the high-fluidity concrete filling property, optimize the high-fluidity concrete matching ratio, adjust the construction technical parameter and other factors, and realize thehigh-quality processing and application of the concrete.

Owner:CCCC FOURTH HARBOR ENG INST +1

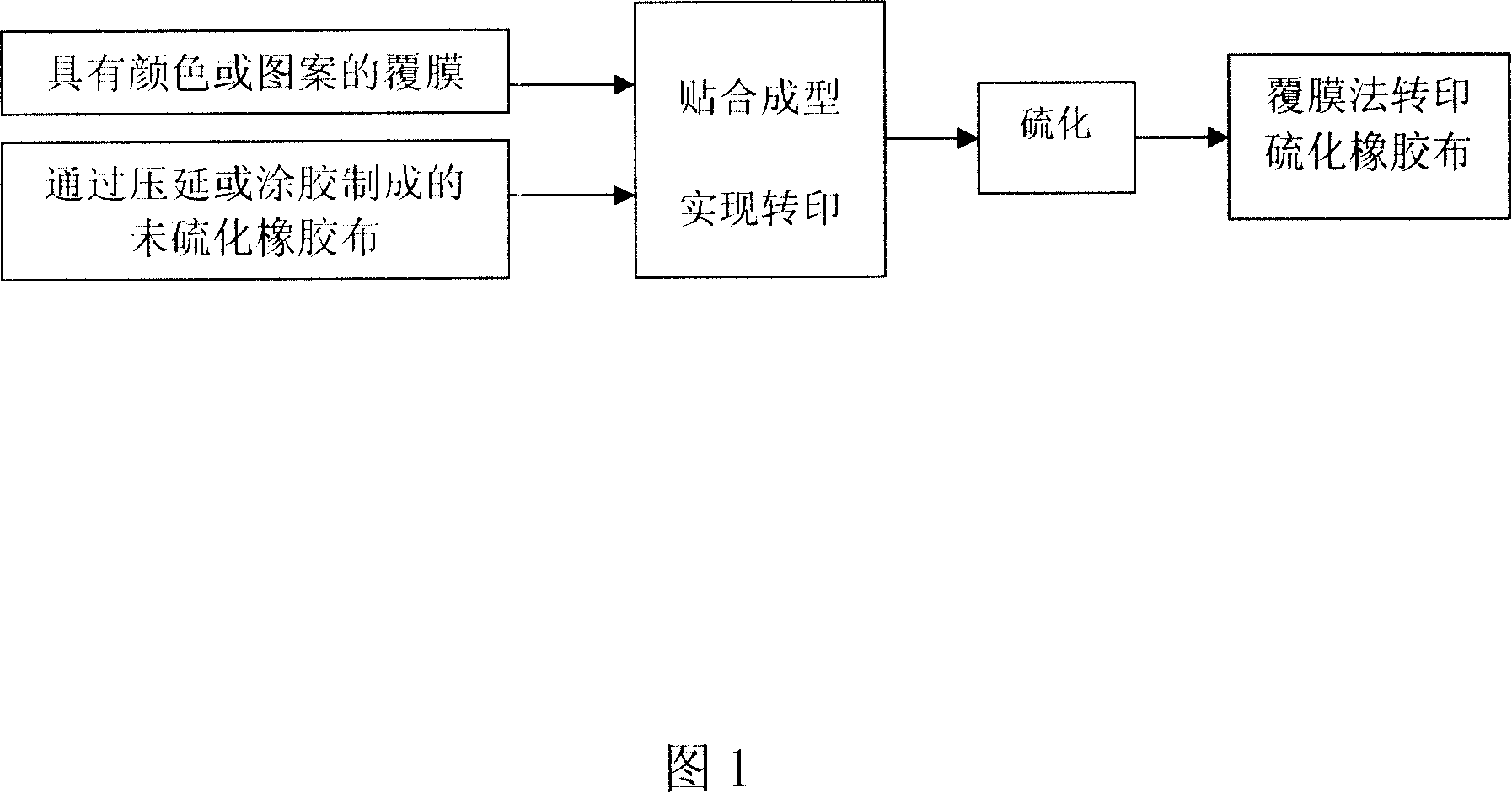

Method for producing colorful rubber cloth

A manufacturing method of color rubber canvas relates to a manufacturing technique of rubber canvas, in particular to a manufacturing technique of non-black rubber canvas. The invention aims to provide a manufacturing method of color rubber canvas with uniform color, stable quality and convenient technique. The invention firstly uses printing means to print color rubber type ink on a polyester film to form an ink layer, and then the ink layer on the polyester film is attached with a compound layer of a non vulcanized rubberized fabric, so that the ink layer is transmitted from the polyester film onto the compound layer of the non vulcanized rubberized fabric, and a whole is formed after vulcanization, and then, the polyester film can be peeled.

Owner:SHENYANG RUBBER RES & DESIGN INST CO LTD

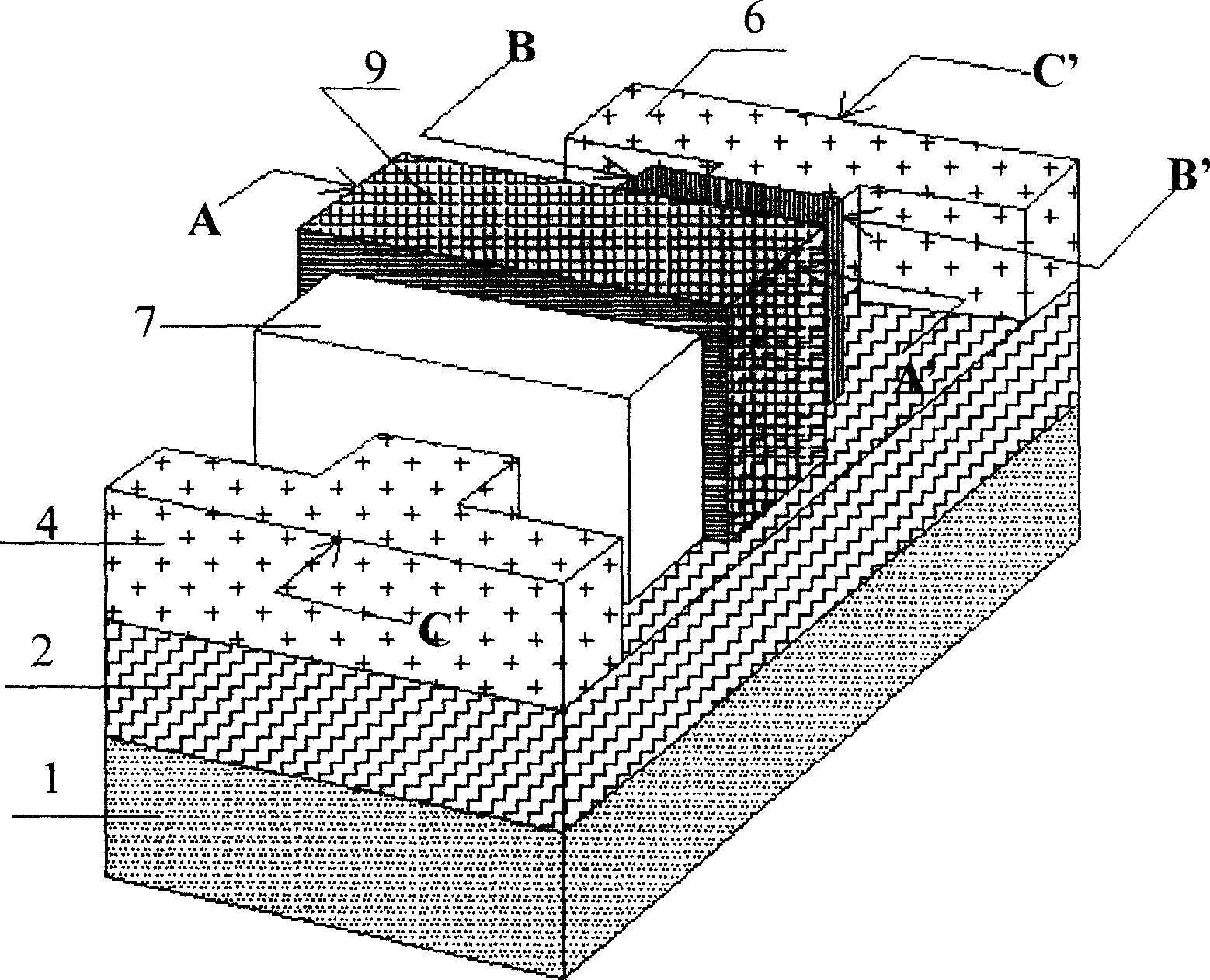

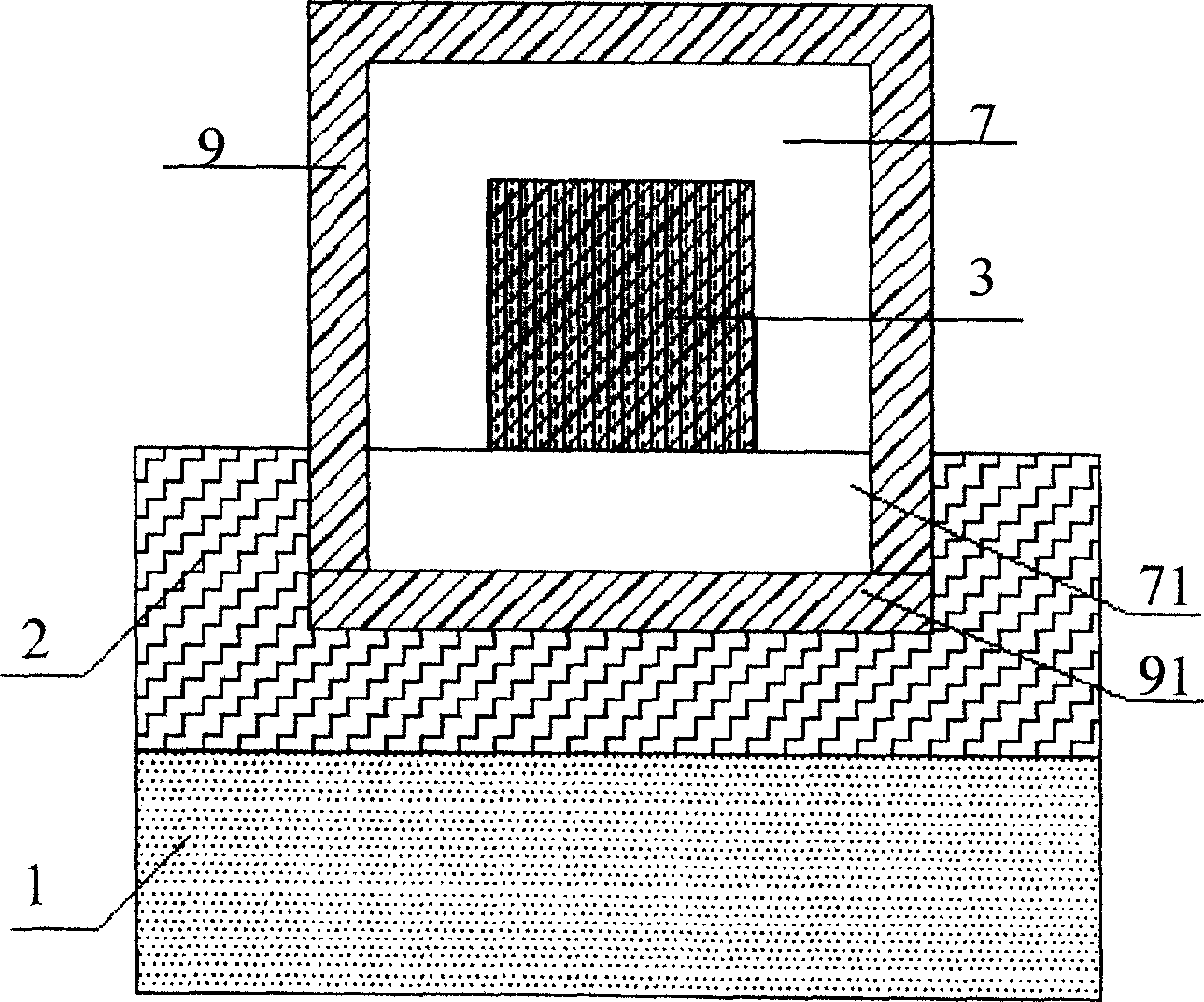

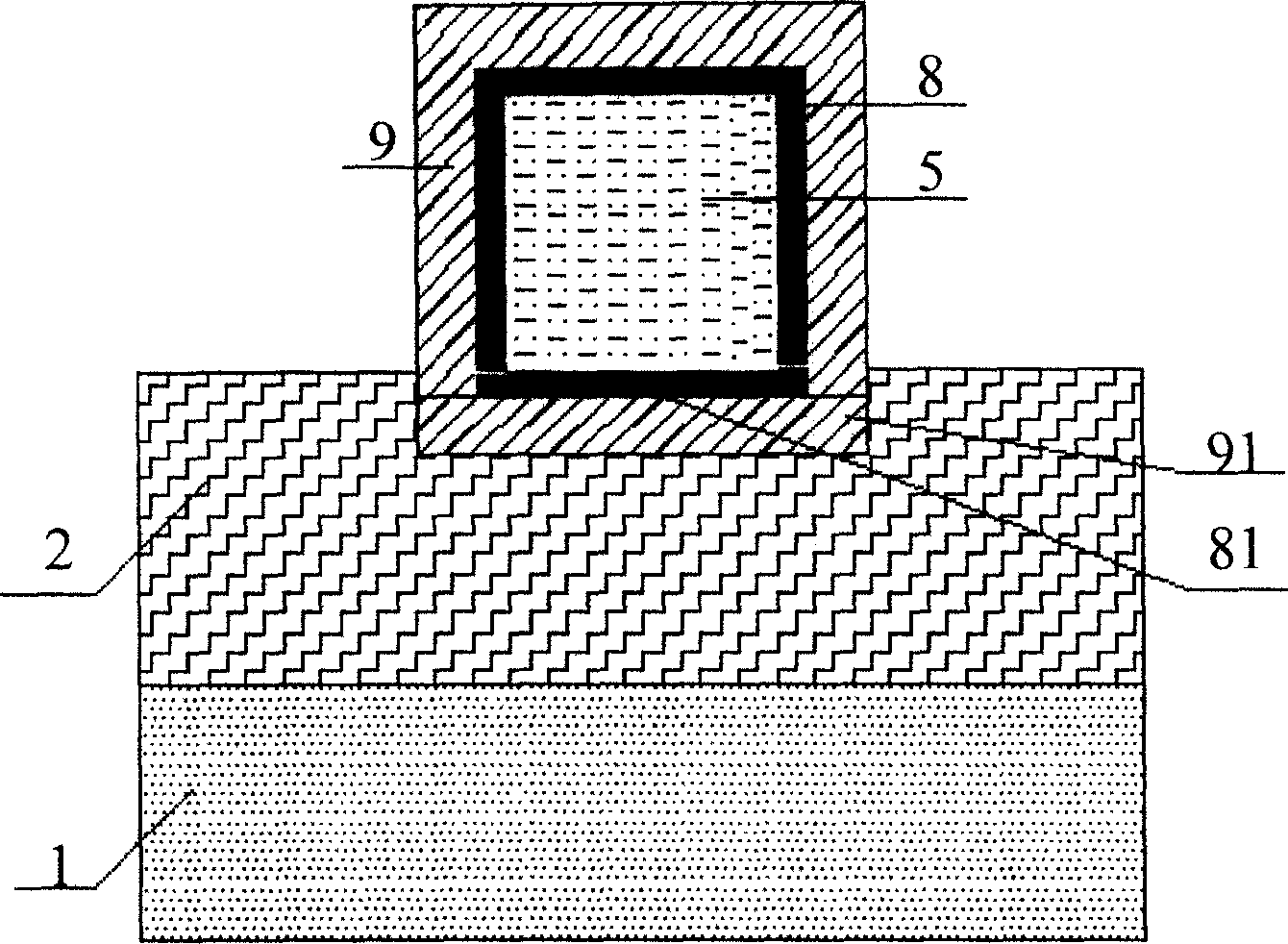

Three-dimensional multi-gate high-voltage N type transverse double-diffused metal-oxide semiconductor device

InactiveCN1763971AGood breakdown characteristicsGood temperature characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesOxide semiconductorOxide

The invention discloses a three-dimension multigrid N-type lateral dual-diffusion MOS transistor used as high-voltage device, which comprises: a P-type substrate with oxidation layer, a column N-type drift region on oxidation layer; a N-type drain and channel on oxidation layer and two ends of N-type drift region, a N-type source on oxidation layer and near N-type channel; a field oxide to cover the surface of N-type drift region, a grid-oxidation layer on N-type channel surface, a polysilicon layer to cover the field oxidation layer and grid-oxidation layer surface. This invention has compact structure, makes conduction resistance less than one third of traditional tube, and increases current density more than two times.

Owner:SOUTHEAST UNIV

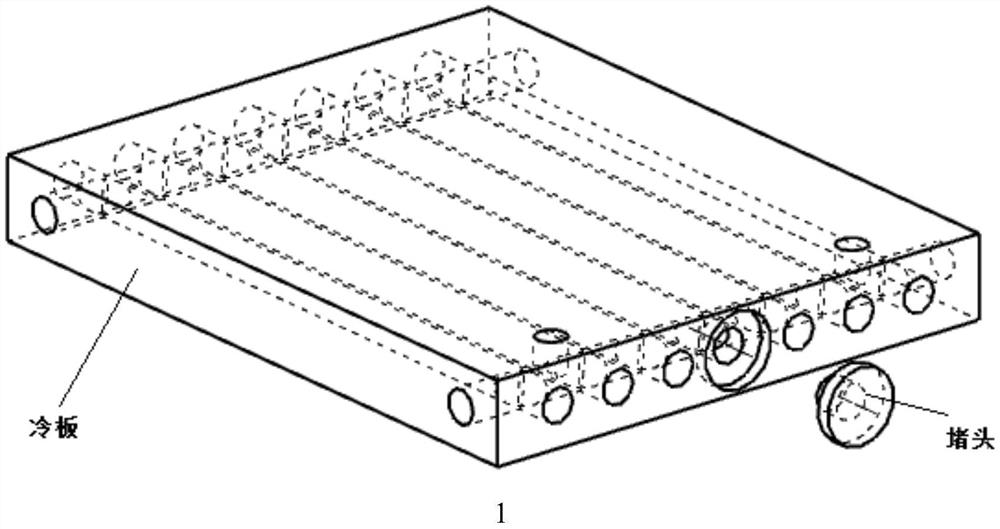

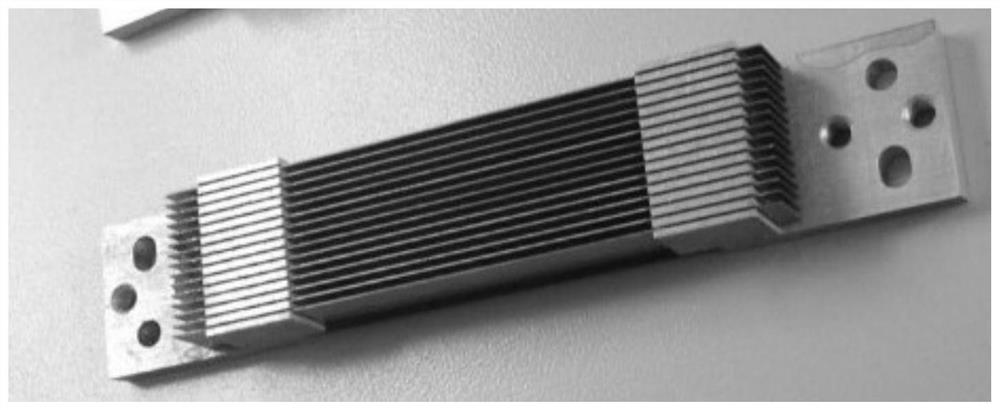

Machining method for internal runner structure of cold plate and application of machining method

InactiveCN113001120ARealize processing and manufacturingReduce manufacturing costCold plateMachining

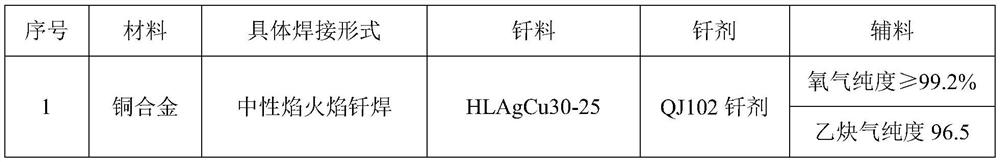

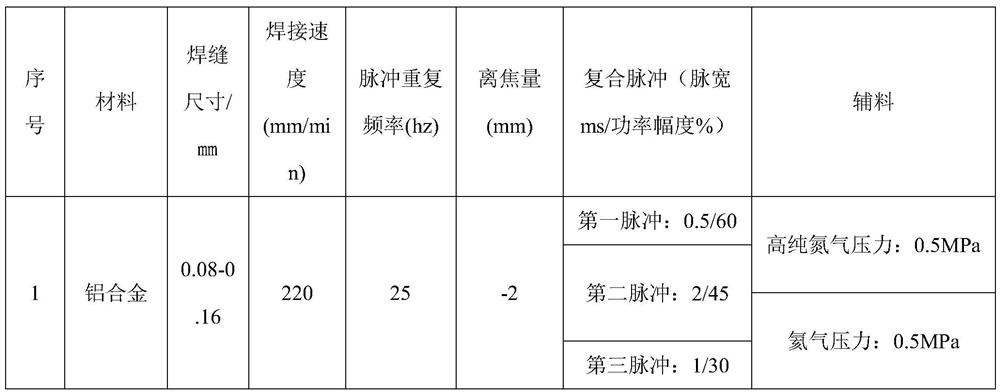

The invention discloses a machining method for an internal runner structure of a cold plate and application of the machining method. The machining method comprises the following steps: S1, drilling a pre-hole in the side wall of a cold plate, and forming a runner according to the pre-hole by adopting a cutting machining mode; and S2, welding plugs to the two ends of the runner by silver brazing or laser welding or argon arc welding, wherein the plugs and the cold plate are made of the same material. According to the runner machining method, cutting machining is conducted firstly, and then welding is conducted. On one hand, compared with the mode that parts are split into two halves and then assembled and welded, the machining method has the advantages that the technological process is more simplified, and the production period is shortened. On the other hand, the requirement on welding equipment is relatively low, the manufacturing difficulty is lowered, and wide application range is achieved. Compared with an existing widely-adopted machining mode, the machining method has the advantages that the efficiency is greatly improved, and the cost is correspondingly reduced.

