System and method for machining nanoscale small holes in hard and brittle materials through conical lens

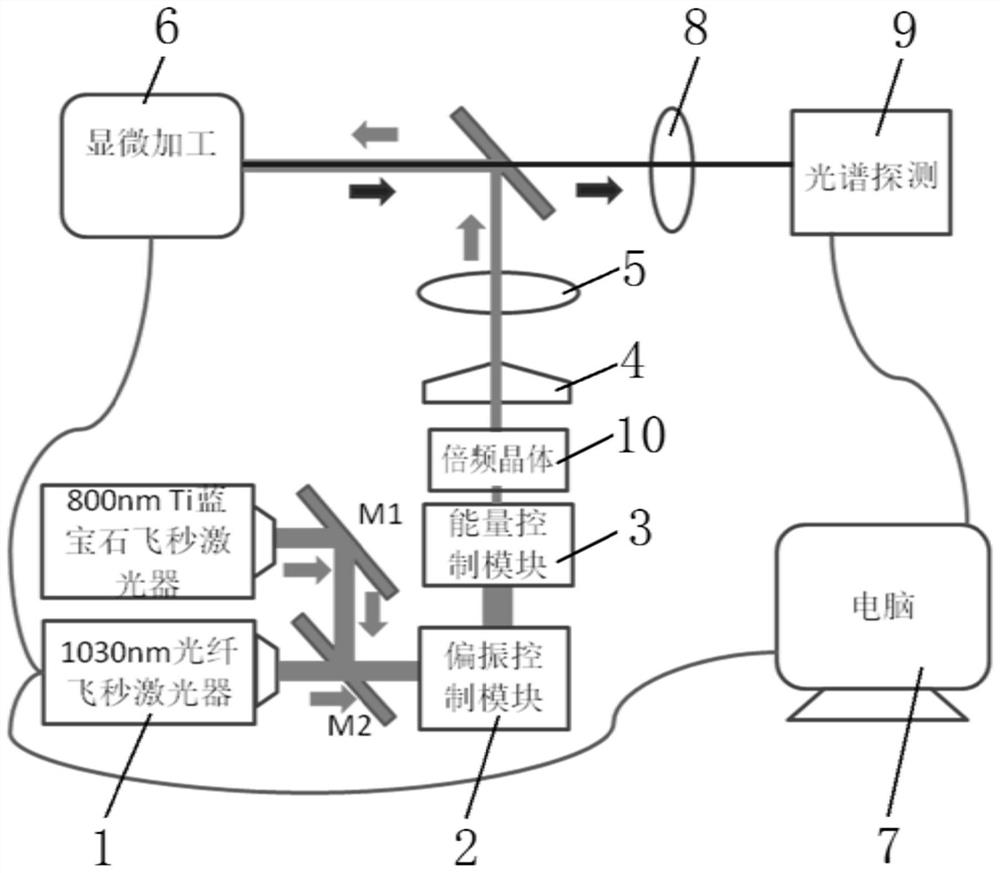

A technology of hard and brittle materials and processing systems, applied in nanotechnology, metal processing equipment, manufacturing tools, etc., can solve the problems of poor uniformity of small hole structure, difficult to process small holes, etc., to reduce feature size and suppress lateral thermal diffusion , to achieve the effect of high-quality uniform nanohole array processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

