Method for producing colorful rubber cloth

A production method and technology of rubber cloth, applied in textiles and papermaking, etc., can solve the problems of pollution, color interference of rubber cloth, etc., and achieve the effect of uniform color of rubber, easy popularization, convenient and practical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

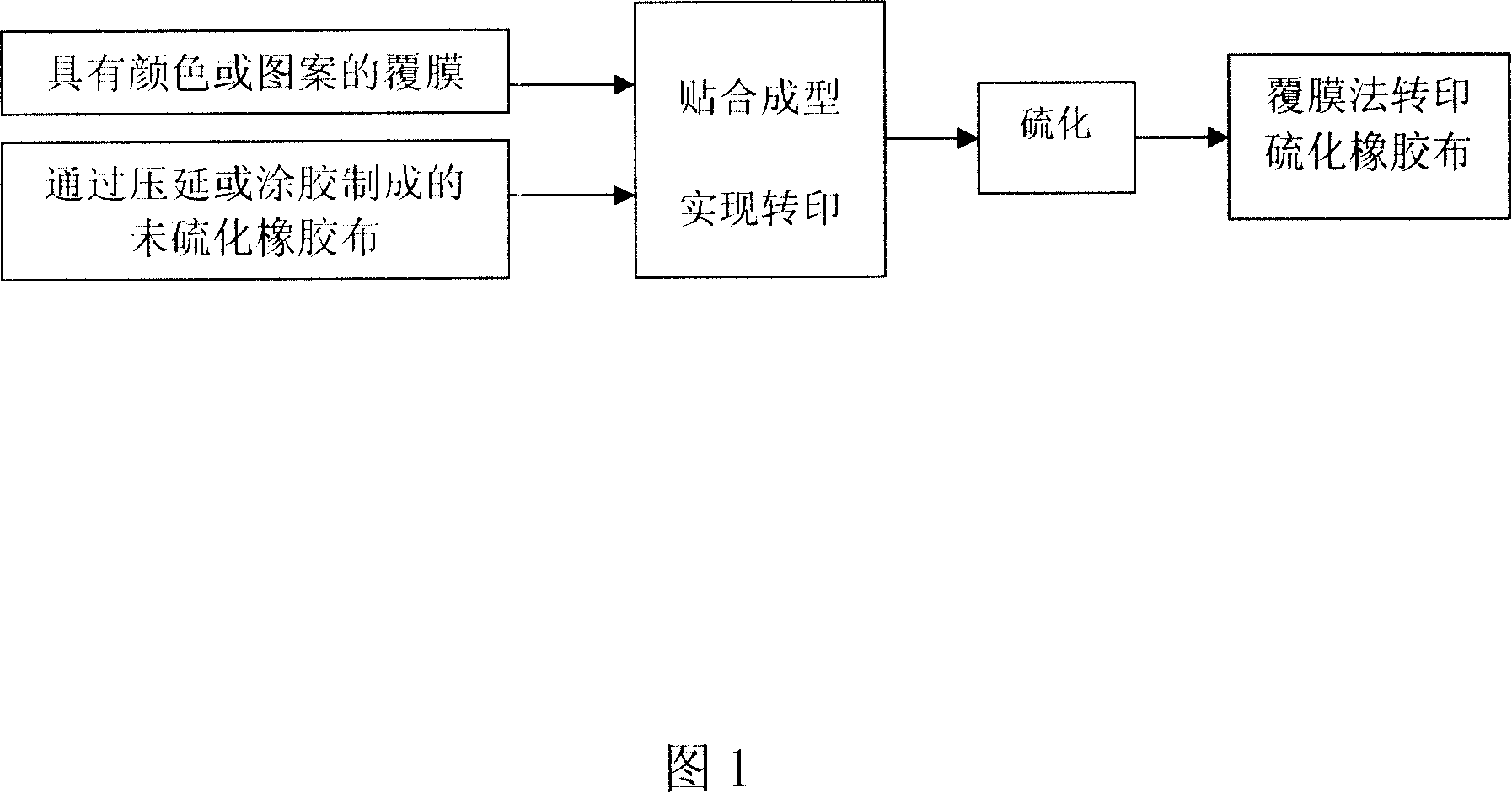

Method used

Image

Examples

Embodiment Construction

[0012] The polyester film can also be made of other film materials. The polyester film is also called the substrate in printing. It should have high temperature resistance, and its high temperature resistance should be between 100°C and 160°C.

[0013] The colored rubber cloth of the present invention can be vulcanized on drum vulcanizers, vulcanization chambers, vulcanization tanks, flat vulcanizers and other equipment. The vulcanization temperature of the present invention can be 170°C-140°C, and the vulcanization time can be controlled according to the glue material of the adhesive tape and the vulcanization conditions. These are all conventional technologies, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com