Owner:SICHUAN JIUZHOU ELECTRIC GROUP

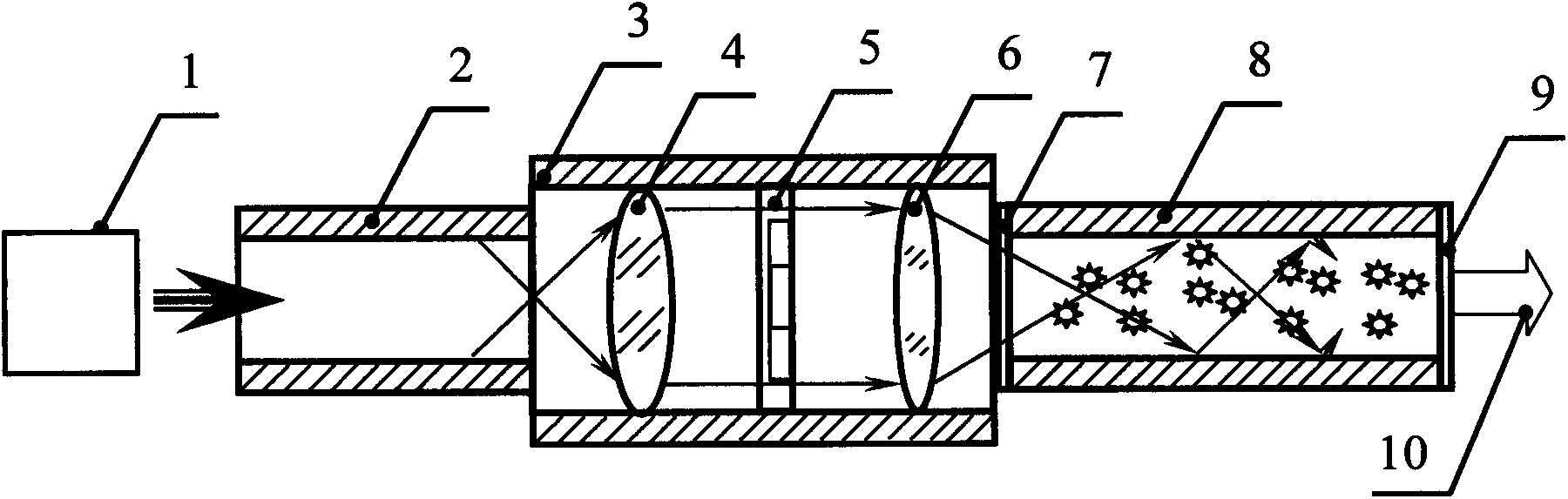

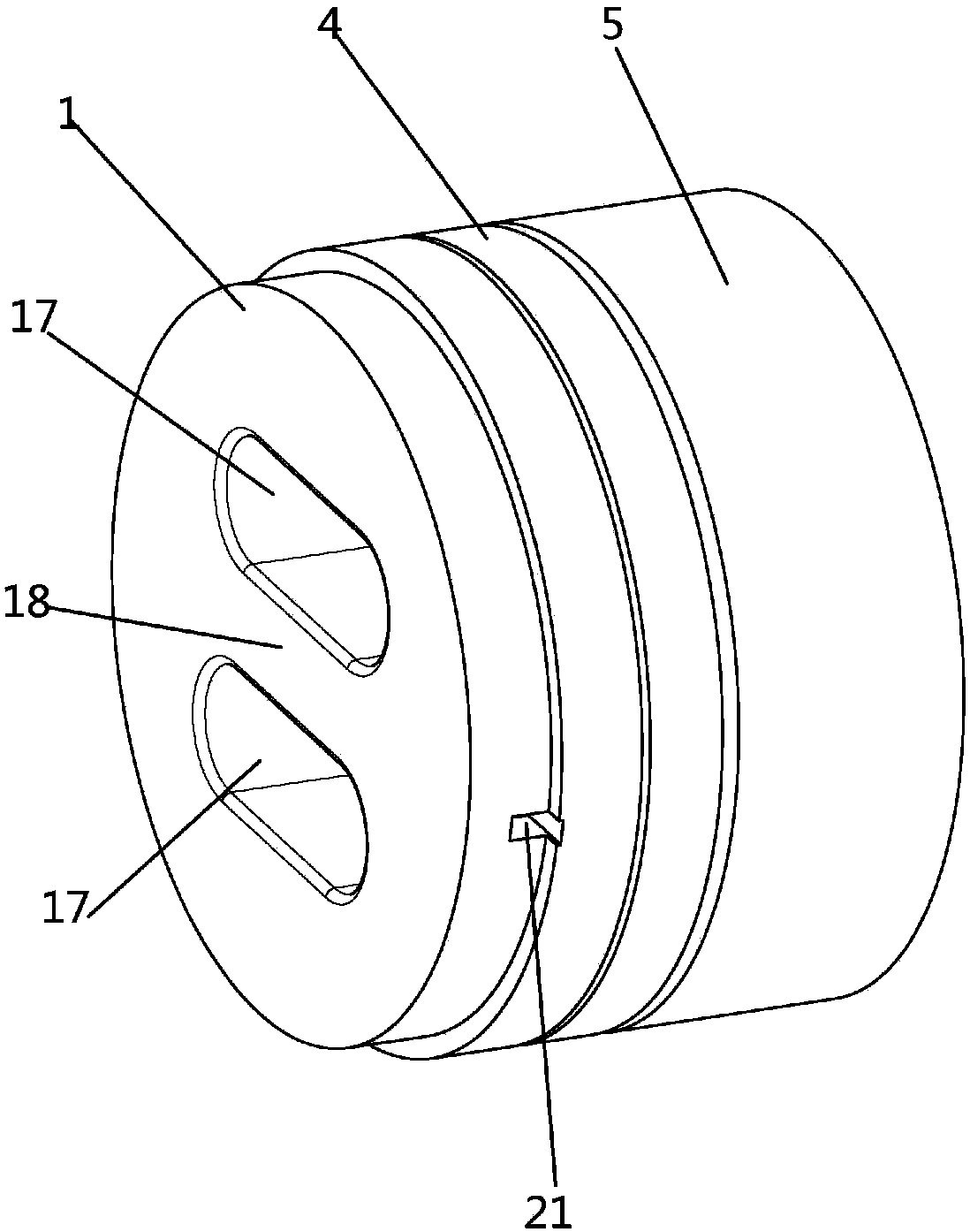

Optical fiber optofluidic dye laser

InactiveCN104037614AFew preparation stepsSimple processActive medium materialOptical pumpingDye laser

The invention discloses an optical fiber optofluidic dye laser. The optical fiber optofluidic dye laser comprises a pump optical source, a pumping optical fiber, a first reflecting mirror, a dye hollow-core optical fiber and a second reflecting mirror which are connected with one another in sequence are arranged along a light beam emitting direction of the pump optical source, dye in sealed space which is formed by the first reflecting mirror, the dye hollow-core optical fiber and the second reflecting mirror serves as a laser gain medium, and a light beam shaping device which is used for adjusting wavefront phase positions of pump light beams is mounted between the pumping optical fiber and the first reflecting mirror. The optical fiber optofluidic dye laser has advantages of existing optofluidic lasers, and meanwhile, has the advantages that the system structure is simple, the miniaturization degree is high, the preparation technology is simple, axial symmetry optical pumping is achieved, the pumping optical energy utilizing ratio is high, the application range is wide, qualities of the light beams are good, output beam modes are controllable, the usage is flexible, and the like.

Owner:高秀敏

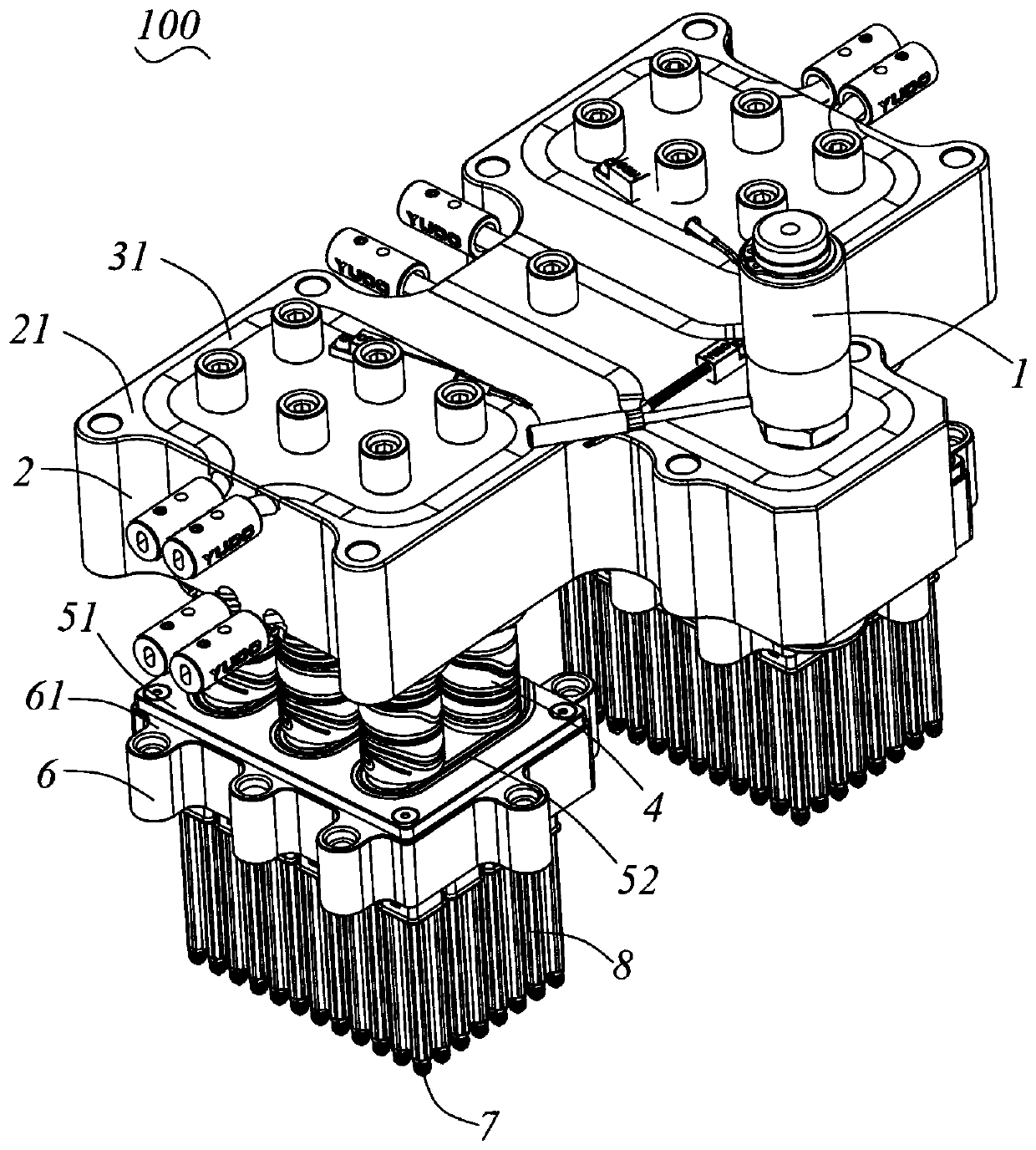

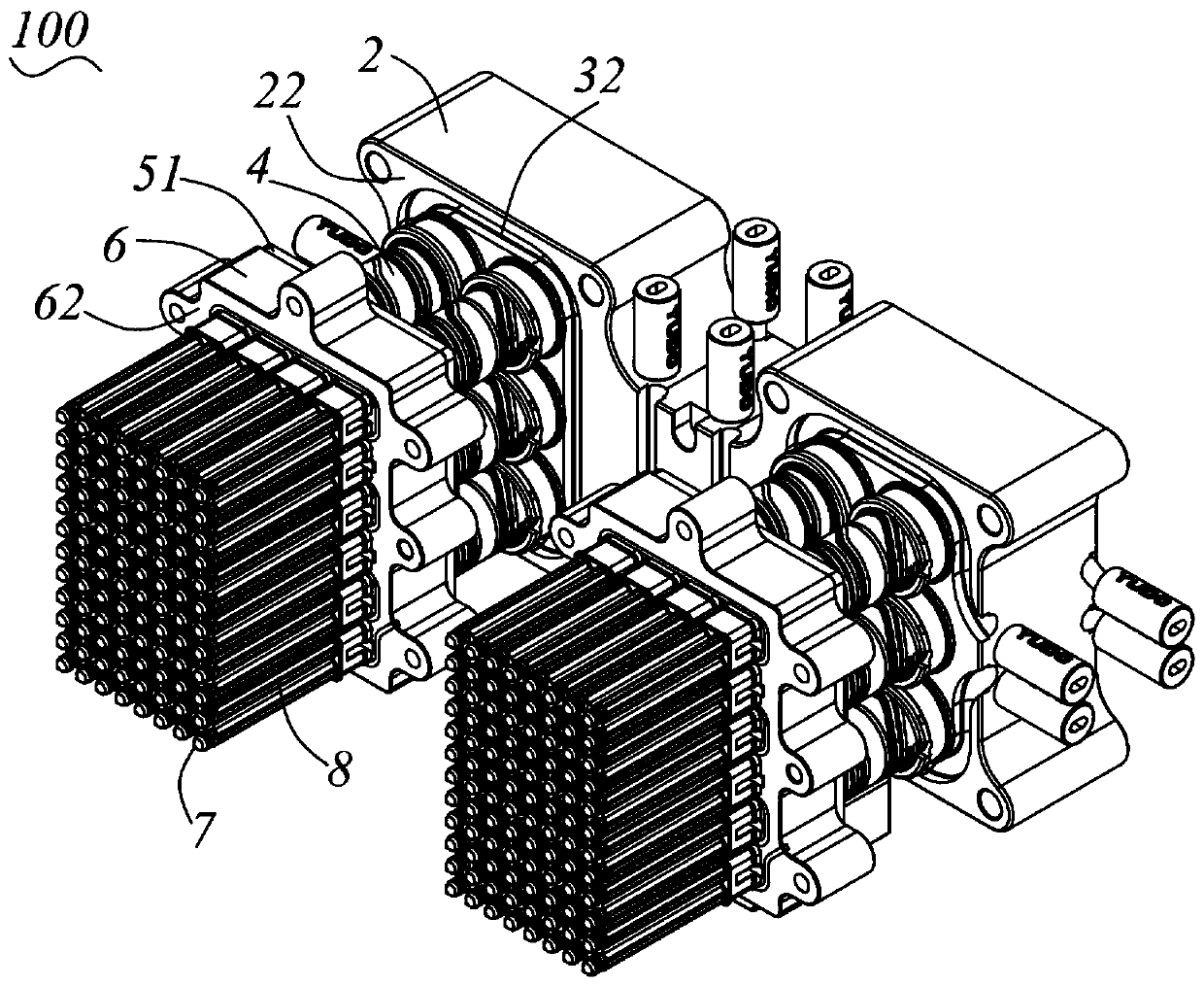

Hot runner mold system for deep hole plate

PendingCN110843178ARealize processing and manufacturingGuarantee product qualityHot runnerEngineering

The invention discloses a hot runner mold system for a deep hole plate. The hot runner mold system for the deep hole plate comprises a template and a hot runner device, wherein the template is provided with a cavity of the deep hole plate and a plurality of pin-point gates corresponding to a plurality of holes of the deep hole plate in a one-to-one mode, the hot runner device comprises a main sprue bushing, a plurality of sharp nozzles matched with the pin-point gates in a one-to-one mode, and a runner mechanism arranged between the main sprue bushing and the sharp nozzles, a sizing material runner is formed in the runner mechanism, and the main sprue bushing communicates to each sharp nozzle through the runner. Compared with the prior art, the hot runner mold system for the deep hole plate has the following beneficial effects that on one hand, a hot runner injection molding process can be adopted to realize processing and manufacturing of the deep hole plate; and on the other hand, byarranging the pin-point gates and the sharp nozzles which are in one-to-one correspondence with the holes of the deep hole plate, the synchronous glue injection of the holes of the deep hole plate isrealized, the product quality of the deep hole plate is ensured, and the defect of the bottoms of the holes caused by the backward pouring of glue materials of part of the holes due to the asynchronous glue feeding of the holes is avoided.