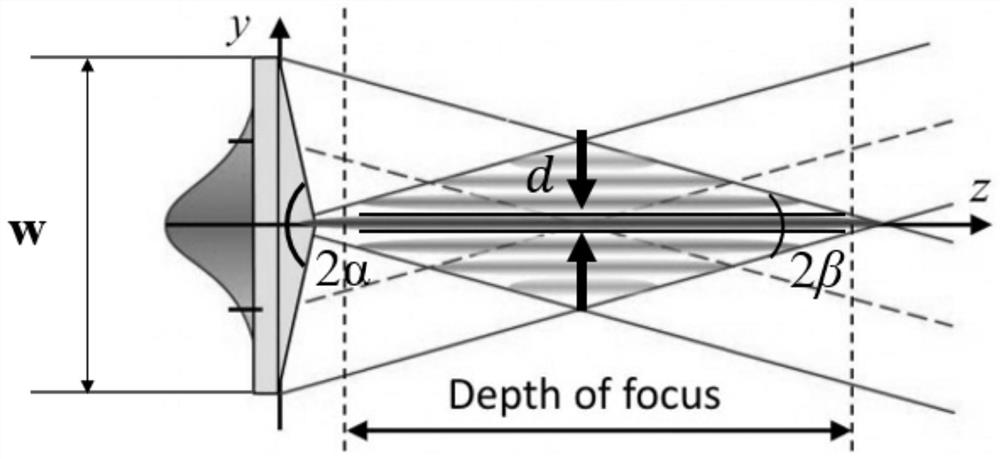

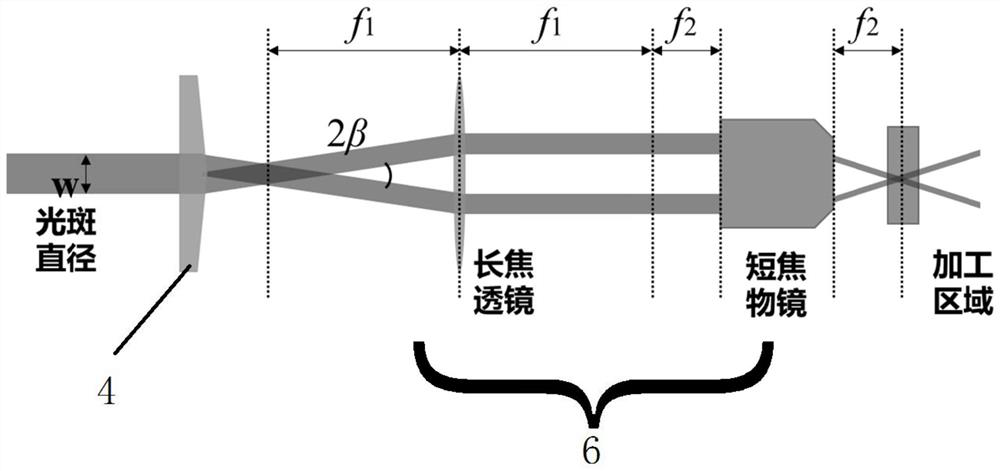

Method used

Image

Examples

Embodiment 1

[0062] Carry out micropore processing on the quartz surface, the laser used in the present invention is the Ti:Sapphire laser independently developed by the Institute of Physics, Chinese Academy of Sciences, the center wavelength is 800nm, the repetition rate is 1kHz, the laser single pulse energy is 1 μ J, and the pulse width is 30fs, and the processing objective lens (ie short-focus objective lens) is a ×50 objective lens with a numerical aperture of 0.6 and a working distance of 10mm. Such as Figure 4 As shown, the processed structure is a "hat-shaped structure" with a disc and a central hole. Among them, for a structure with a large central hole, the diameter of the central hole accounts for 1 / 2 to 1 / 3 of the overall diameter, and the size of the hole is between 100-200nm. For structures with smaller central holes, the diameter of the central hole accounts for 1 / 10 to 1 / 5 of the overall diameter, and the diameter of the central hole is less than 100nm. These structures a...

Embodiment 2

[0065] The laser used in this example is a fiber laser produced by Anyon Laser, with a maximum output power of 20W. The objective lens used in processing is ×50, the repetition frequency is 100Hz, the laser single pulse energy is 1.5μJ, the center wavelength is 1030nm, and the pulse width is 300fs. After frequency doubling, the BBO crystal can generate a femtosecond laser with a center wavelength of 515nm. Compared with the 800nm Ti:Sapphire laser, the 515nm laser pulse has a shorter light wavelength, which is conducive to processing smaller structures. The pulse repetition frequency can be flexibly adjusted through external triggering. With the internal repetition frequency setting of the laser, the repetition frequency of the laser can be flexibly adjusted in a wide range from 1Hz to 5MHz, which is convenient for adjusting the mobile platform to a stable operating speed. By connecting the photodiode to the oscilloscope and observing the waveform, it can be found that the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com