Hot runner mold system for deep hole plate

A technology of hot runner and deep orifice plate, applied in the field of hot runner, can solve the problems of unfavorable economy and environmental protection, a large amount of waste, etc., and achieve the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

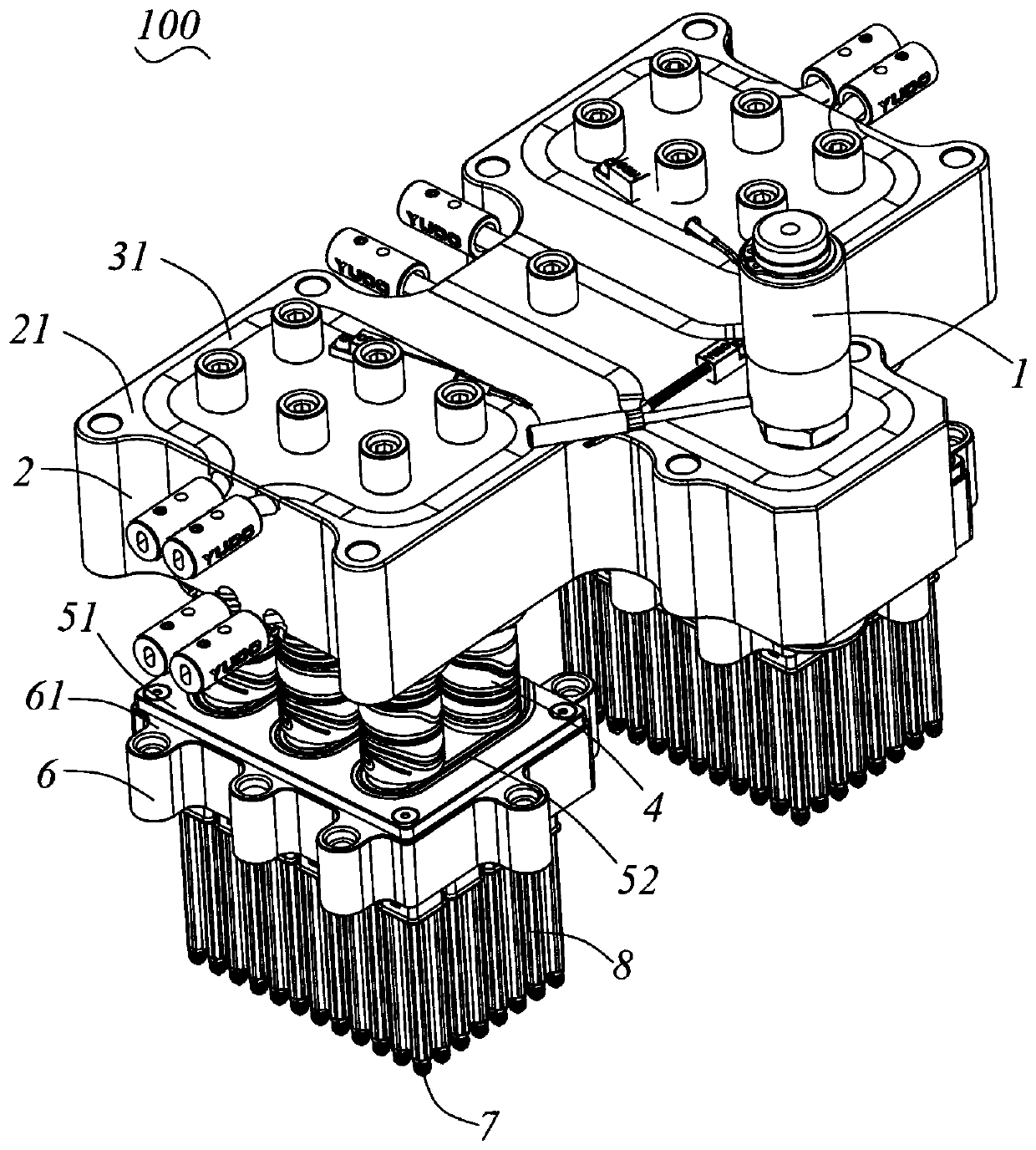

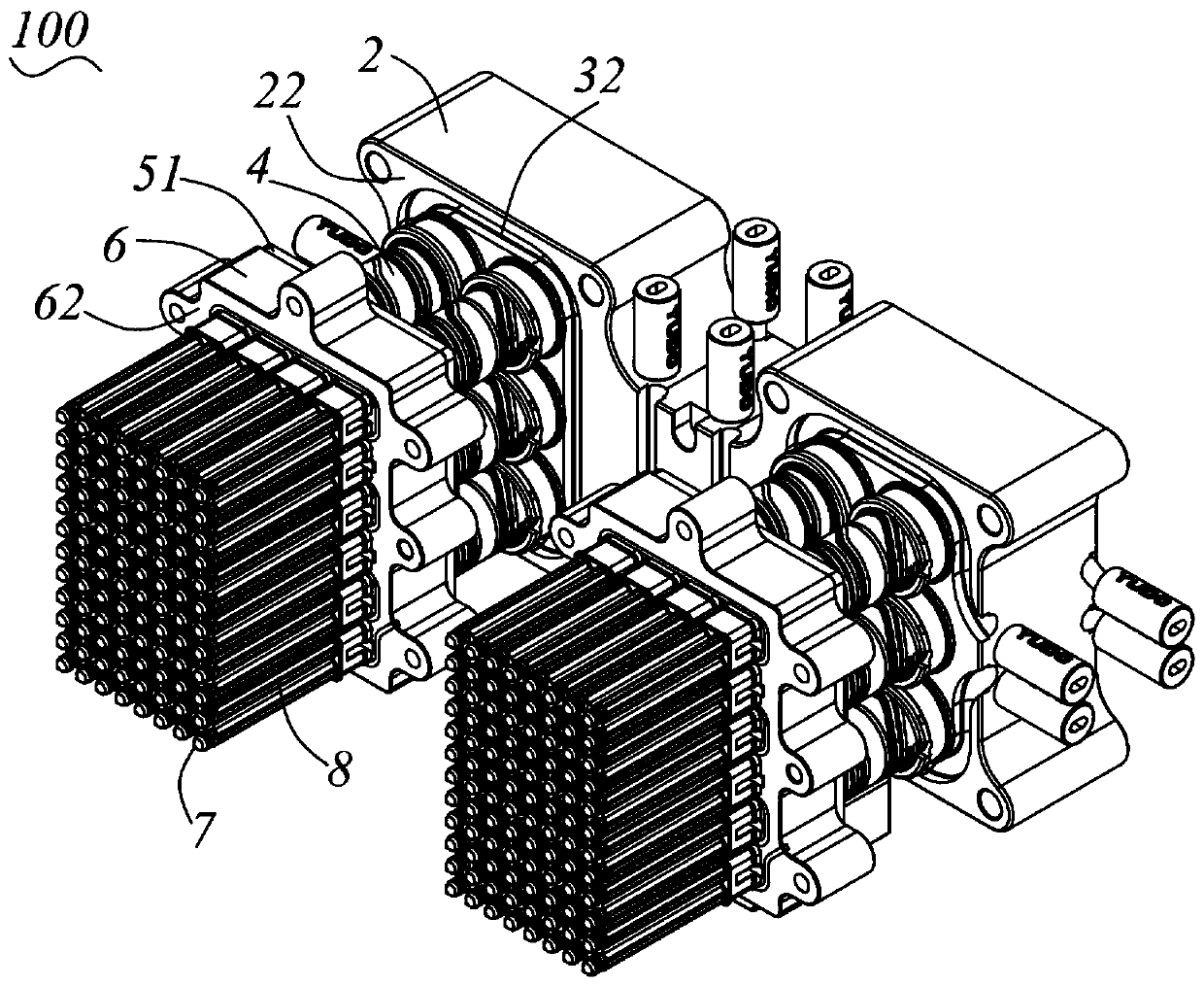

[0051] see Figure 2a-10 , the first embodiment of the present invention provides a hot runner mold system, which is suitable for the injection molding preparation of deep-hole plates, specifically an open hot runner mold system, that is, it is matched with the injection molding machine and injected The start and stop of injection molding production is realized under the pressure provided by the machine to the injection molding compound.

[0052] Specifically, see Figure 2a and Figure 2b , the hot runner mold system includes a template 200 and a hot runner device 100 .

[0053]The template 200 has a cavity of a deep-hole plate and a plurality of point gates corresponding to the holes of the deep-hole plate. That is, the mold cavity of the template 200 is suitable for deep-hole plate products, and when the injection molding compound enters the cavity, the injection compound can be molded into a deep-hole plate in the cavity. As mentioned in the background technology, the ...

no. 2 example

[0100] The second embodiment of the present invention provides a hot runner mold system, which differs from the first embodiment only in that: Figure 11 , The fit between the tip 7 and the lower splitter plate 6. This difference will be introduced below, and the rest of the content that is the same as the first embodiment will not be repeated.