Owner:YUDO SUZHOU HOT RUNNER SYST

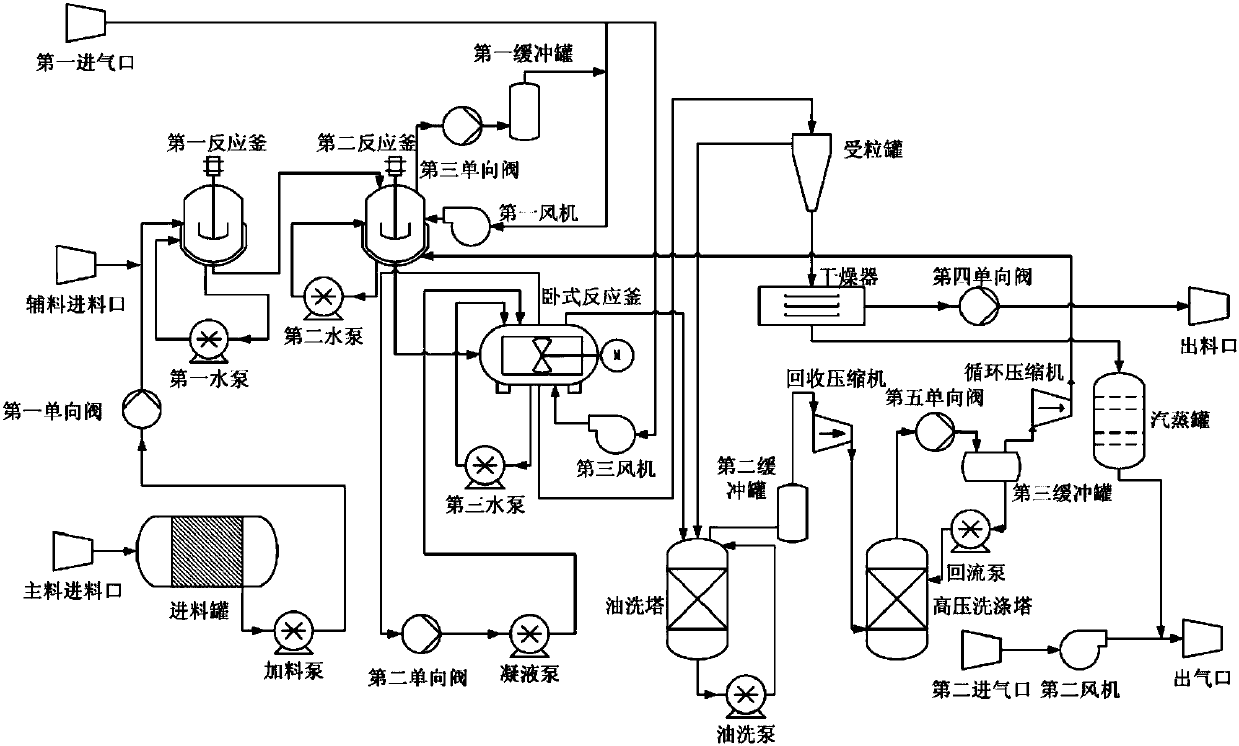

Chemical mechanical system with T-type paddle horizontal reactor

InactiveCN107670611ARealize processing and manufacturingEnables multiple reaction processingSequential/parallel process reactionsRotary stirring mixersCompound (substance)Engineering

The invention discloses a chemical mechanical system with a T-type paddle horizontal reactor. A horizontal stirring paddle of a horizontal stirrer is a T-type paddle and is prepared from stainless steel. A distance between the tail end of the T-type paddle and the inner wall of a horizontal tank is in a range of 3-5mm and is larger than the maximum particle diameter of the stirred material. The system comprises the 96 T-type paddles divided into 24 groups uniformly distributed along an axial direction of a horizontal stirring shaft at equal intervals and a ratio of the thickness to length of the T-type paddle is 1: 10. The four T-type paddles in each group are uniformly distributed along the circumferential direction of the horizontal stirring shaft at an angle of 90 degrees. The two adjacent groups of the T-type paddles are arranged at 0 degree along the circumferential direction of the horizontal stirring shaft. The back surface of each T-type paddle is provided with reinforcing ribs.

Owner:SHANDONG LONGSHENGHE CHEM CO LTD

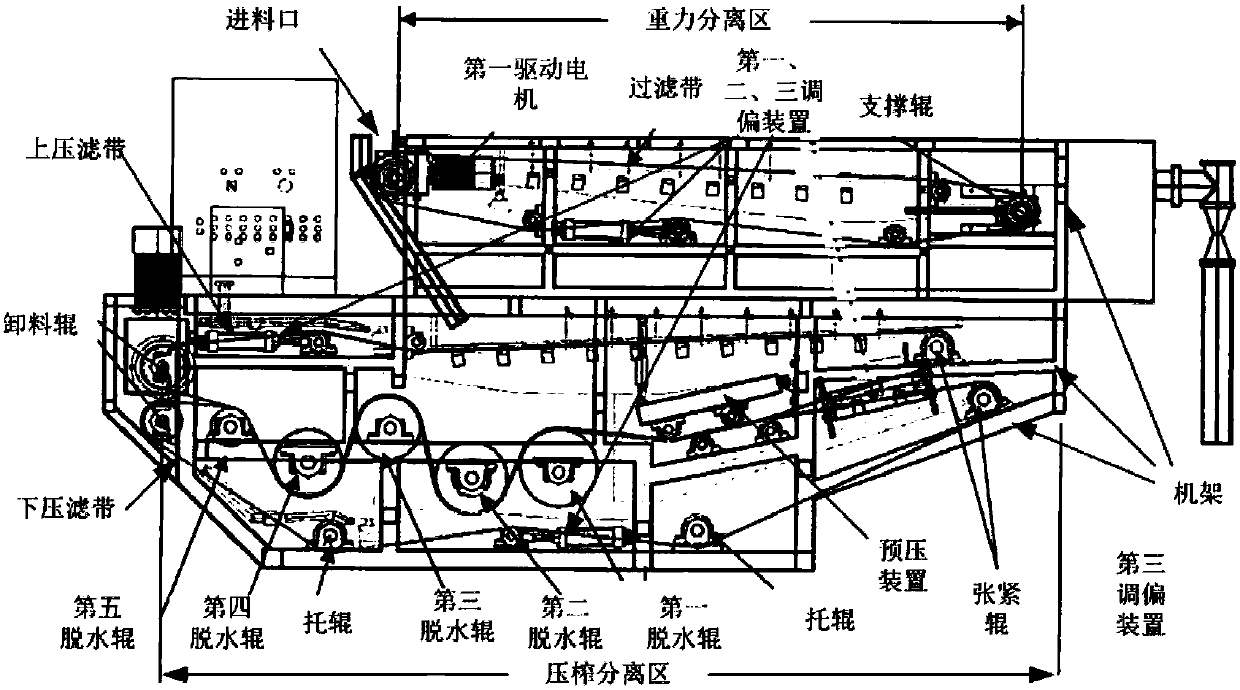

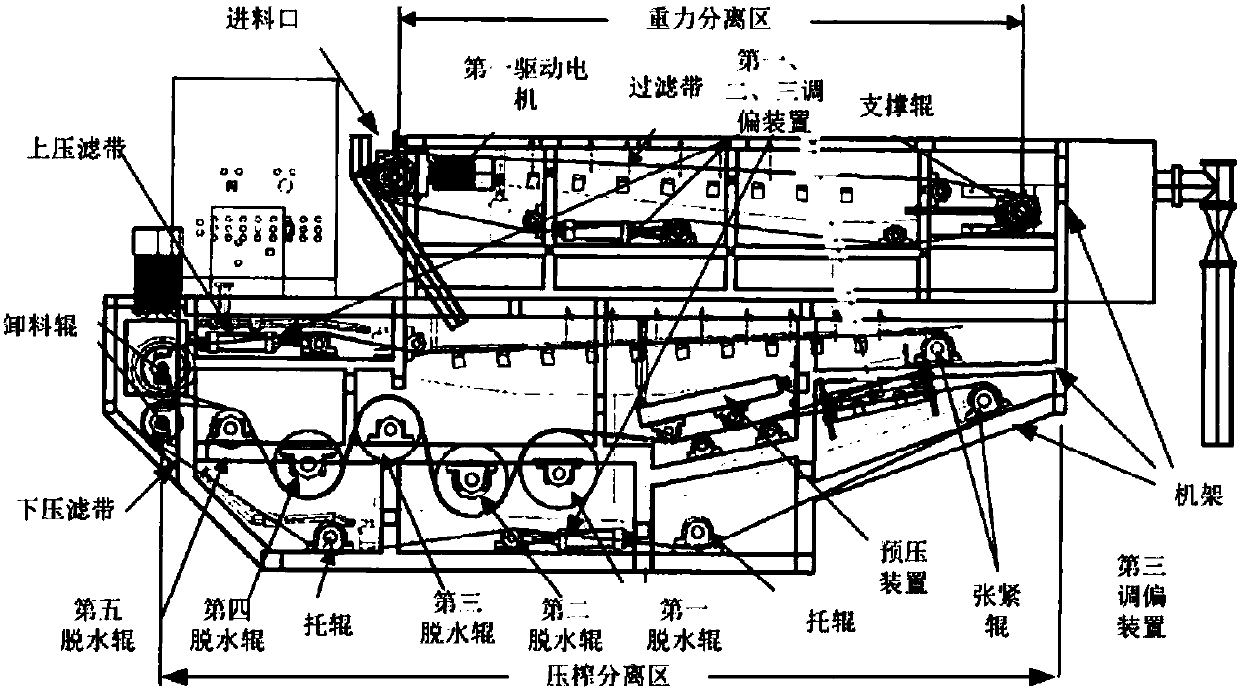

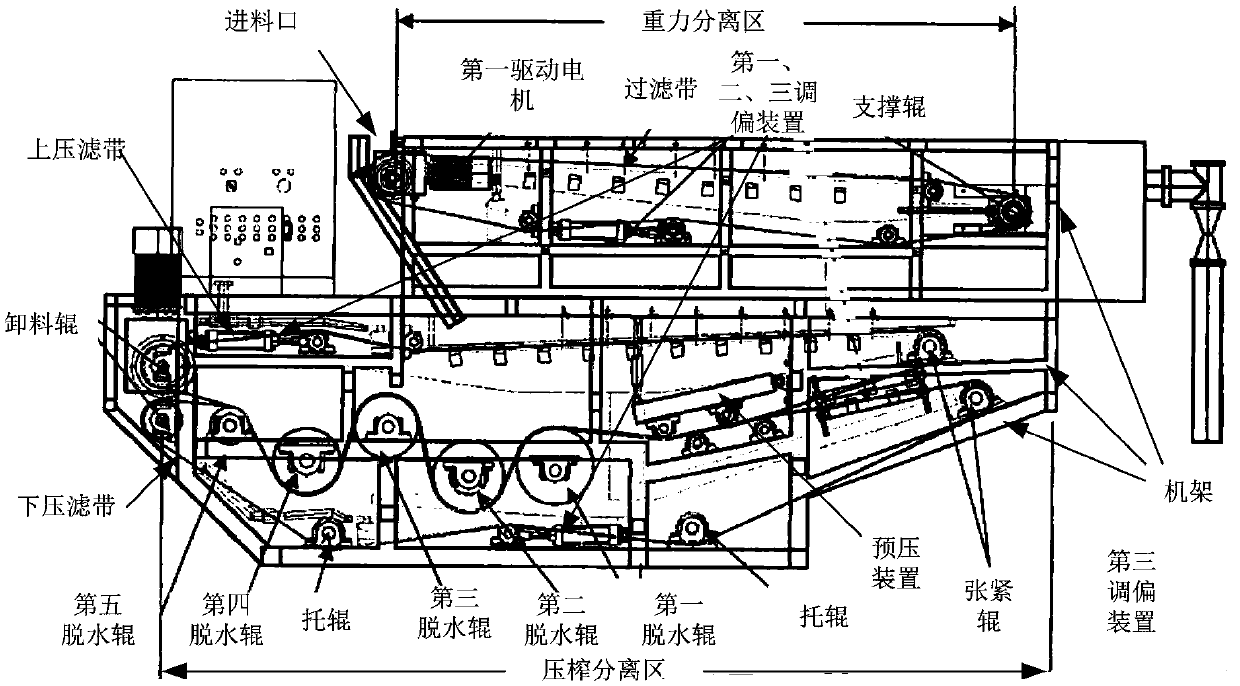

Filter press system with dewatering wheel system

ActiveCN107670387AExtended gravity separation timeFiltration pressure is highWater treatment parameter controlSpecific water treatment objectivesSlagGravity separation

The invention discloses a filter press system with a dewatering wheel system. The filter press system comprises one belt filter press, one box filter, one pressure filter, one squeezing filter, one sterilization device, one sedimentation tank, one waste liquid pool, one liquid collection pool, four slag storage tanks, three buffer tanks, six feeding pumps, five circuit switches and fifteen valves.The belt filter press comprises a frame, a gravity separation zone, a squeezing separation zone and a liquid guide device. The squeezing separation zone comprises a second driving motor, a third driving motor, a pre-pressing device, an upper pressure filtering belt, a lower pressure filtering belt, a tensioning roller, a discharge roller, a dewatering roller system, a carrier roller, a second deviation adjustment device and a third deviation adjustment device. The dewatering roller system comprises five dewatering rollers respectively arranged in the upper pressure filtering belt and the lower pressure filtering belt.

