Machining method for internal runner structure of cold plate and application of machining method

A processing method and cold plate technology, which are applied to the processing field of the internal flow channel structure of the cold plate, can solve the problems of high cost, complex processing method and high degree of professionalism, shorten the manufacturing cycle, have low equipment requirements, and ensure the dimensional accuracy of parts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

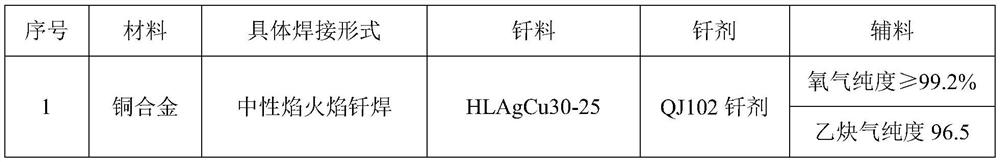

Embodiment 1

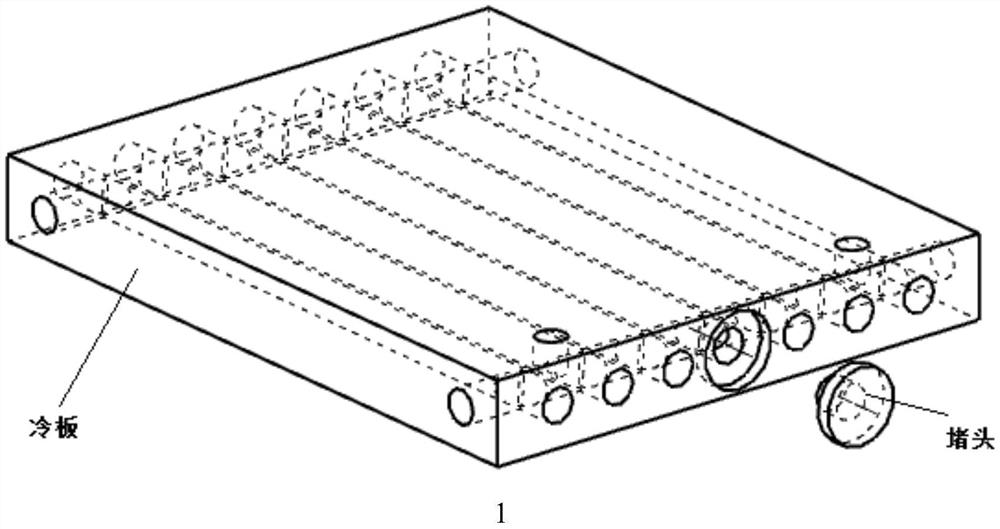

[0052] A method for processing an internal flow channel structure of a cold plate, comprising the following steps:

[0053] S1. Drill a pre-hole on the side wall of the cold plate, and use a wire cutting molding process to form a flow channel according to the pre-hole, and the cross-section of the flow channel is circular;

[0054] The specific process of wire cutting molding process is as follows:

[0055] 1) According to the actual size of the through hole or the through frame, drill the wire and cut the pre-hole;

[0056] 2) After alignment through the shape and pre-hole positioning, draw the wire path on the operation interface of the wire cutting machine tool;

[0057] 2) The diameter of the molybdenum wire used for processing is Φ0.18㎜, the processing voltage is 80V, the maximum current is 3A, and the cutting speed is 20㎜ 2 / min to set parameters to complete the processing of the flow channel through hole;

[0058] 3) After the processing is completed, clean the wire ...

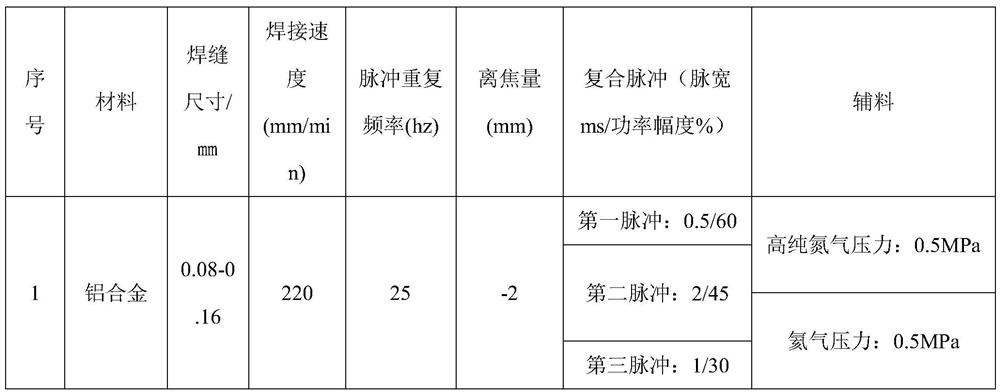

Embodiment 2

[0072] A method for processing an internal flow channel structure of a cold plate, comprising the following steps:

[0073] S1. Drill a pre-hole on the side wall of the cold plate, and use a wire cutting molding process to form a flow channel according to the pre-hole, and the cross-section of the flow channel is circular;

[0074] The specific process of wire cutting molding process is as follows:

[0075] 1) According to the actual size of the through hole or the through frame, drill the wire and cut the pre-hole;

[0076] 2) After alignment through the shape and pre-hole positioning, draw the wire path on the operation interface of the wire cutting machine tool;

[0077] 2) The diameter of the molybdenum wire used for processing is Φ0.18㎜, the processing voltage is 80V, the maximum current is 3A, and the cutting speed is 20㎜ 2 / min to set parameters to complete the processing of the flow channel through hole;

[0078] 3) After the processing is completed, clean the wire ...

Embodiment 3

[0088] A method for processing an internal flow channel structure of a cold plate, comprising the following steps:

[0089] S1. Drill pre-holes on the two symmetrical side walls of the cold plate, adopt the drilling process on both sides, and use the wire cutting molding process to form the flow channel according to the pre-hole, and the cross-section of the flow channel is circular;

[0090] The specific process of wire cutting molding process is as follows:

[0091] 1) Scribing and aligning, marking the center of the holes on both sides; or the center holes on both sides of the clamping point on the CNC equipment; then drill pre-holes from both sides, pay attention to the drilling depth should be greater than half the length of the through hole;

[0092] 2) After using the shape of the cold plate and the pre-hole positioning to align, draw the wire path on the operation interface of the wire cutting machine;

[0093] 3) The diameter of the molybdenum wire used for processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com