Chemical mechanical system using electromagnetically driven reactor

A technology of chemical machinery and electromagnetic drive, which is applied in chemical/physical/physical-chemical fixed reactors, computer components, chemical instruments and methods, etc. It can solve the problems of inability to adjust in time, single product, inaccurate production information and process data To prevent the formation of fibrous and blocky materials, prevent the formation of flocculent polymers, and reduce the inaccuracy of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] Embodiments of the present invention refer to Figure 1-5 shown.

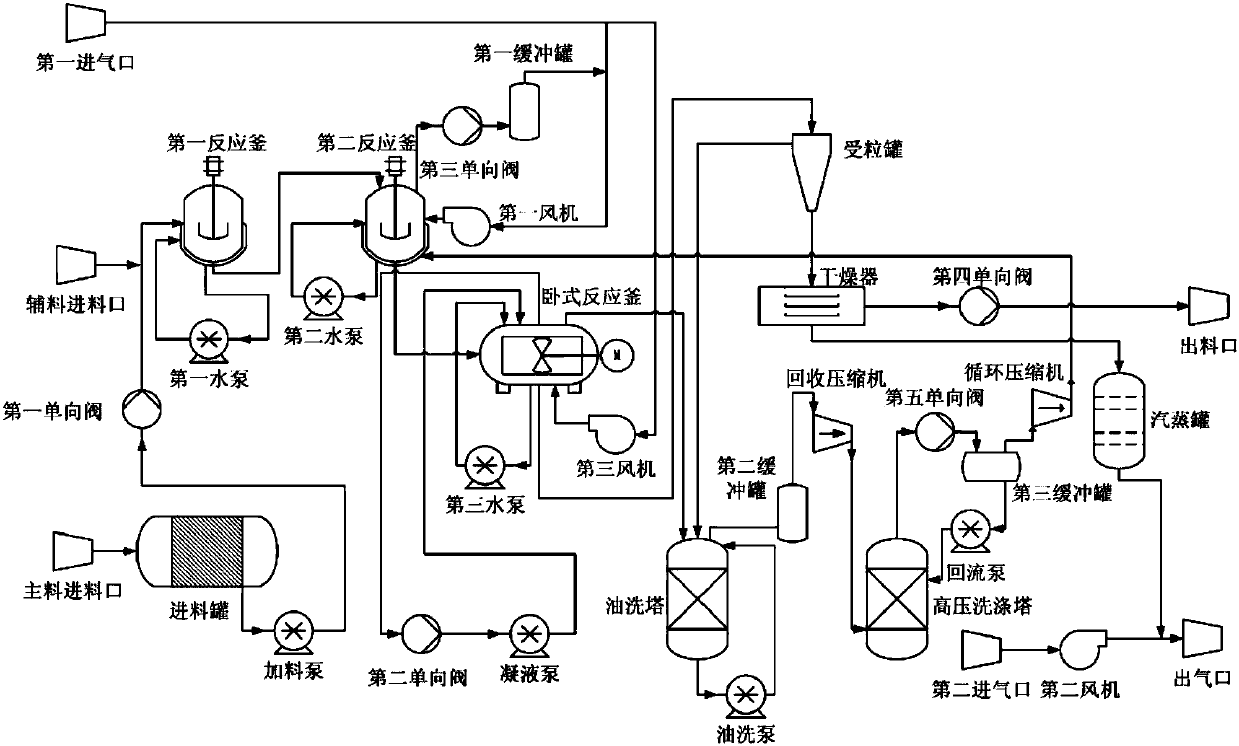

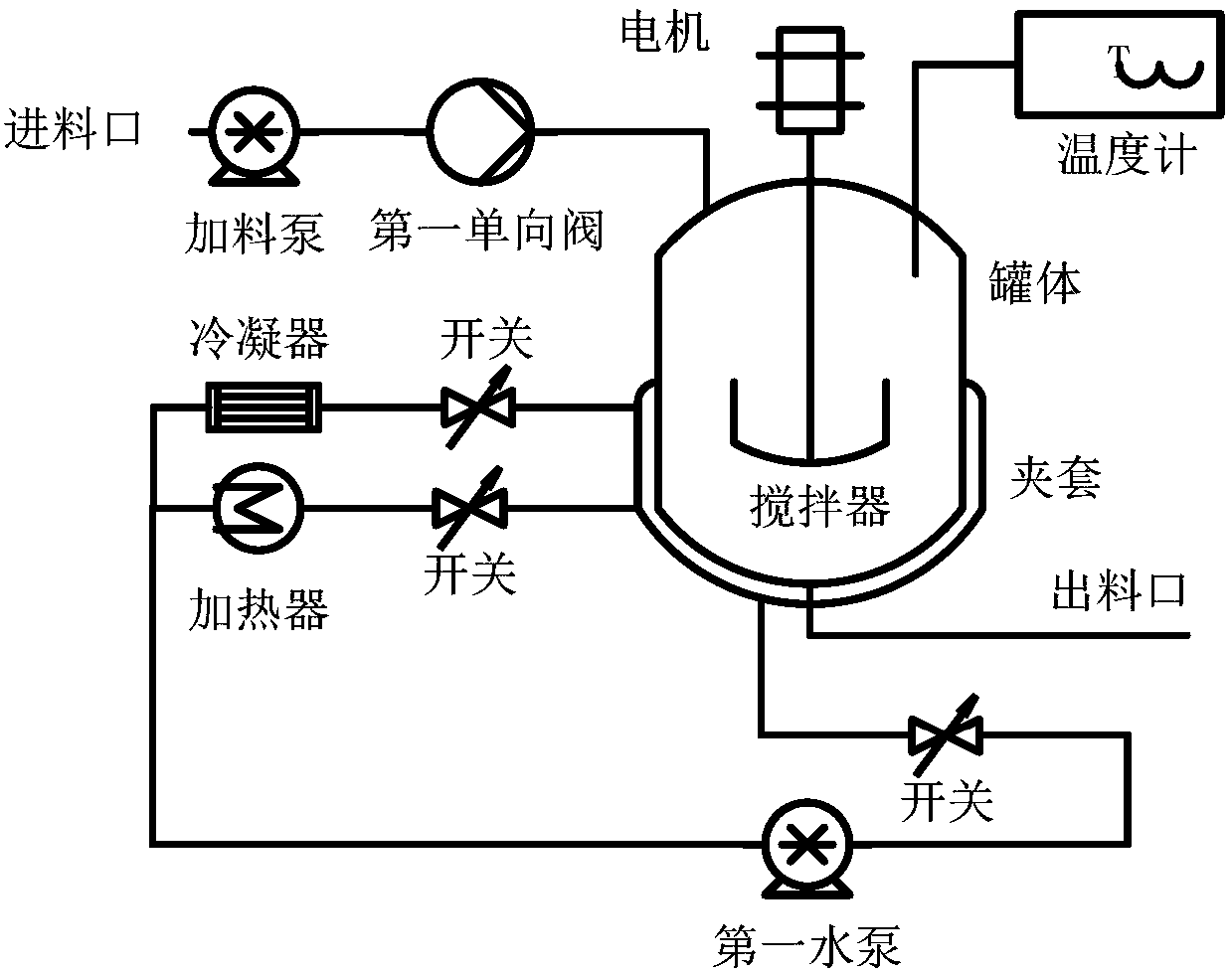

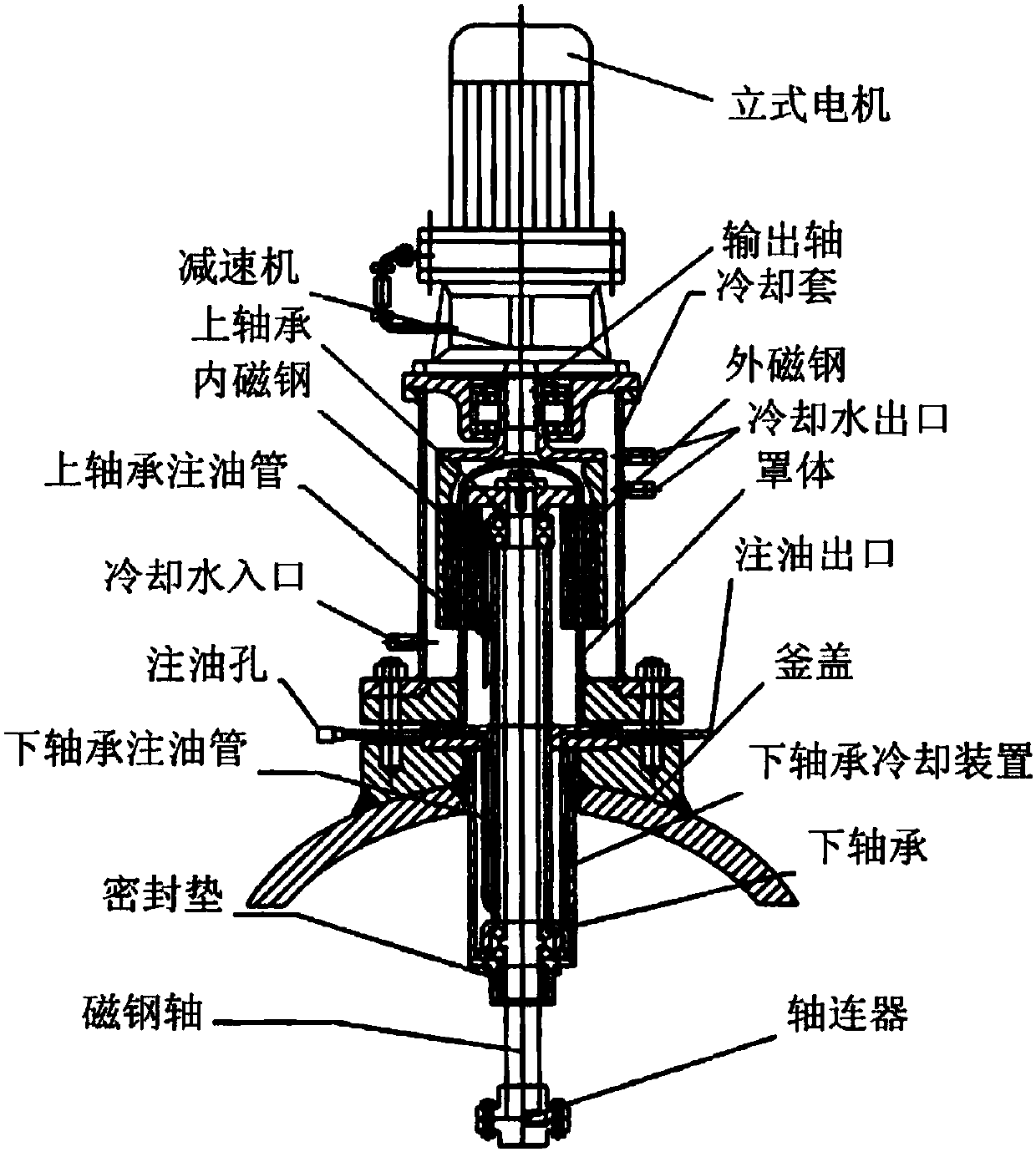

[0026] A chemical machinery system using an electromagnetically driven reactor, including a main material inlet, an auxiliary material inlet, a first air inlet, a second air inlet, a first reactor, a second reactor, and a horizontal reactor , oil washing tower, high pressure washing tower, feed tank, steam tank, granulation tank, first buffer tank, second buffer tank, third buffer tank, dryer, first one-way valve, second one-way valve , the third one-way valve, the fourth one-way valve, the fifth one-way valve, the first water pump, the second water pump, the third water pump, the feeding pump, the condensate pump, the oil washing pump, the return pump, the first blower fan, the third water pump The second fan, the third fan, the recovery compressor, and the circulation compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com