Owner:福州清河源环保科技有限公司

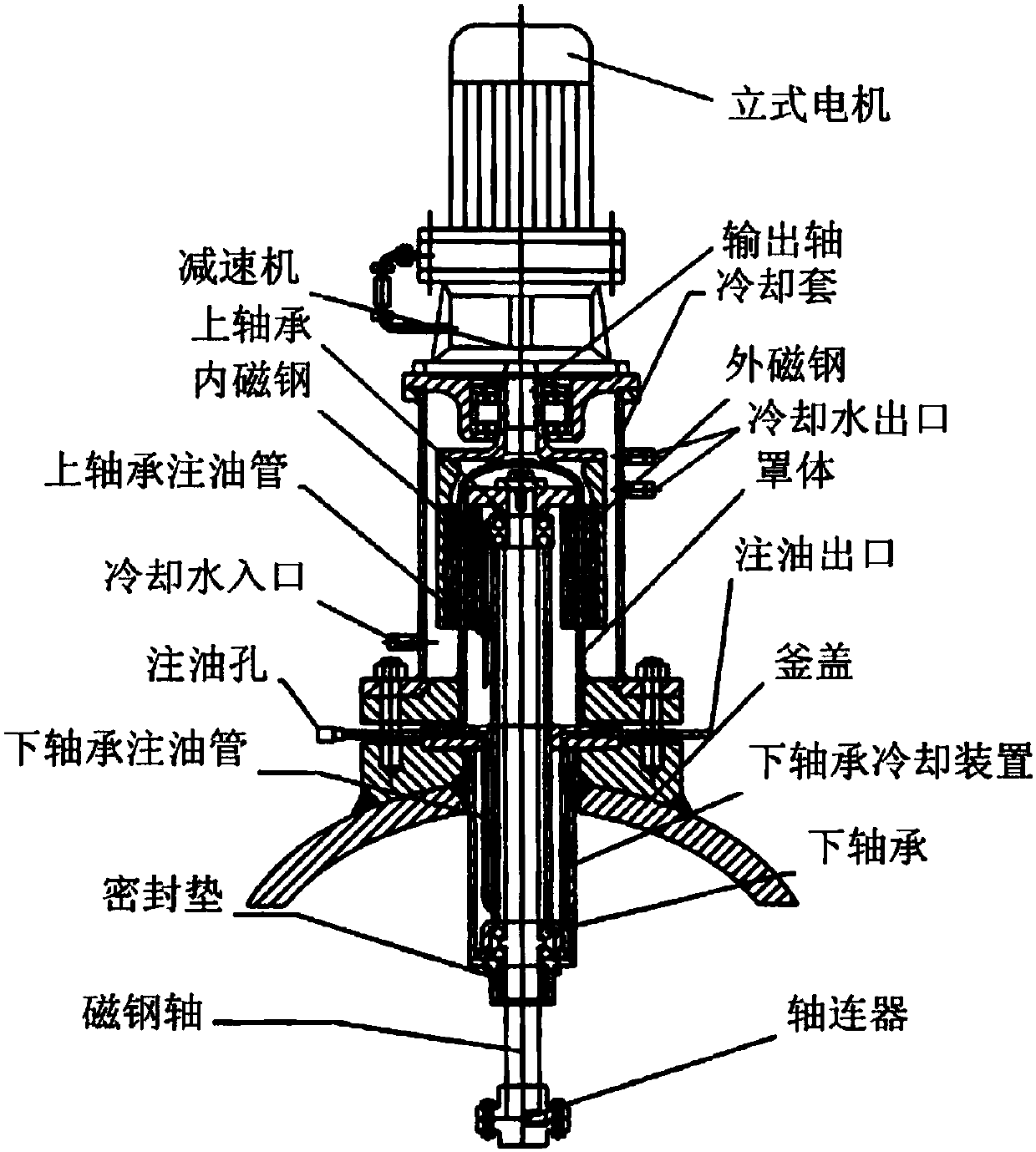

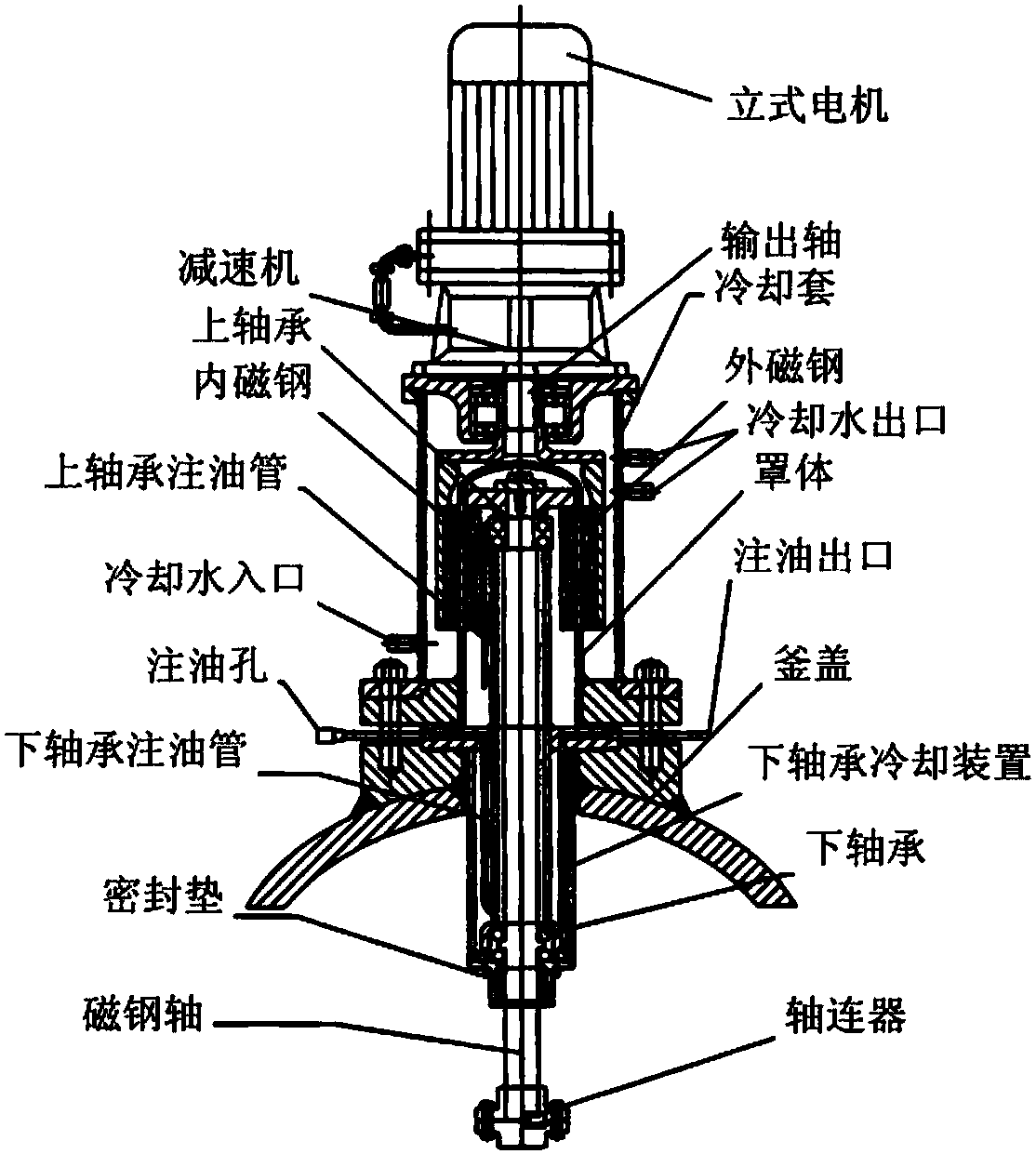

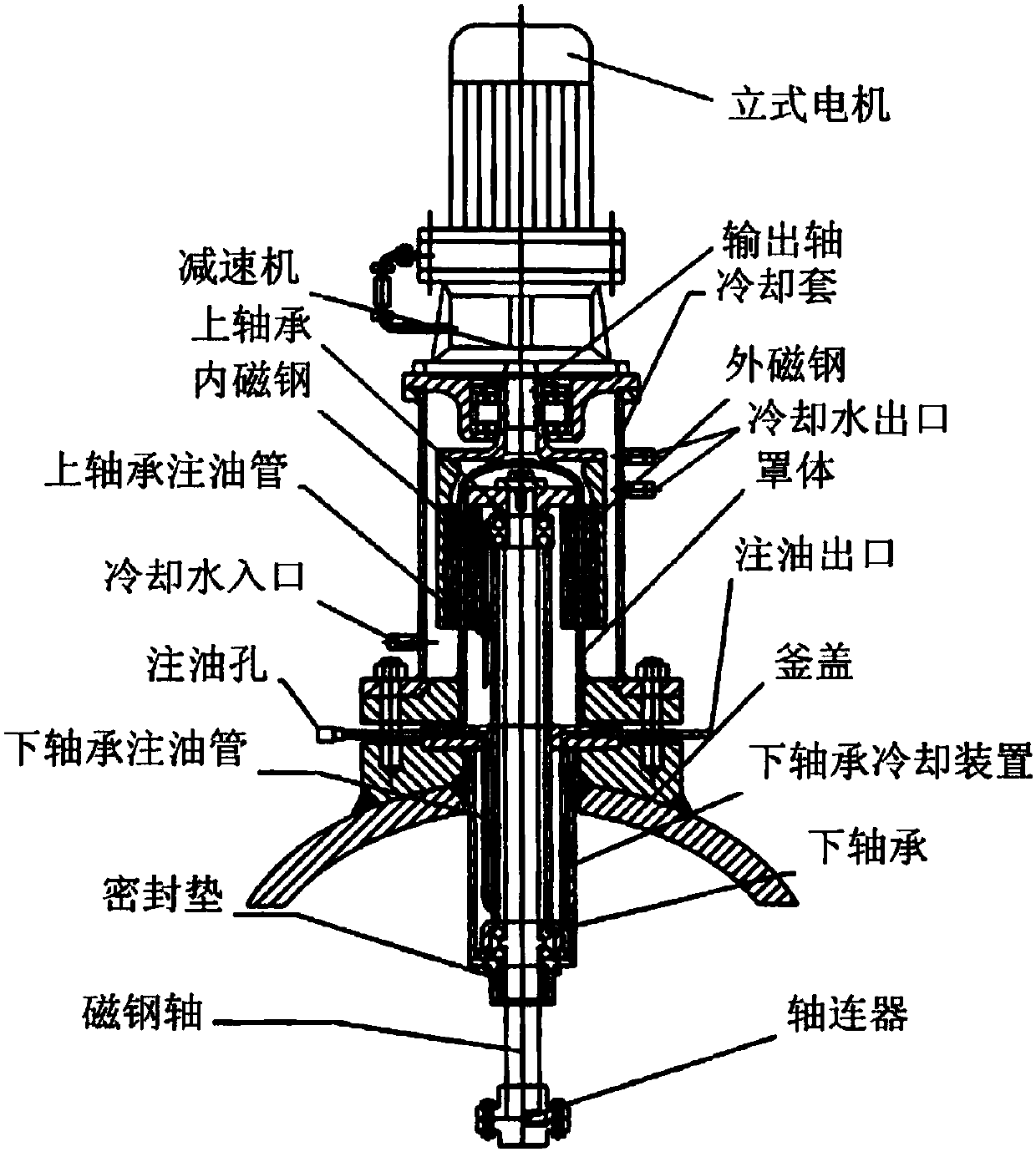

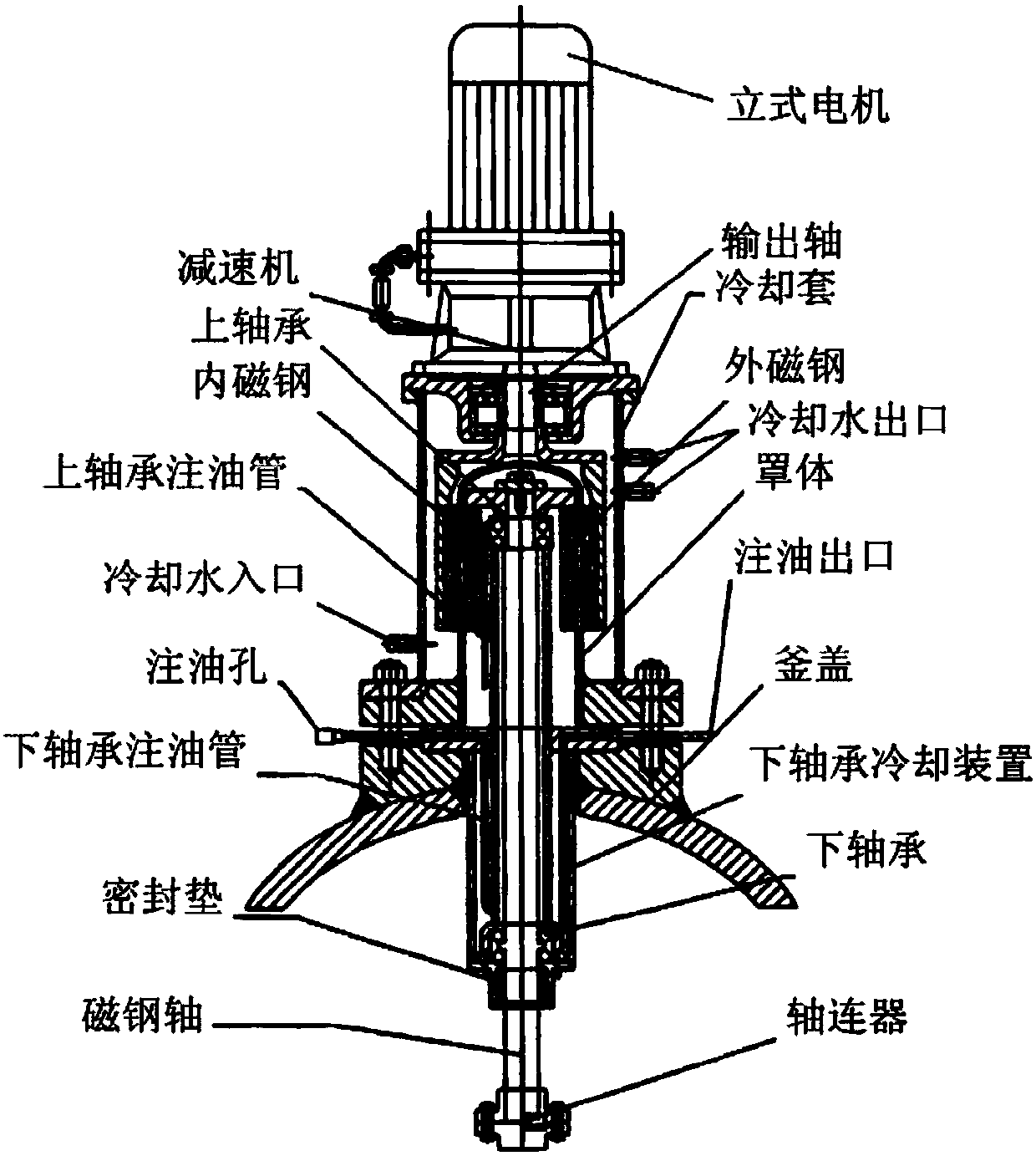

Chemical mechanical system with magnetic torque adjustable reactor

InactiveCN107670610ARealize processing and manufacturingEnables multiple reaction processingProcess control/regulationChemical/physical/physico-chemical stationary reactorsElectromagnetic driveMechanical system

The invention discloses a chemical mechanical system with a magnetic torque adjustable reactor. A first reactor is an electromagnetic driven reactor with a magnetic torque adjustment function. A stirrer comprises a magnetic driver, a vertical stirring shaft and a vertical stirring paddle. A vertical stirring paddle is arranged on the vertical stirring shaft. The magnetic driver is connected to thevertical stirring shaft and drives the vertical stirring shaft to rotate so that a stirring function is realized.

Owner:SHANDONG LONGSHENGHE CHEM CO LTD

Chemical mechanical system using electromagnetically driven reactor

ActiveCN107670609ARealize processing and manufacturingEnables multiple reaction processingCharacter and pattern recognitionChemical/physical/physico-chemical stationary reactorsEngineeringHigh pressure

The invention discloses a chemical mechanical system using an electromagnetically driven reactor. A first reactor is electromagnetically driven. A vertical agitator comprises a magnetic driver, a vertical agitating shaft and a vertical agitating paddle, the vertical agitating paddle is disposed on the vertical agitating shaft, the magnetic driver is connected to the vertical agitating shaft and drives the vertical agitating shaft to rotate, and the first reactor is provided with a pressure gauge connector, a thermocouple and a burst valve so that forced outage and pressure relief are realizedunder conditions of too high temperature and too high pressure and production process safety is guaranteed.

Owner:WEIHAI INNOVATION INST QINGDAO UNIV

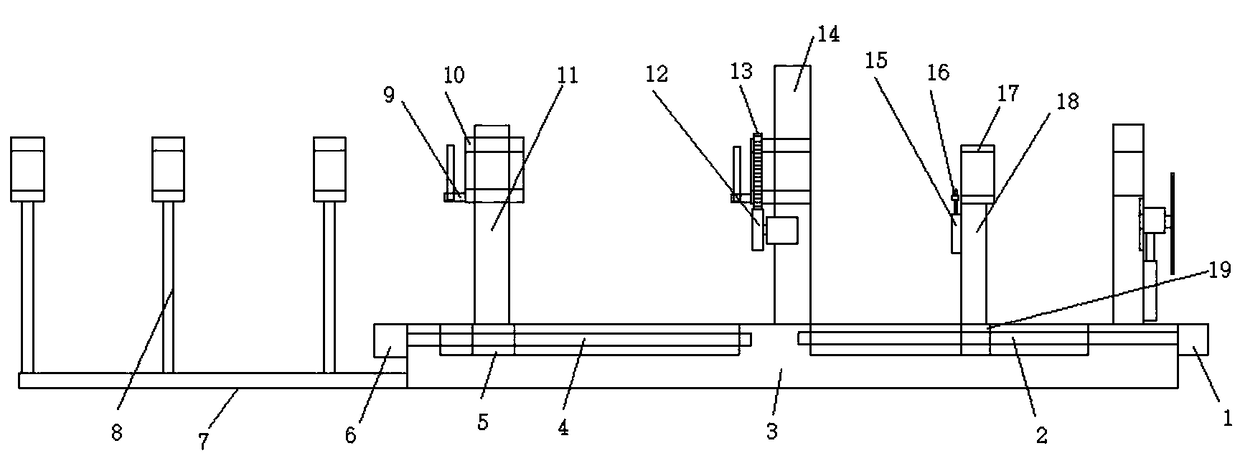

Intelligent manufacturing equipment

ActiveCN108608077ARealize continuous feedingNo need for manual loadingThread cutting feeding devicesThread cutting machinesEngineeringFixed length

The invention discloses intelligent manufacturing equipment comprising a base. One side of the base is welded with an auxiliary support plate arranged horizontally, and the auxiliary support plate iswelded with a plurality of auxiliary support frames arranged in an array manner; the middle position of the top end of the base is welded with a fixed column arranged vertically, and the both sides ofthe top end of the base are each provided with a first sliding chute and a second sliding chute which are arranged horizontally; the second sliding chute is located on the side, close to the auxiliary support plate, of the fixed column, and the interior of the first sliding chute is slidably connected to a first sliding block; one side wall of the base is provided with a first motor by screws; and an output shaft of the first motor is connected to a first threaded rod rotatably connected to the interior of the first sliding chute, and the first threaded rod is in threaded connection with thefirst sliding block of which the top end is welded with the fixed column arranged vertically. According to the intelligent manufacturing equipment, continuous feeding for processing of the threaded rod can be achieved, and manual feeding is not required; the threads of the threaded rod can be processed and manufactured, and the threaded rod is cut according to the fixed length; and the processingefficiency is improved.

Owner:宣城市创道智能技术开发有限责任公司

Method for producing all-cotton lap waste yarns

The invention discloses a method for producing all-cotton lap waste yarns. The method sequentially comprises the following steps of: (1), treating raw materials; (2), blow-carding; (3), drawing; (4), preparing rovings; (5), preparing spun yarns; and (6) obtaining a bobbin. By the method for producing the all-cotton lap waste yarns, lap waste fiber can be used for manufacturing cotton threads.

Owner:SHANGHAI FEILONG TEXTILE

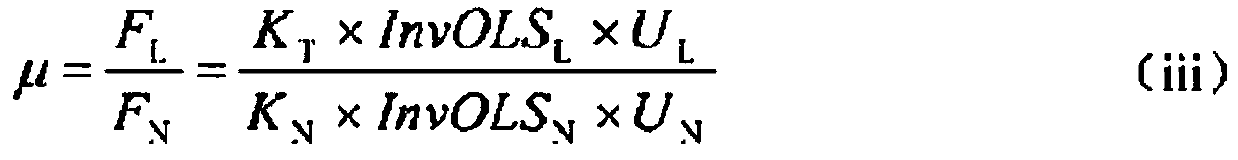

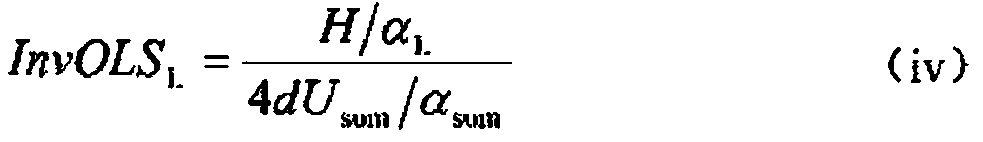

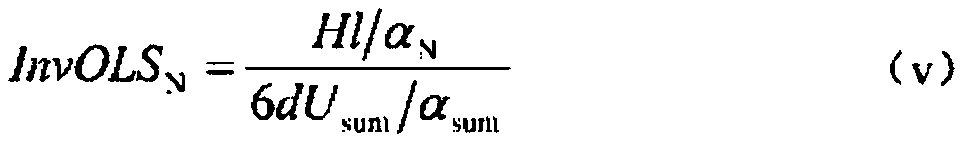

Processing method of a micro-cantilever probe for ultralow friction coefficient measurement

InactiveCN110542768ARealize processing and manufacturingScanning probe microscopySize parameterMicroscope

The invention relates to the technical field of atomic force electron microscope probes, and provides a processing method of a micro-cantilever probe for ultralow friction coefficient measurement. Themethod comprises the following steps: 1) establishing a micro-cantilever probe friction coefficient measuring model; according to the measurement principle of an atomic force microscope, establishingexpressions for measuring friction force and positive pressure through torsion and bending of the probe; and establishing the probe friction coefficient measuring model through the simultaneous expressions; 2) determining size parameters, including length l, width w and thickness t and the like, of the micro-cantilever probe according to the model; and 3) processing the probe. By establishing themicro-cantilever probe friction coefficient measuring model and determining the size parameters of the micro-cantilever probe according to the model, the probe is processed and manufactured. According to the invention, the micro-cantilever probe friction coefficient measuring model is established, and processing and manufacturing of the probe are realized by utilizing a high-precision optical imaging system and a high-precision motion control system of an existing atomic force microscope.

Owner:HEFEI UNIV

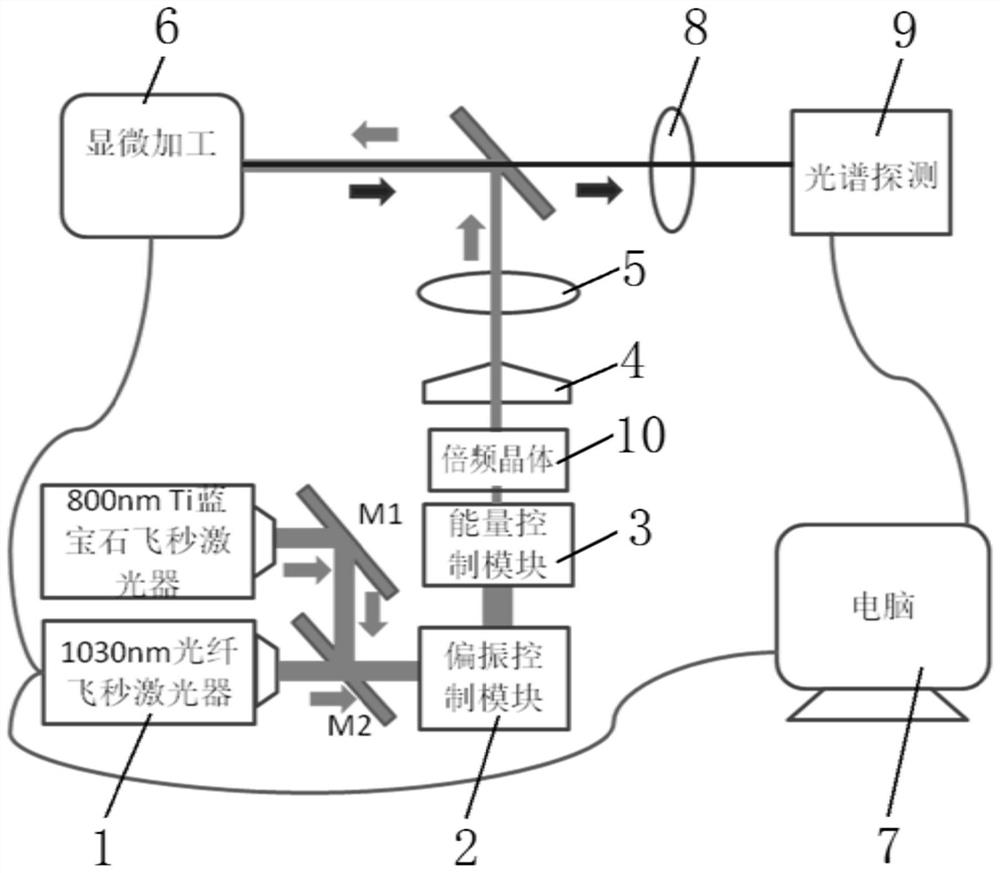

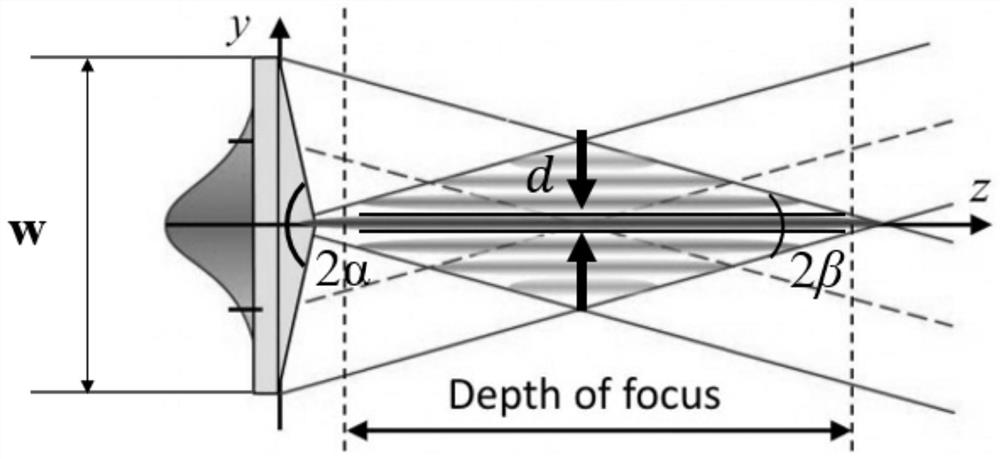

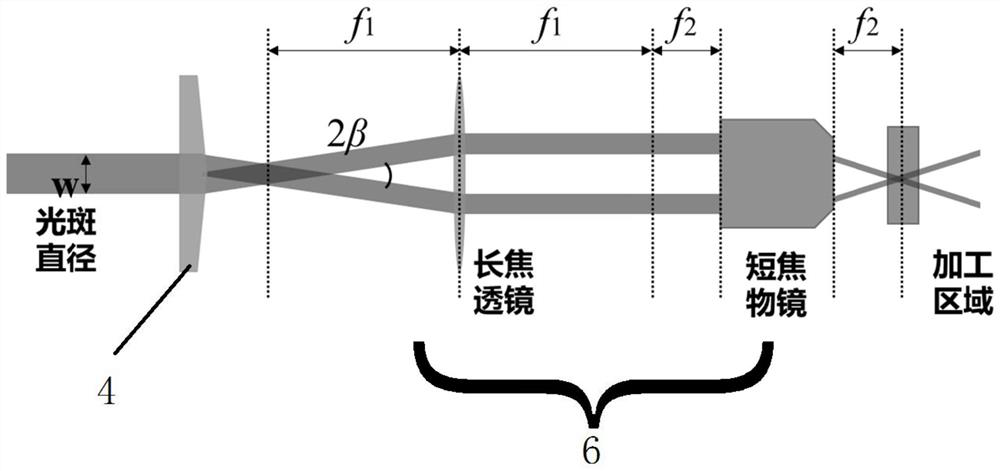

System and method for machining nanoscale small holes in hard and brittle materials through conical lens

ActiveCN112570911AImprove processingImprove quality uniformityNanotechnologyLaser beam welding apparatusFemto second laserEnergy control

The invention provides a system and method for machining nanoscale small holes in a hard and brittle material through a conical lens. The problems that when small holes are prepared in the surface ofthe hard and brittle material through an existing conical lens, the small holes with the sub-wavelength being 30 nm or below are difficult to machine, and the structural uniformity of the small holesis poor are solved. The processing system comprises a femtosecond laser, a polarization control module, an energy control module, the conical lens, a collimating lens, a micromachining module, a control system, a spherical lens and a spectrum detection module, wherein the polarization control module, the energy control module, the conical lens, the collimating lens and the micromachining module are sequentially arranged along an emergent light path of the femtosecond laser, and the control system controls the spectrum detection module, the femtosecond laser and the micromachining module respectively; the spectrum detection module collects light scattering information of the nanometer small holes through the spherical lens and feeds back the information to the control system, and the control system carries out accurate compensation control and correction on the position of a Bessel light needle in the hard and brittle material according to the information.

