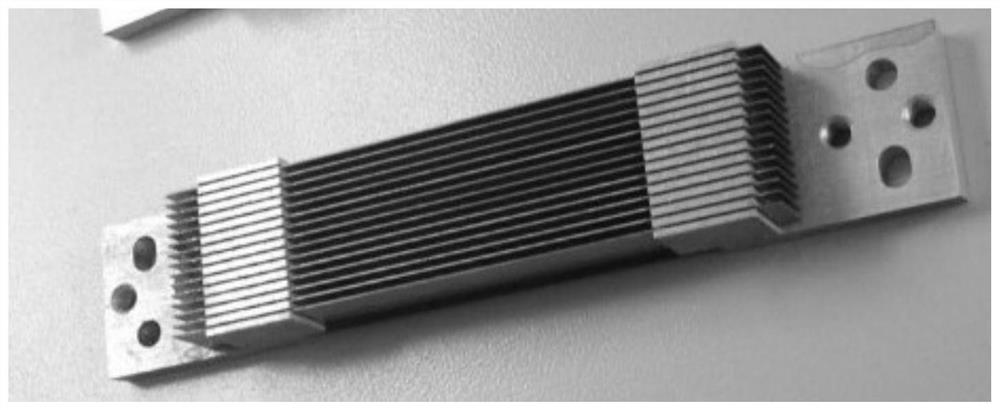

Preparation method of two-dimensional collimator

A technology of collimator and equipment, applied in the field of medical devices, can solve the problems of difficult processing, large thickness of the sheet, and high failure rate, and achieve the effects of reducing volume and quality, reducing scattered signals, and improving image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

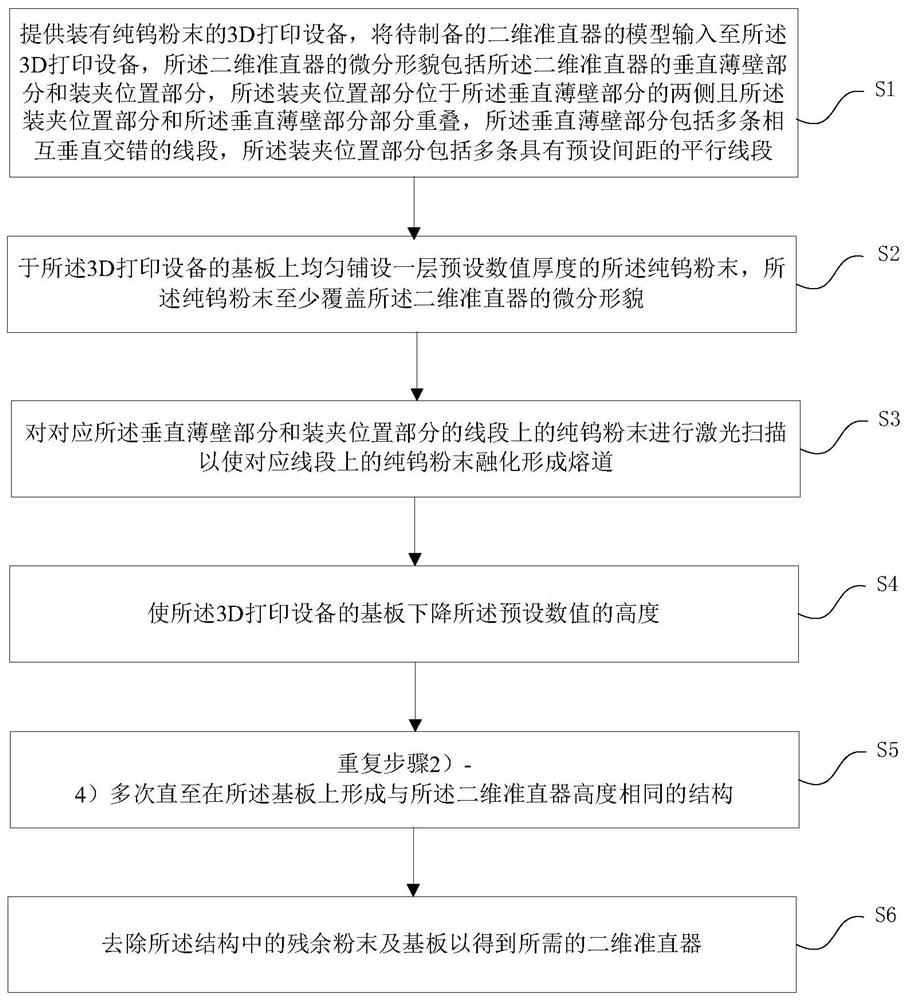

[0037] Such as figure 2 As shown, the present invention provides a kind of preparation method of two-dimensional collimator, comprises steps:

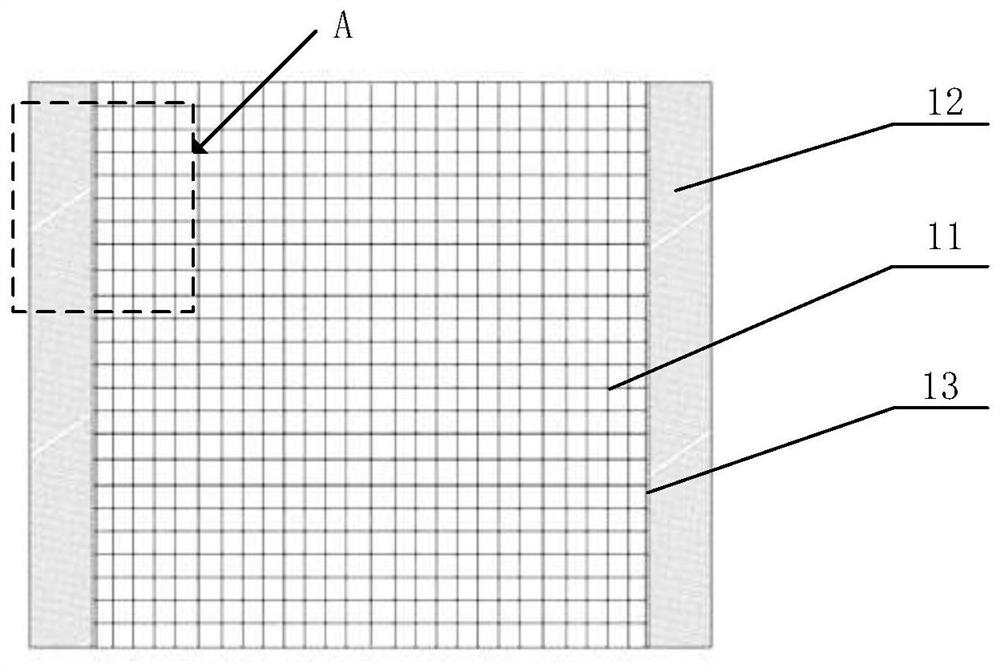

[0038]S1: Provide a 3D printing device equipped with pure tungsten powder, input the model of the two-dimensional collimator to be prepared into the 3D printing device, and the differential shape of the two-dimensional collimator includes the two-dimensional collimator The vertical thin-walled part 11 and the clamping position part 12 of the device, the clamping position part 12 is located on both sides of the vertical thin-walled part 11 and the clamping position part 12 and the vertical thin-walled part 11 partially overlap, The vertical thin-walled portion 11 includes a plurality of vertically staggered line segments, and the clamping position portion 12 includes a plurality of parallel line segments with preset intervals;

[0039] S2: evenly laying a layer of the pure tungsten powder with a predetermined thickness on the substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com