[0101] Different from the main body 8 provided between the nozzle 7 and the lower distributor plate 6 in the first embodiment, in this embodiment, a plurality of glue outlets are formed on the lower surface of the lower distributor plate 6, and the nozzle 7 is set as a nozzle core And through the flange 14, it is attached to the lower surface of the lower distributor plate 6, so that the nozzle 7 can be directly connected with the flow channel of the flow channel mechanism.

[0102] For the 96-orifice plate, the number of glue outlets is 96. Correspondingly, the lower surface of the lower manifold 6 has 96 nozzles 7 fitted through th...

no. 3 example

[0104] The third embodiment of the present invention provides a hot runner mold system, which differs from the first embodiment only in that: Figure 12 , The fit between the tip 7 and the lower splitter plate 6. This difference will be introduced below, and the rest of the content that is the same as the first embodiment will not be repeated.

[0105] Different from the nozzle 7 of the first embodiment and the main body 8 provided between the lower distributor plate 6, in this embodiment, the lower surface of the lower distributor plate 6 is formed with a plurality of glue outlets, and each of the glue outlets is surrounded by a Groove; the nozzle 7 is set as a nozzle core, and the upper end of the nozzle core is embedded into the groove through the pressure cap 15, thus the flow channel between the nozzle 7 and the flow channel mechanism can be directly realized butt.

[0106] For the 96-hole plate, the number of glue outlets is 96, and correspondingly, the lower surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com