Owner:XI AN JIAOTONG UNIV

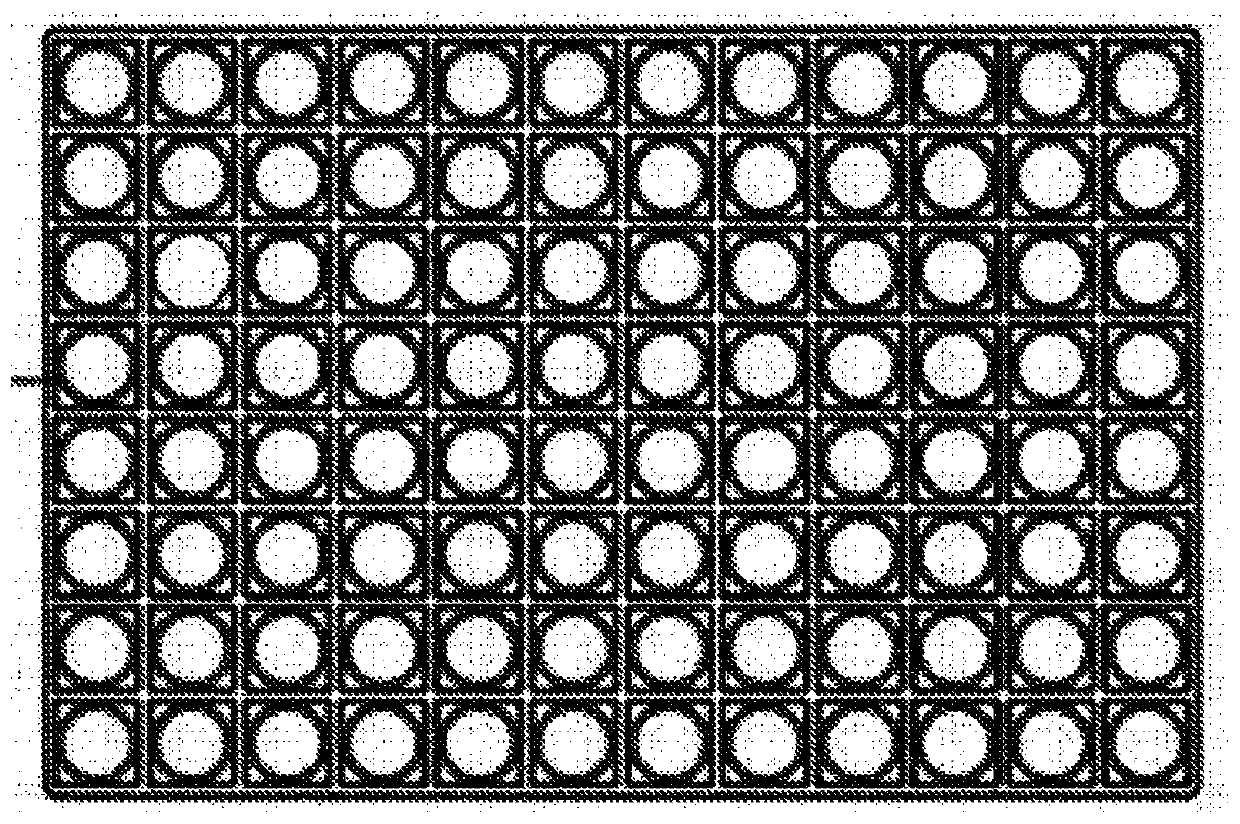

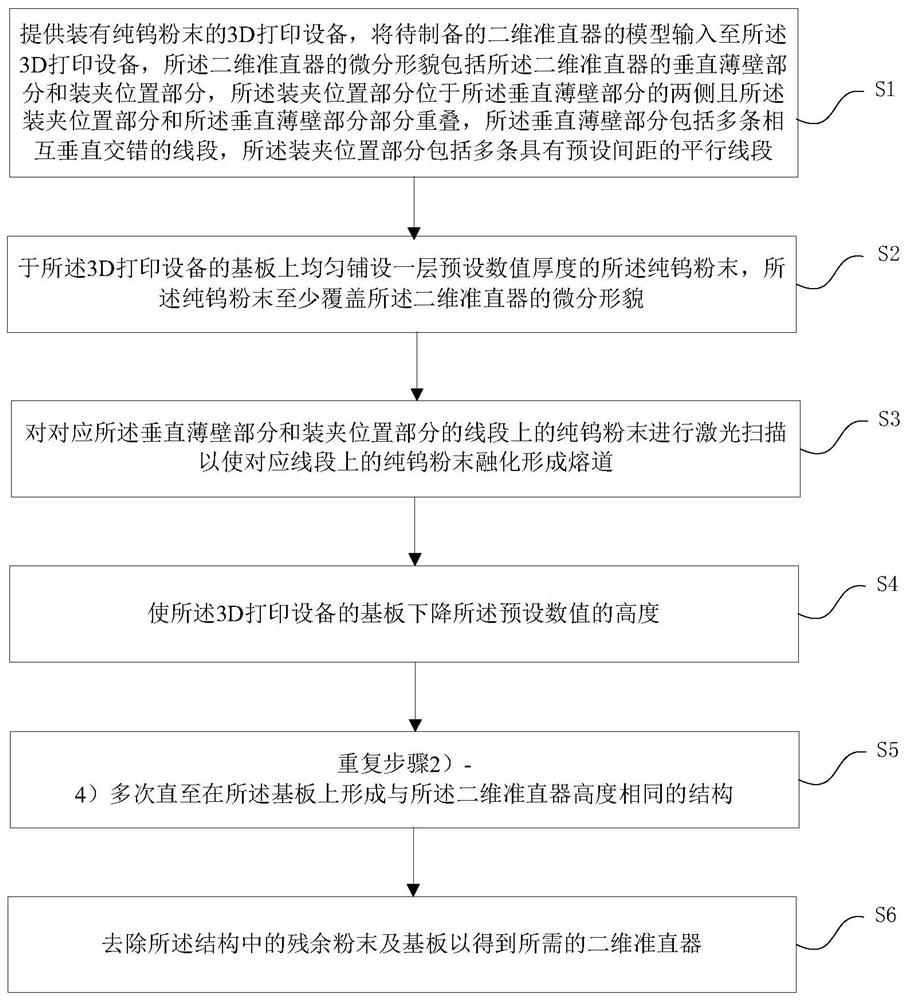

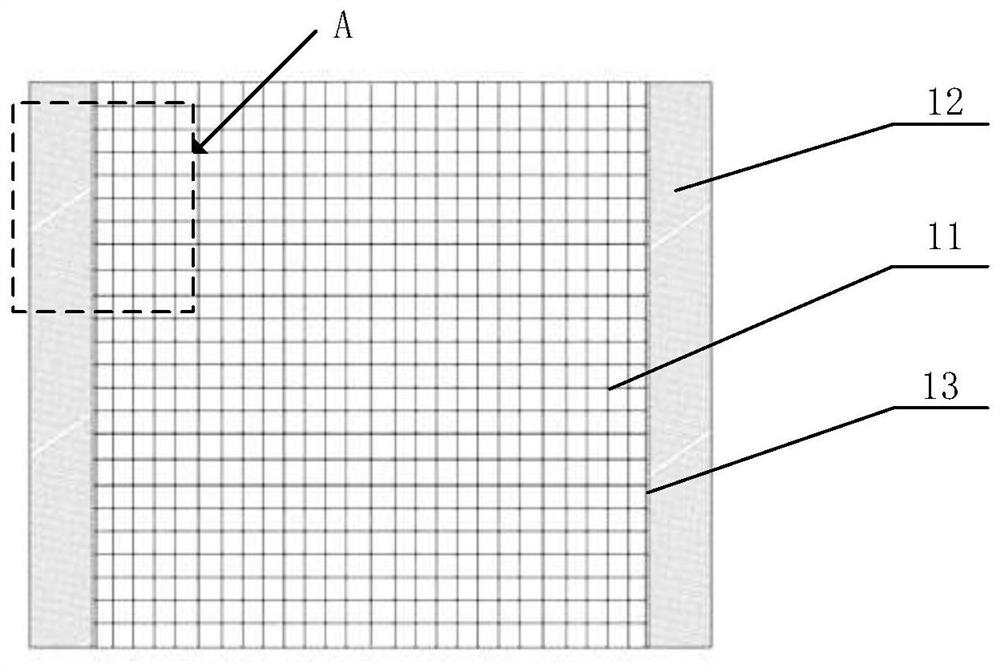

Preparation method of two-dimensional collimator

ActiveCN112570716ARealize processing and manufacturingImprove shielding effectAdditive manufacturing apparatusIncreasing energy efficiencyImaging qualityLaser scanning

The invention provides a preparation method of a two-dimensional collimator. The preparation method comprises the following steps of 1), providing 3D printing equipment filled with pure tungsten powder, and inputting a model of a two-dimensional collimator to be prepared into the 3D printing equipment; 2), uniformly paving a layer of pure tungsten powder with a preset numerical thickness; 3), performing laser scanning on the pure tungsten powder to melt the pure tungsten powder on the corresponding line segment to form a melt channel; 4), lowering a substrate by a height of a preset numericalvalue; 5), repeating the step 2) to the step 4) for multiple times until a structure with the same height as the two-dimensional collimator is formed on the substrate; and 6), removing the residual powder and the substrate to obtain the required two-dimensional collimator. According to the preparation method, the two-dimensional collimator can be prepared, a better X-ray shielding effect can be achieved, the imaging quality can be improved, light weight and miniaturization of CT equipment are facilitated, meanwhile, pure automation can be achieved in the whole preparation process, and the product consistency and quality controllability can be effectively improved.

Owner:苏州徕泽丰材料科技有限公司

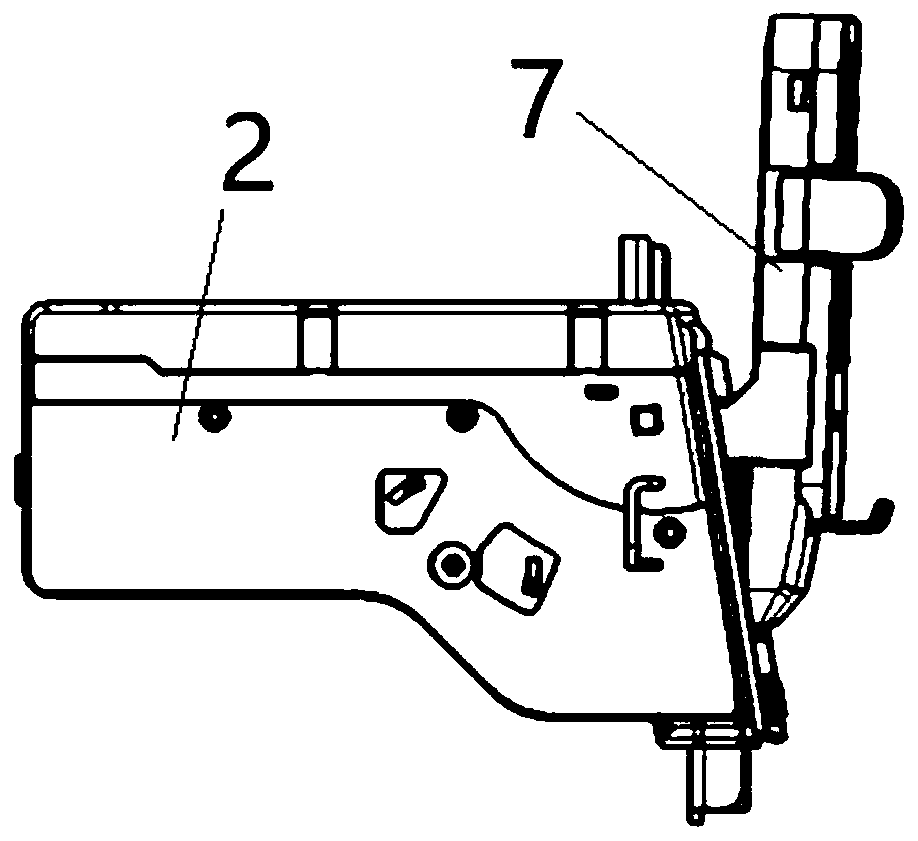

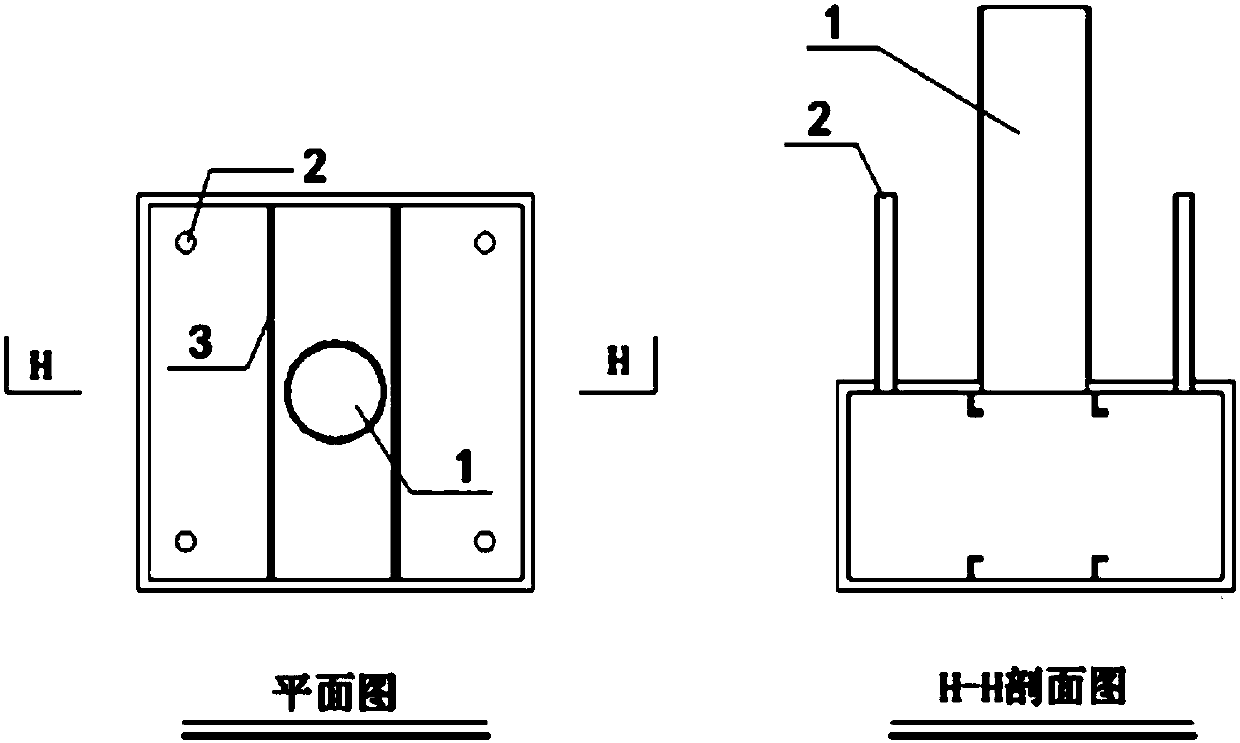

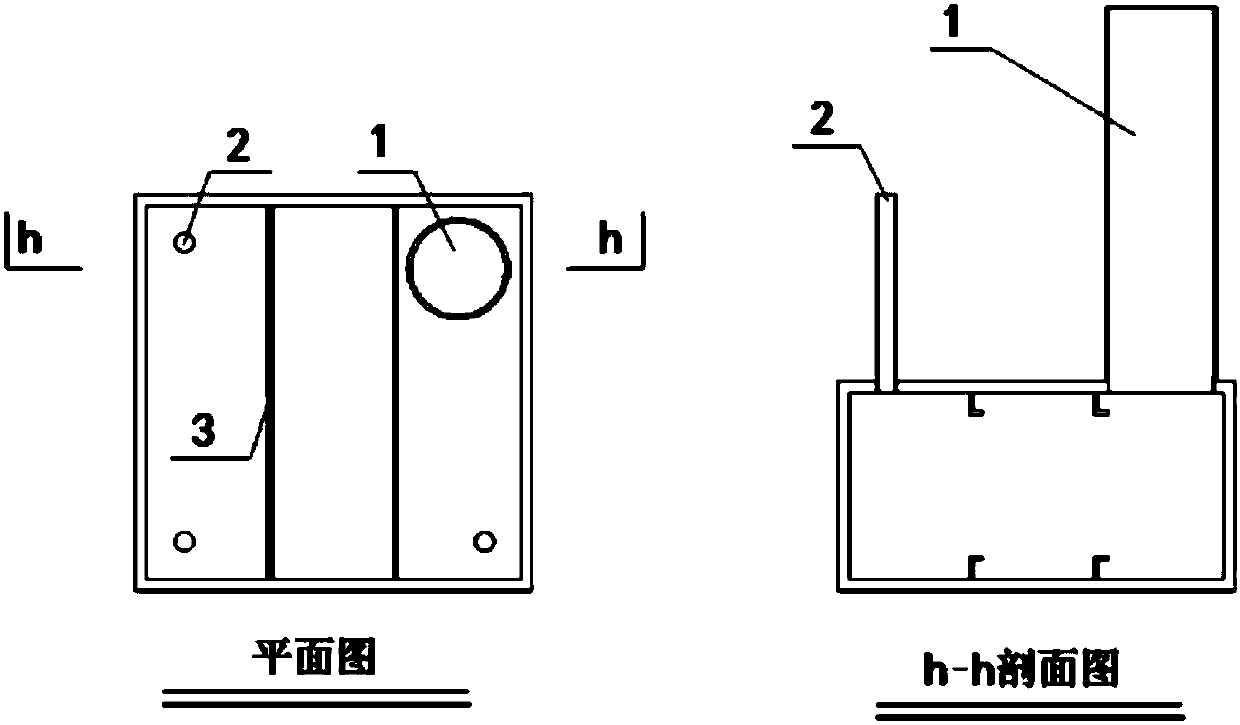

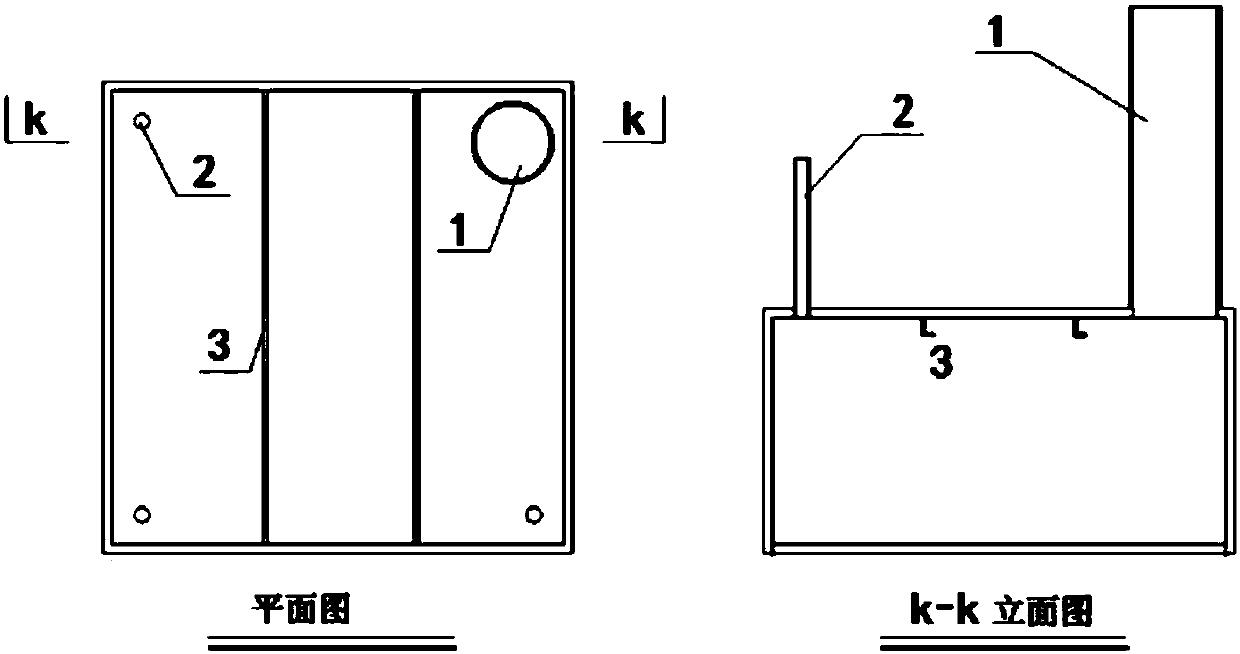

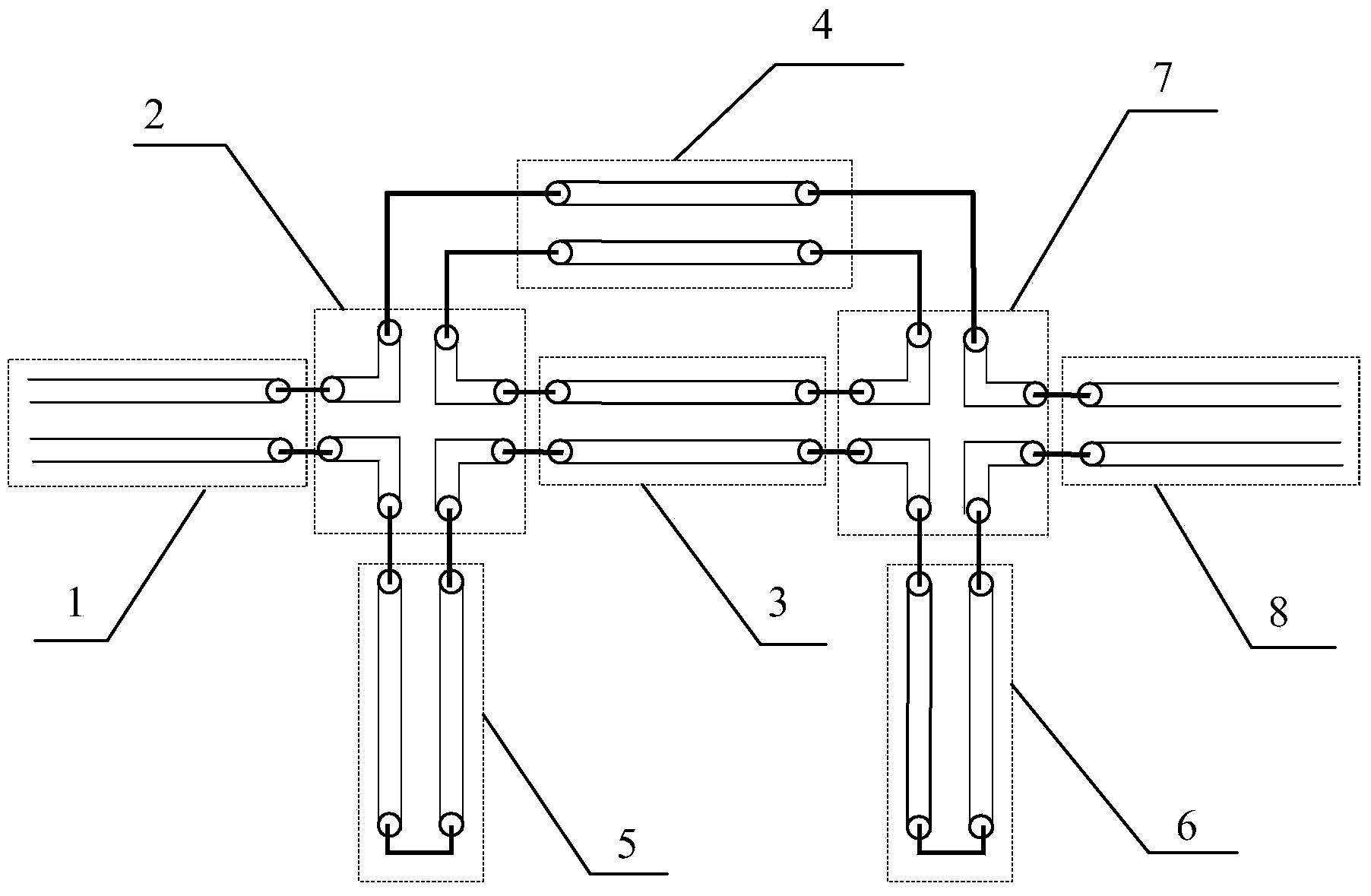

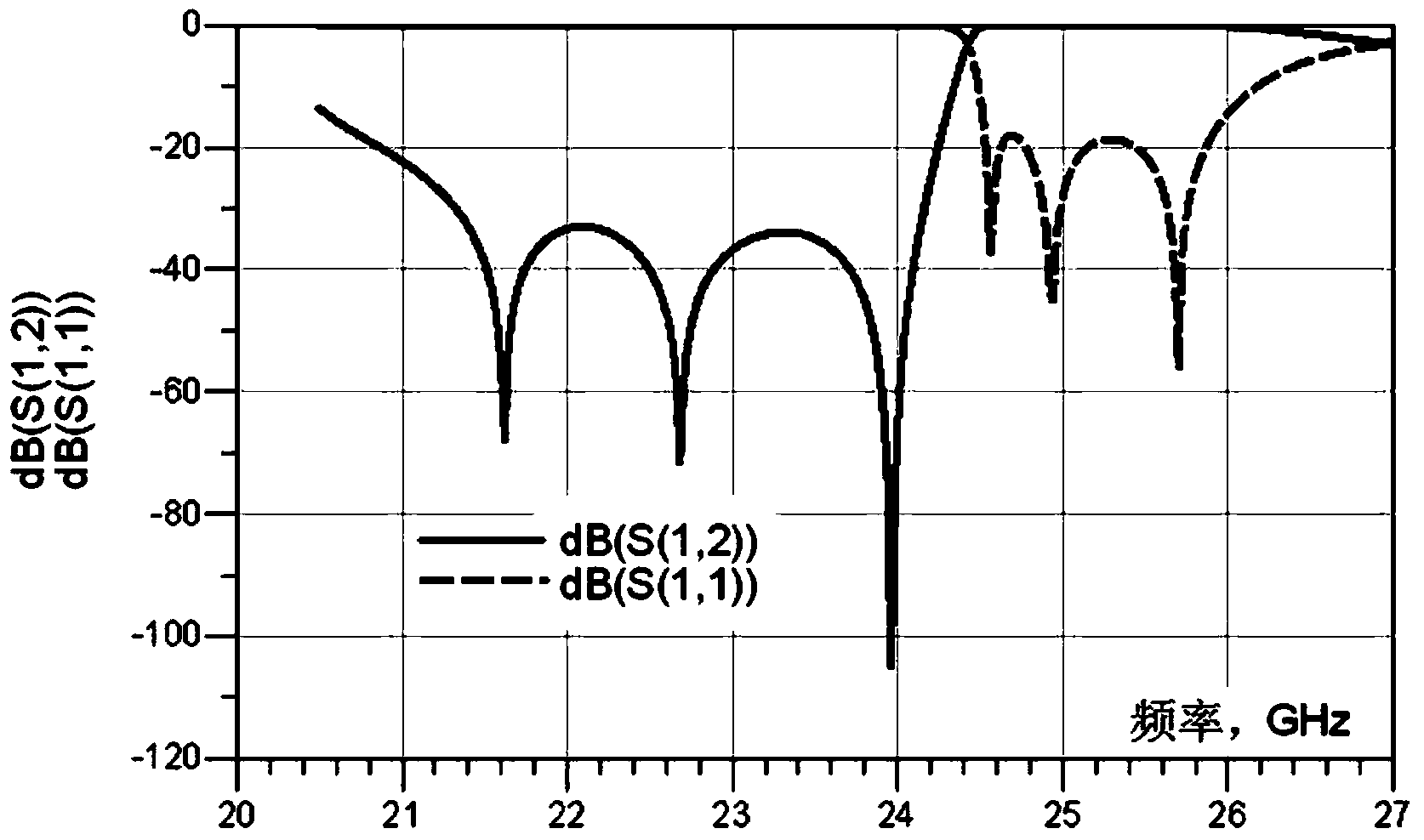

Series connection type unilateral elliptic function transmission line filter

The invention provides a series connection type unilateral elliptic function transmission line filter. A distributed parameter network is composed of an input transmission line, an output transmission line, series connection cross joints, short circuit transmission line branch joints, a cascading transmission line joint, a series connection transmission line joint and other transmission line elements. The first series connection cross joint (2) and the second series connection cross joint (7) are arranged oppositely, opposite ports of the first series connection cross joint (2) and the second series connection cross joint (7) are connected through the cascading transmission line joint (3), ports in the same sides of the series connection cross joint (2) and the second series connection cross joint (7) are connected through the series connection transmission line joint (4), another two ports of the first series connection cross joint (2) are connected with the input transmission line (1) and the first short circuit transmission line branch joint (5) respectively, and another two ports of the second series connection cross joint (7) are connected with the output transmission line (8) and the second short circuit transmission line branch joint (6) respectively. All transmission line element parameters in the filter are appropriately designed, so that transmission characteristics of a unilateral elliptic function are achieved. The filter is suitable for bandwidths below the medium degree of microwave and millimeter wave frequency bands, low in loss, and high in selectivity.

Owner:10TH RES INST OF CETC

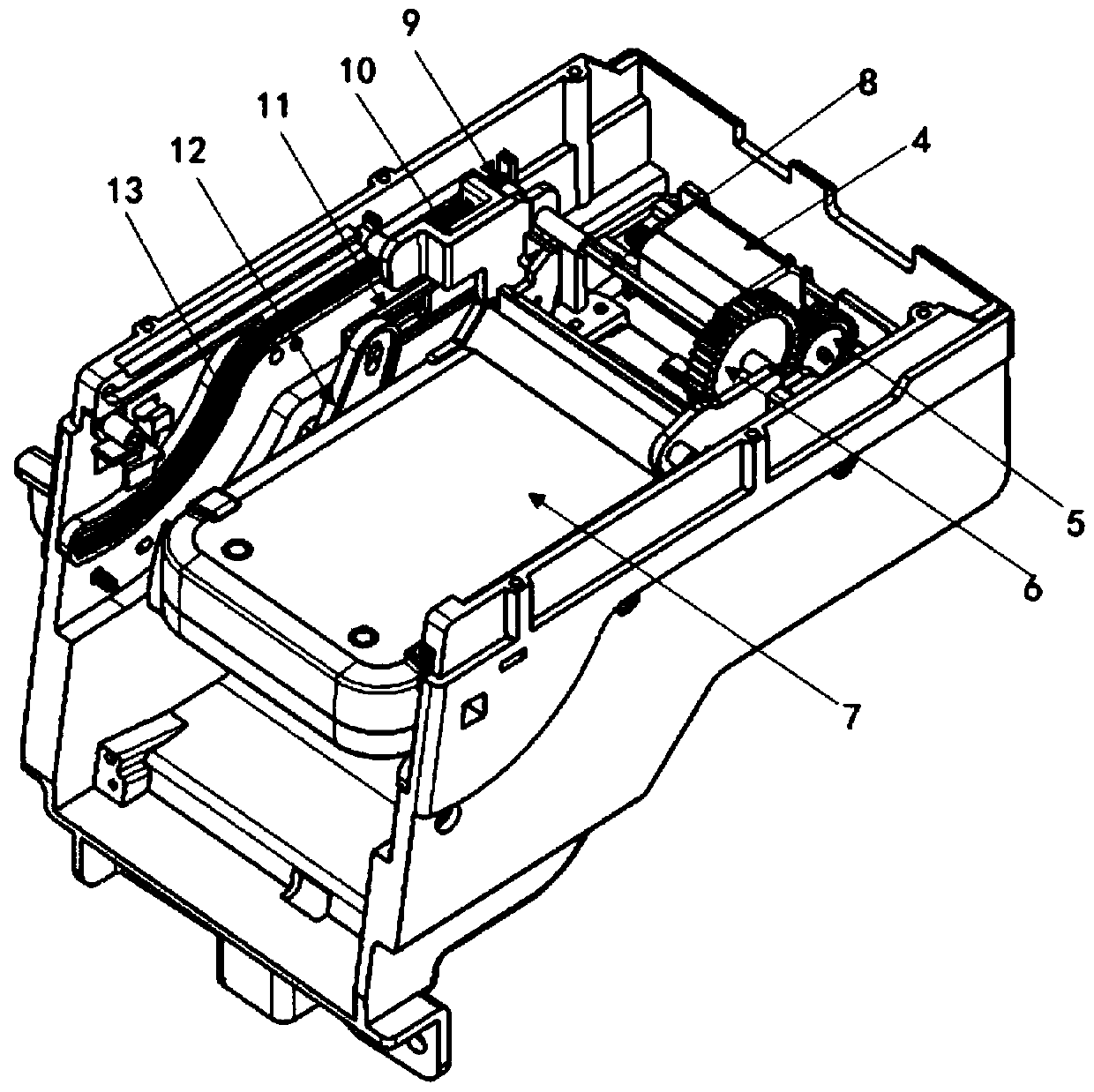

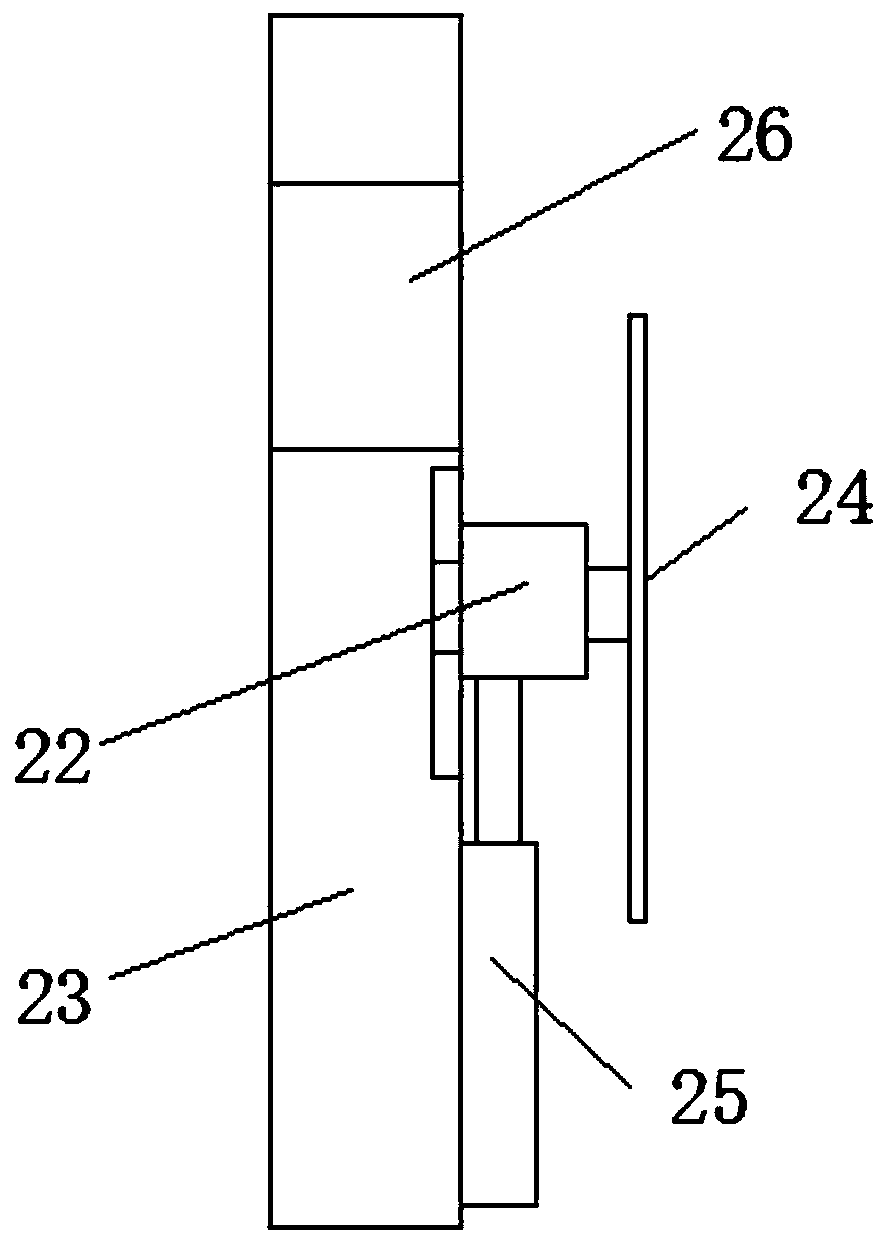

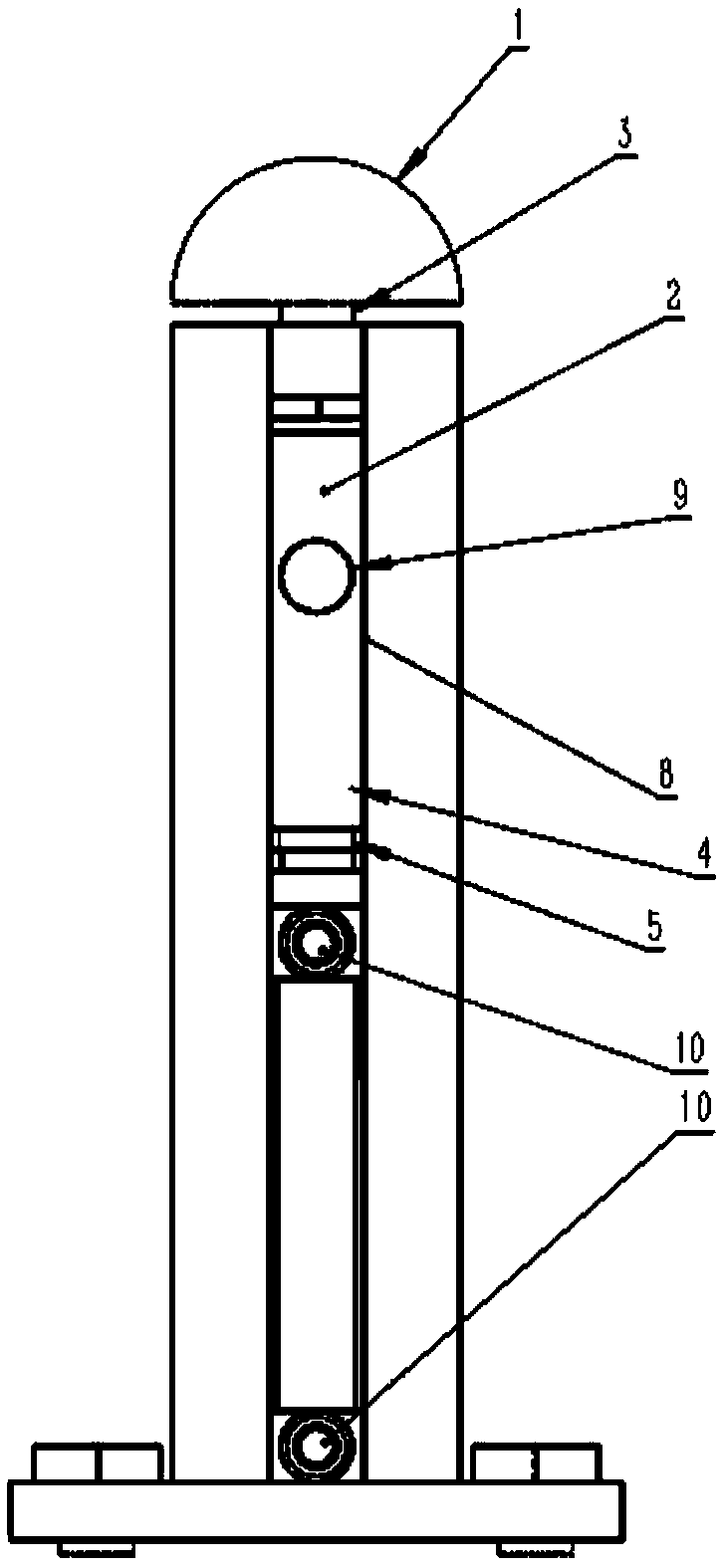

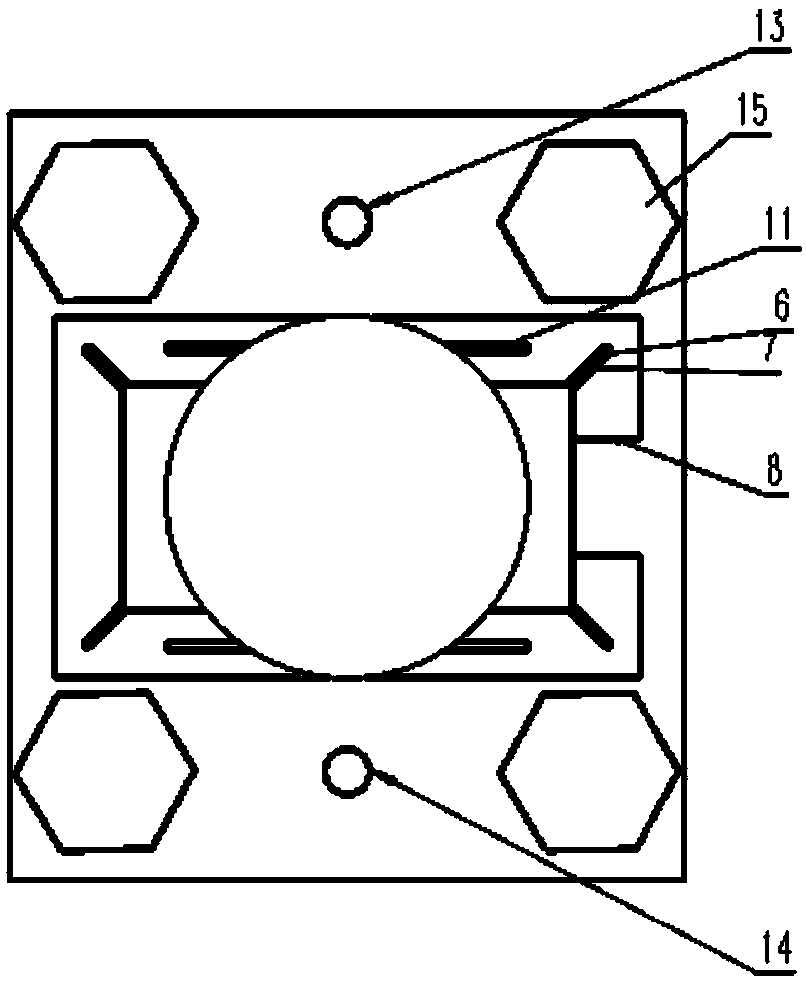

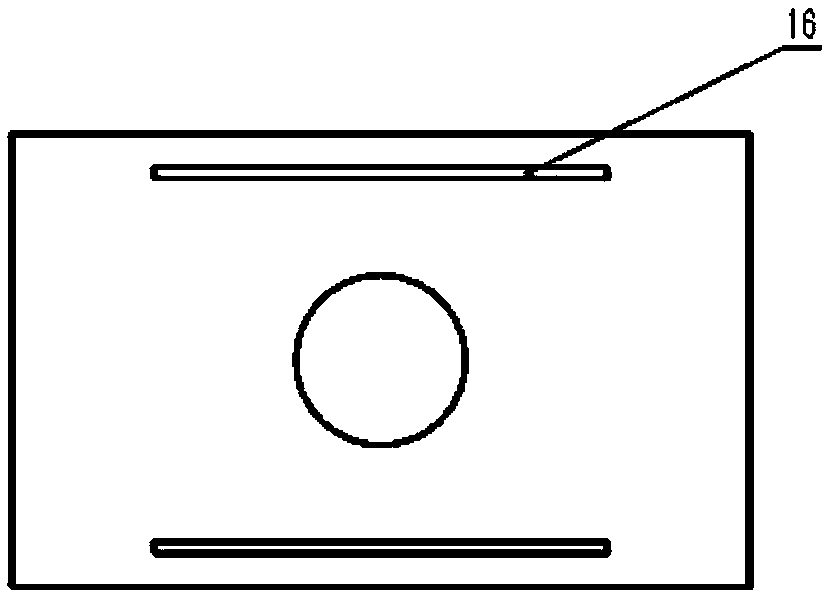

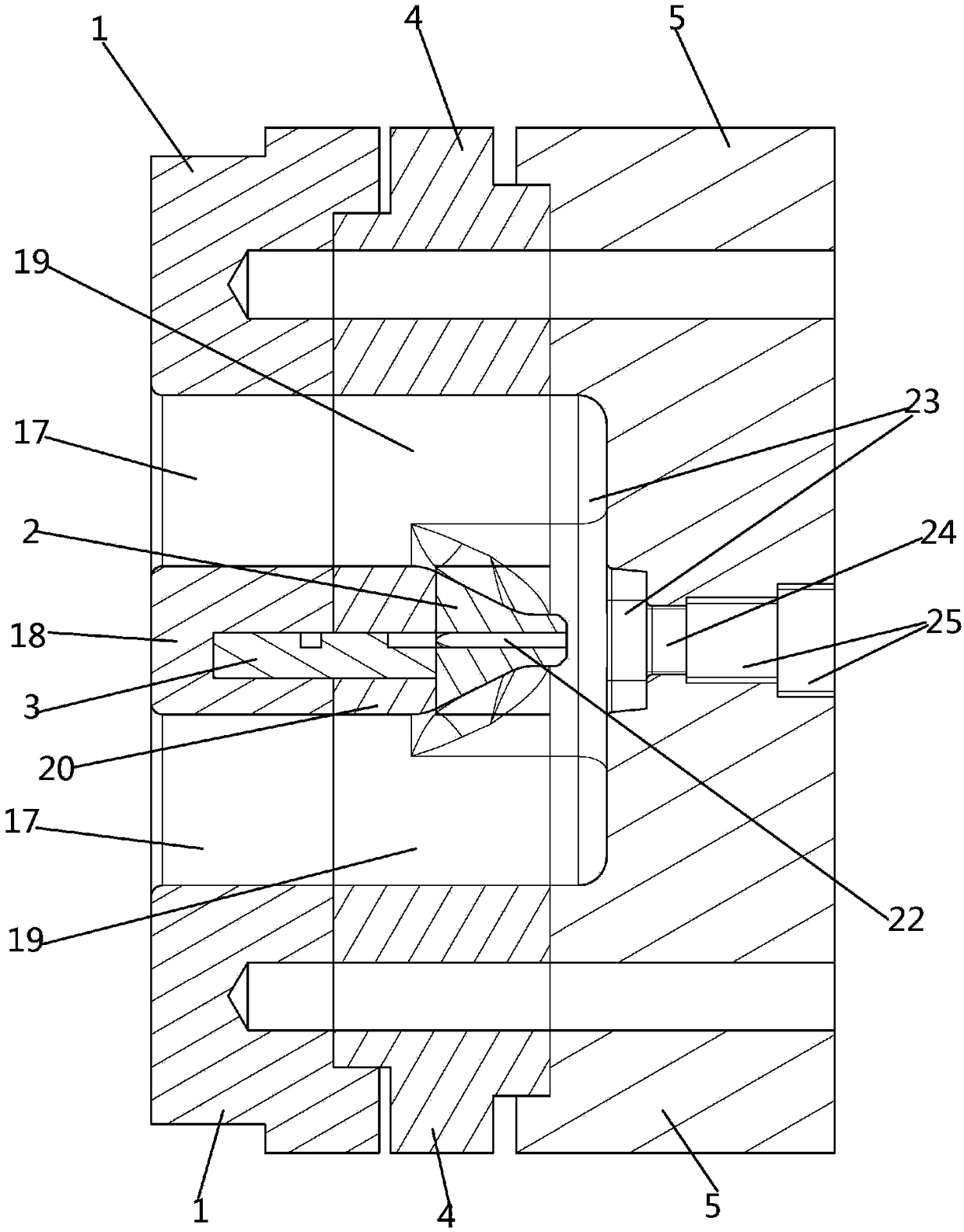

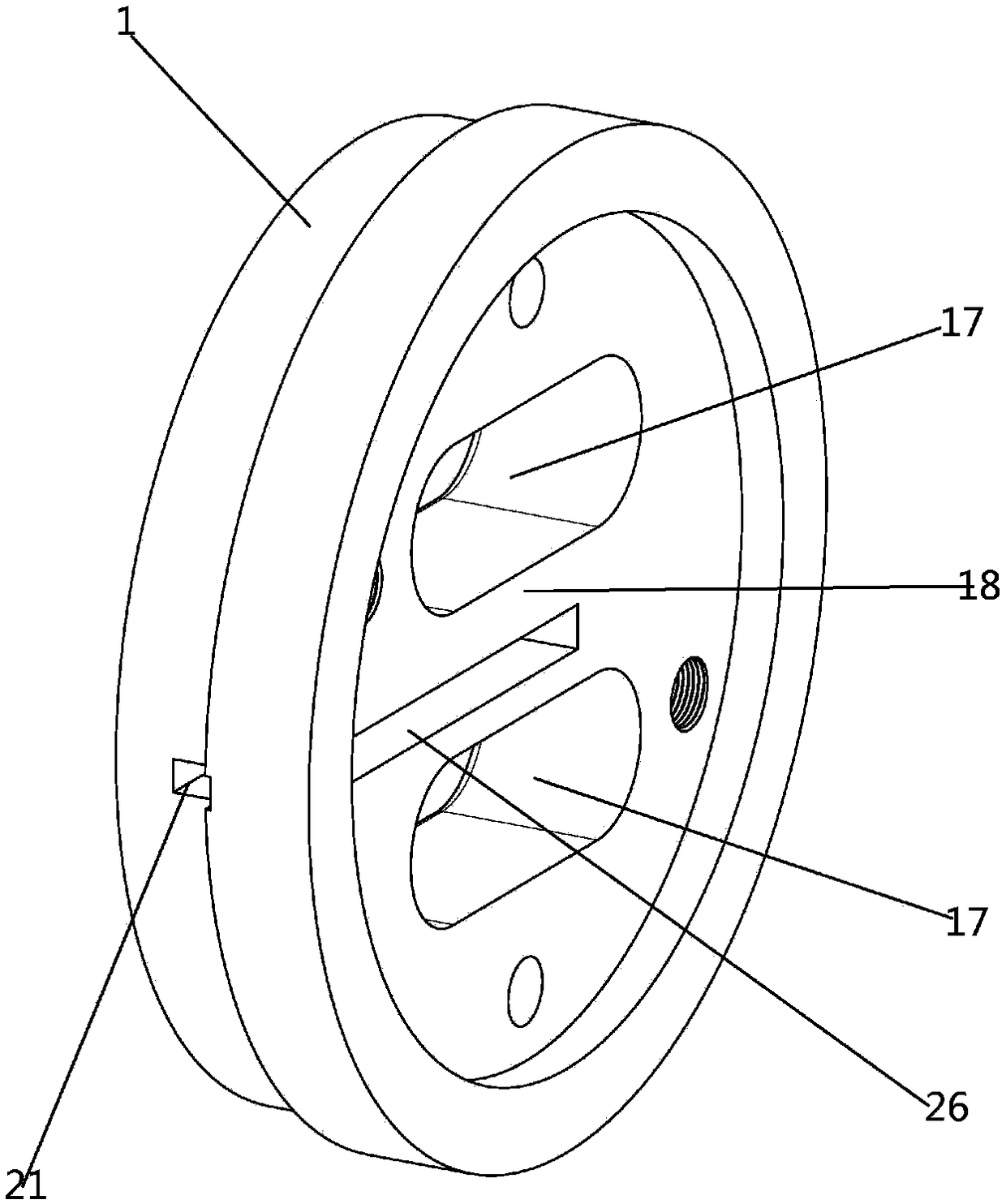

Robot rapid tool changing self-adaptive force control tail end executing device design

InactiveCN108942679ASmooth, efficient and high-precision grindingRealize processing and manufacturingGrinding wheel securing apparatusGrinding feed controlGear wheelActuator

The invention discloses a robot rapid tool changing self-adaptive force control tail end executing device design. The control tail end executing device design comprises a hemispherical clamping device, a Z-shaped tension sensor, a pressure control air cylinder, an interface device between a tail end actuator and a mechanical arm. The hemispherical clamping device, the Z-shaped pulling pressure optical sensor and the pressure control air cylinder are divided into an upper part, a middle part, and a lower part to form a pressure self-adaptive controller and a core part, and the pressure self-adaptive controller and the core part are connected and arranged as a whole; the set constraint effect of the pipe butt joint position points achieves butt joint and solid connection of the data line andthe air pipe, that is the soft tubular objects. According to the tube butt joint position points, and the data lines and the air pipes extending out of each pressure self-adaptive controller are orderly integrated into the butt joint plane for butt joint; a central bevel gear is adopted at the joint of the tail end executor to drive a surrounding bevel gear to rotate and tighten a fixing bolt andan air hole interface, and the position of the tail end executor is fixed at the same time to realize the connection of the air pipes. The robot rapid tool changing self-adaptive force control tail end executing device design has the advantages that clamping and detecting force control operation is integrated and real-time three-dimensional force control is achieved.

Owner:CHONGQING UNIV

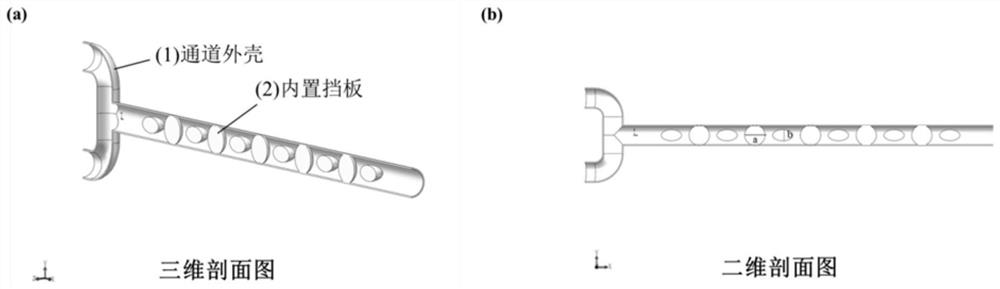

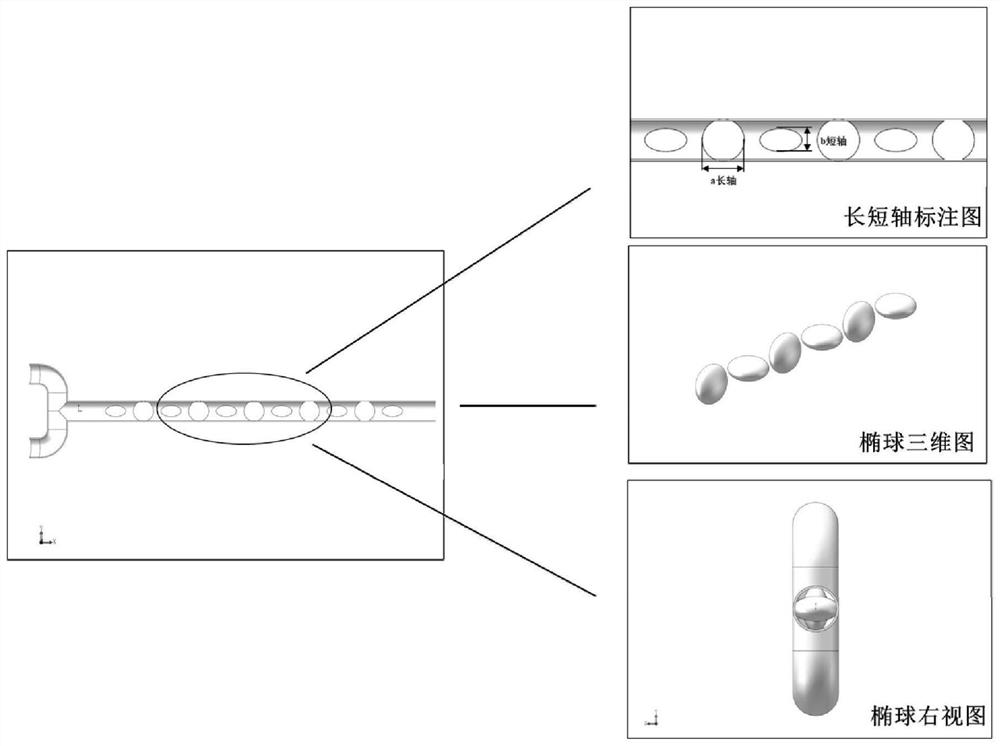

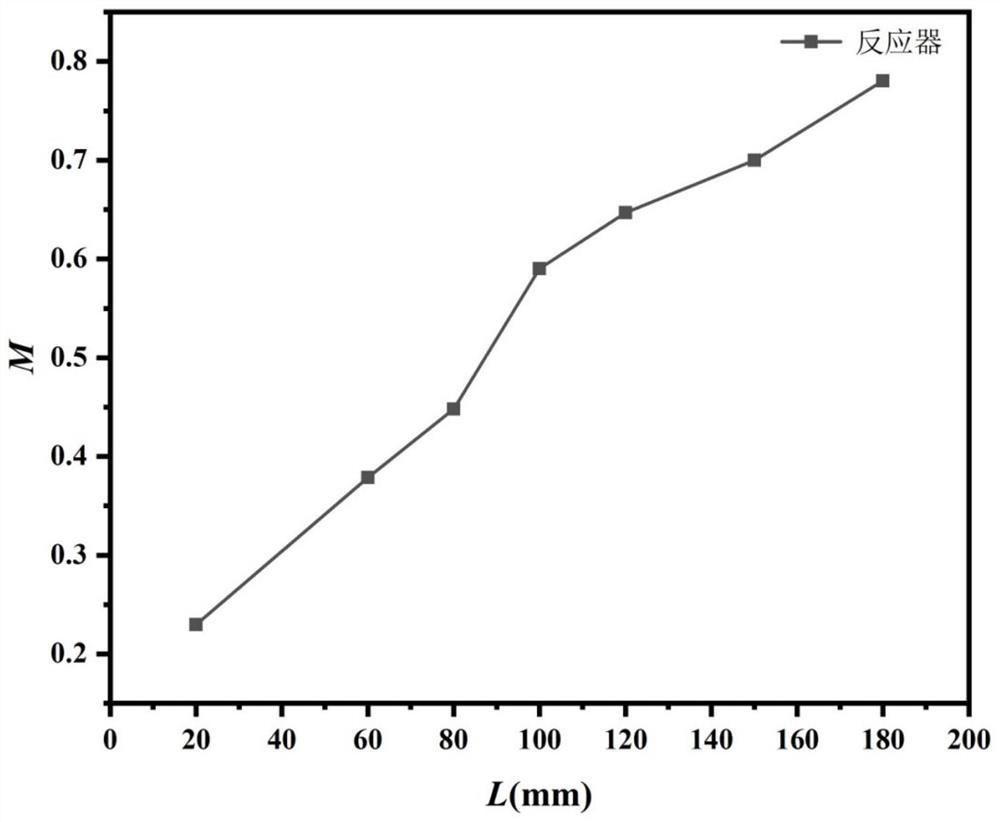

Novel reactor and processing method thereof

ActiveCN114146671AImprove mixing efficiencyEfficient mixingAdditive manufacturing apparatusChemical/physical/physico-chemical reactor detailsProcess engineeringRepeat unit

The invention discloses a novel reactor and a processing method thereof. The novel reactor comprises a shell and a built-in baffle, a plurality of inlet channels are formed in the front end of the shell, a mixing channel is formed in the middle, and an outlet is formed in the rear end; the built-in baffles are arranged in the mixing channel at intervals in the fluid flowing direction, the two sides of each built-in baffle and the shell are integrally formed, and the fluid flowing through the built-in baffles is divided into an upper fluid and a lower fluid. The reactor can be prepared by any 3D printing forming technology of fused deposition forming, light curing forming, material spraying forming, material extrusion forming, adhesive powder spraying forming, powder bed smelting and sheet stacking. According to the reactor, a plurality of baffle structures of repetitive units are arranged in the mixing channel, and fluid entering from two inlets continuously changes a flowing path through impact of the baffles, so that the mixing process is enhanced, the mixing efficiency is improved, and efficient mixing is completed within a short time.

Owner:NANJING UNIV OF TECH

Mixing chemical mechanical system with function of multi-sensor monitoring

InactiveCN107670612ARealize processing and manufacturingEnables multiple reaction processingProcess control/regulationChemical/physical/physico-chemical stationary reactorsEngineeringAmplifier

The invention discloses a mixing chemical mechanical system with a function of multi-sensor monitoring. The mixing chemical mechanical system comprises a master control station and sensors. A master control computer receives signals from the sensors through a sampling circuit, a filter circuit, an amplifier, a holding circuit and an A / D converter. The sensors comprise a rotation speed sensor, a thermometer, a pressure sensor, a vibration sensor and a noise sensor.

Owner:SHANDONG XINHUA LONGXIN CHEM

Chemical slurry pressure filter system

ActiveCN107670393ARealize processing and manufacturingFilter thoroughlyLavatory sanitoryDisinfectionBall bearingSlag

The invention discloses a chemical slurry pressure filter system. The system comprises one belt filter press, one box filter, one pressure filter, one squeezing filter, one sterilization device, one sedimentation tank, one waste liquid pool, one liquid collection pool, four slag storage tanks, three buffer tanks, six feeding pumps, five circuit switches and fifteen valves. The pressure filter comprises a driving motor, a clutch, a transmission shaft, a distributor head, a ball bearing, a left end cover, an outer cylinder main body, a sealing cover plate, a sealing spacer block, a filter screen, an inner cylinder main body, a drainage pipe, a packing seal, a right end cover, a roller bearing, an outer cylinder support base, a side support, a scraper discharge device, an unloading box, a reducer and a lubrication device.

Owner:宝应县有机食品质量监督检验中心

Rotatable type regular hexagonal rock sample cutting device

InactiveCN107884241AHigh cutting reliabilityAchieve relative motionPreparing sample for investigationHydraulic motorRock sample

The invention relates to the technical field of preparing a rock sample for testing, and particularly relates to a rotatable type regular hexagonal rock sample cutting device, which solves the problems that rock samples with conventional shapes adopted in the existing tests cannot completely reflect the deformation and destruction of complicated rock layers. The rotatable type regular hexagonal rock sample cutting device comprises a testbed and a counter top, wherein a disk with scales is arranged in the middle of the counter top, a connecting bush which is concentric to the disk is fixedly arranged on the lower part of the counter top, the connecting bush is in internally threaded connection with an adjustment shaft, the upper end of the adjustment shaft is connected with a crank, the crank is fixedly provided with an indicator in the radial direction of the disc, a mounting block is fixedly arranged on the lower end of the adjustment shaft, a principal axis is connected with a cutterhead symmetrically on two ends of the mounting block, a hydraulic motor is fixedly arranged on the front end of the mounting block, and a cooling device is fixedly arranged on the rear end of the mounting block. The invention provides a hexagonal rock sample cutting device better reflecting the true deformation and destruction form of the rock sample, the truer test data compared with the traditional quadrangular rock sample or cylindrical rock sample can be finally obtained, and the rotatable type regular hexagonal rock sample cutting device has more profound significance on the study on thedeformation and destruction form of the rock layers of complex landform.

Owner:TAIYUAN UNIV OF TECH

Fiber reinforced wallboard type sectional material composite extruding device and extruding method thereof

ActiveCN108356086AAchieve modularityRealize processing and manufacturingExtrusion diesWear resistanceMaterials science

The invention discloses a fiber reinforced wallboard type sectional material composite extruding device and an extruding method thereof. The composite extruding device comprises a composite extrudingmold and a fiber traction device; the composite extruding mold comprises a flow guiding plate, an upper mold, a lower mold, a feeding plate and a mandrel; the upper mold is provided with a second flowdividing hole which is internally provided with a second flow dividing bridge; one end of the second flow dividing bridge and one end of a first flow dividing bridge are each provided with a feedingplate clamping groove; the feeding plate is connected in the two feeding plate clamping grooves in a clamped manner; the feeding plate is provided with a plurality of fiber feeding channels; and the other end of the second flow dividing bridge is connected with the mandrel which is provided with a through hole parallel with the sectional material extruding direction. According to the composite extruding device and the extruding method thereof, a sectional material can be continuously reinforced at the assigned position of the cross section of the sectional material, and continuous and composite extruding is achieved; and meanwhile, compared with a traditional fiber particle mixed blank material, a conventional blank material is used by the fiber reinforced wallboard type sectional materialcomposite extruding device, the production cost is reduced, and the abrasion resistance of a mold is also improved.

Owner:SHANDONG UNIV

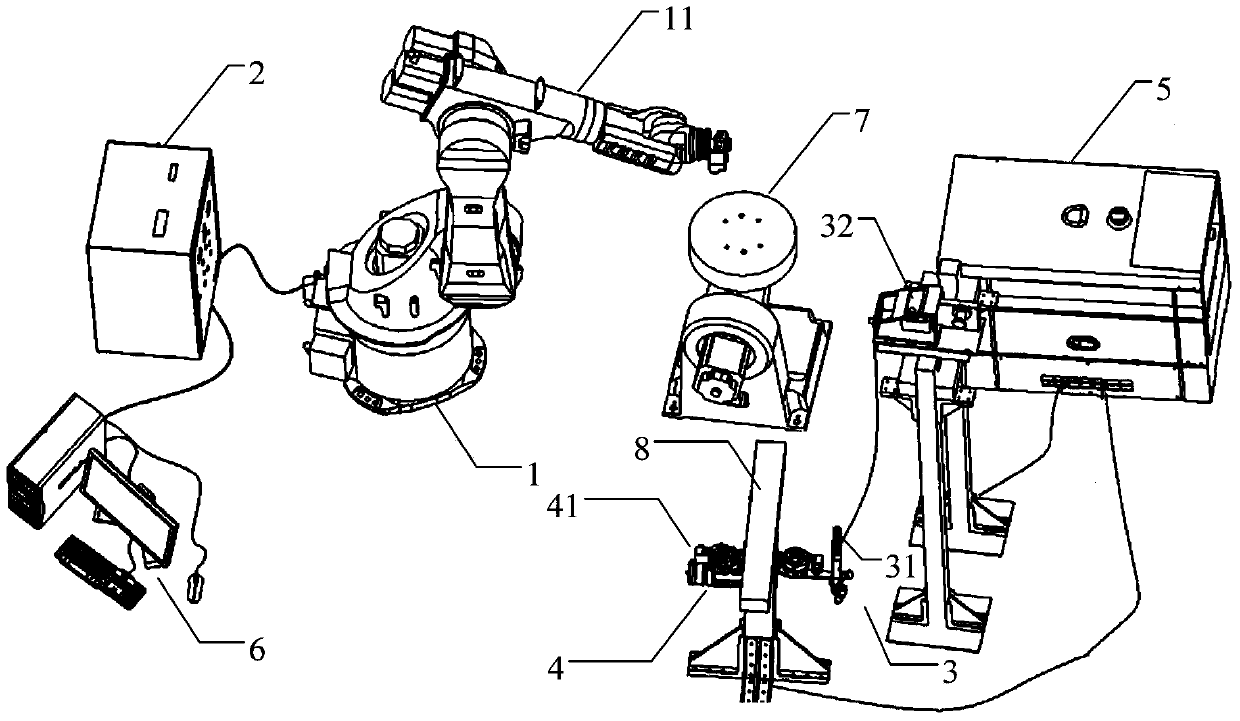

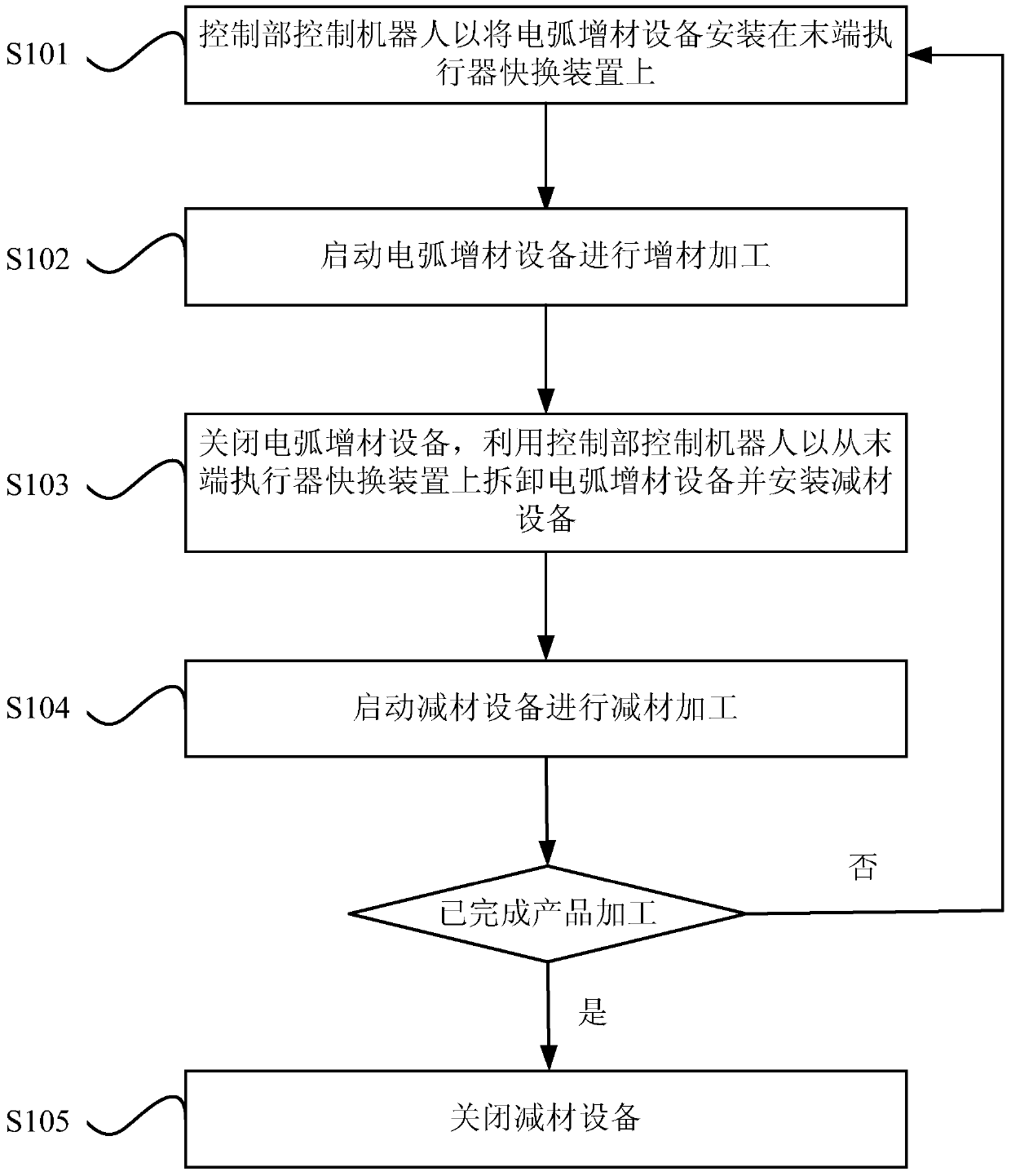

Additive and subtractive composite processing system and method

ActiveCN105574254BRealize processing and manufacturingImprove machining accuracyGeometric CADOther manufacturing equipments/toolsWorking environmentActuator

The invention provides a material increasing / decreasing composite processing system and method. The composite processing system comprises a robot, a control part, electric arc material increasing equipment and material decreasing equipment, wherein the robot is equipped with a tail end executor quick-changing apparatus; the control part is electrically connected with the robot, and can control the robot by processing and controlling information codes; the electric arc material increasing equipment can be mounted on the tail end executor quick-changing apparatus for performing material increasing processing; and the material decreasing equipment can be mounted on the tail end executor quick-changing apparatus for performing material decreasing processing. The composite processing system is simple in composition, free of too many limitations on the working environment, and capable of realizing high-precision processing of products of any dimensions at any time and any place.

Owner:BEIHANG UNIV

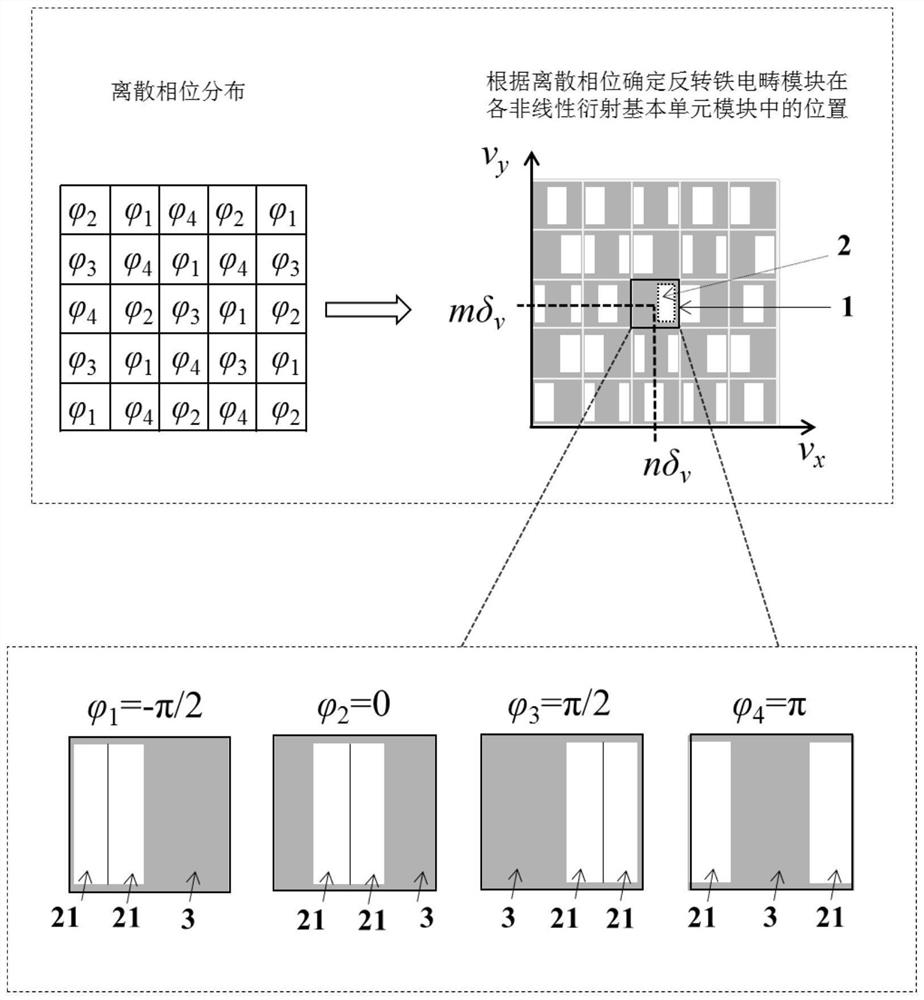

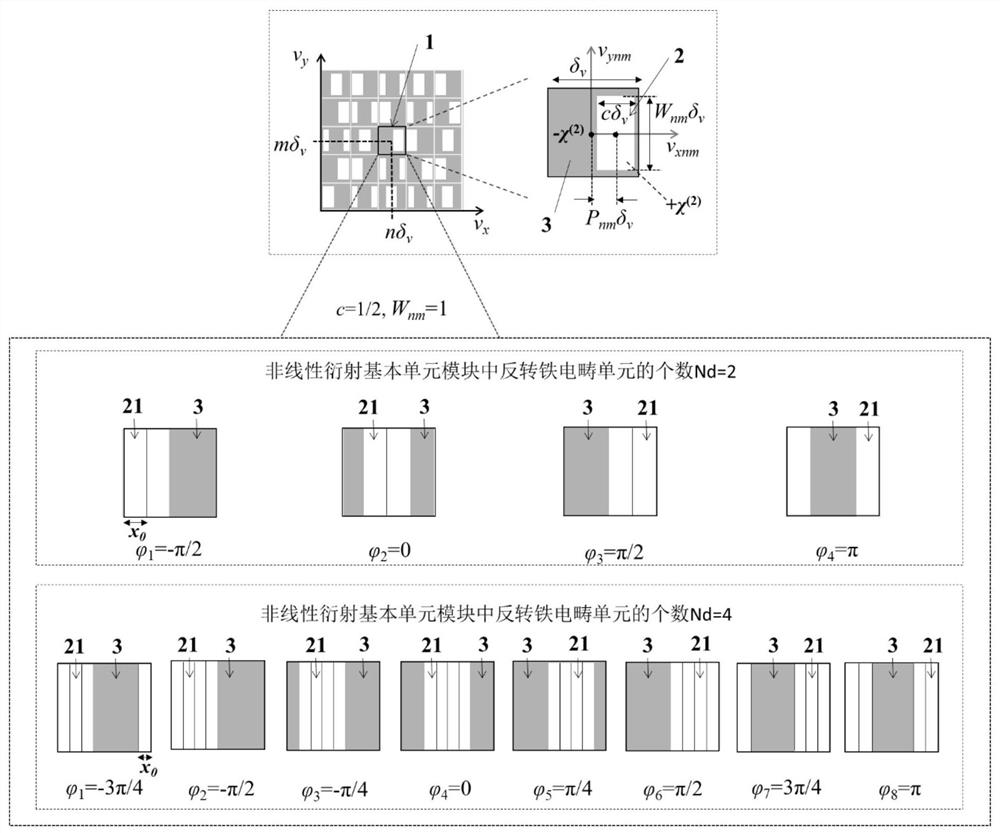

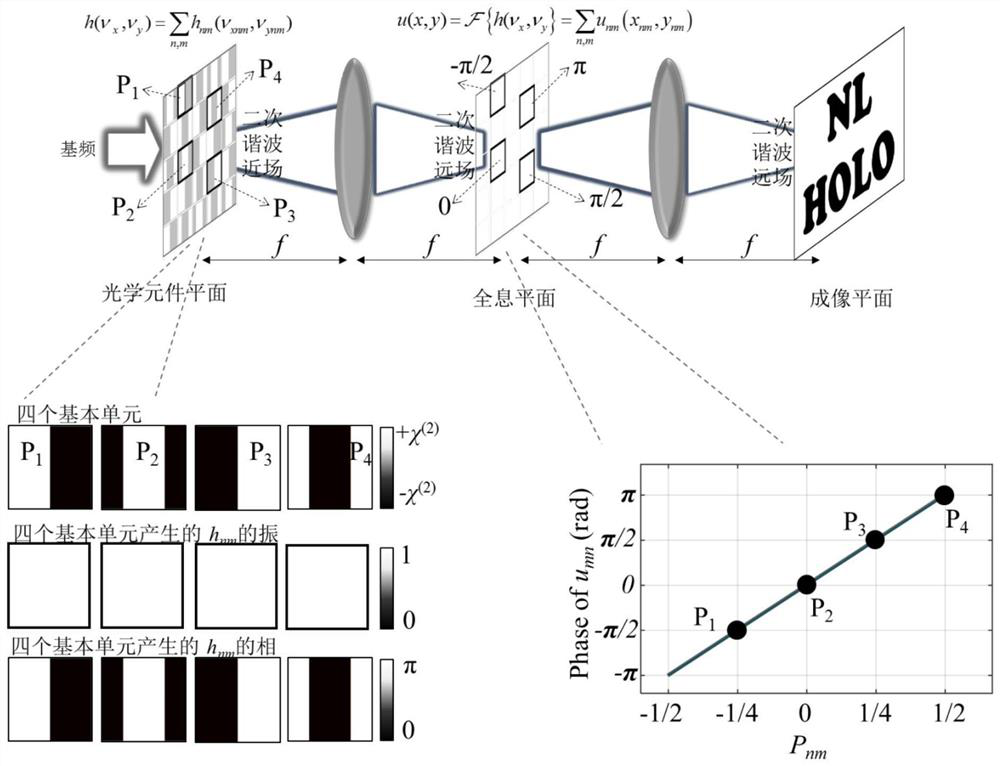

Design method and application of nonlinear diffractive optical element

The invention belongs to the field of nonlinear photonics, and particularly relates to a design method and application of a nonlinear diffractive optical element. A nonlinear diffractive optical element comprises a plurality of nonlinear diffraction basic unit modules; according to target second harmonic light field distribution in the far field, discrete phase distribution at different spatial positions of the holographic plane is determined, and then basic unit modules in one-to-one correspondence with the discrete phases are determined; and each basic unit module comprises a reverse ferroelectric domain module and a ferroelectric domain background substrate module, the position of the reverse ferroelectric domain module in the basic unit module is determined through the discrete phase,the value range of the discrete phase is 0-2 [pi], and the nonlinear diffractive optical element is obtained. The arrangement of different basic unit modules at the corresponding spatial positions isdetermined according to the discrete phase values at the different spatial positions, the phase of the generated coherent second harmonic wavefront can be randomly regulated and controlled, and the method has high universality and flexibility, small design error and low manufacturing difficulty.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com